Downloads

What is this for?

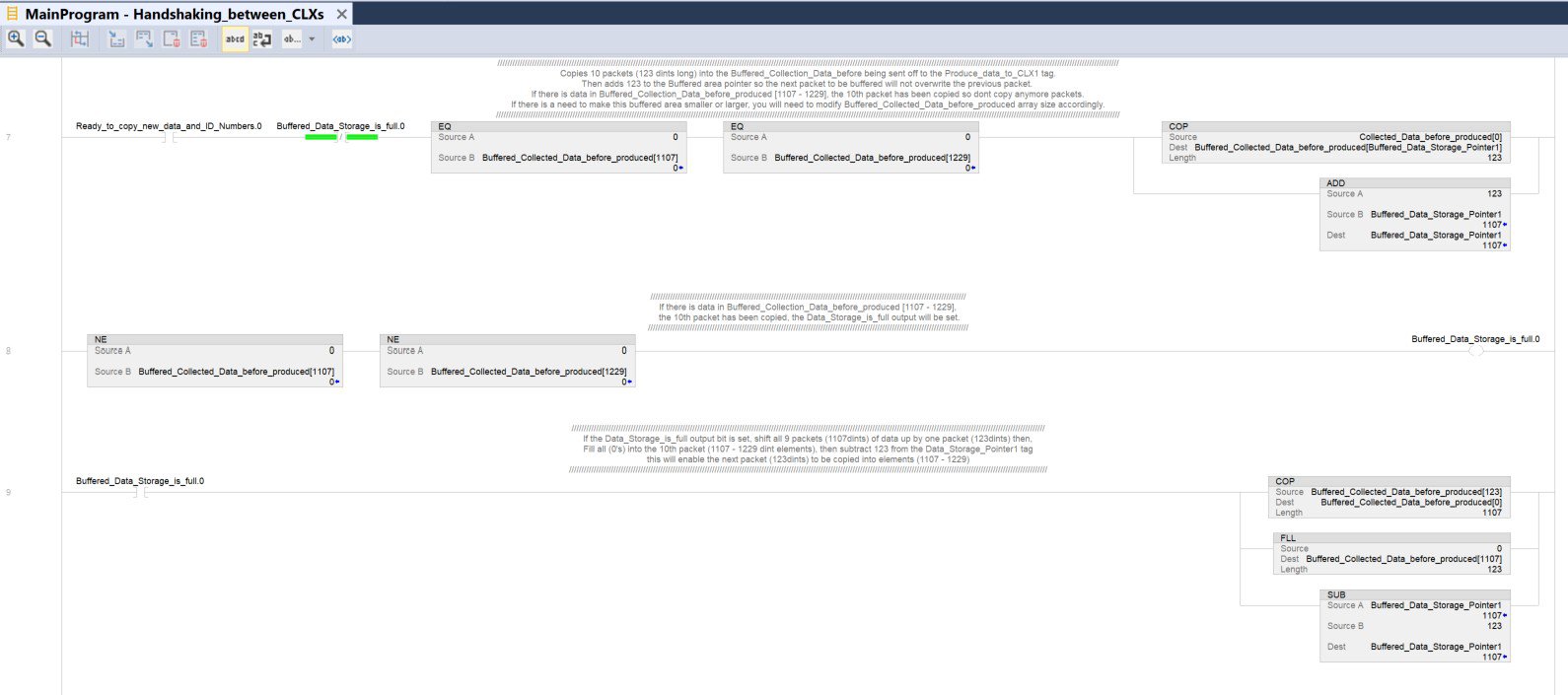

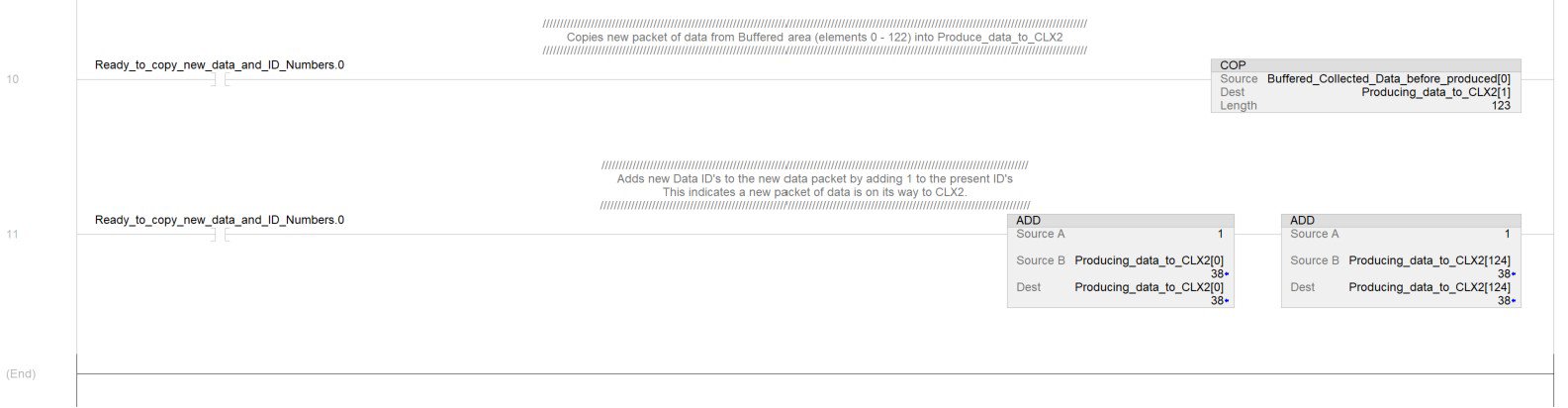

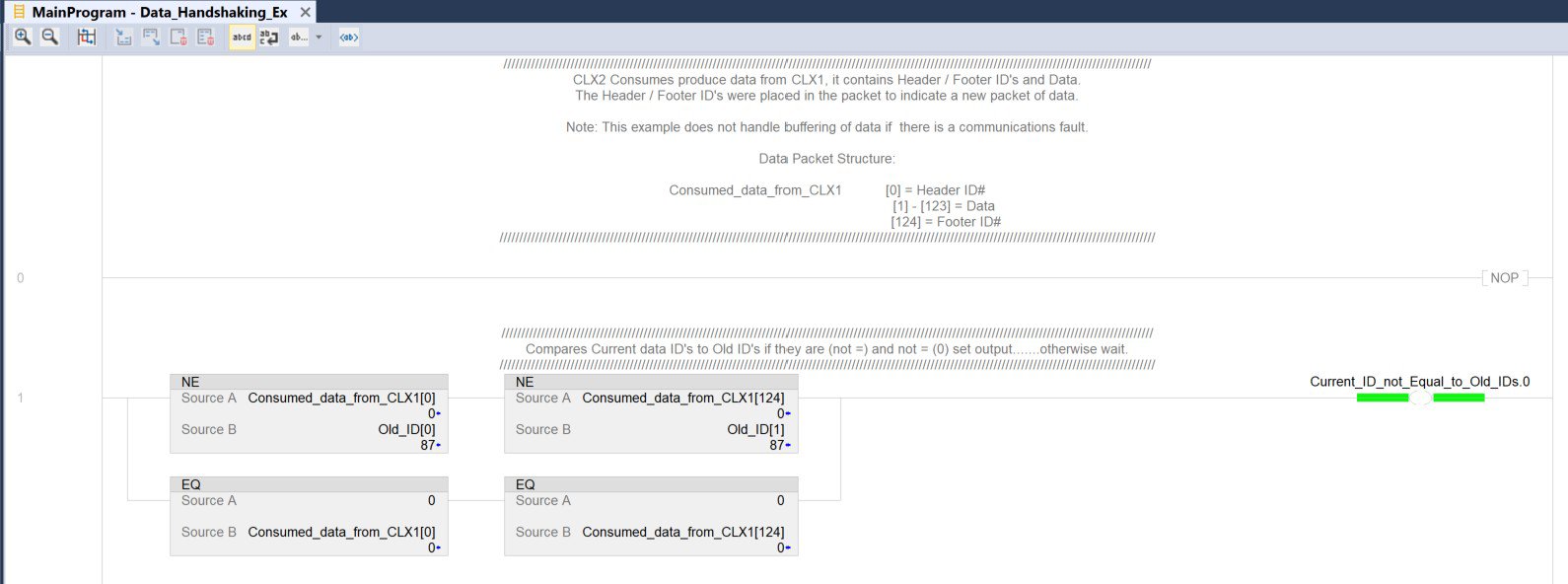

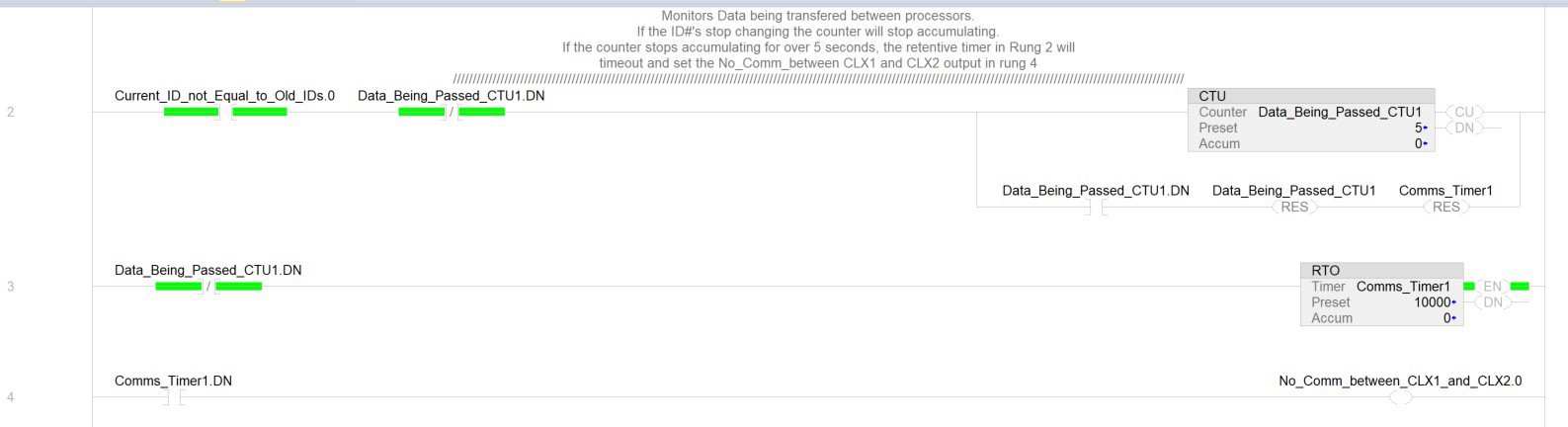

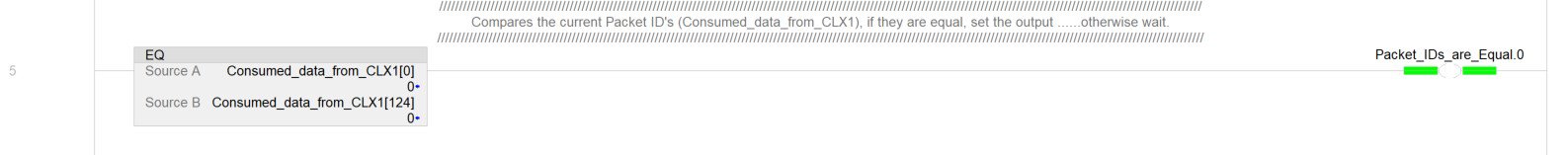

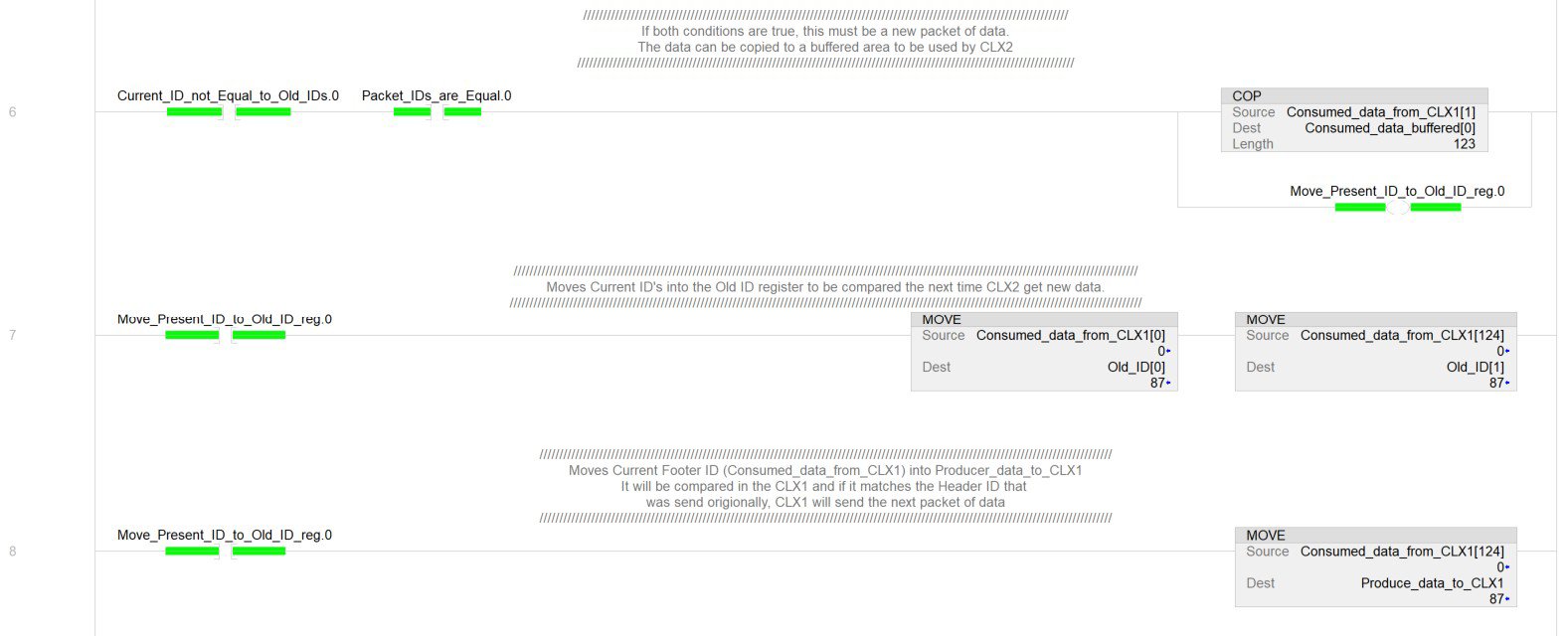

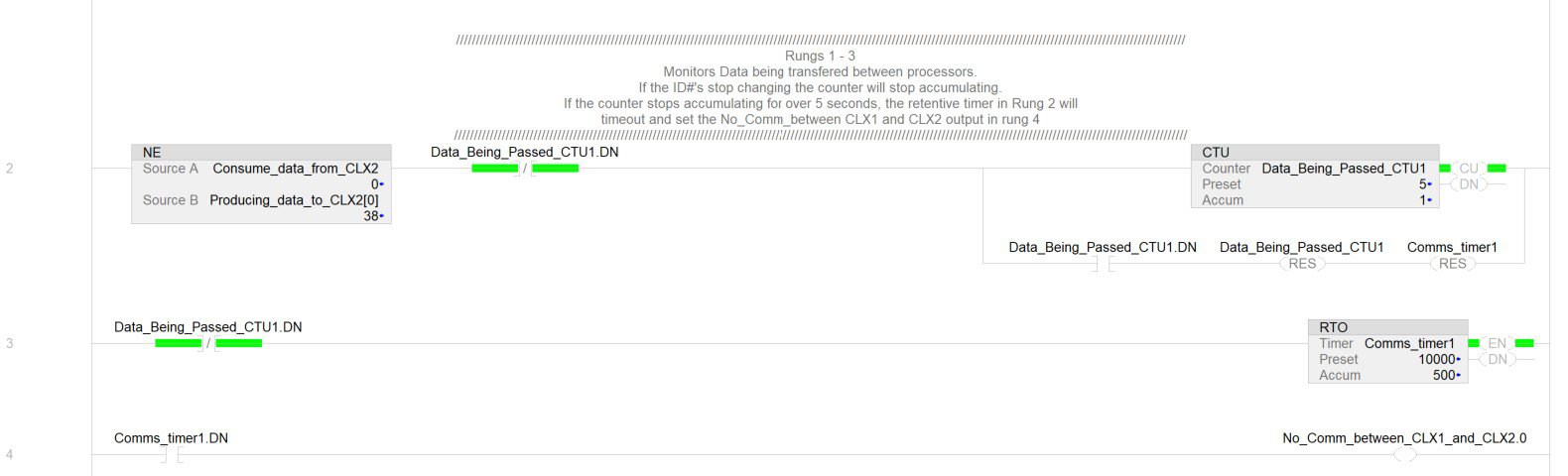

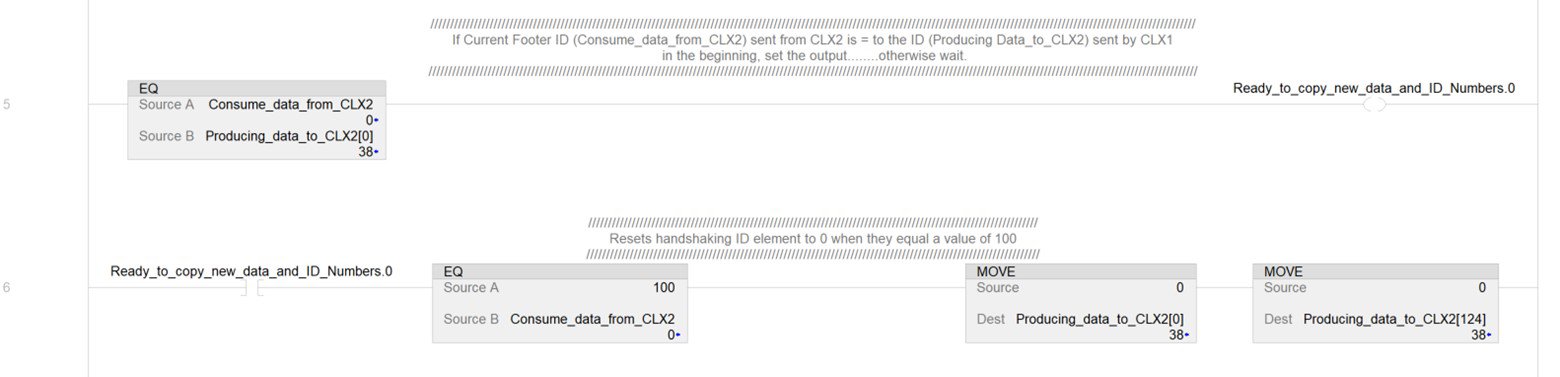

Sometimes there is a need to send data from one controller to another and be confident the data being sent/ received is accurate and not a combination of old and new data. This application note shows how to send one (500byte) packet of buffered data using a Produce / Consume (Class 1) connection over Ethernet/IP.

General Features

- Data Buffer

- Handshake

Advantages: This sequence facilitates the implementation and quick configuration when is need it to send one packet of buffered data using a Produce / Consume (Class 1) connection over Ethernet/IP, without any other hardware.

Limitations/Disadvantages: This sequence is available for CompactLogix / ControlLogix Controllers.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Is this helpful?

This code is defined for applications when it is needed to send one packet of buffered data over Ethernet/IP.

Application areas: Food, Manufacturing, Beverage

How can I get this working?

- Hardware

- Personal computer with an available USB port

- CompactLogix, ControlLogix Controller

- Software

- Studio 5000, version 21 or later

- Previous knowledge:

- Intermediate knowledge of programming and configuration in Studio 5000 software: Ladder language (LD)

Implementation Guide

Send Data between Controllers with Handshake in Studio 5000

Version 1.0 - November 2024