Downloads

What is this for?

The Multibelt system is a storage/transport system and consists of two or more independently driven belts. Each belt contains two or more trains (collators) that are built to carry a tray or built for a variable number of pockets. Trains vary in mechanical design. In the case of using a tray, the tray is placed inside the train in the loading position by any loading module. Products are fed from an infeed conveyor to the train at the filling position. If the feed train is full, it moves to the unloading position. If this is done, the train moves in positive rotation (recovery motion) behind the next train. This sequence guarantees a continuous flow of product in the filling area, while the other trains can be loaded with a tray and unloaded passing through the unloading position. The Multibelt equipment module can be configured with a large number of parameters, which are described in other chapters. A standardized interface for the load, supply and output module allows flexible adaptation.

General Features

The Multibelt System module concludes the following features:

• Multibelt storage sequence procedure for 2 axes (production mode)

• Automatic homing / reference move procedure

• Automatic synchronize move procedure

• Variable speed override adaption while production

• Jog function for each axis separately (service mode)

• Handling of multiple trains per belt

• Interface data handling to any other loading, infeed and outfeed module device

• Wide range of parameters to configure the module

Advantages:

The Mutibelt system has the advantage of being flexible and with the possibility of adaptation according to the application needs - number of collators (train).

From a software point of view, the system is relatively easy to implement using specific AddOn and Data DataTypes: Multibelt_AOI and Q_MAM_P (developed for this application, in order to reduce configuration, commissioning and startup time.

Limitations/Disadvantages

• Speed – Depends on the Drag Mechanism

• Number of mechanical elements - gears, belts

• Fixed space between cleats, if need change, mechanical change neededc

Is this useful for me?

In general, multibelt systems can be recommended to OEM manufacturers such as:

- Conveyor belt manufacturers

- Special machine manufacturers

- Palletizers manufacturers

- Packing machines manufacturers

Application areas:

Food, Manufacturing, Beverage

Benefits of applications with multibelt systems:

• Production gain and speed

• Increased dynamism in production

• 60% reduction in commissioning and startup time

• Easy of integration with devices: Robot, transfer devices

How can I make it work?

Requirements: Products, Tools, Previous Knowledge.

Hardware

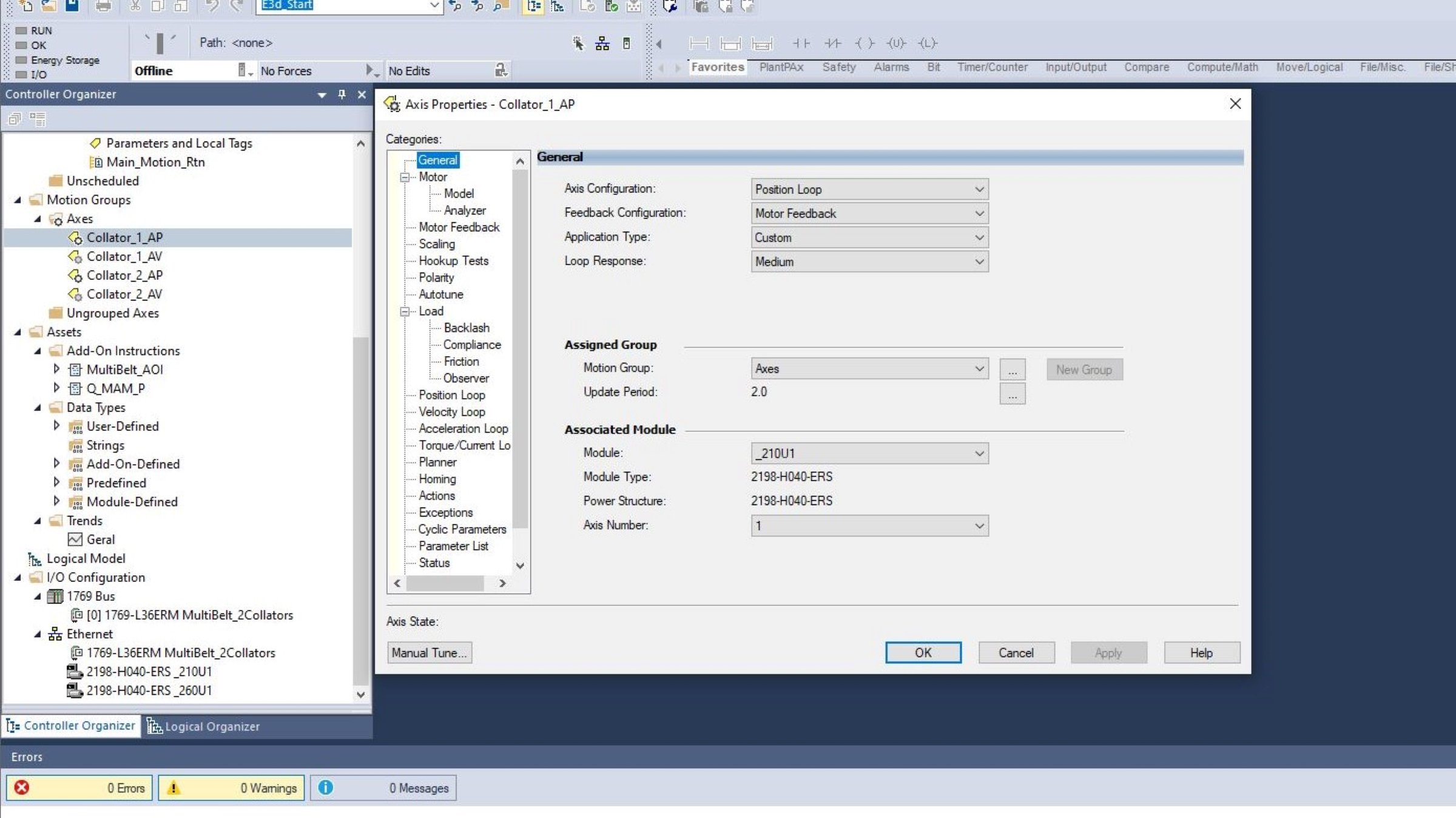

- Kinetix 5300, Kinetix 5500, Kinetix 5700 with CIP Motion and CIP Sync

- PowerFlex 755 with Position control/ CIP Motion

- CompactLogix L18ERM or high

- Firmware revision 30 or high

Software

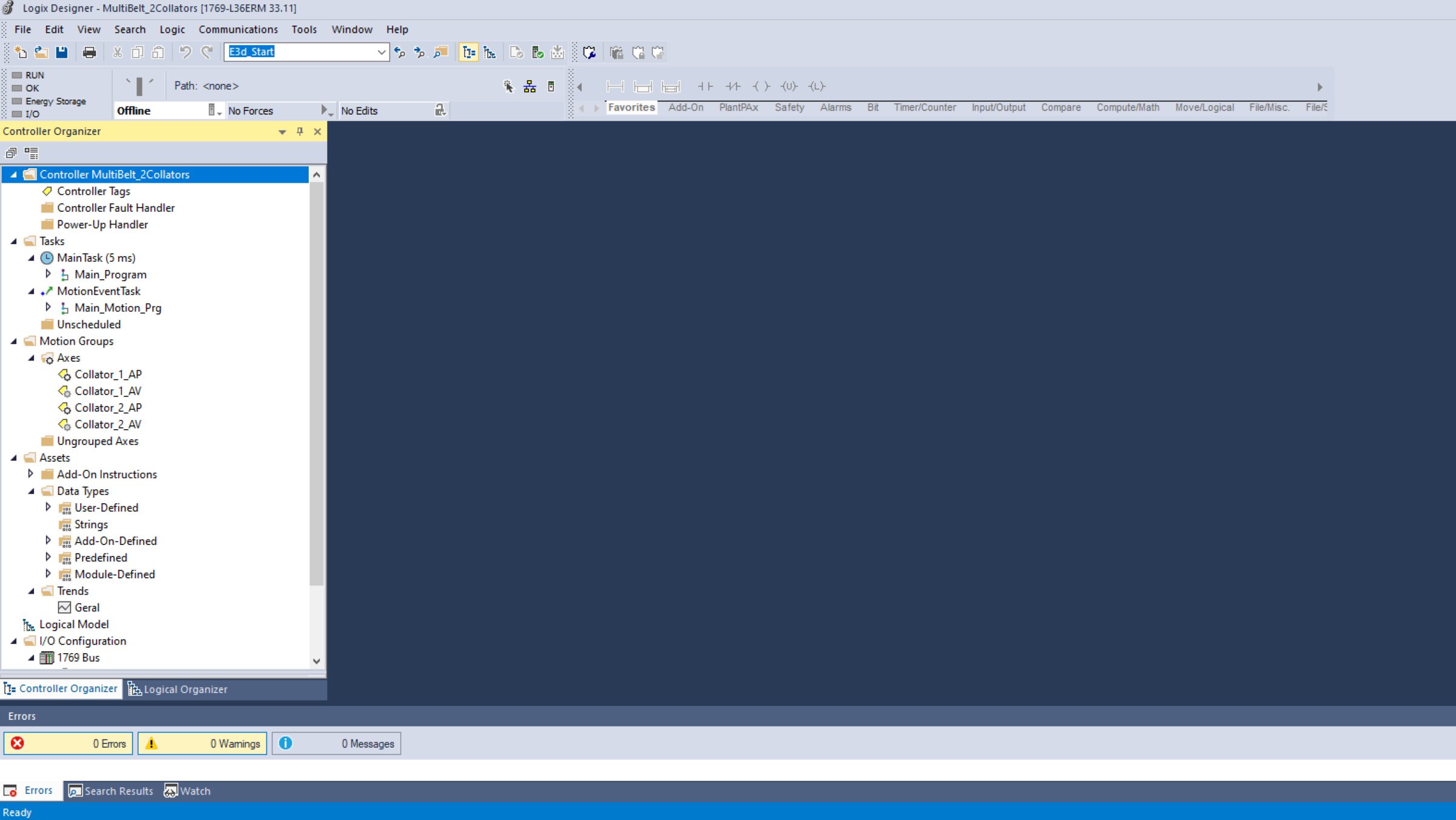

- Logix Design Studio 5000

- Program Multibelt_2Collators.ACD

- AddOn instructions: Multibelt_AOI, Q_MAP_P

Knowledge

Intermediate knowledge of programming and configuration in Logix Design Studio 5000 software:

- Ladder language (LD)

- Motion configuration.

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

Additional information is in the "Multibelt.pdf" document in Downloads >> GeneralFiles.zip

Step 1:

Instructions:

- Open program Multibelt_2Collators.ACD – This file is located inside the Generalfiles.zip package in the Downloads section.

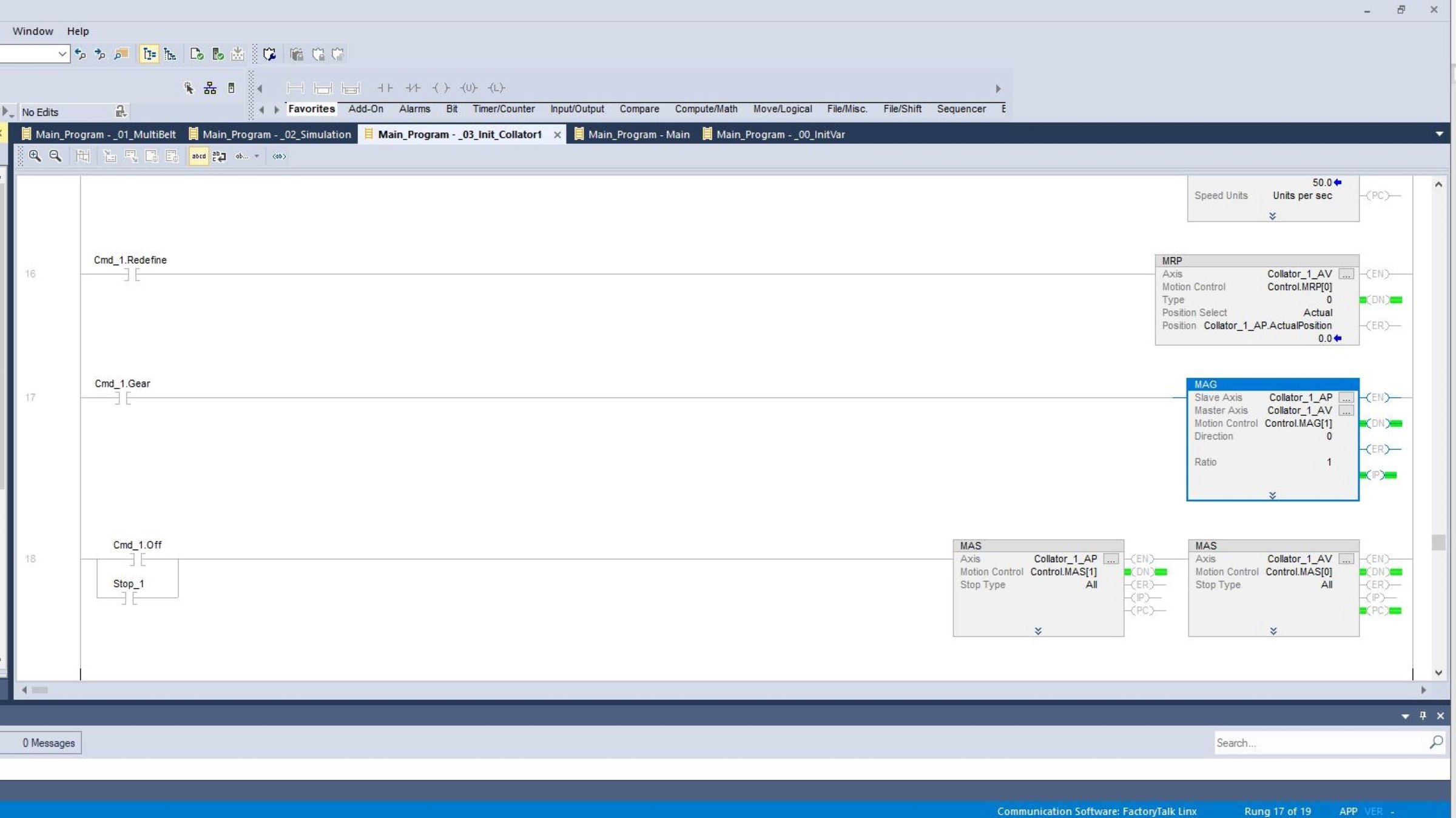

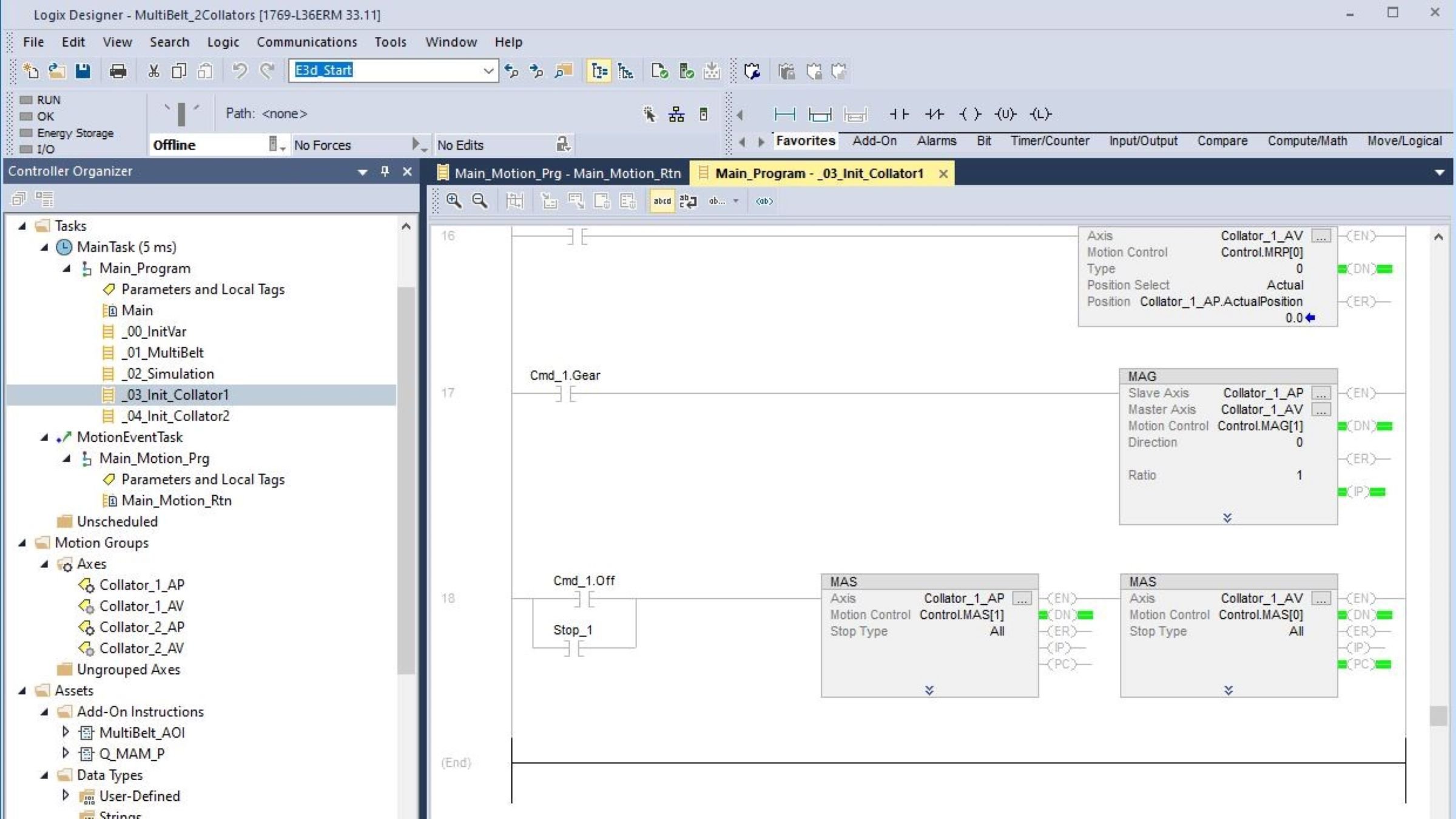

- Initially you can use this program with Virtual Axis for tests. After that you can couple the virtual axis with physical axis using Motion Axis Gear (MAG).

Step 2

Motion Configuration:

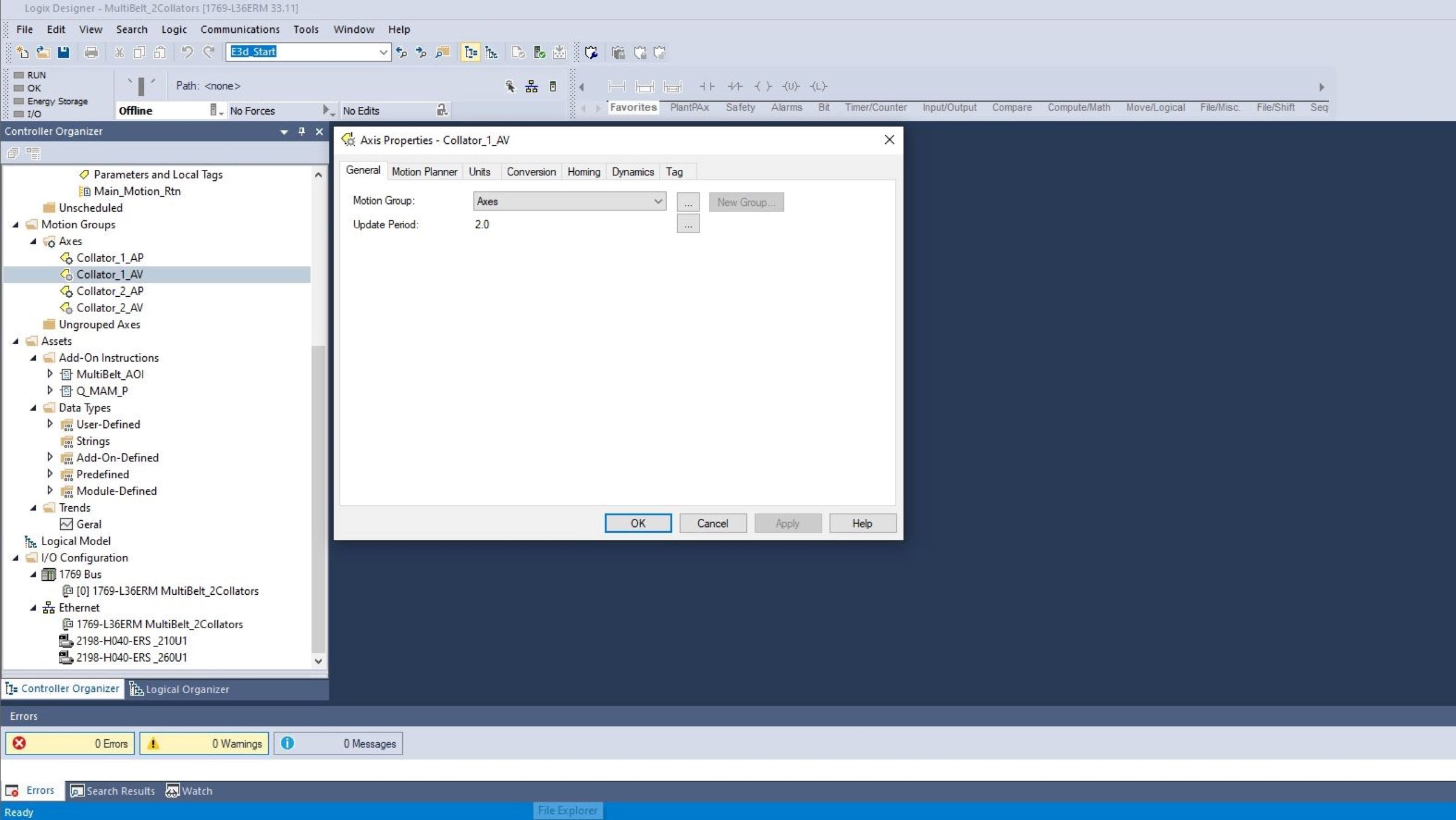

- Configure the Axes Parameters Virtual (Collator_X_AV) and Physical (Collator_X_AP) . For Physical: Model of operation: Position Loop.

- Configure the virtual axes.

- Couple virtual axis with real – This function is already in the program example (Multibelt_2Collators.ACD) .

Step 3:

Configure Add-ons Data parameters:

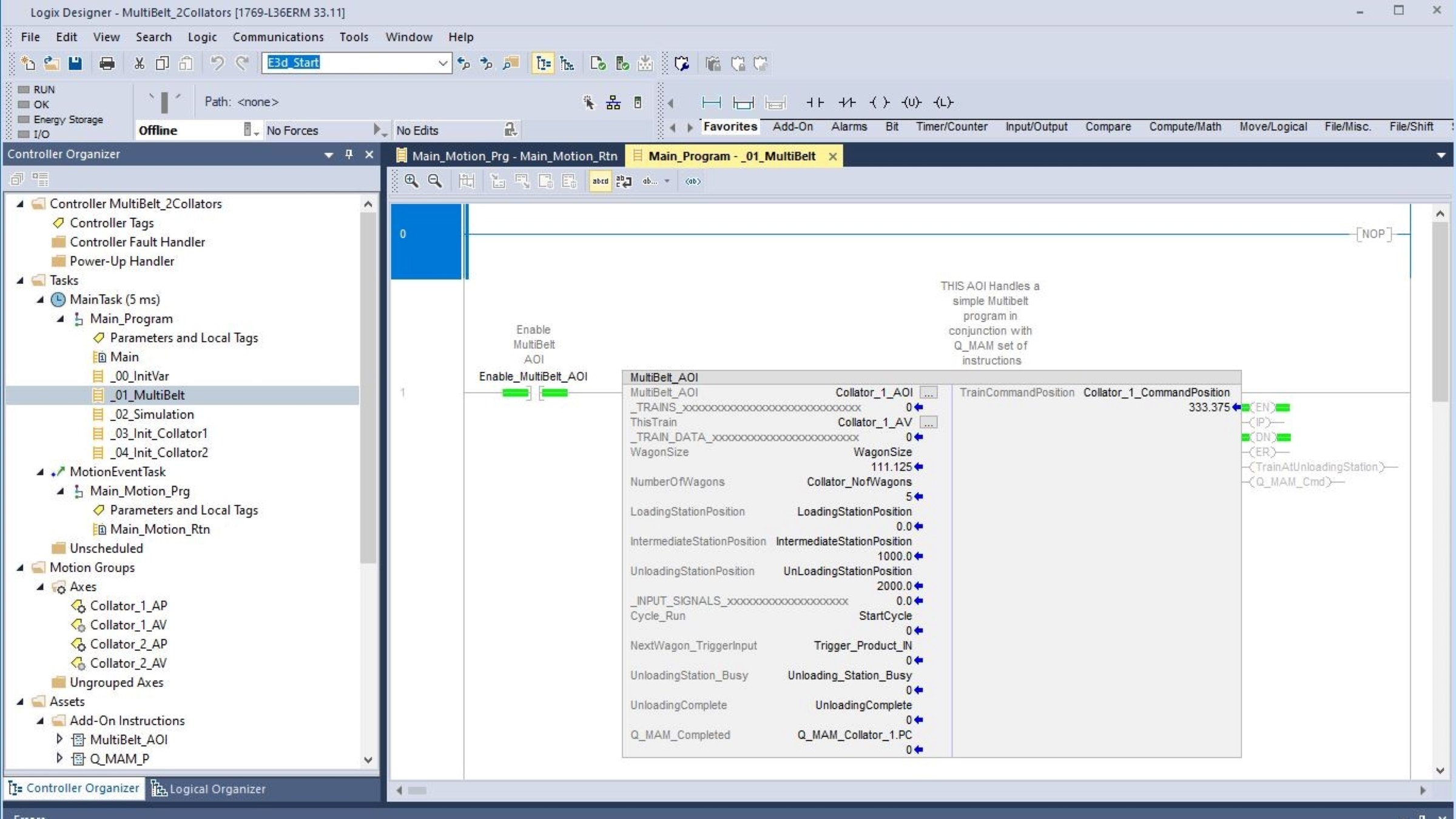

1. MainTask > MainProgram > _01_Multibelt, Configure Add-on MultiBelt_AOI.

- Axis

- Axis Preceding

- Wagon Size

- Number of Wagons

- Loading Station Position

- Waiting Station Position

- Unloading Station Positions

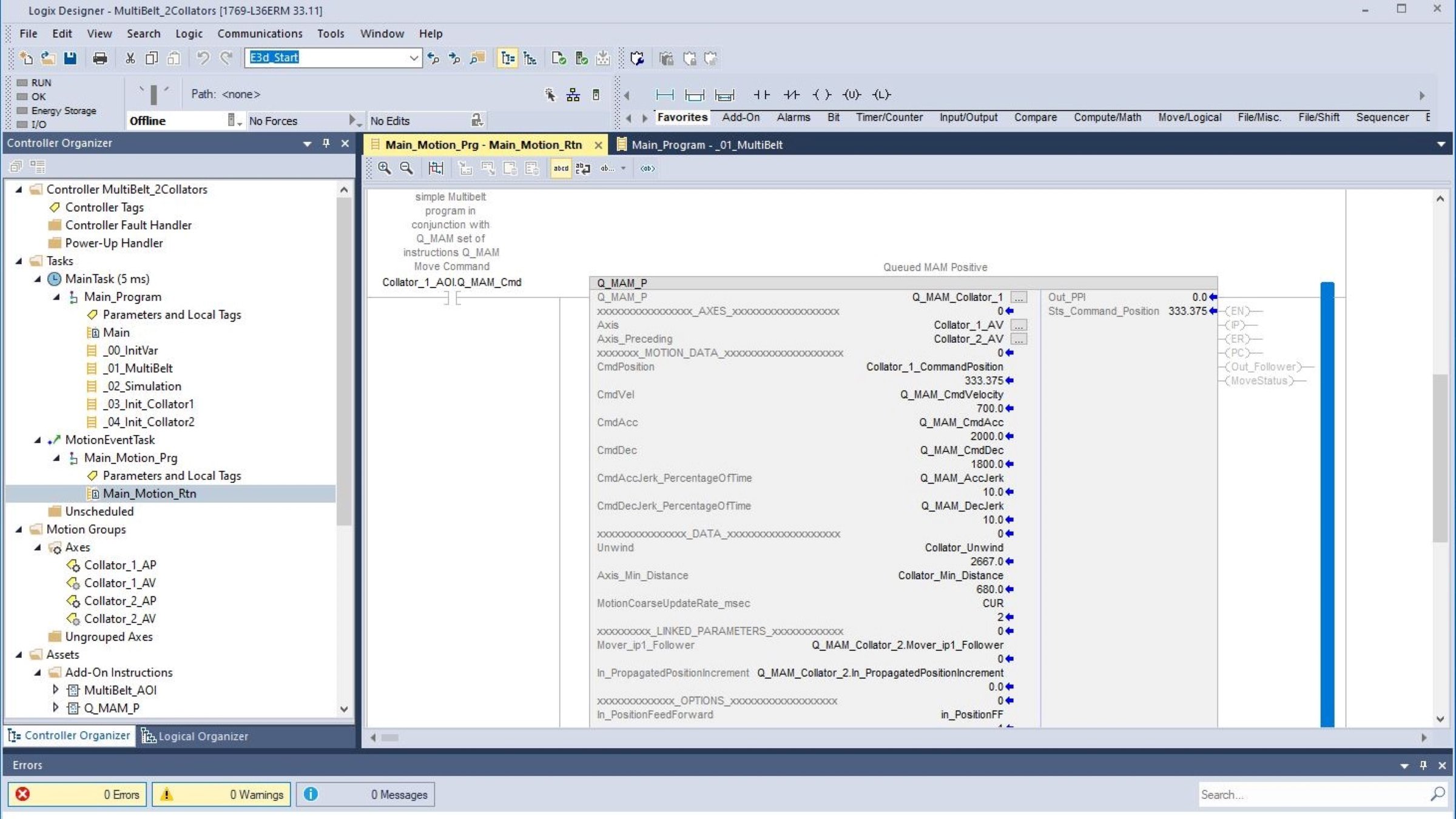

2. MotionEventTask > Main_Motion_Rtn, configure Add-ON Q_MAM_P parameters (Setup and configure Train Data).

- Axis

- Axis Preceding

- Command Position

- Velocity

- Acceleration

- Deceleration

- Acceleration Jerk

- Decceleration Jerk

Step 4:

Download and commissioning

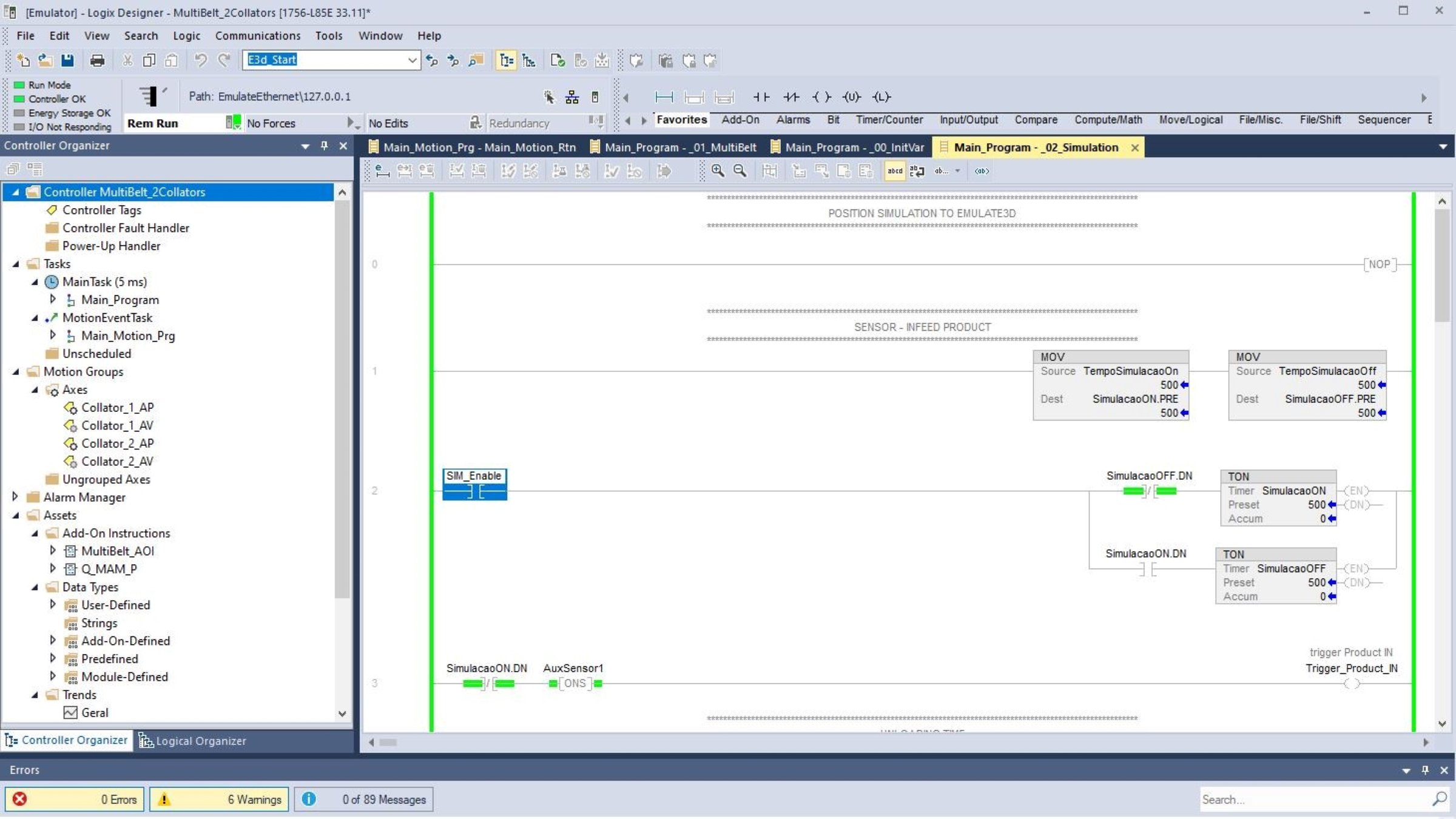

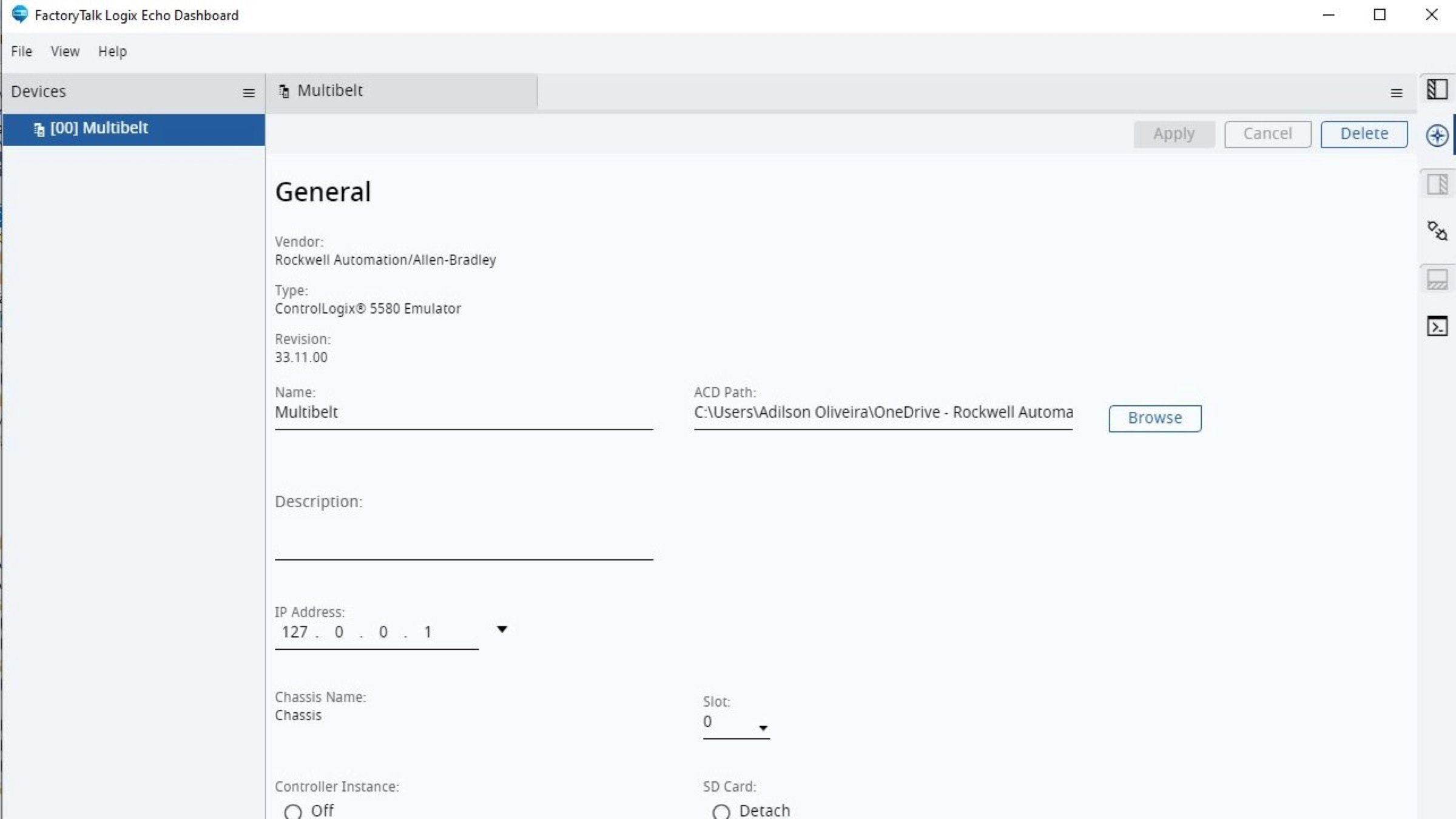

- You can use the Emulator (Factory Talk Logix Echo)

- For simulation, use MainTask > MainProgram > _02_Simulation program