Downloads

What is this for?

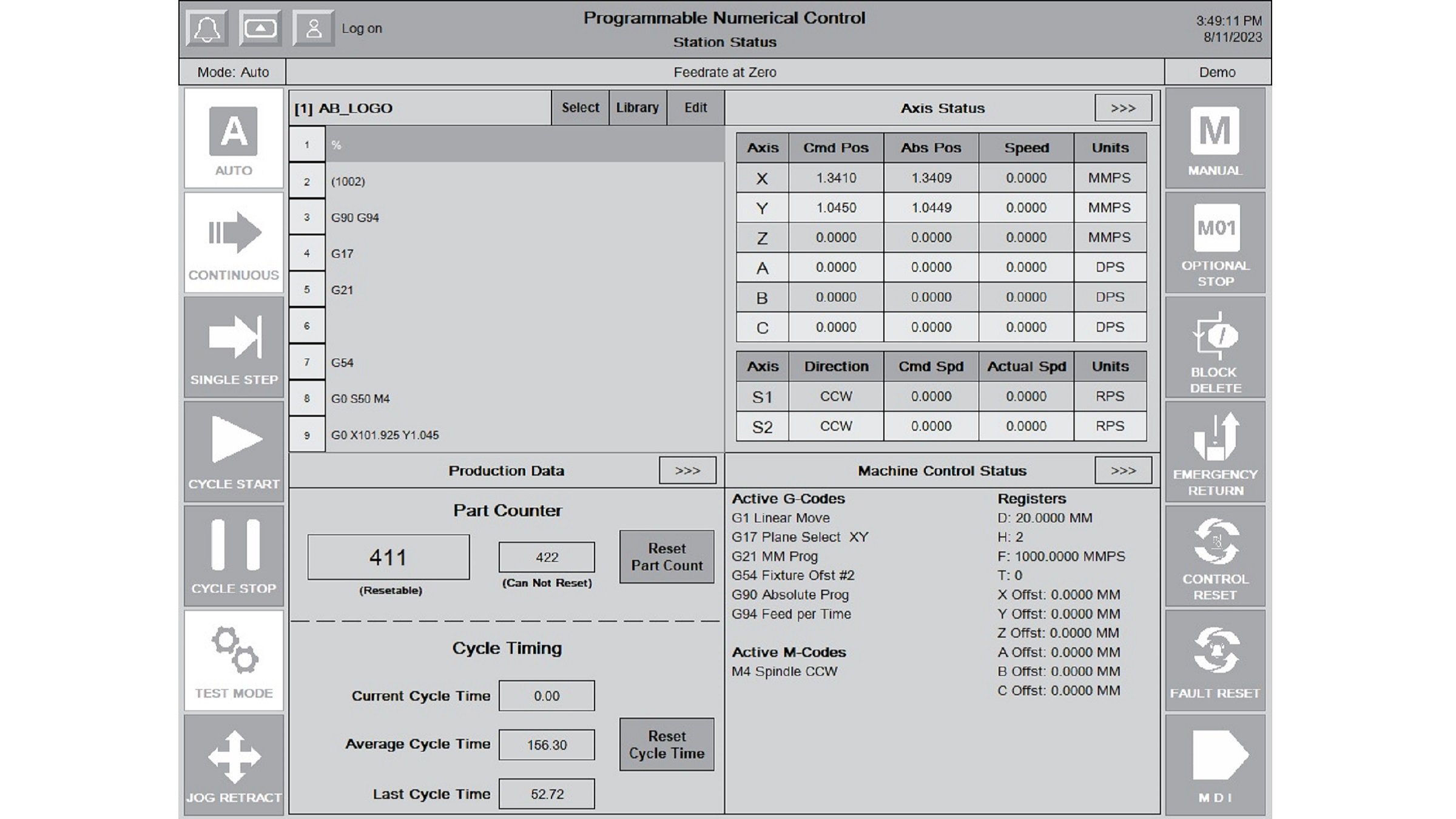

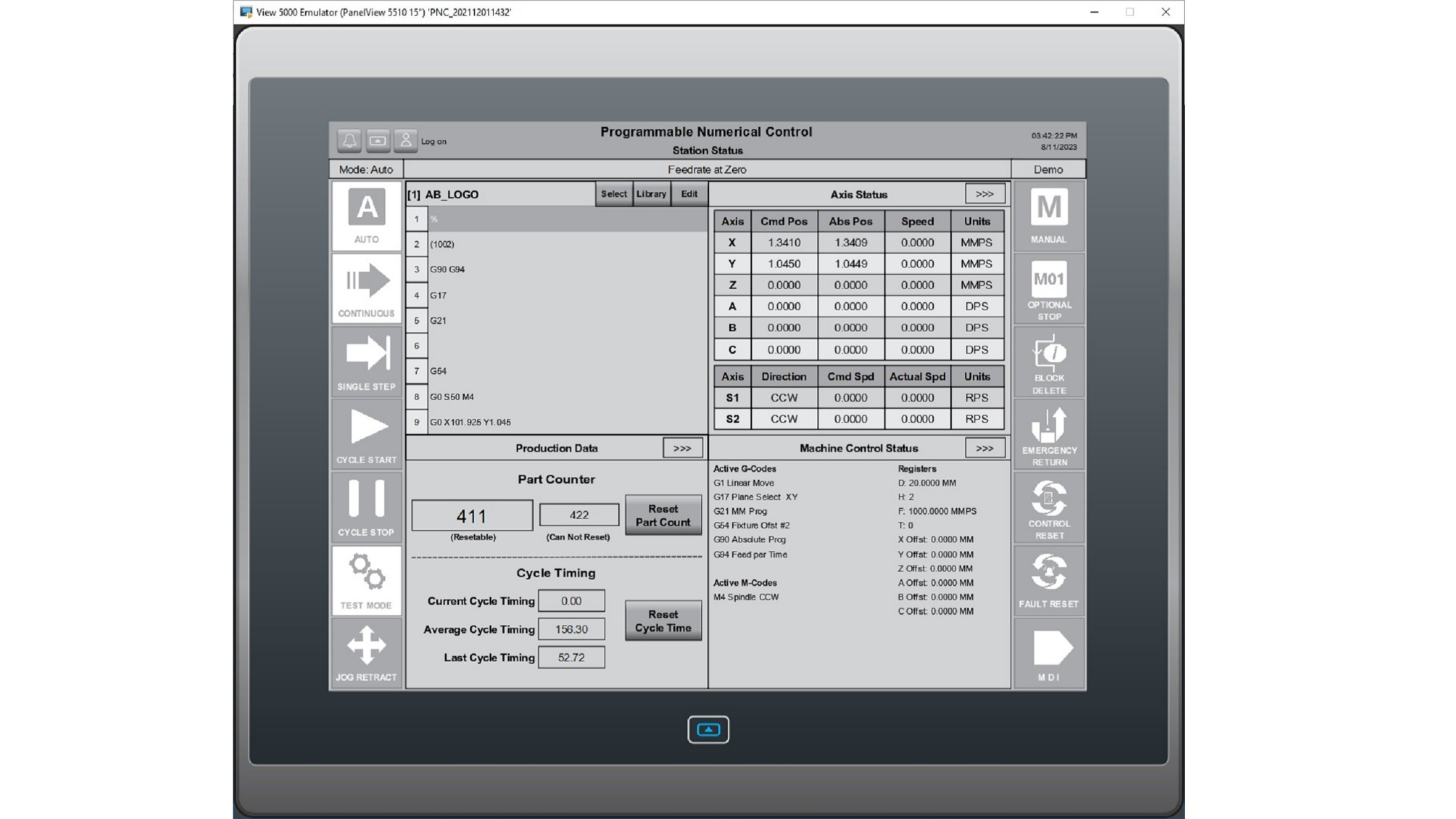

PNC stands for Programmable Numerical Control and it is a paired Logix Controller and HMI program solution which provides midrange computer numeric control (CNC) functionality in the Logix architecture which is capable of executing RS274D tool path programs. These programs are often referred to as CNC part program, or M&G code files. The M&G codes are provided by the PNC, that start with the letter ‘M’ and ‘G’, and provide instructions for the machine.

General Features

- Executes RS274D based Part Files

- Core set of M&G codes supported

- Codes may be modified or added by machine builder

- Executes on Compact or ControlLogix controllers, PanelView Plus or PV5xx0 HMI, any CIP Motion standard drives or servo drives

- Support for up to 6 axis of coordinated motion and 2.5D contouring

- Supports a wide variety of machine types (X Y Z table, gantry, mill, lathe, grinder)

- Provided as sample code at no-charge to customers

- Provides a good value for medium axis count coordinated motion applications, which use RS274D

- Cutter or Tool compensation

Advantages:

Modular and Flexible Equipment

- Adaptable/customizable for new or rebuild machines

- Wide variety of machines supported

- Scalable standard control and safety solutions to meet application specific requirements

Compatible with Industry Standard RS274D CNC Programs

- Broad compatibility across design tools and utilities

- Expandable to meet application requirements

Design Flexibility and Productivity

- Standards conformity and modular programming

- Faceplates, code libraries, Add-On Instruction, Integrated Architecture system, EtherNet/IP offers a pre-engineered solution

Lower-cost solution

- Can provide a lower-cost TCD3 than traditional or PC-based CNC solutions

- Right sized solutions for medium axis count machines

Limitations/Disadvantages

- Offers a subset of features to those found in a CNC controller

- Max. 6 axis of coordinated motion

- Automatic Tool changer (ATC) not included on sample code

- Works with ControlLogix (L8) or CompactLogix (5380) controllers only

Is this useful for me?

In general, PNC solution can be recommended to OEM manufacturers of following machine types:

- Boring machines

- Broaching machines

- Drilling machines

- Grinding machines

- Honing machines, vertical spindle

- Lapping machines

- Laser cutting or drilling systems

- Laser marking systems

- Laser welding and cladding machines

- Lathes

- Machining Centers

- Milling machines

- Pipe and tube bending machines

- Plasma cutting machines

- Plastic cutting and slitting

- Riveting machines

- Roll finishing machines

- Roll forming and bending machines

- Sawing machines

- Thread cutting and Thread rolling machines

- Threading and cutoff machines, pipe and bar

- Turn/mill machines, CNC

- Turning centers

- Ultrasonic machining equipment

- Water jet cutting machines

- Welding machines

- Woodworking equipment

Application areas:

Automotive, Manufacturing, Metals, Plastics, Wood, Glass

Benefits of applications with PNC solution:

- Allows the use of same control platform as used on other machine type

- Customizable solution (open-source application sample code), improves machine flexibility

- Easy of integration with other devices

How can I make it work?

Hardware

- Kinetix 5300, Kinetix 5500, Kinetix 5700 with CIP Motion and CIP Sync

- PowerFlex 755 with CIP Motion

- CompactLogix L340ERM, ControlLogix L82E or higher

- Firmware revision 33 or higher

- PanelView Plus / PanelView 5000

Software

- Studio 5000 Logix Designer

- FactoryTalk View Machine Edition / Studio 5000 View Designer

- PNC_202111291223.ACD / PNC_202111291223_CompactLogix.ACD

- PNC_202110261632.mer / PNC_202112011432.vpd

Required Knowledge

Intermediate knowledge of Motion control, programming and configuration using Studio 5000 Logix Designer. Basic knowledge of HMI programming using FactoryTalk View ME or Studio 5000 View Designer. Familiarity with CNC programming (Part program, G-Code). Training on PNC Solution.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation guide

To implement, check the steps below.

Step 1

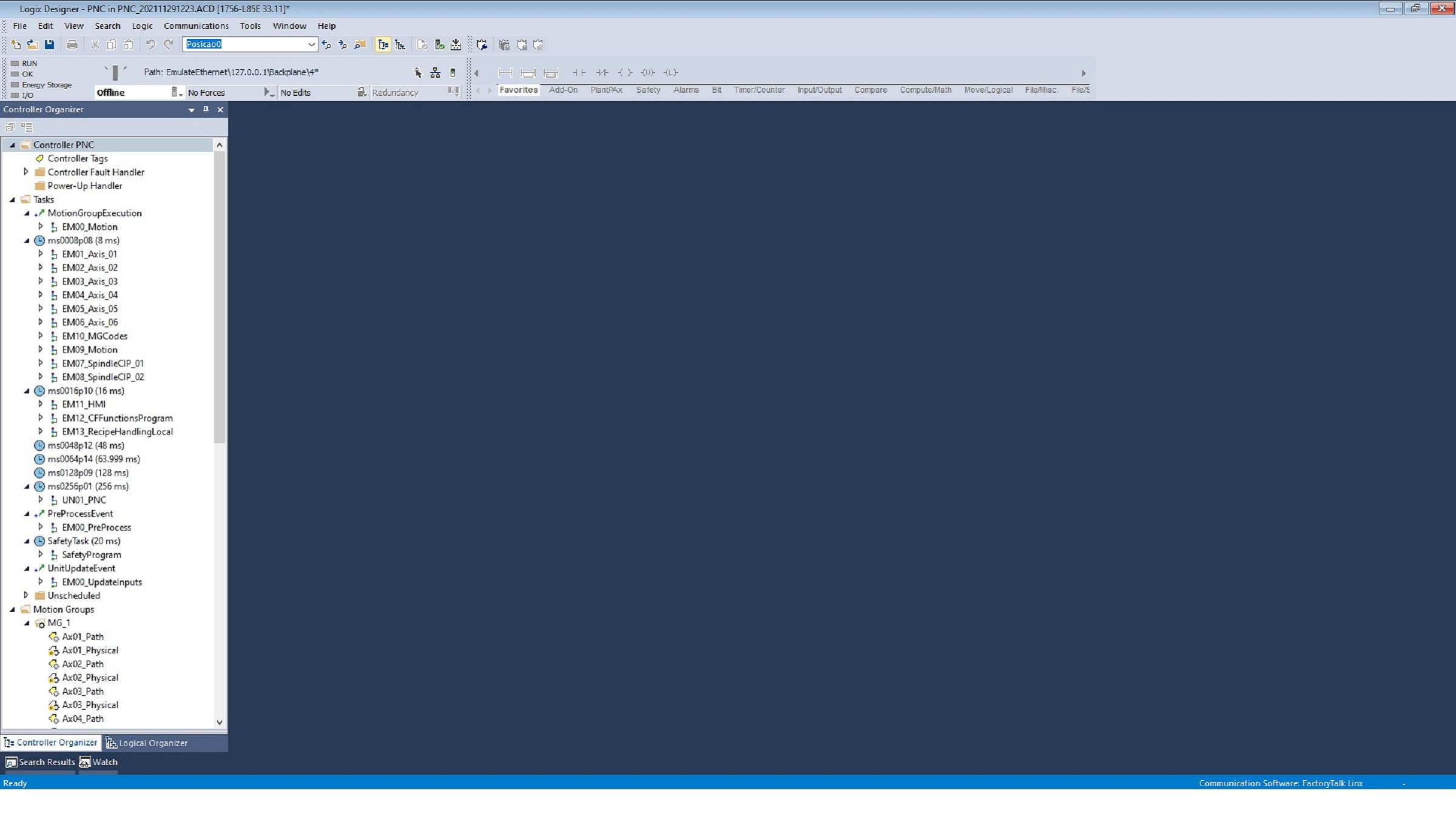

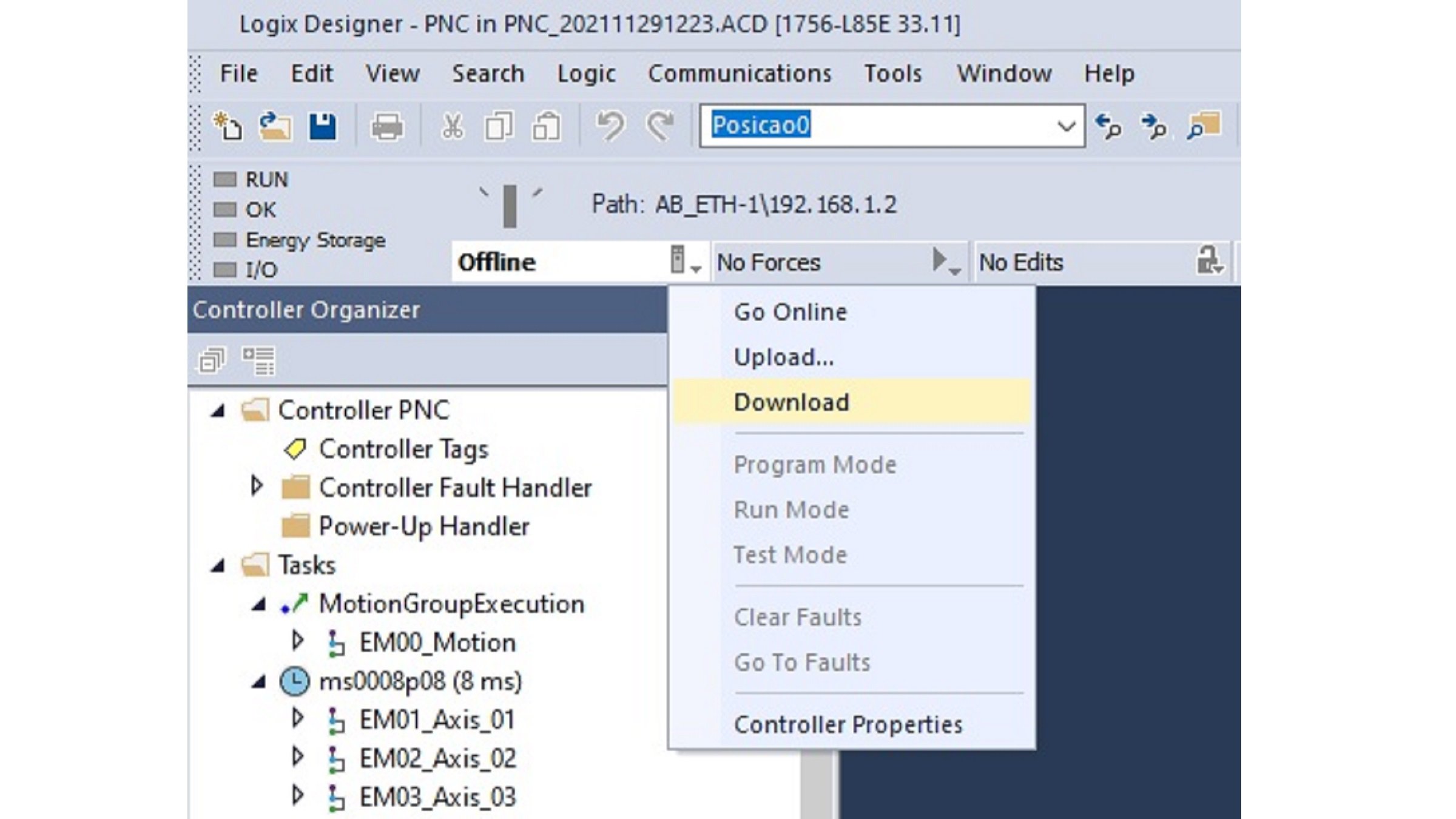

Open the file PNC_202111291223_CompactLogix.ACD (for a CompactLogix 5380 controller) or PNC_202111291223.ACD (for a ControlLogix L8 controller)

Step 2

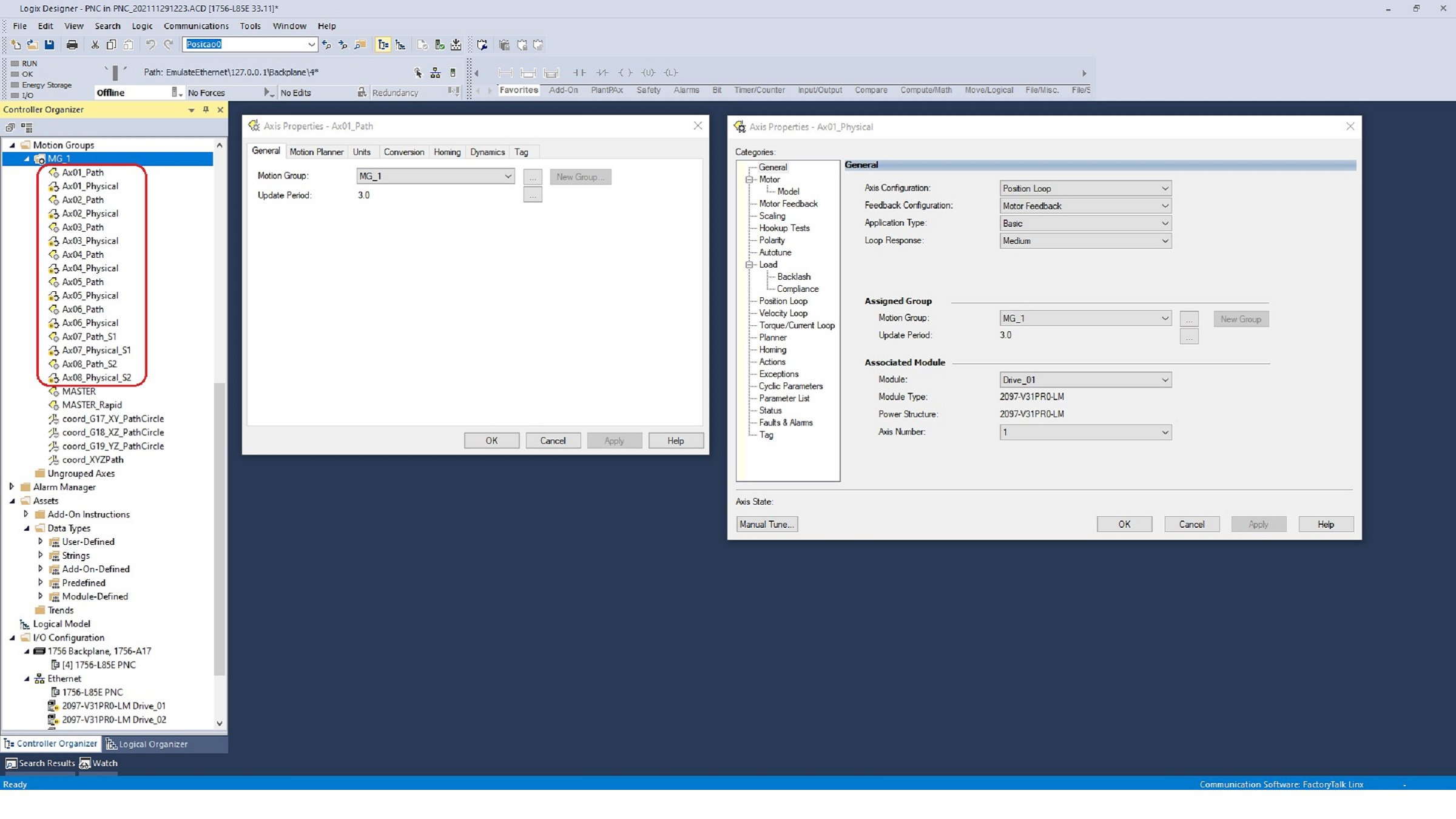

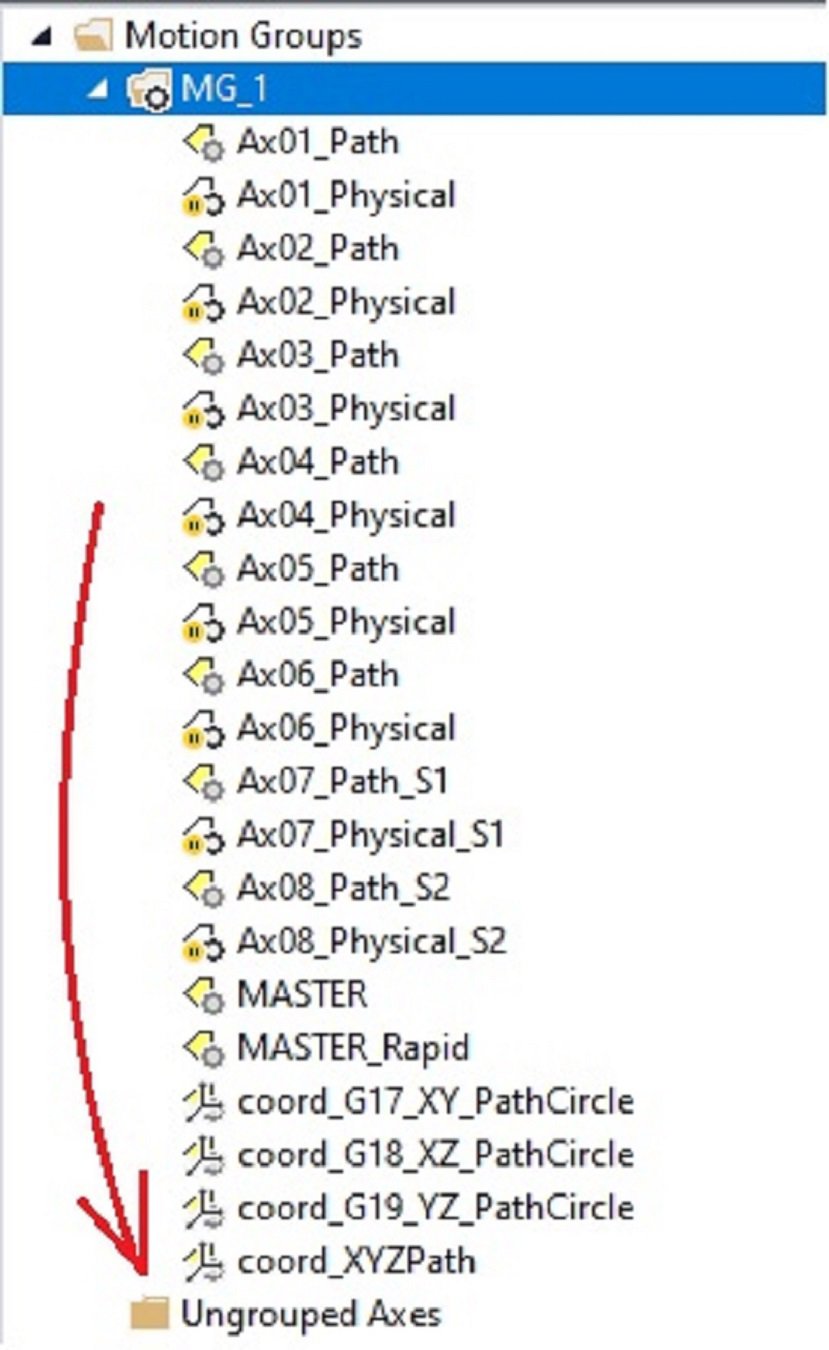

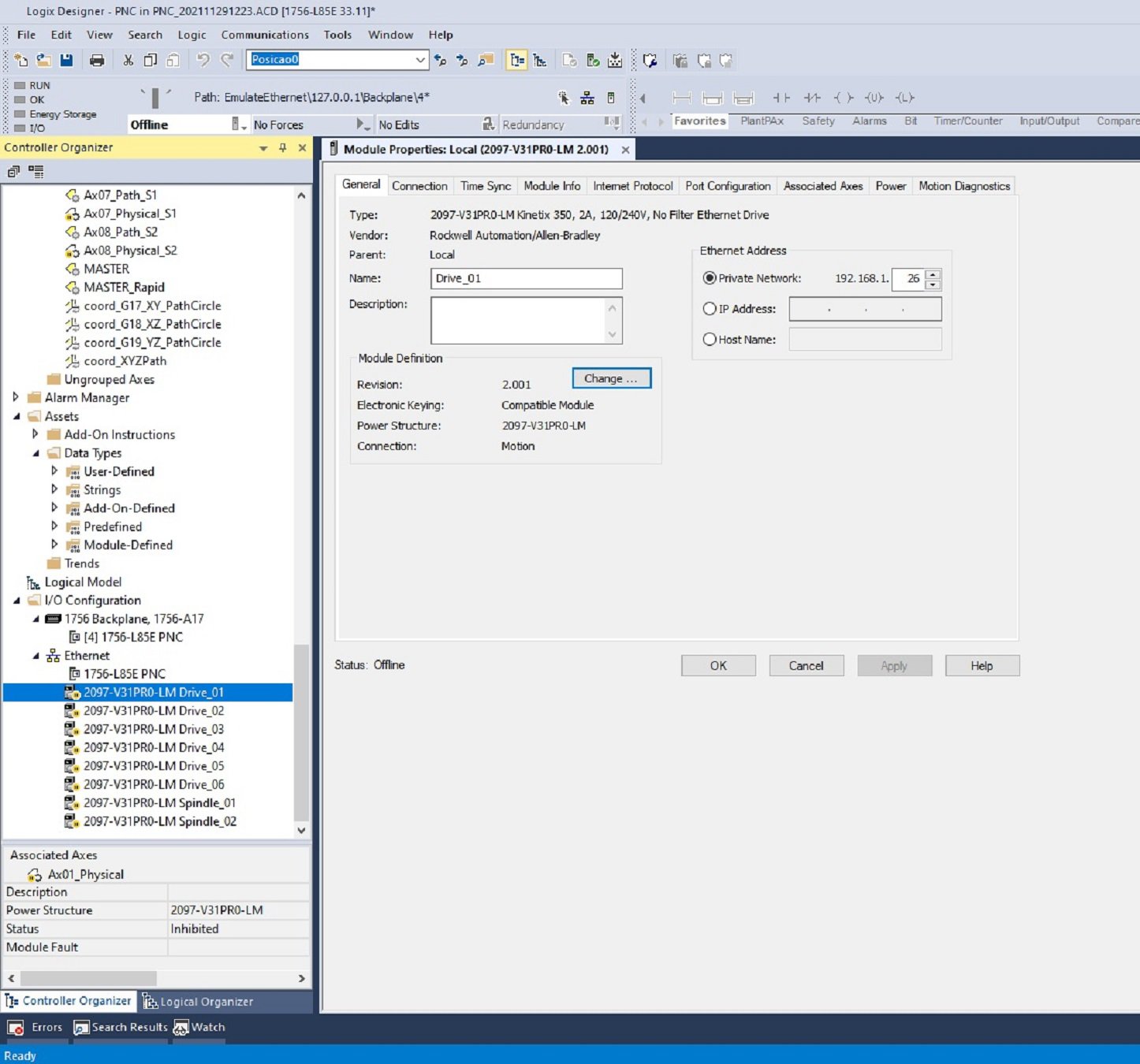

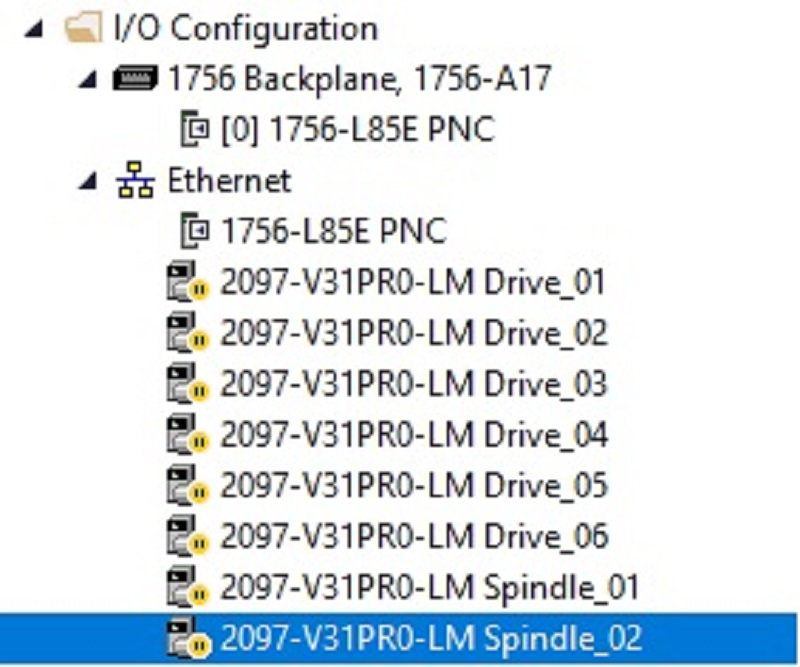

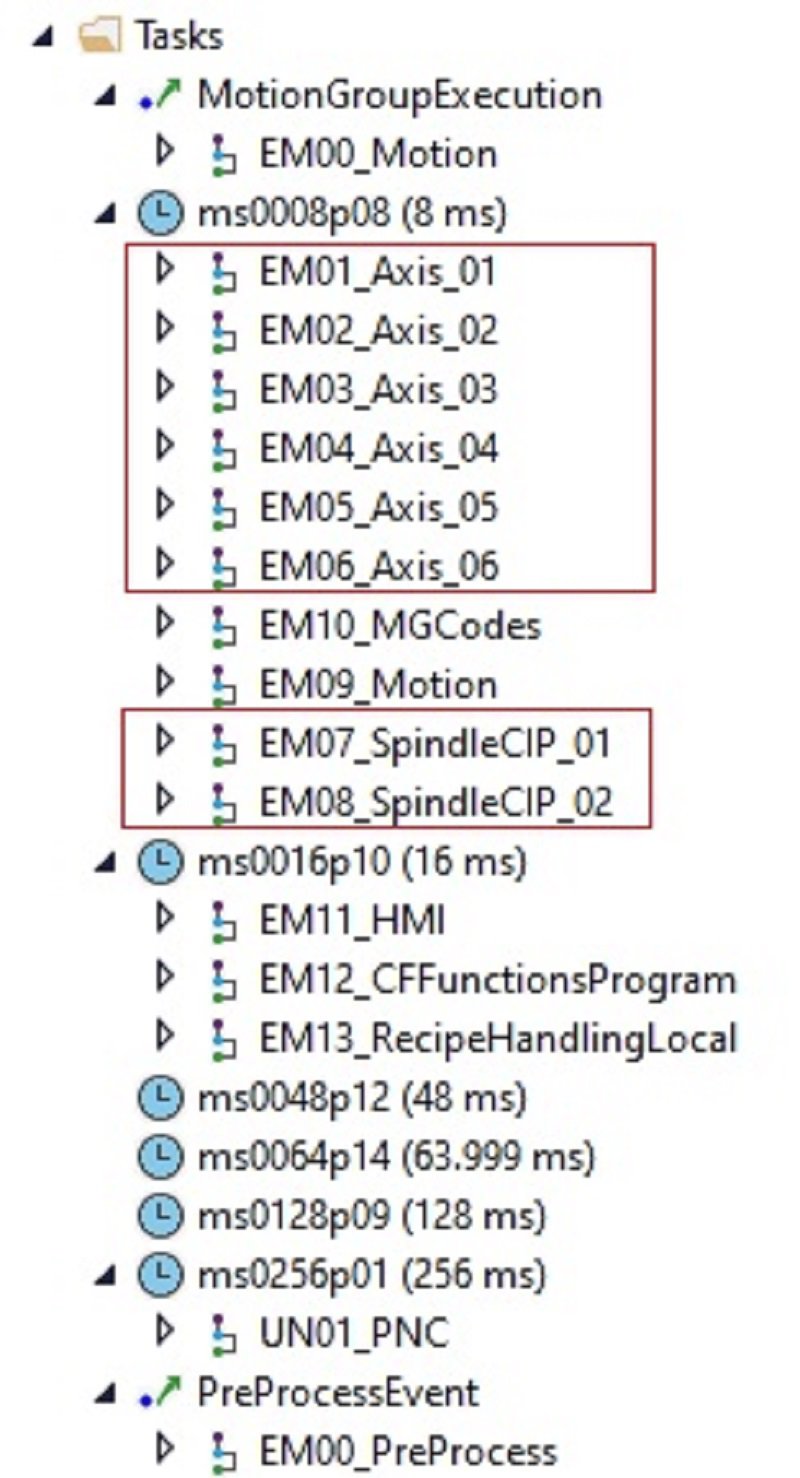

Motion Configuration

- Configure the Axis Properties of both virtual (Ax.._Path) and physical (Ax.._Physical) axis for all applicable axes, according to application requirements

- Move unused axes to Ungrouped Axes folder

- Replace and configure the Drive Modules according to the application

- Either inhibit or delete unused Drive Modules

- If a Drive module is deleted, the corresponding Program module must be deleted as well

Step 3

Step 4

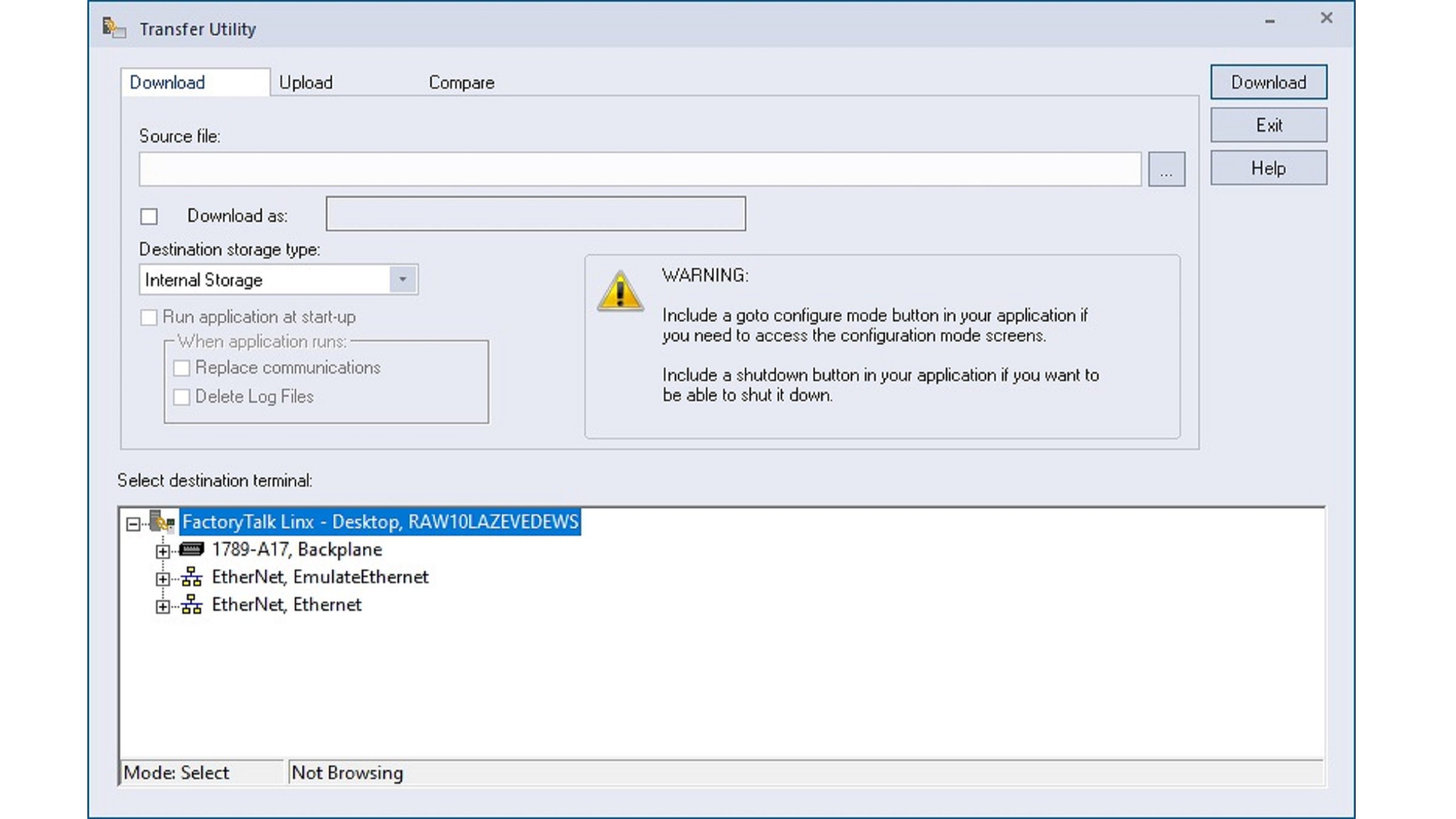

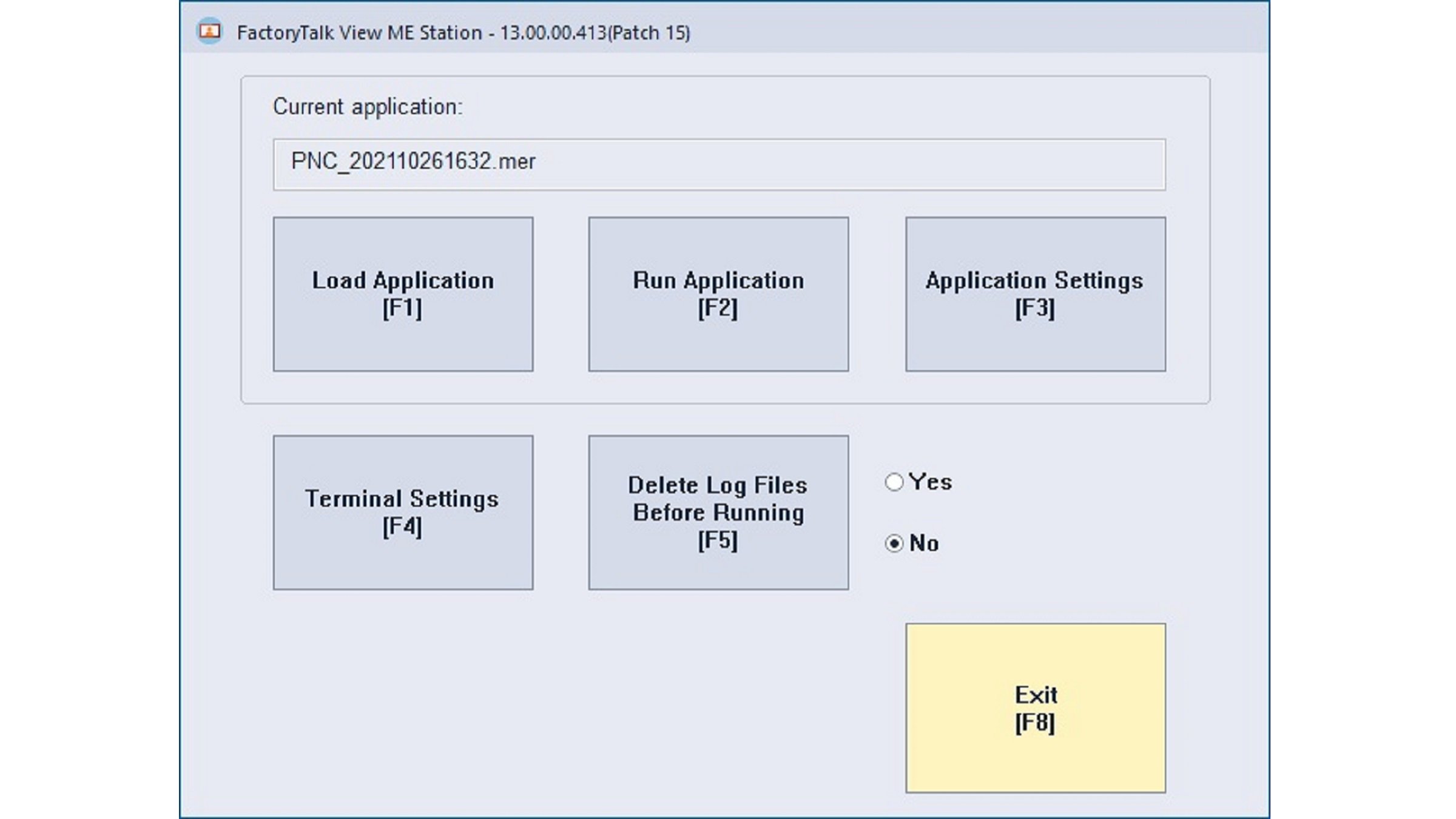

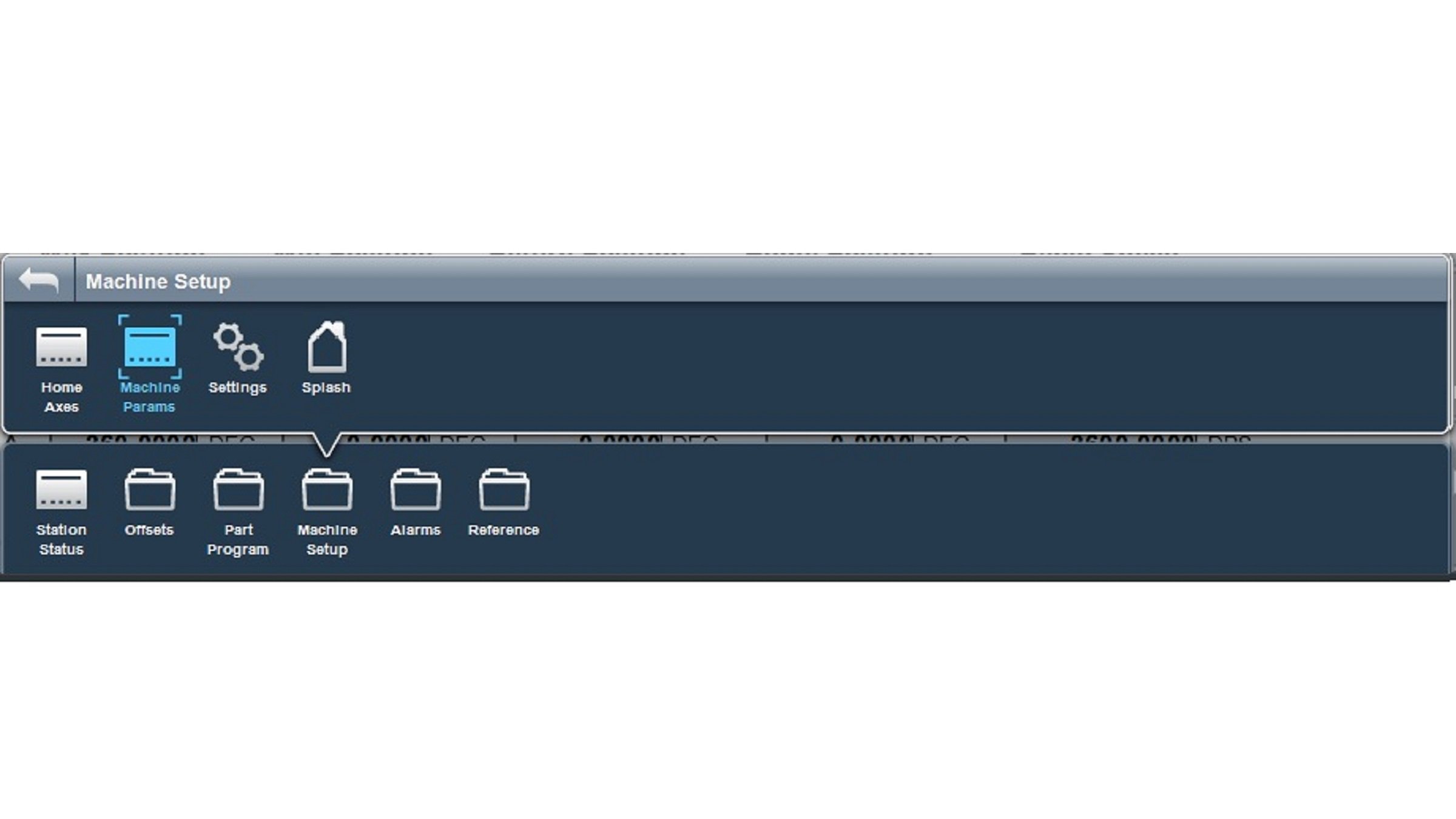

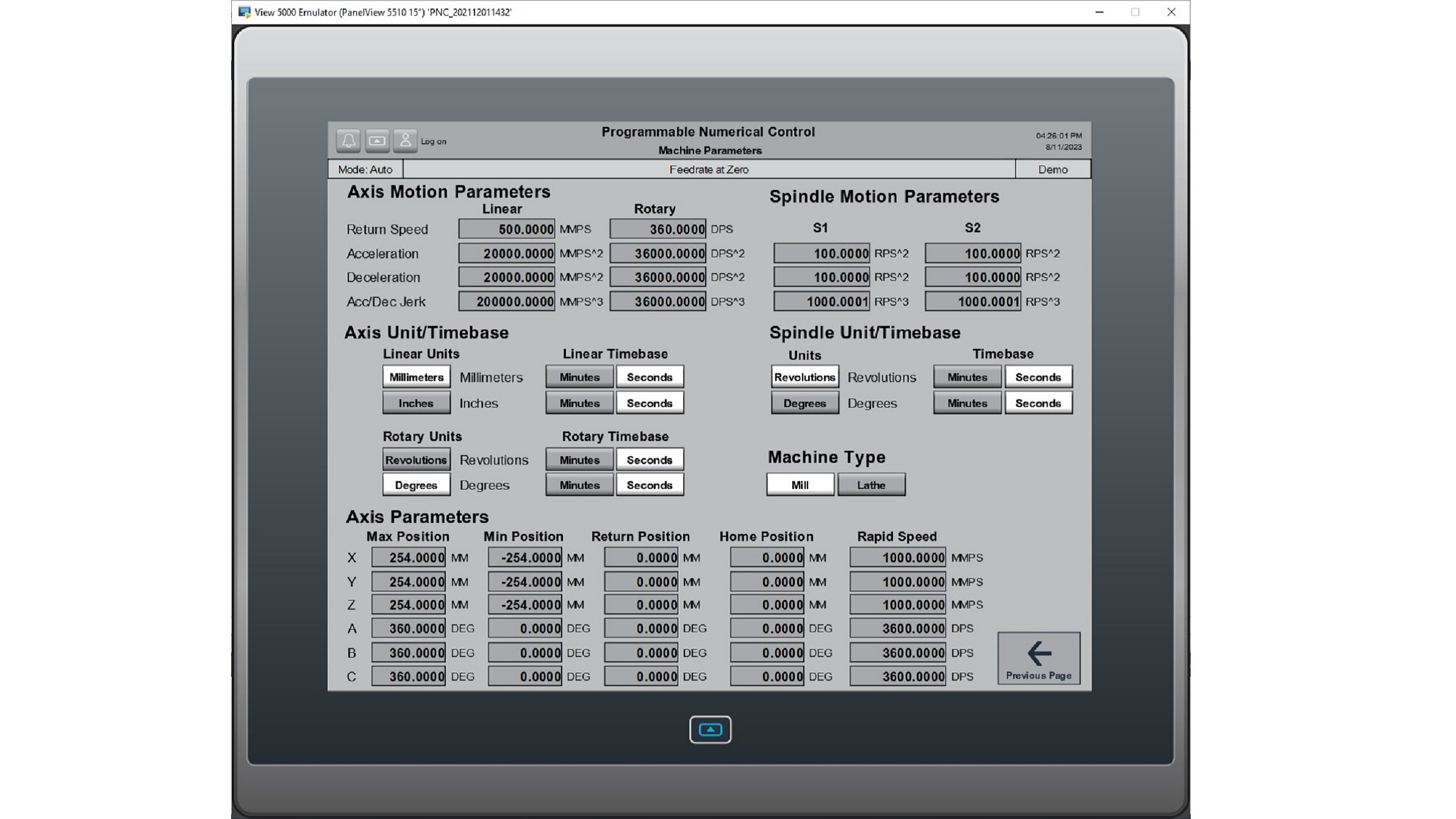

HMI – FactoryTalk View ME application (for PanelView Plus only)

- Open the ME Transfer Utility

- Select the file PNC_202110261632.mer and download to the terminal

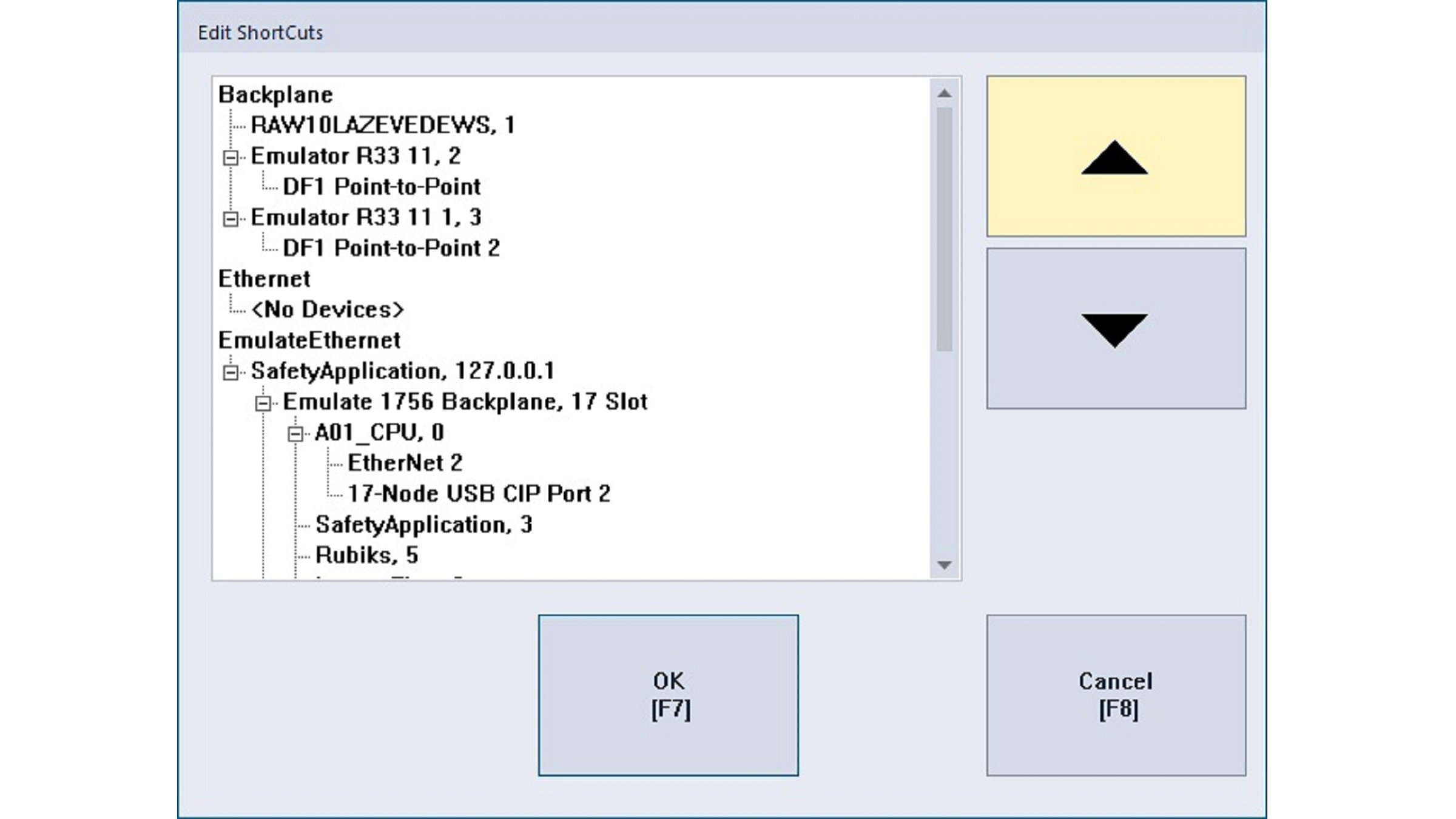

- Configure the Application Settings > Device Shortcuts in order to connect to the right Controller

- Run the Application

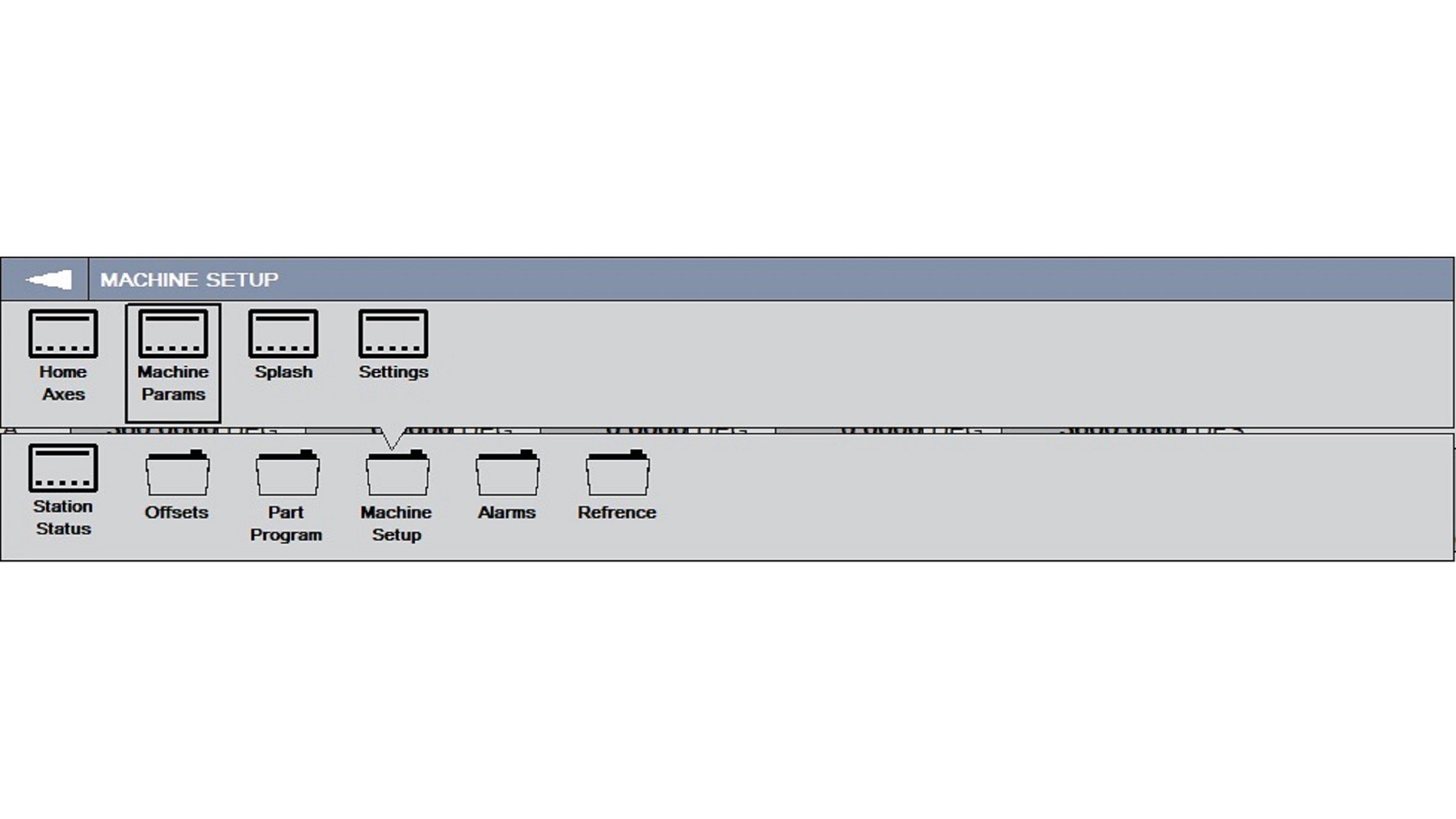

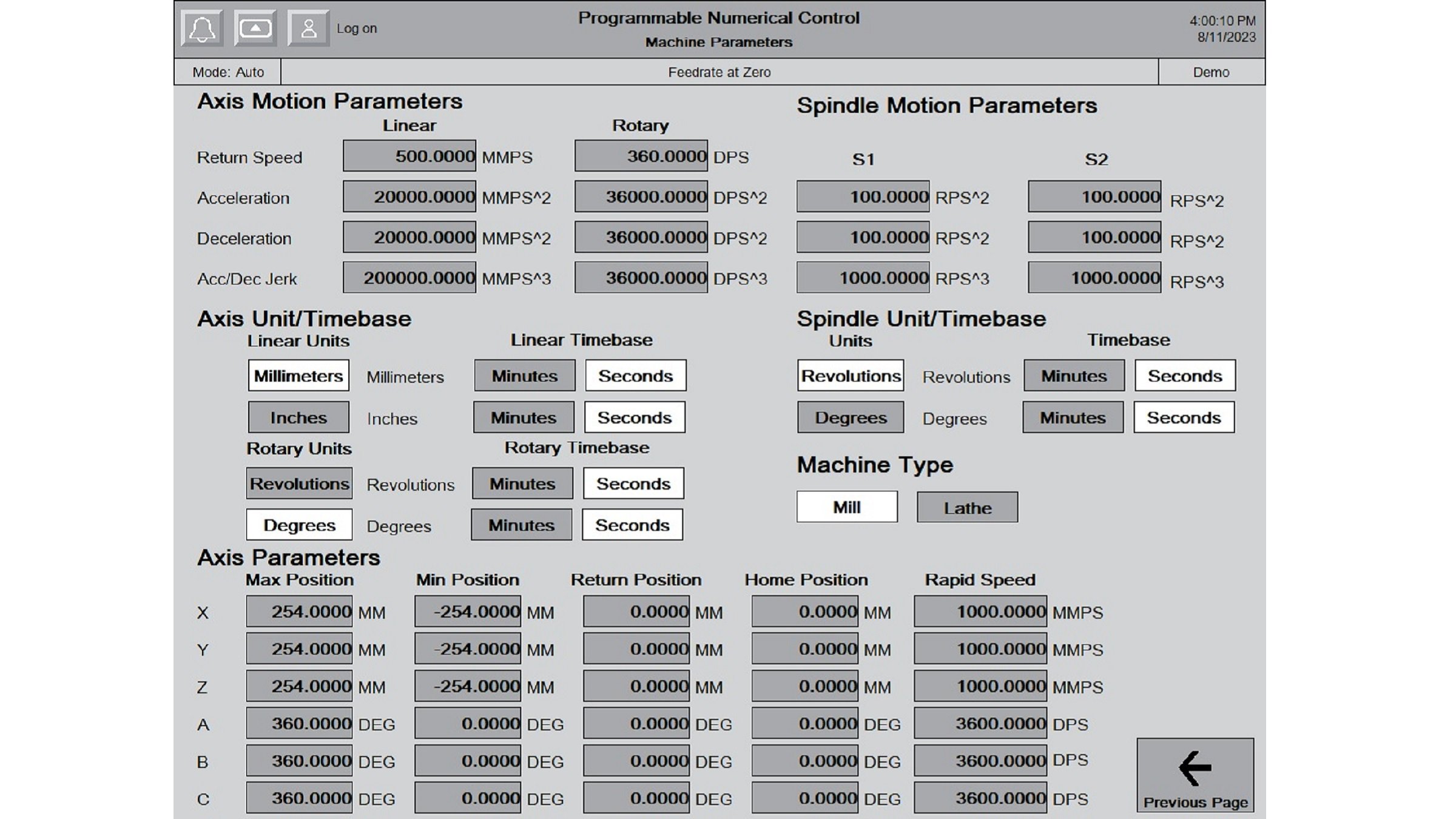

- Access Machine Parameters through the Menu: Machine Setup > Machine Params

- Configure the Machine Parameters according to the application requirements

Step 5

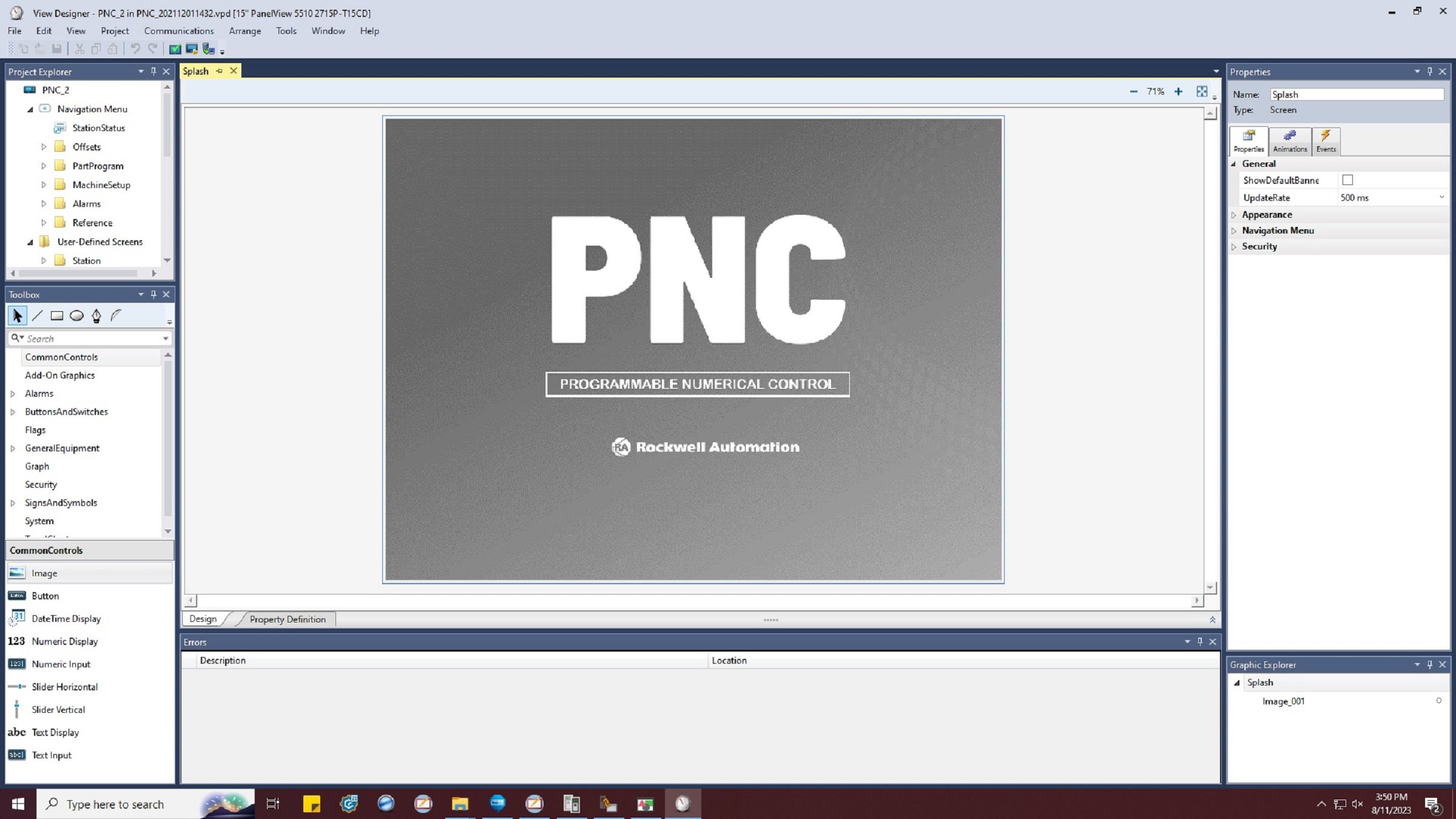

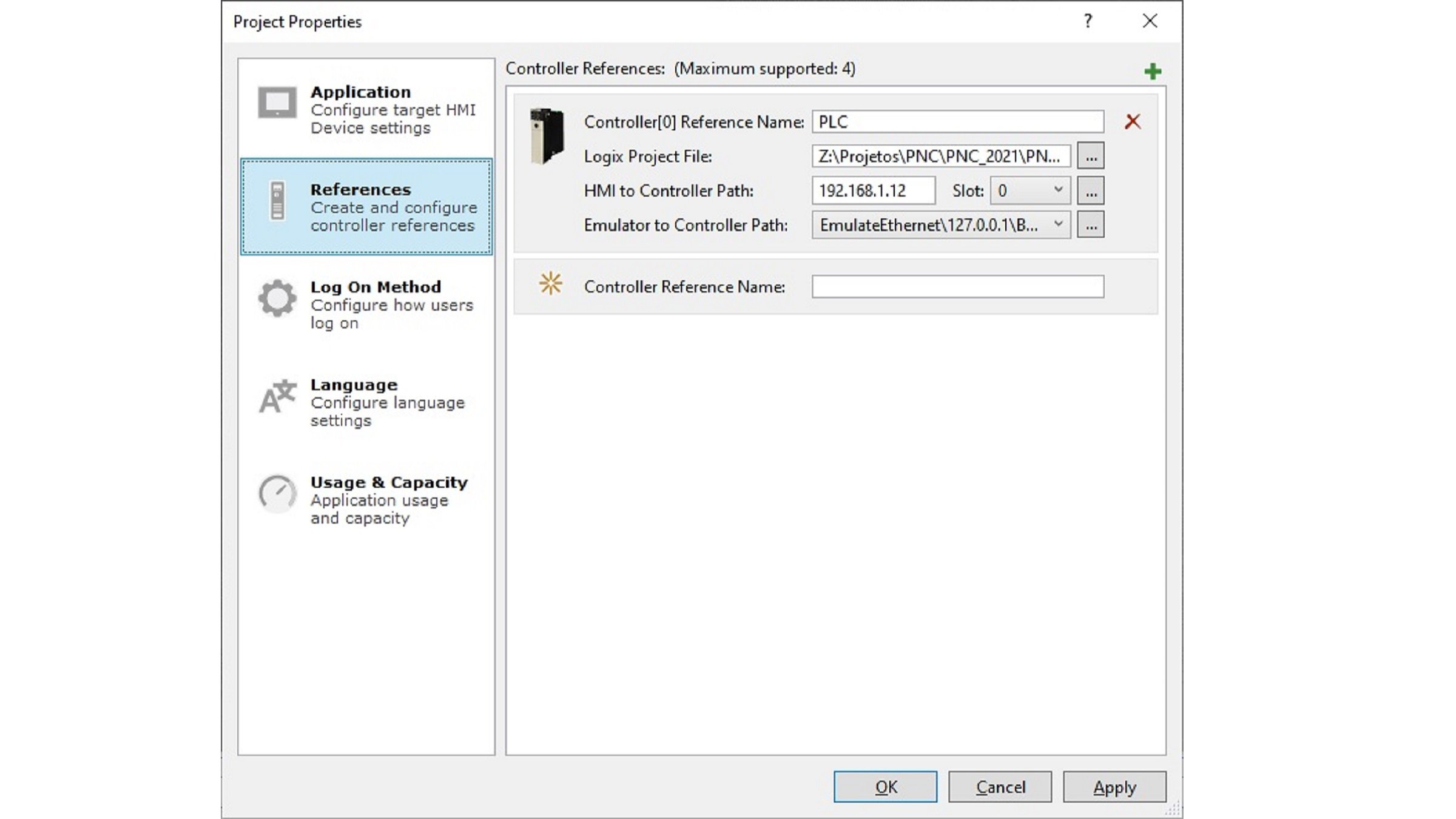

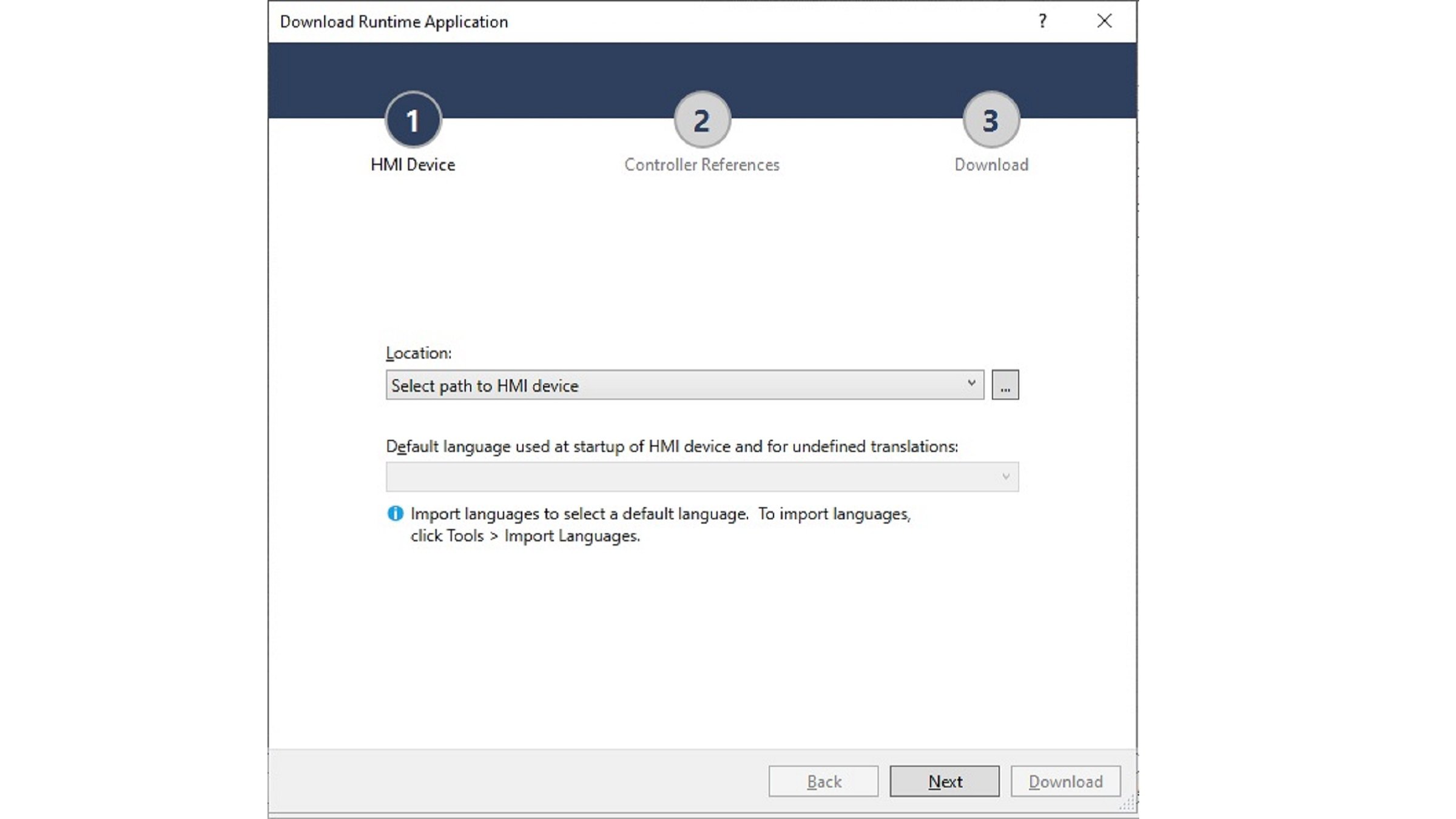

HMI – Studio 5000 View Designer (for PanelView 5000 only)

- Open the file PNC_202112011432.vpd

- Configure the Project Properties to match your application

- Download the Runtime Application to the terminal

- Run the application

- Access Machine Parameters through the Menu: Machine Setup > Machine Params

- Configure the Machine Parameters according to the application requirements