Downloads

What is this for?

Simplify the calculation of the motor feedback torque in torque units for servo motors, as well as the conversion of the maximum torque from a given value in torque units to percent.

General Features

The use of the block or AOI (for Add-On Instruction) is extremely simple, just open the attached file labeled “AOI_TorqueCalculator_ForServoMotor - Application Code.ACD” and copy to your project file.

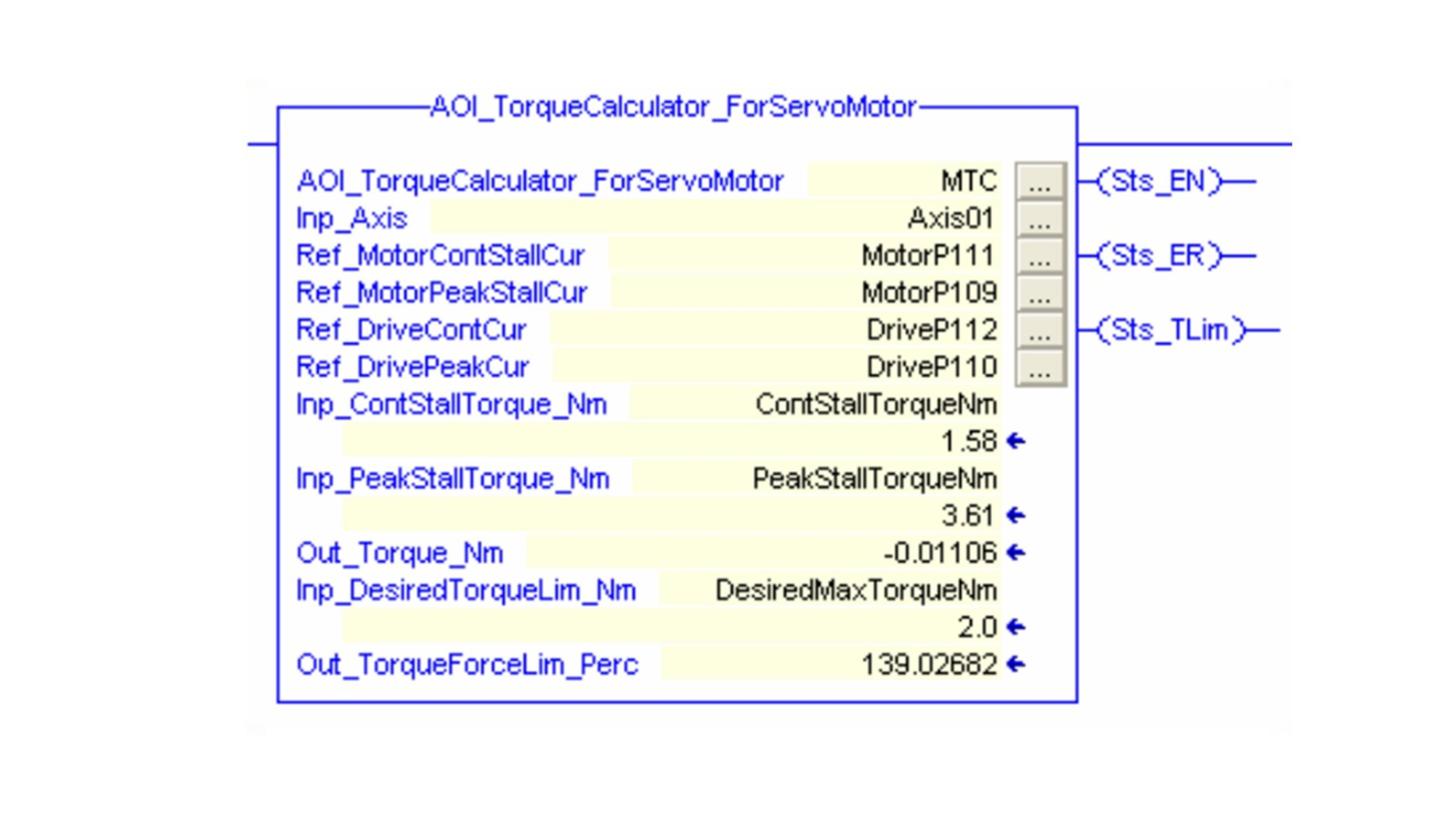

Add-On Instruction should look like this:

Limitations/Disadvantages

It can be used only with Servodrives with SERCOS network.

How can I make it work?

The AOI_TorqueCalculator_ForServoMotor automatically calculates the motor Torque Feedback in torque units. This AOI can also calculate the Peak Torque/Force Lim in percent from a desired maximum motor torque limit given in torque units.

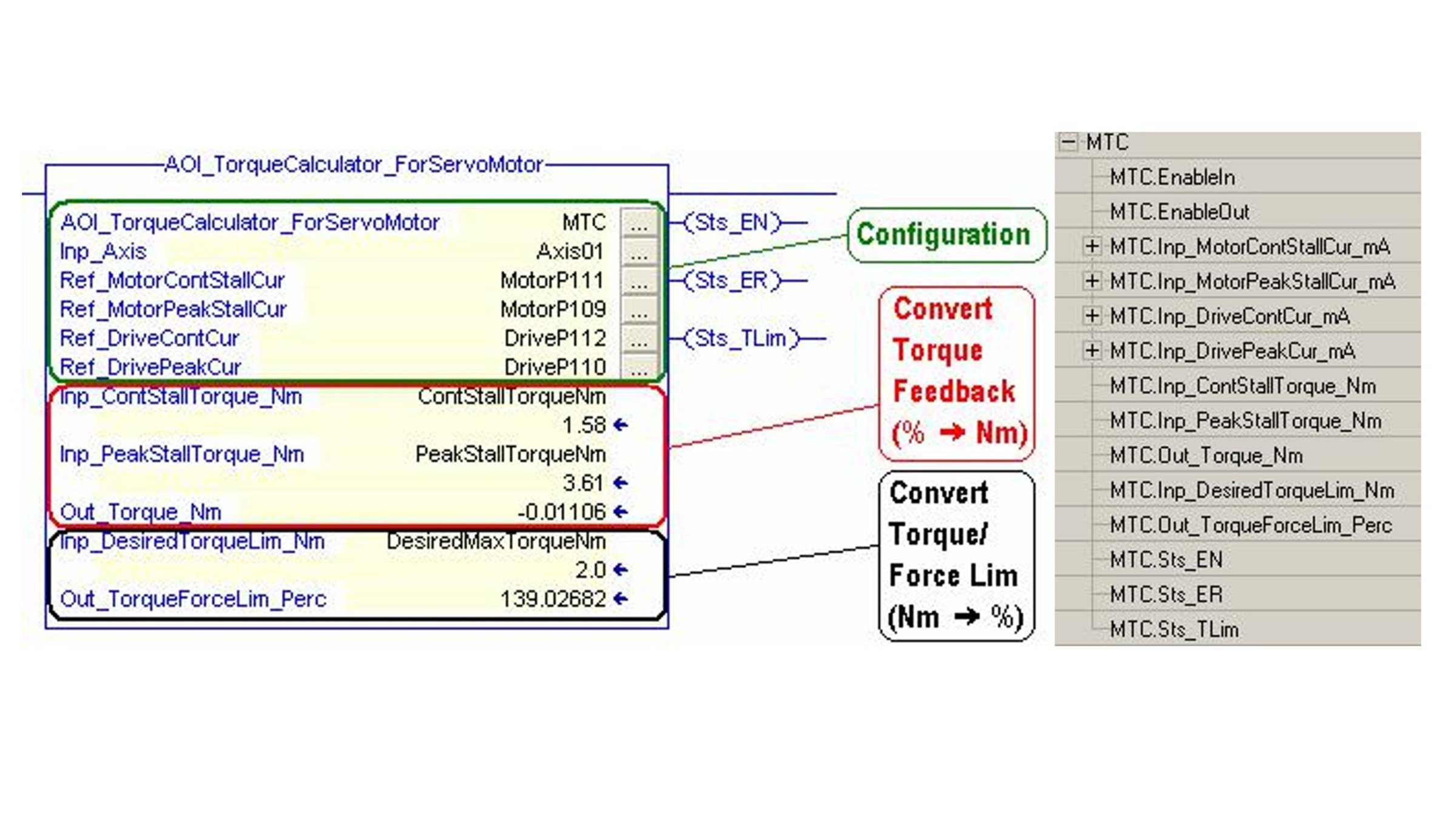

This AOI is constituted by three sets of parameters: one set for configuration of the AOI, one set to convert Torque Feedback from % to torque units, and a set to convert the Peak Torque/Force Lim from torque units to %.

The user needs to enter only two motor parameters in the AOI: Continuous Stall Torque and Peak Stall Torque found in datasheets. All the other parameters needed in this AOI are automatically read from the drive when this AOI is enabled. This AOI continuously converts the Torque Feedback from percent to a given toque unit while enabled. The result is placed in the parameter Out_Torque_Nm. The torque unit is the same of the parameters Inp_ContStallTorque_Nm and Inp_PeakStallTorque_Nm. Meanwhile, this AOI can be used to calculate the parameter Peak Torque/Force Lim from the torque entered in the parameter Inp_DesiredTorqueLim_Nm, which corresponds to the maximum peak torque required for a particular application. The parameter Inp_DesiredTorqueLim_Nm is entered in torque units and the result for the Peak Torque/Force Lim stored in the parameter Out_ForceTorqueLim_Perc is given in percent.

This AOI must remain enabled to calculate Torque Feedback in a given torque unit.

AOI Control

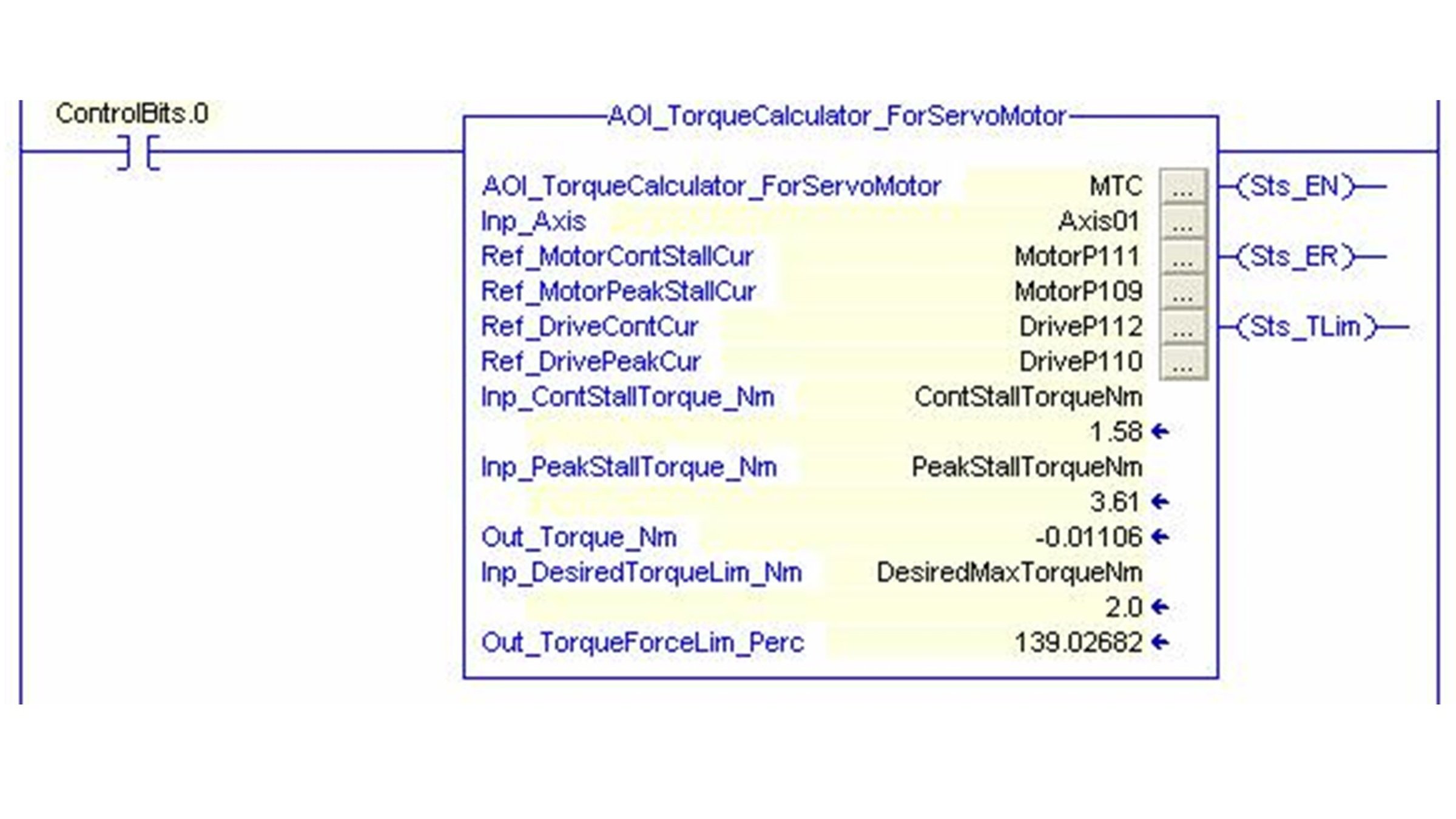

Typically, the AOI_TorqueCalculator_ForServoMotor instruction can be executed when torque feedback needs to be read in torque units or when the Peak Torque/Force Lim needs to be calculated for specific torque limit as shown below.

Appendix: Parameter Definitions

Inp_Axis:

Axis (Servo_Axis_Drive data structure) that will have torque converted torque units.

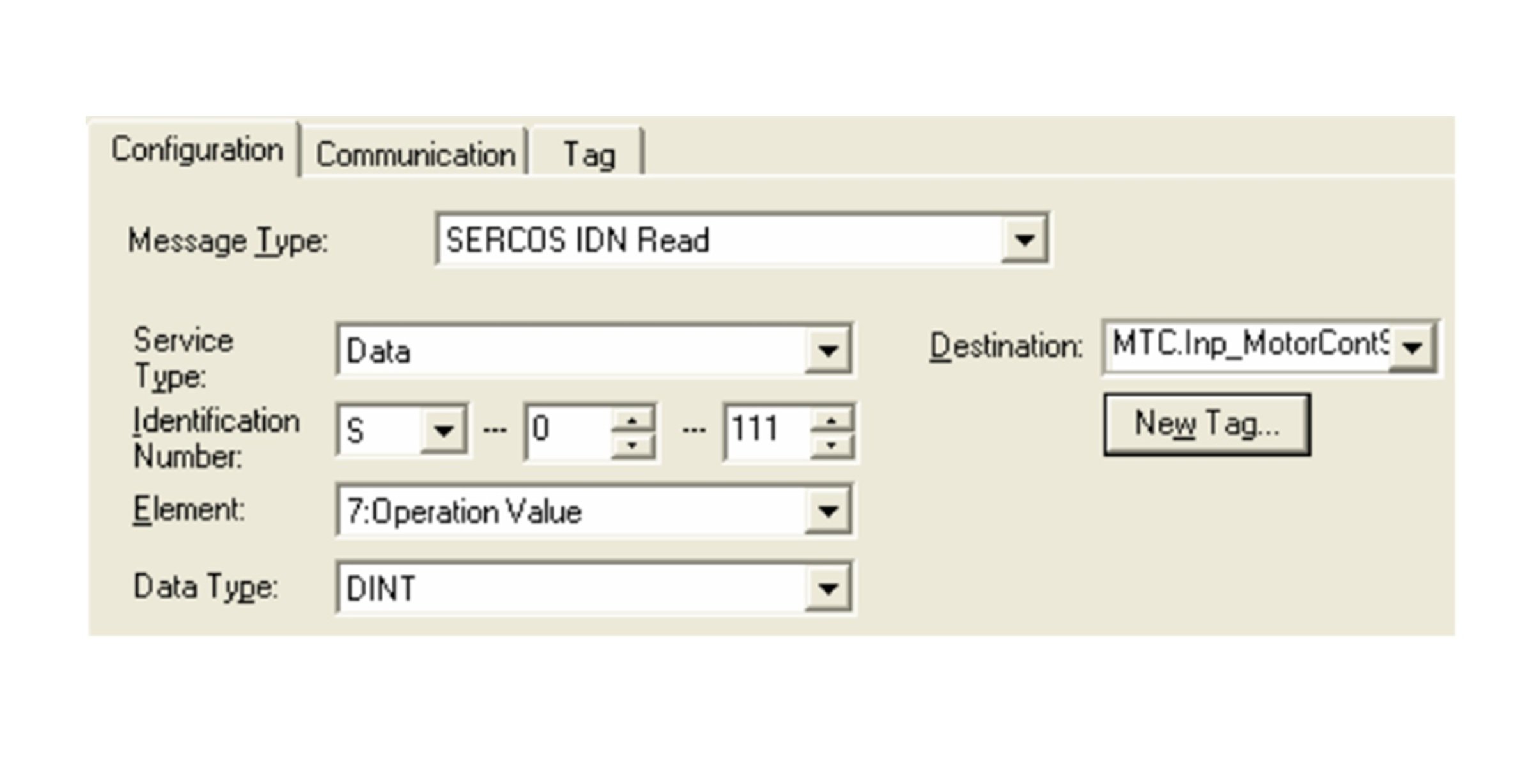

Ref_MotorContStallCur:

This is a Message data type tag. This parameter is used to read the Motor Continuous Stall Current from the drive. The Motor Continuous Stall Current is parameter 111 (S:0:111) in a Kinetix drive. The Ref_MotorContStallCur tag is configured in the AOI as shown below. The Destination is the tag MTC.Inp_DriveContCur_mA.

Ref_MotorPeakStallCur:

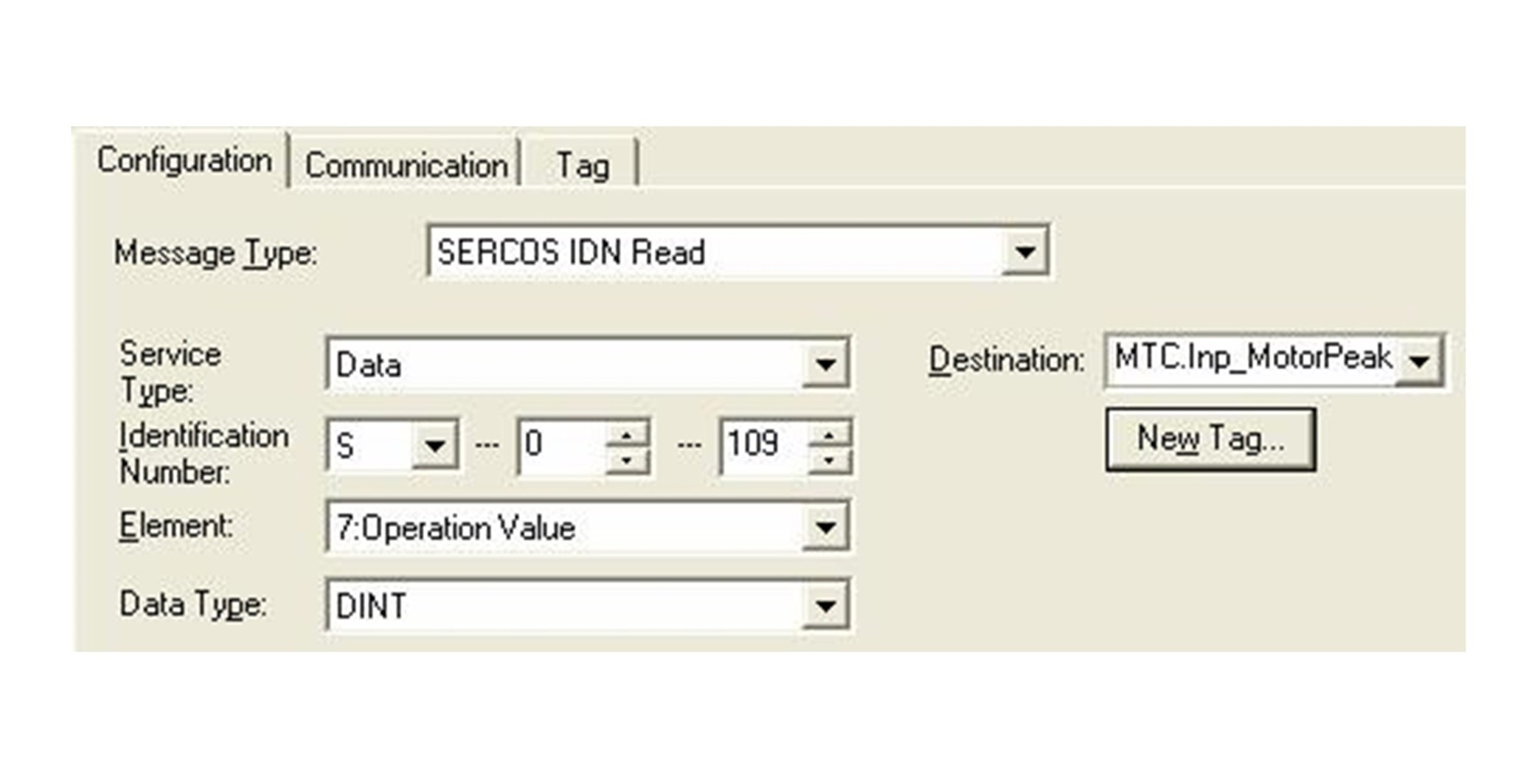

This is a Message data type tag. This parameter is used to read the Motor Peak Stall Current from the drive. The Motor Continuous Peak Current is parameter 109 (S:0:109) in a Kinetix drive. The Ref_MotorPeakStallCur tag is configured in the AOI as shown below. The Destination is the tag MTC.Inp_MotorPeakStallCur_mA.

Ref_DriveContCur:

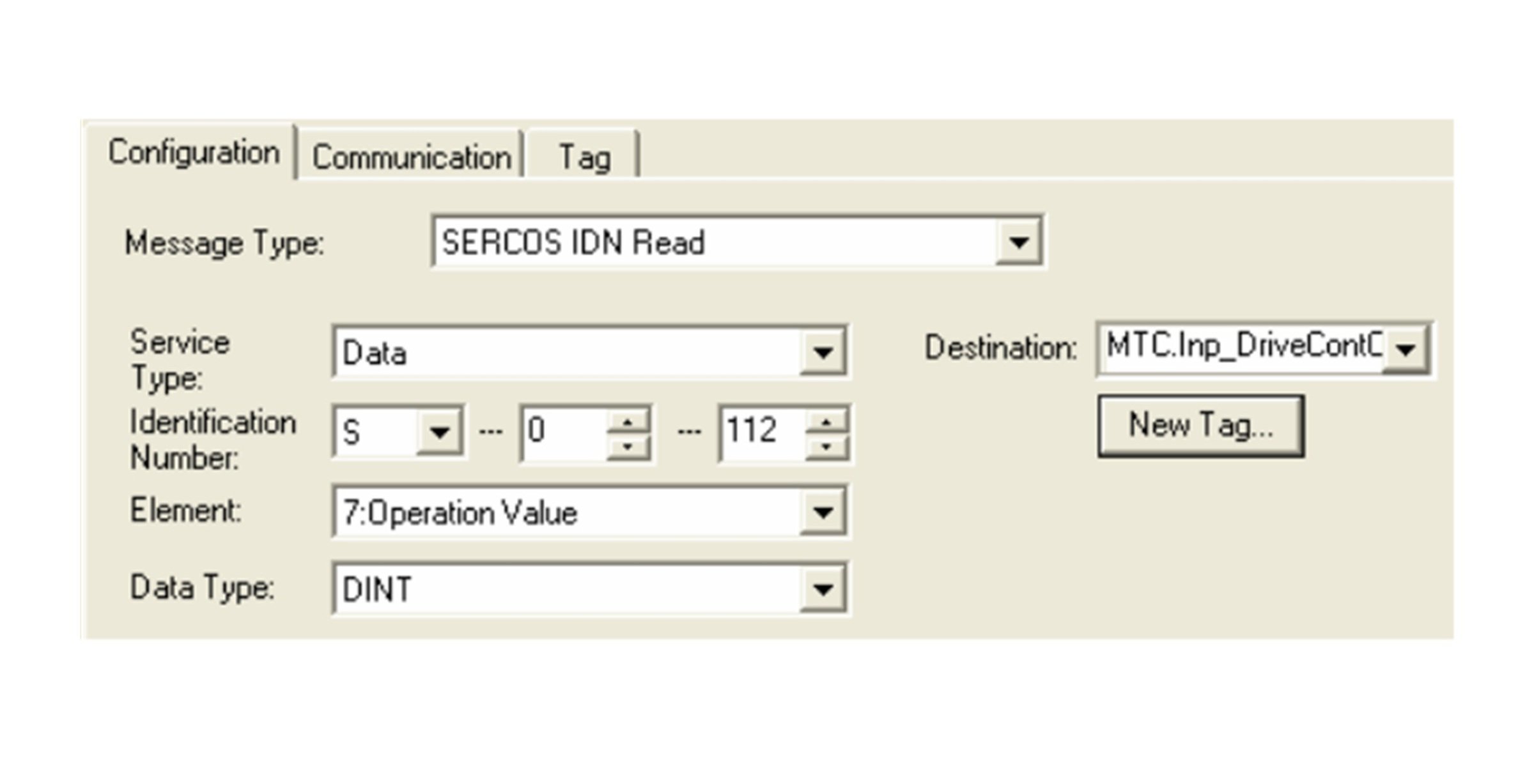

This is a Message data type tag. This parameter is used to read the Drive Continuous Current from the drive. The Drive Continuous Current is parameter 112 (S:0:112) in a Kinetix drive. The Ref_DriveContCur tag is configured in the AOI as shown below. The Destination is the tag MTC.Inp_DriveContCur_mA.

Ref_DrivePeakCur:

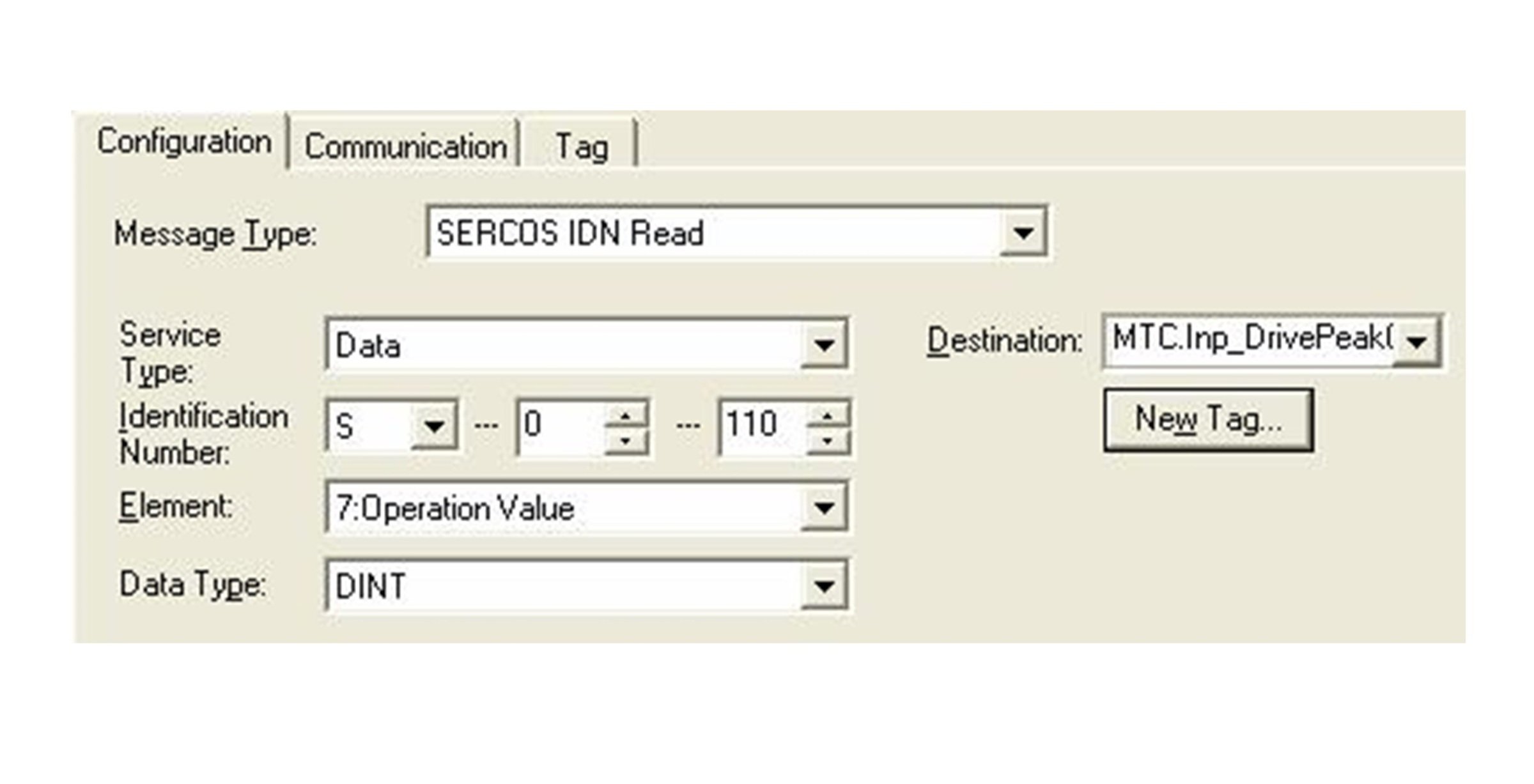

This is a Message data type tag. This parameter is used to read the Drive Peak Current from the drive. The Drive Peak Current is parameter 110 (S:0:110) in a Kinetix drive. The Ref_DrivePeakCur tag is set in the AOI as shown below. The Destination is the tag MTC.Inp_DrivePeakCur_mA.

Inp_ContStallTorque_Nm:

This is a REAL data type tag. The user uses this parameter to enter the Motor Continuous Stall Torque, which is found in the motor nameplate or in the Motion Selection Guide. This parameter is shown to be given in Nm. However, any other torque unit can be used if the Inp_PeakStallTorque_Nm be also set in the same toque unit. Thus, the torque feedback given in the Out_Torque_Nm will also be given in this same torque unit.

Inp_PeakStallTorque_Nm:

This is a REAL data type tag. The user uses this parameter to enter the Motor Peak Stall Torque, which is found in the Motion Selection Guide.

Out_Torque_Nm:

This is a REAL data type tag. This parameter shows the Torque Feedback converted from percent to the torque unit given by the parameters Inp_ContStallTorque_Nm and Inp_PeakStallTorque_Nm.

Inp_DesiredTorqueLim_Nm:

This is a REAL data type tag. This parameter is used to enter in torque units the torque limit for a particular application. The AOI converts this torque from torque units to percentage. This torque in percent is the Peak Torque/Force Lim to be manually entered in the Limits tab of the Axis Properties. The torque entered in this parameter must be in the same unit as the parameters Inp_ContStallTorque_Nm and Inp_PeakStallTorque_Nm.

Out_TorqueForceLim_Perc:

This is a REAL data type tag. This parameter returns the Peak Torque/Force Lim necessary to limit the motor torque to the value entered in the parameter Inp_DesiredTorqueLim_Nm. This parameter is given in percentage.

Sts_EN:

The Enable bit is set while the rung is on.

Sts_TLim:

This Torque Limit bit is set when the value entered in the Inp_DesiredTorqueLim_Nm parameter is higher than the torque that the motor-drive system can deliver.

Sts_ER:

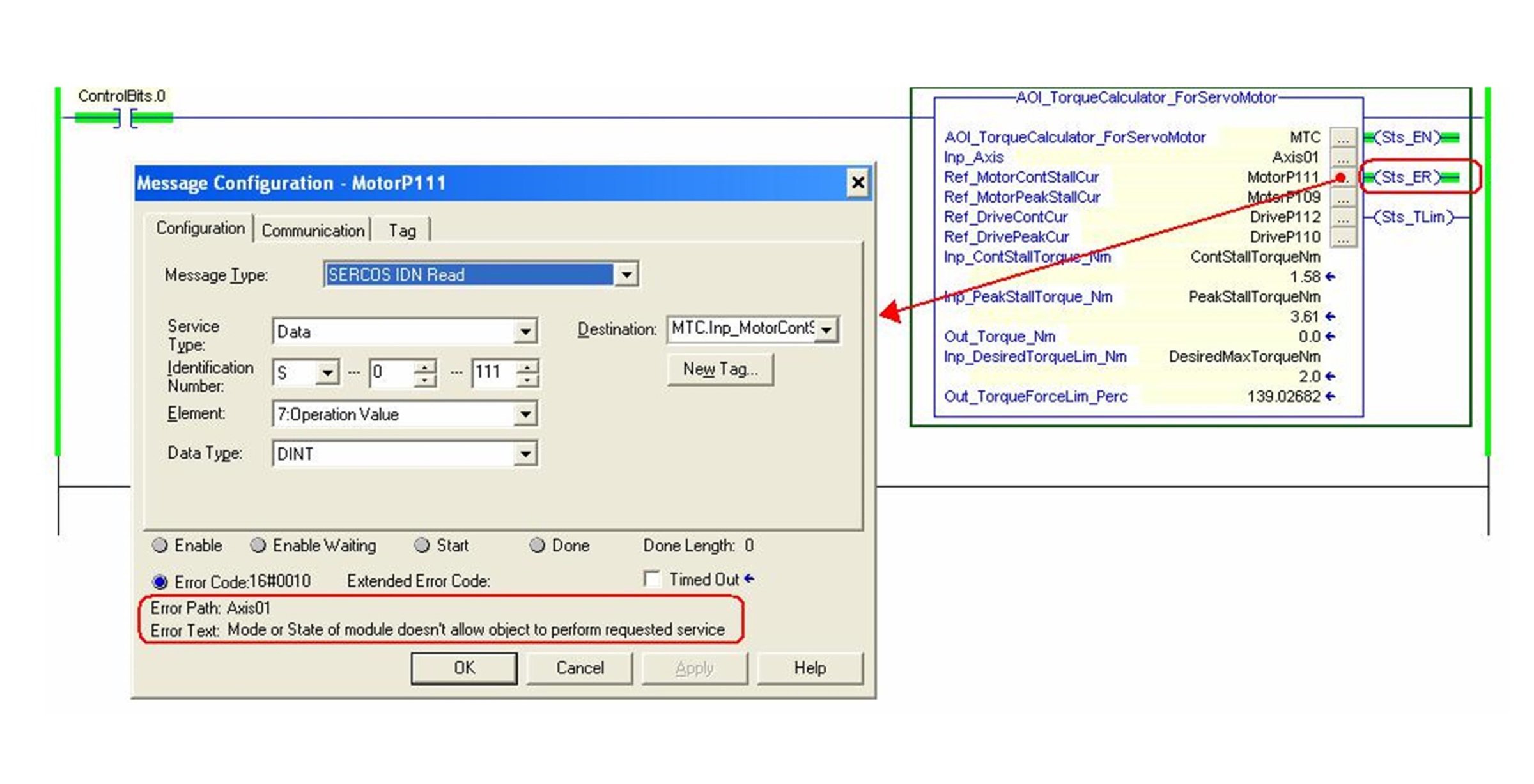

The Error bit is set if same of the message instructions used to read parameters from the drive fail to communicate with the drive. This bit is reset when the AOI is enabled. When an error occurs, the error message can be read in the Message Configuration window which can be accessed by hitting the box beside the tag name as shown below.

Inp_MotorContStallCur_mA:

This is a DINT data type tag. This parameter is the Destination in the Ref_MotorContStallCur message. This parameter contains the Motor Continuous Stall Current in mA read from the drive by the Ref_MotorContStallCur message.

Inp_MotorPeakStallCur_mA:

This is a DINT data type tag. This parameter is the Destination in the Ref_MotorPeakStallCur message. This parameter contains the Motor Peak Stall Current in mA read from the drive by the Ref_MotorPeakStallCur message.

Inp_DriveContCur_mA:

This is a DINT data type tag. This parameter is the Destination in the Ref_DriveContCur message. This parameter contains the Drive Continuous Current in mA read from the drive by the Ref_DriveContCur message.

Inp_DrivePeakCur_mA:

This is a DINT data type tag. This parameter is the Destination in the Ref_DrivePeakCur message. This parameter contains the Drive Peak Current in mA read from the drive by the Ref_DrivePeakCur message.

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.