Downloads

What is this for?

Smartbelt is a conveyor system using intelligent belts. It seeks to organize a queue of products coming in a disordered manner into an orderly position. The system is commonly used to control the positioning of flight conveyors. Correction can be made by one or more conveyors, depending on the dynamics required.

The application uses AOI resources that perform the correction based on the size of the conveyor, registration sensors to check the current position of the Servodrive movement, the size of the product on the conveyor, and the correction distance to the target. In this way, each conveyor performs independent movement control.

The Smartbelt feature is recommended for OEM manufacturers who use movement mechanisms to deliver loads using flighted conveyors with product separation:

- Boxing machines

- Packaging machines

- Special machines

General Features

Flexible system that can change between different product sizes using just a few parameters:

- Add-on instruction for calculating position correction error.

- Follower x master working regime for target position from 0 to 360 degrees.

- Use of the Virtual Axis as the main axis for the follower axes.

- Use of the Machine Builder Library as a reference for motion control via Axis Handler.

Limitations/Disadvantages

- For positioning on perpendicular belts, the correction of each belt must not be greater than the gap between products, to avoid product collisions.

- High speeds depend on the mechanics available for correct movement.

- Tight product delivery window.

How can I make it work?

The architecture involves the use of Compactlogix or Contrologix hardware with CIP Motion and CIP Sync capabilities, as well as the use of ServoDrives from the Kinetix 5300, 5500 or 5700 families. In this program, the K5500 is being used.

And that's the software you need:

- Logix Design Studio 5000.

- Firmware Revision 33 or higher.

- Program SmartBelt.ACD

- User-defined function blocks:

- AOI_CalcCorrectionDistance

- FactoryTalk View Studio V13.0

- Program SmartBelt.MER

Knowledge required:

We recommend having an intermediate understanding of programming ladder logic in Logix Design Studio 5000 software and configuring the Motion Control system. As well as basic knowledge of the FactoryTalk View ME application in order to set up the HMI application to restore and run it.

Need help?

If you need help with an application or have feedback from the Innovation Center, please, contact us.

Installation Guide

Step 1

- Open the SmartBelt.ACD program - The file is located in the Generalfiles.zip folder in the Download area.

- Download in a virtual environment (Logix Echo - optional) or physically on a Logix controller.

- Restore the HMI file for use in simulation mode or physically as a runtime.

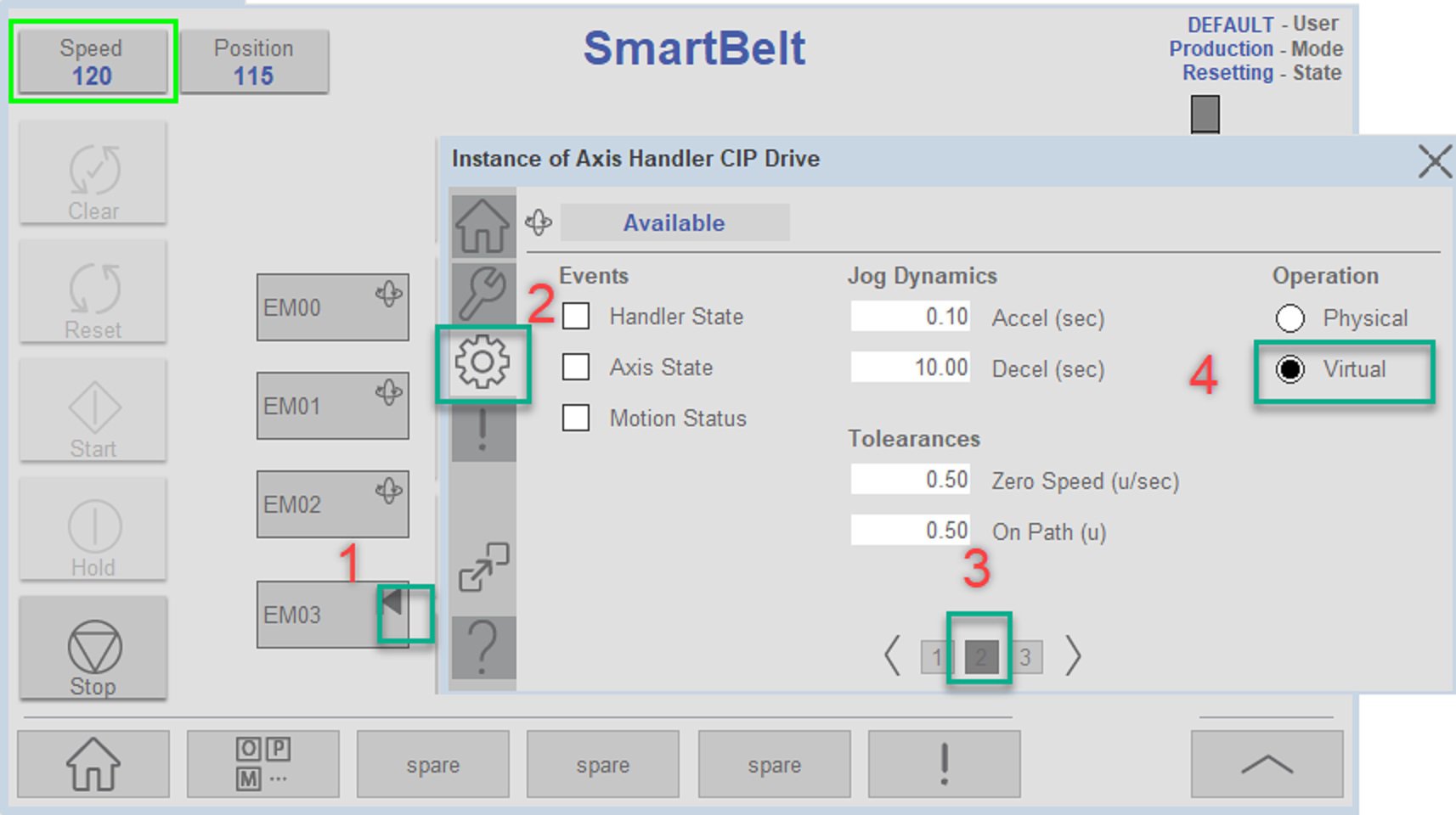

- Initially, you can use the program with Virtual Axis, enabling this option for existing Kinetix Drives via the HMI faceplate.

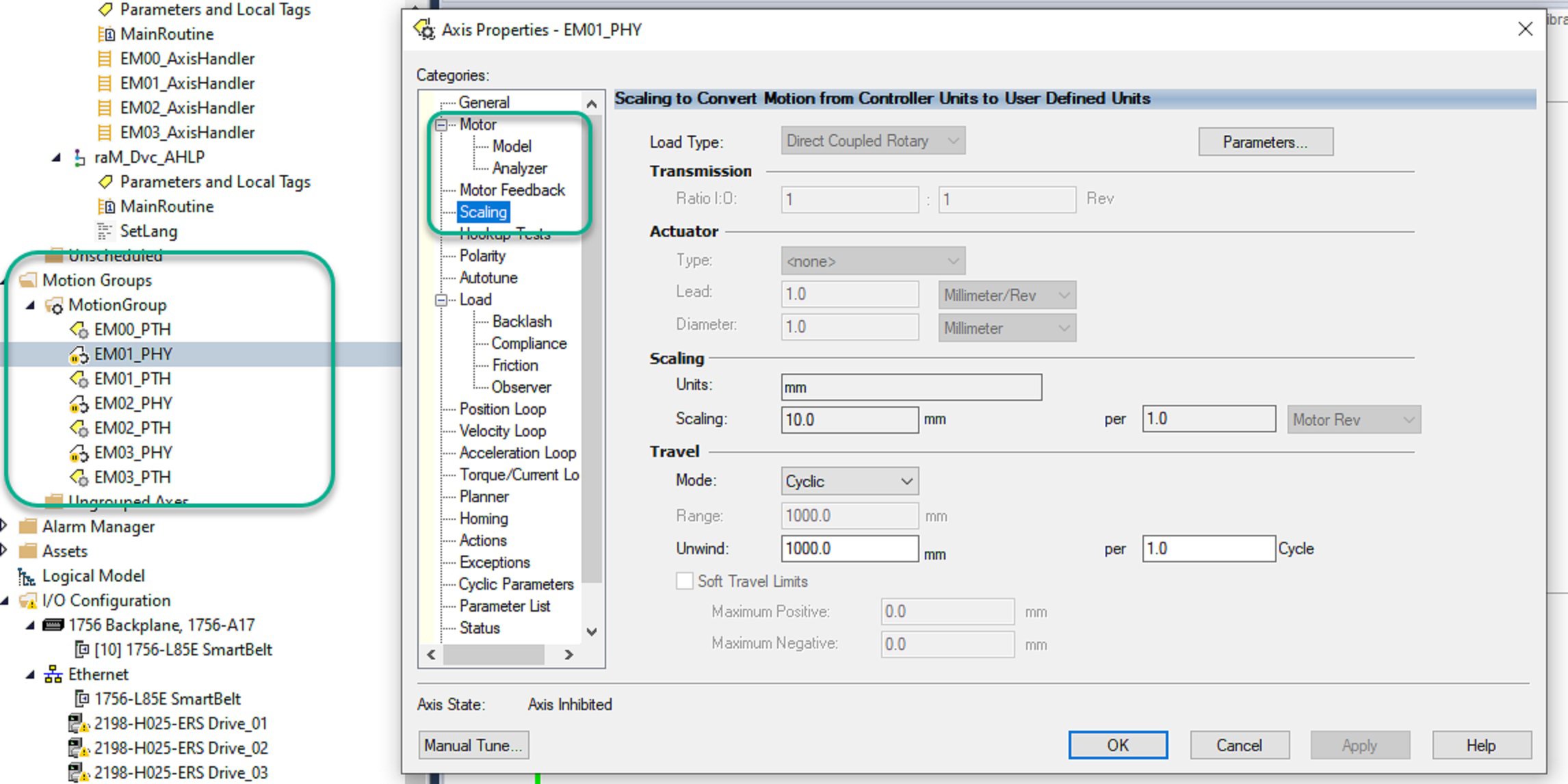

Step 2

Check the physical configurations of the axes, changing them as required by the project:

- EM00 - Virtual Master Axis

- EM01PHY - First conveyor belt axis

- EM02PHY - Second conveyor belt Axis

- EM03PHY - Third conveyor belt Axis

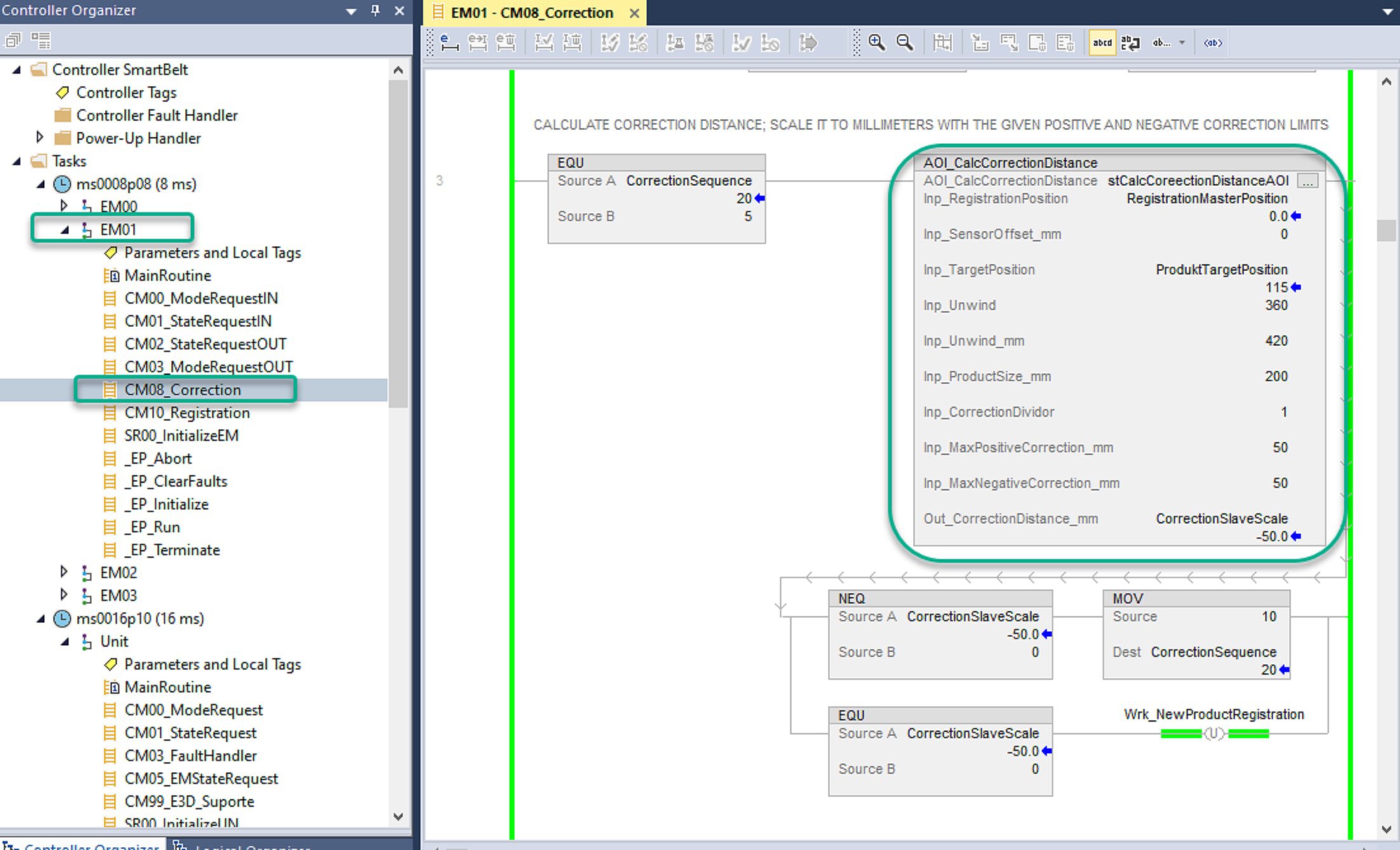

Step 3

In the EM01 to EM03 programs, in the CM08_Correction routines, adjust the respective measurements in the AOI as required by the project:

- Inp_Unwind - One-turn cycle in degrees of the EM00 Master - Default 360.

- Inp_Unwind_mm - Belt length in millimeters.

- Inp_ProductSize_mm - Product length in millimeters to be corrected on the belt.

- Inp_MaxPositiveCorrection_mm - Maximum positive correction value for each belt.

- Inp_MaxNegativeCorrection_mm - Maximum negative correction value for each belt.

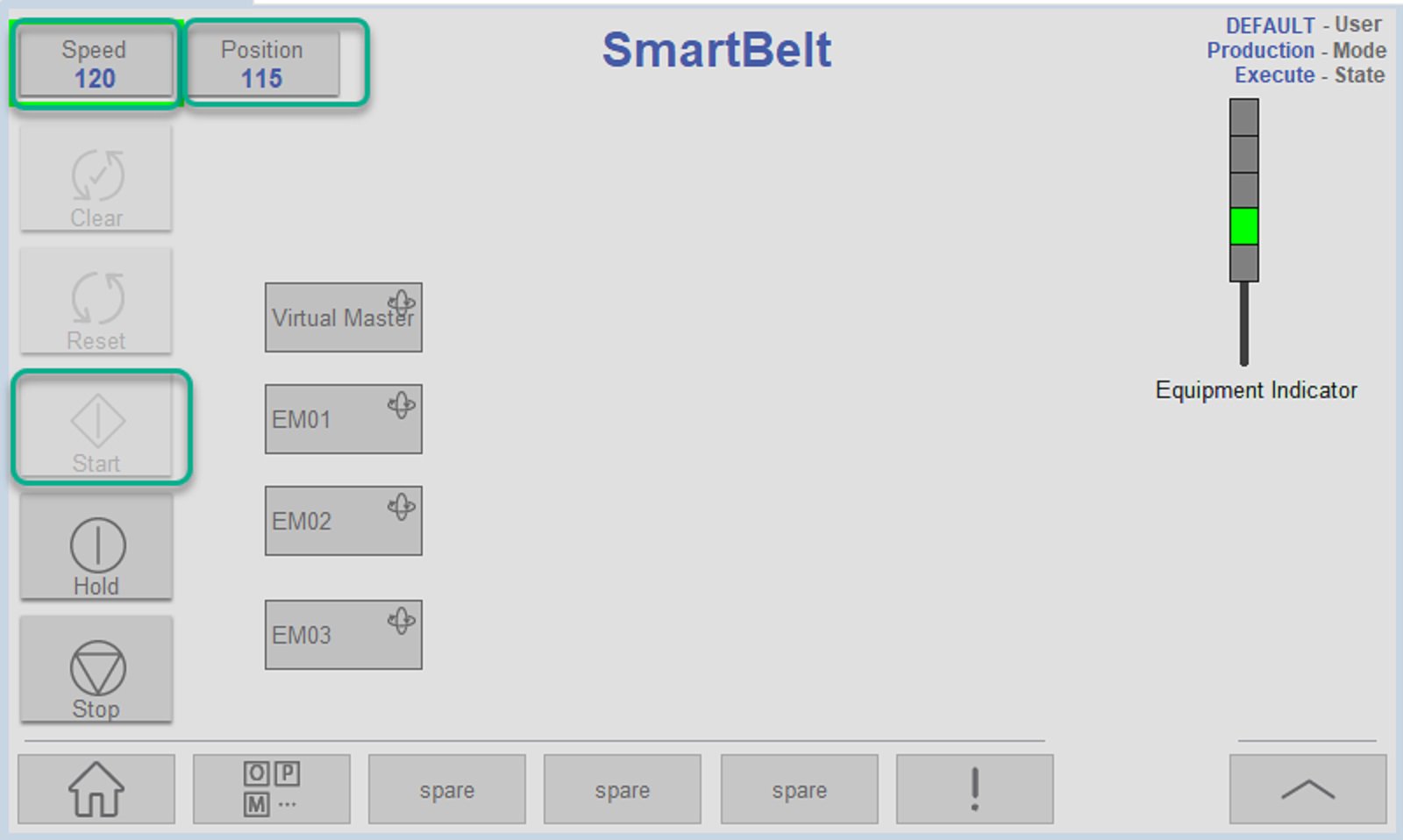

Step 4

- Start the Factory Talk View application to begin the motion tests. You can change the speed of products per minute. Always respect the frequency at which the products are released, which must be lower than the frequency of packages per minute requested. This avoids overloading the conveyor belt and congesting products for correction.

- The system should be able to hold a maximum of one product per conveyor belt, thus avoiding correction errors. Check the project presentation in the support material.

- The position set point is the desired flight conveyor target in degrees (Example 115 degrees).

- To use Emulate 3D to simulate the application, Class 1 MSG must be enabled for the Point IO to operate as a remote and Emulate 3D test sensors.