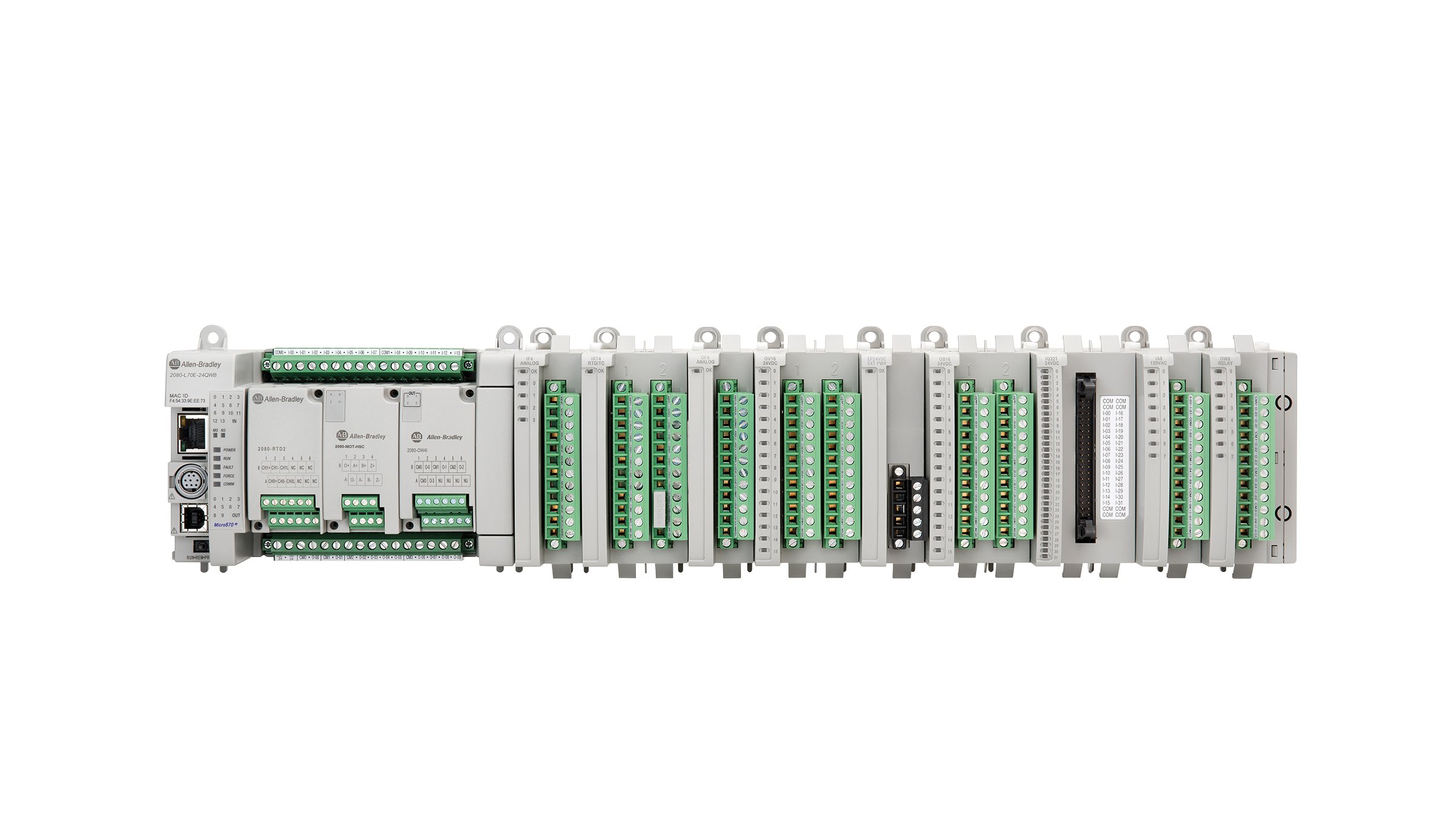

Designed for large standalone machine applications, the Micro870 controller comes with great memory capacity — a double of Micro850® controller — to enable more modular program and use of user-defined function blocks.

The embedded motion capabilities support up to two axes of motion with TouchProbe instruction that registers the position of an axis more precisely than using interrupts. It can shorten machine development time with up to 280 KB memory size and support for up to 20,000 programming steps. Also, it can reduce wiring time with removable terminal blocks

Programming the Micro870 controller is simple with the latest Release 11.00 for Connected Components Workbench™ software, which feature a look and user experience that closely resembles Studio 5000 Logix Designer software.

It provides controller programming, device configuration and data sharing with the human machine interface (HMI) editor for PanelView™ 800 graphic terminals. Users who are familiar with Studio 5000 will find it easy to use Connected Components Workbench software r11.00 to program their Micro800 controllers for their standalone machines.

Their programming time can be shortened substantially as the software’s new code-sharing feature allows users to copy and paste ladder codes and instruction sets from RSLogix 500® and Studio 5000 to the Connected Components Workbench software.

A Right-sized Visualization Solution for Applications At Any Size

The new Allen-Bradley PanelView 5310 family of graphic terminals brings the benefits of greater integration between the HMI and controller to both large and small applications.

The PanelView 5310 graphic terminals deliver the same usability benefits and enhanced integration with Logix 5000 controllers as the PanelView 5500 terminals. But the new terminals are specifically designed for applications of up to 50 HMI screens. The terminals are available in 6, 7, 9 and 12-inch display sizes.

Companies can also use the enhanced integration to create high-speed jog buttons in place of cumbersome hardwired buttons. These auto-diagnosing buttons can interact with the controller at I/O speeds to help reduce downtime and improve productivity. Other benefits of the PanelView 5310 graphic terminals include:

- The intuitive Studio 5000 design environment allows users to create reusable faceplates, screens and custom graphics to help reduce development time

- Emulation capabilities allow engineers to test run projects in the development environment.

- VNC connectivity allows operators to remotely monitor operations via a smartphone, tablet or personal computer.

- Historical-trending and data-logging features allow operators to easily troubleshoot issues directly on the panel.

Better Access to Production Information

The updated ThinManager® v10.0 software platform provides new visualization, mobility and security features, helping machine operators and technicians produce more with less downtime.

With a new virtual-screening capability, users can customize how they see applications and data from multiple sources, all without rewriting a single line of code. This capability can help them view the information that is most relevant to their job.

The updated version introduces authentication pass-through to help improve productivity. Before the updates, users had to log in to ThinManager and other software applications separately, adding time onto costly operations. Now the software can natively pass users’ credentials to supported HMI products like FactoryTalk View Site Edition.

Moreover, with its built-in mobility solution, Relevance® software technology, the platform can deliver supported software components directly to mobile devices at specific locations within a facility.

Relevance uses location resolvers such as Bluetooth beacons and Wi-Fi so mobile users and devices can only receive content in authorized areas. This capability can help users achieve greater connectivity with better operational security.

Updated HMI Software Boosts Operator Efficiency

New features in the FactoryTalk View HMI software version 10.0 include greater access to information, new mobile device support and better cross-software integration to improve productivity.