Downloads

What is this for?

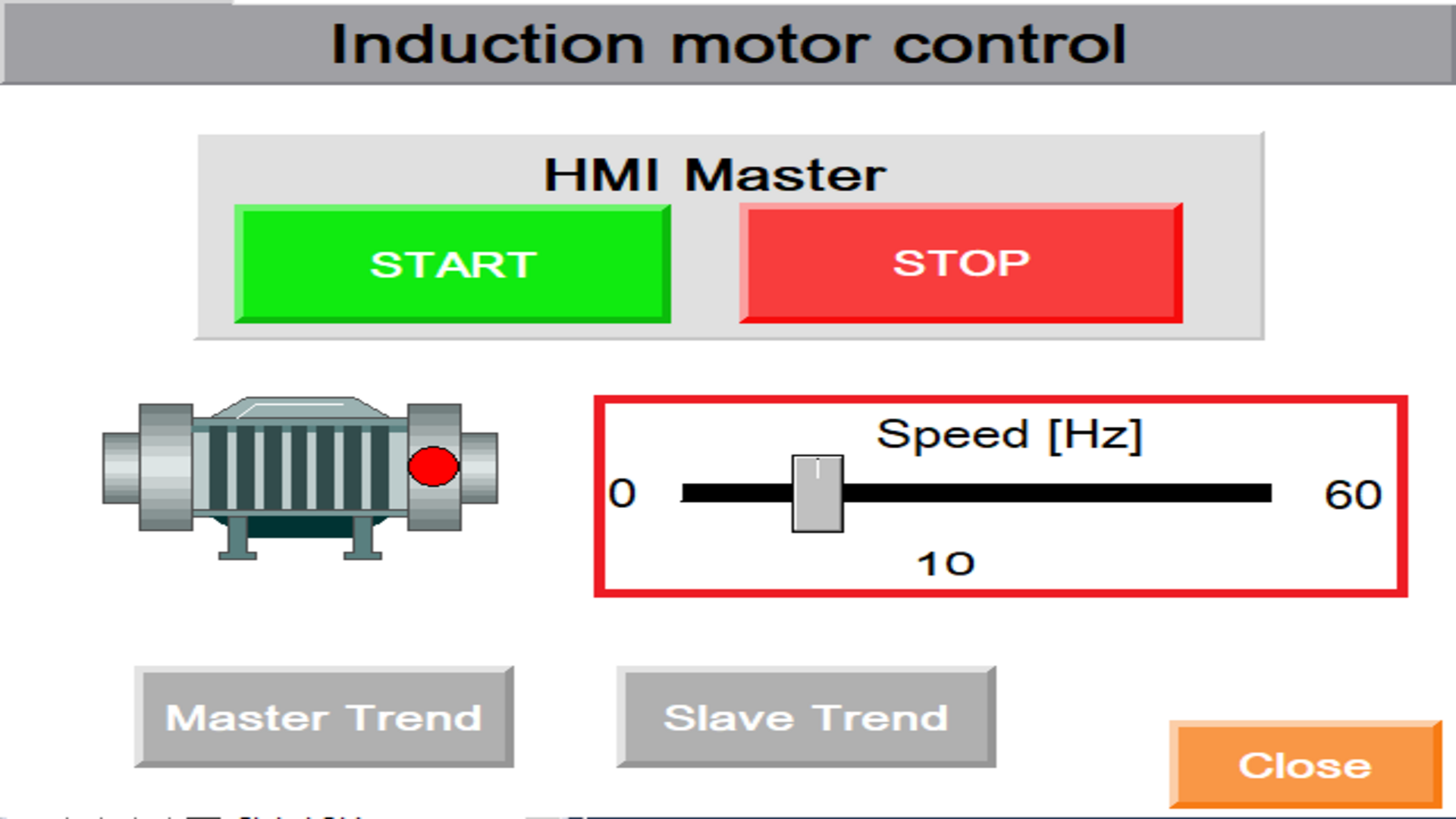

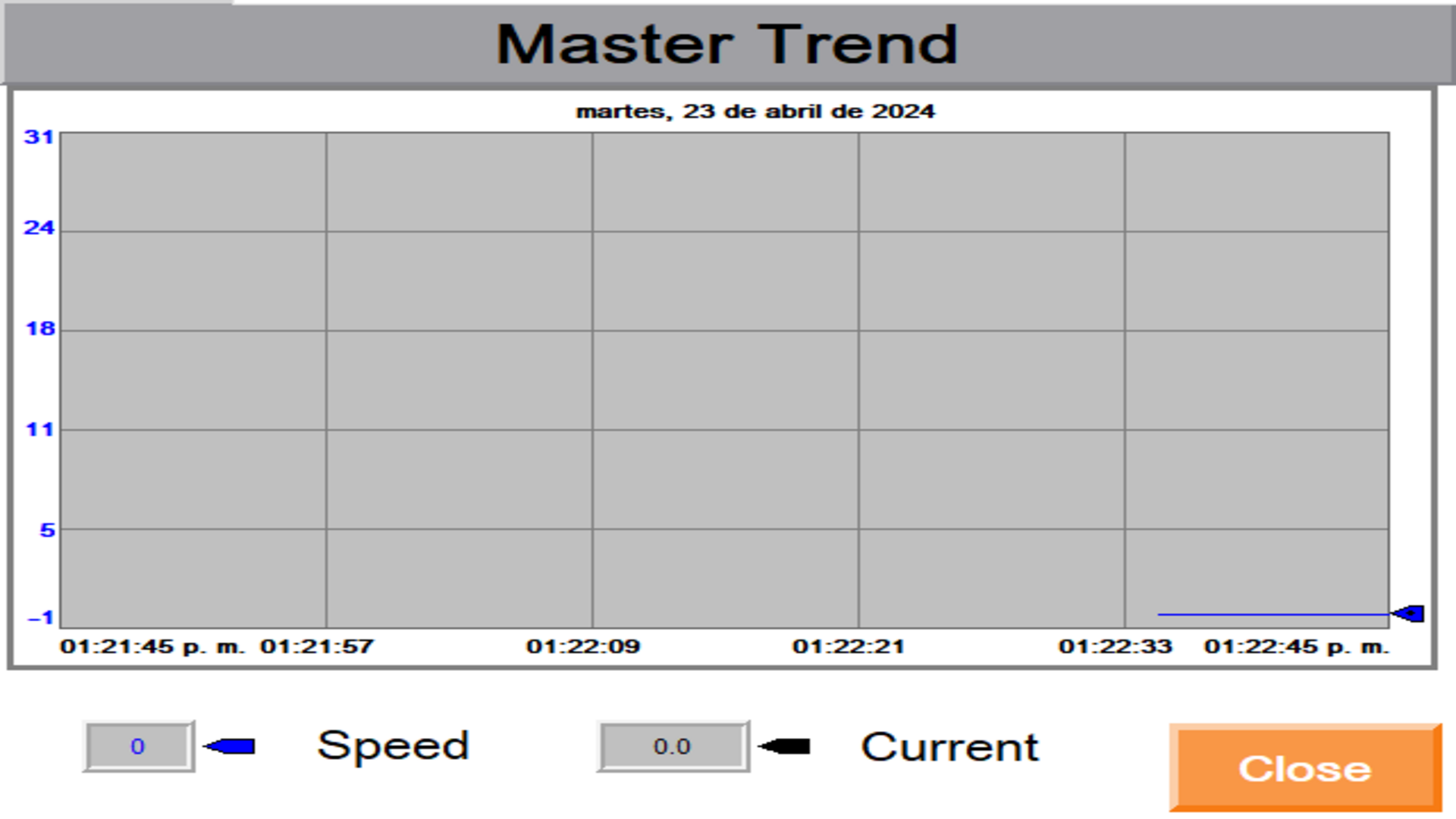

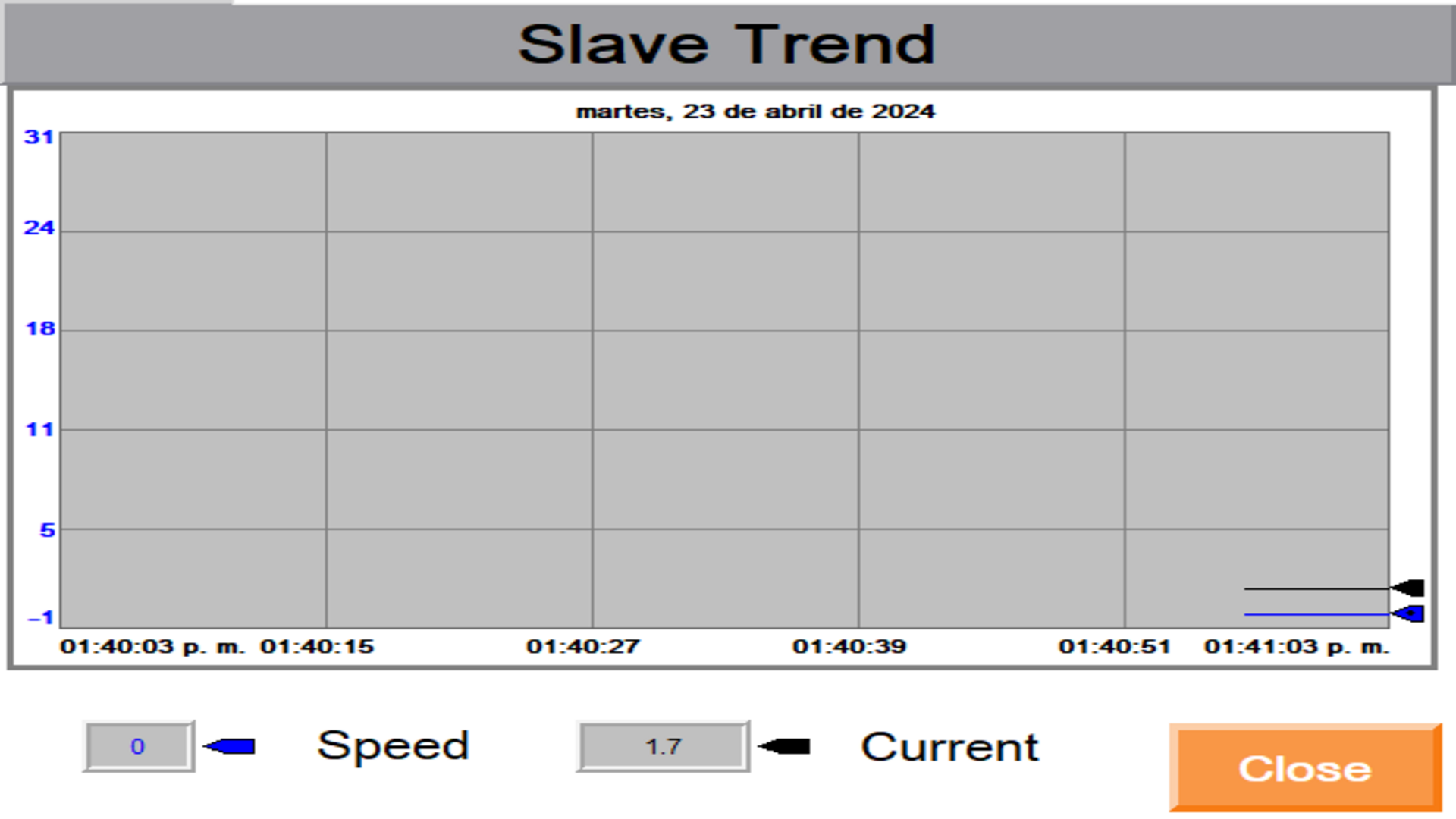

The master-slave application using frequency drives with load variations on the motor shaft demonstrates the PowerFlex 755TS frequency drive's ability to respond to these changes with rapid response and precise speed control, as well as the adaptive control operation in response to load variations.

This system enables the synchronization of two AC motors with PowerFlex 755TS frequency drives using a master-slave scheme, along with the use of DC motors as loads.

This demonstration includes operating in both automatic and manual modes. It offers a comprehensive solution that combines visualization tools, integration with the Logix platform, and operation to visualize the response of the frequency drives.

General Features

The master-slave application with load variations offers the following features:

- Operating modes: Automatic and manual.

- Adjustable speed reference.

- Simulation of load variations with DC motors.

- Flexibility and adaptability to a variety of industrial applications.

Advantages

- Demonstrates the integration of monitoring and operation tools.

- Streamlines the programming time of frequency drives.

- Exhibits scalability and repeatability to adapt to various industrial environments.

- Allows agile and precise modifications according to changing needs.

- Provides versatile control that adjusts to different application scenarios.

- Optimizes performance in terms of efficiency and productivity.

Is this useful for me?

Frequency drives with Total Force technology represent an effective solution because the adaptive control of the PowerFlex 755TS can adapt to changes in motor load, fluctuations in supply voltage, and other variable operating conditions. This ensures an optimal response of the frequency drive to different operating scenarios, enhancing system stability and reducing the possibility of failures or performance issues.

This improvement in energy efficiency brings significant benefits, including reduced carbon emissions and compliance with increasingly stringent environmental regulations in the industry. Additionally, by smoothly controlling the speed and torque of the motors, mechanical wear on the equipment is reduced, extending its lifespan and lowering maintenance costs.

The master-slave application minimizes the time required to configure slave parameters, reducing the total system startup time, allowing for quicker and more efficient implementation in the workplace.

How can I make it work?

Hardware

- 2 AC Motors IDVSNM3581T-5.

- 2 DC Motors Bulletin 1325R.

- 2 PowerFlex 755TS Frequency Drives.

- 2 PowerFlex DC Frequency Drives.

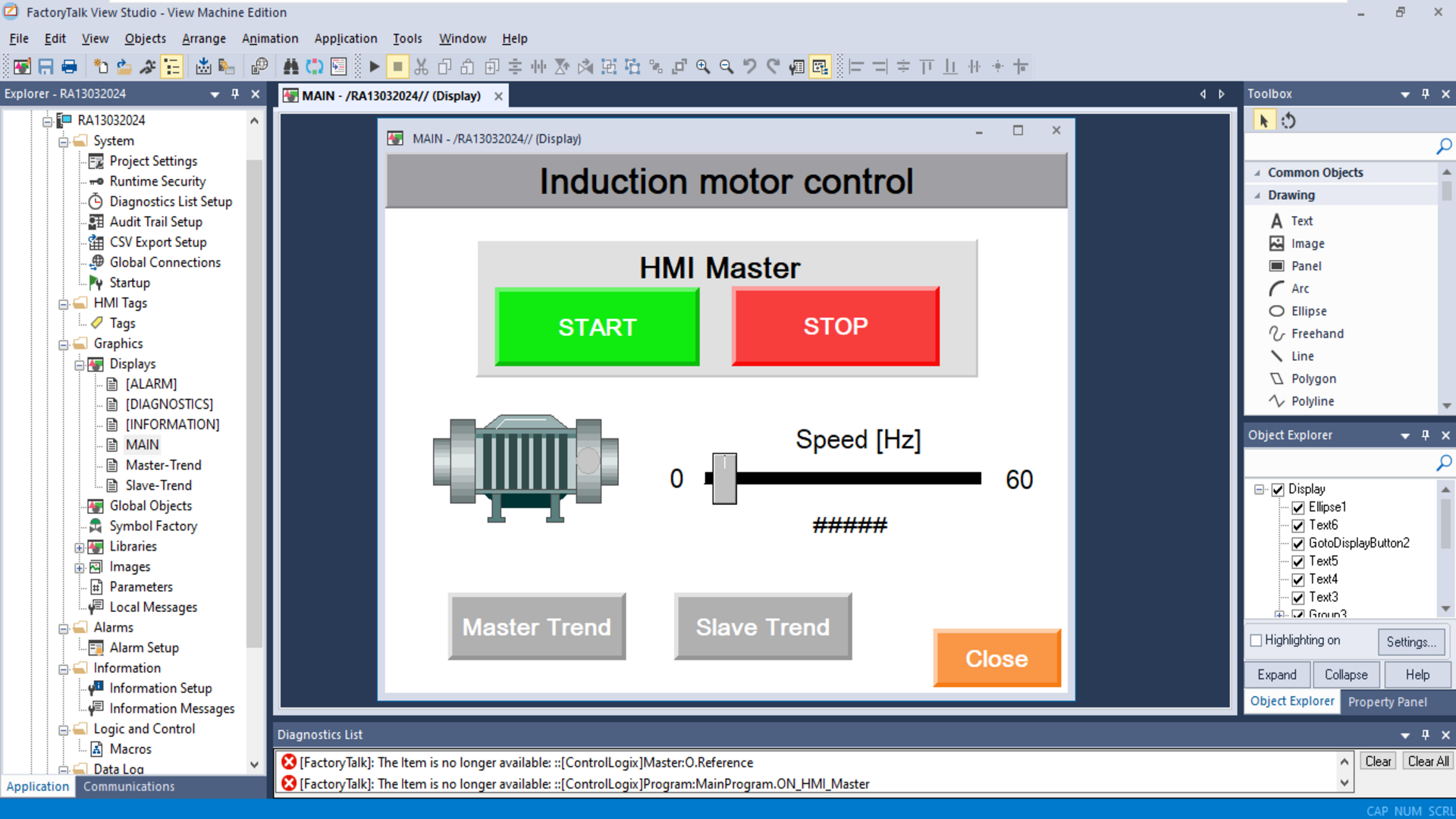

- PanelView Plus 7.

- ControlLogix 5573.

Software

- Studio5000(V35)

- FactoryTalk View(V12)

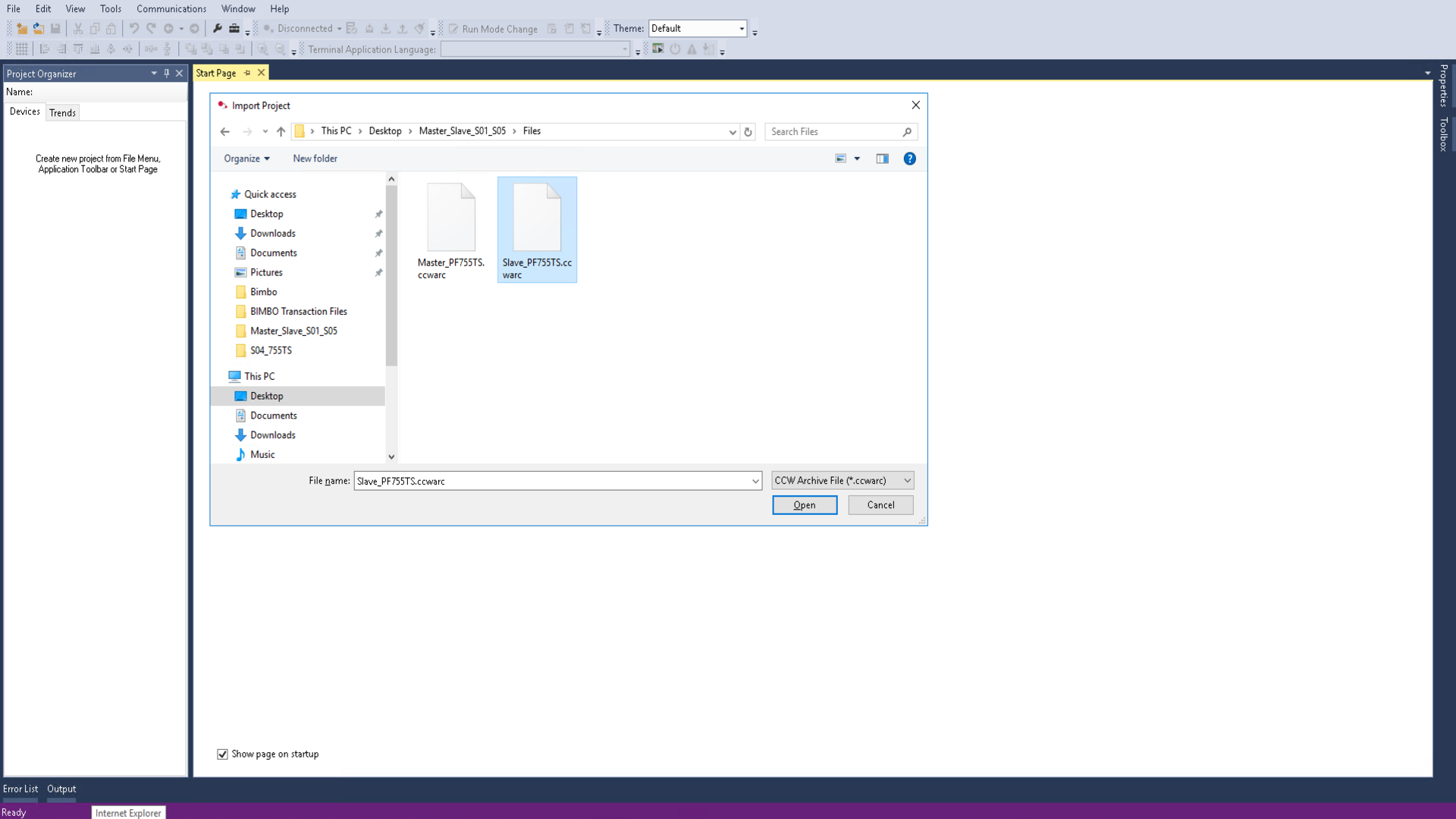

- Connected Components Workbench(CCW - V21)

Required knowledge

Knowledge of CCW, AC and DC motors, and Studio 5000.

Links of Interest:

https://www.rockwellautomation.com/es-mx/products/hardware/allen-bradley/new/powerflex-755ts.html

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

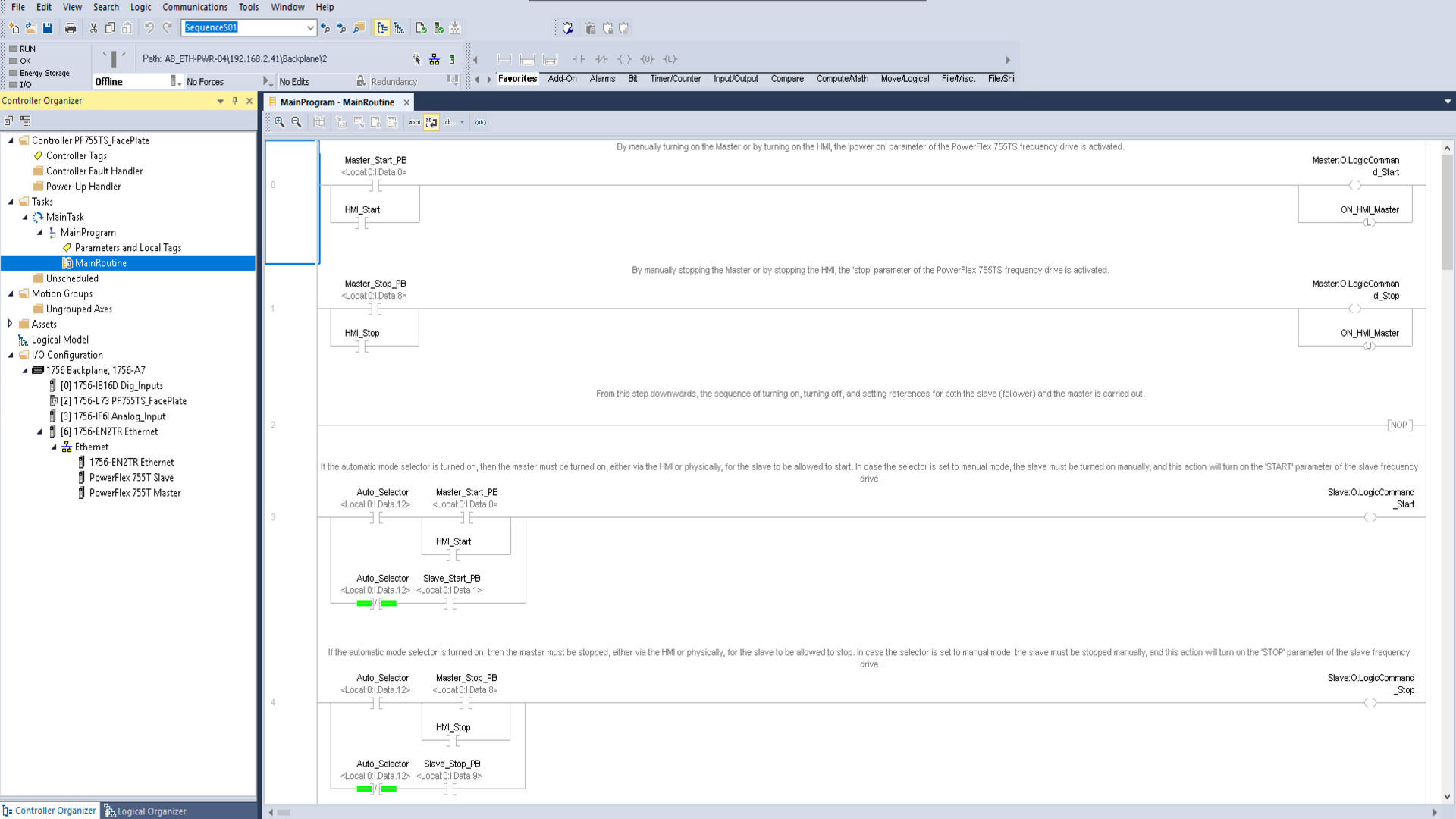

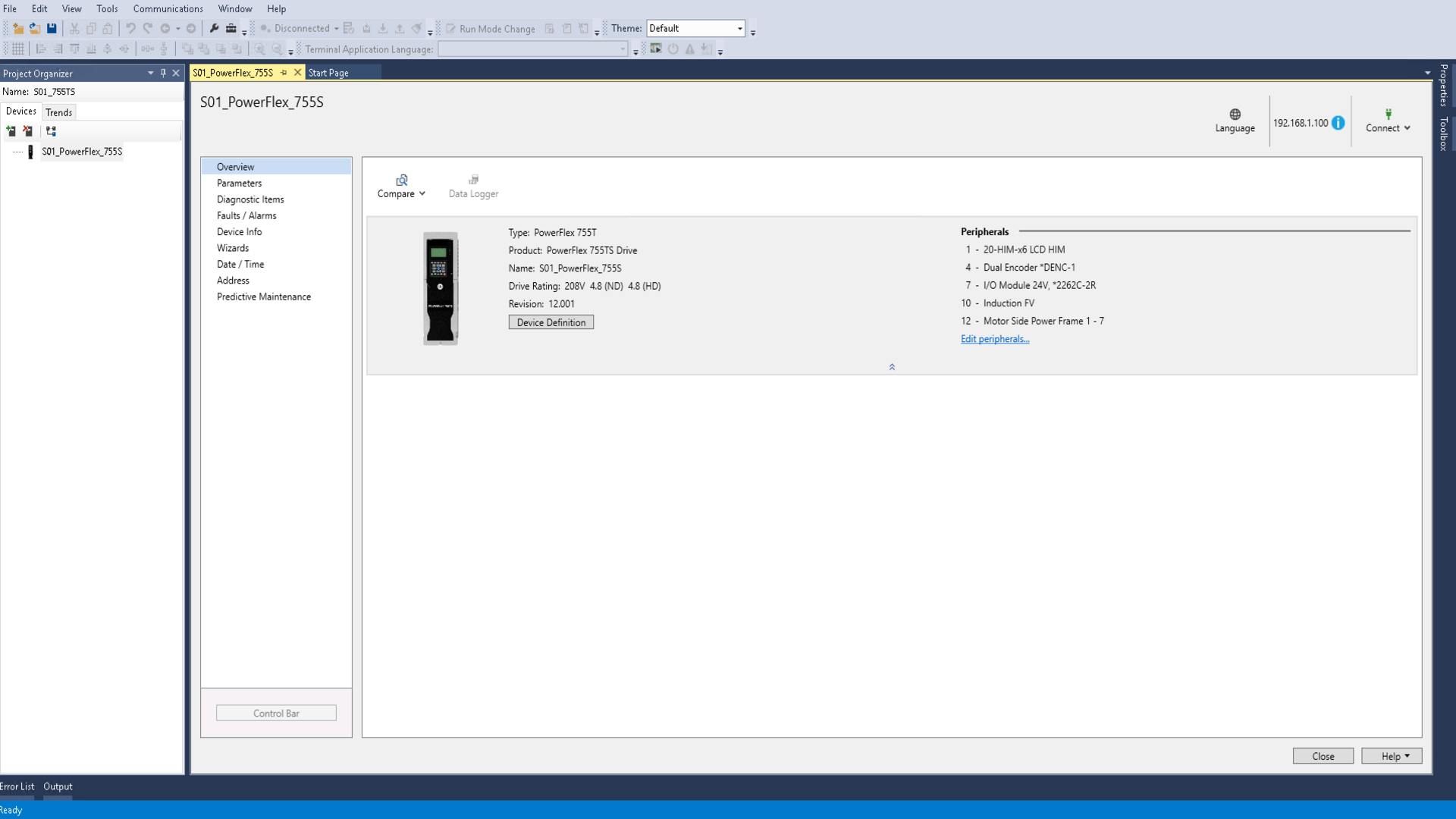

Step 1

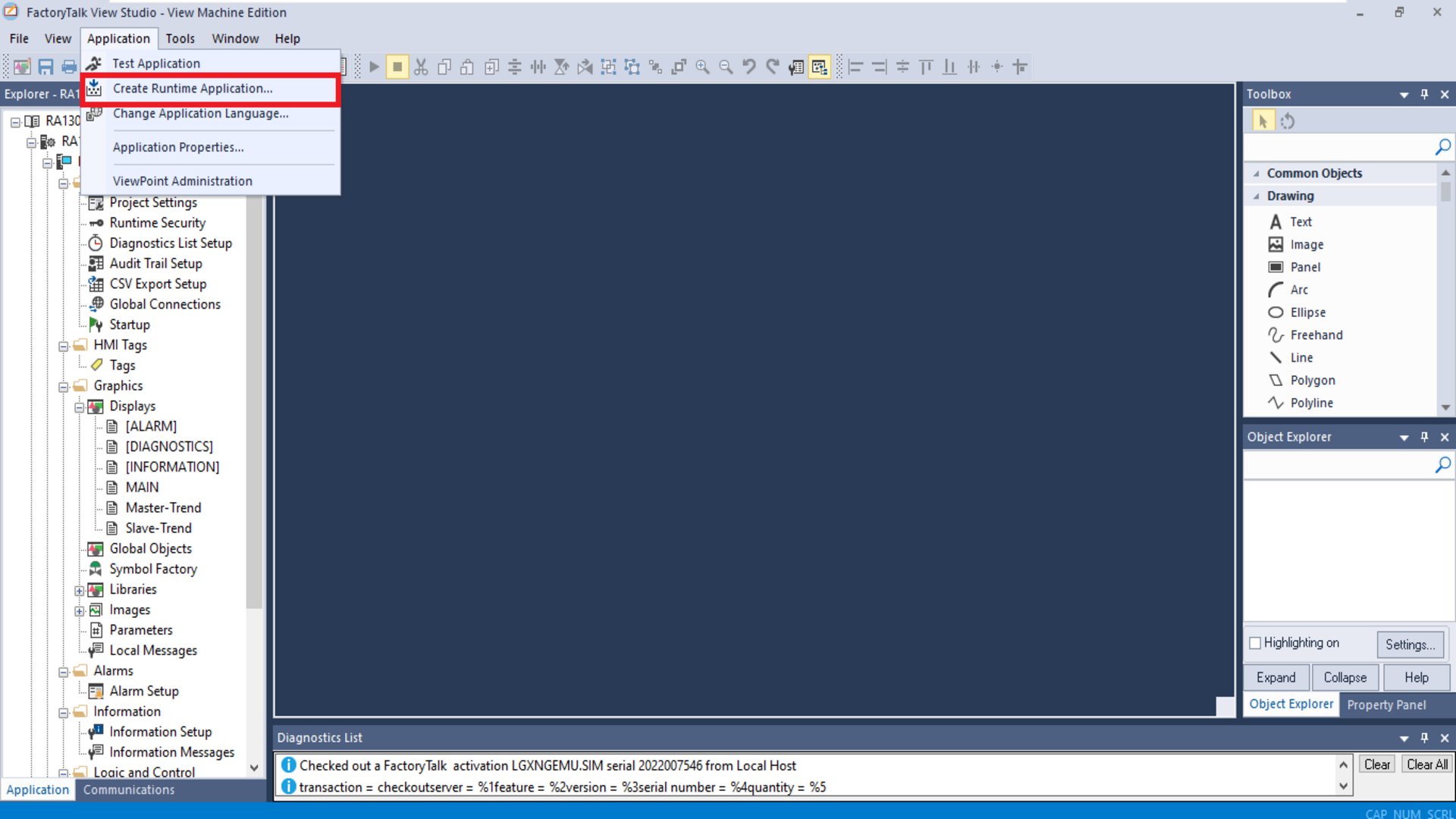

Identify the applications used for implementation: CCW, Studio 5000, and FactoryTalk View.

Step 2:

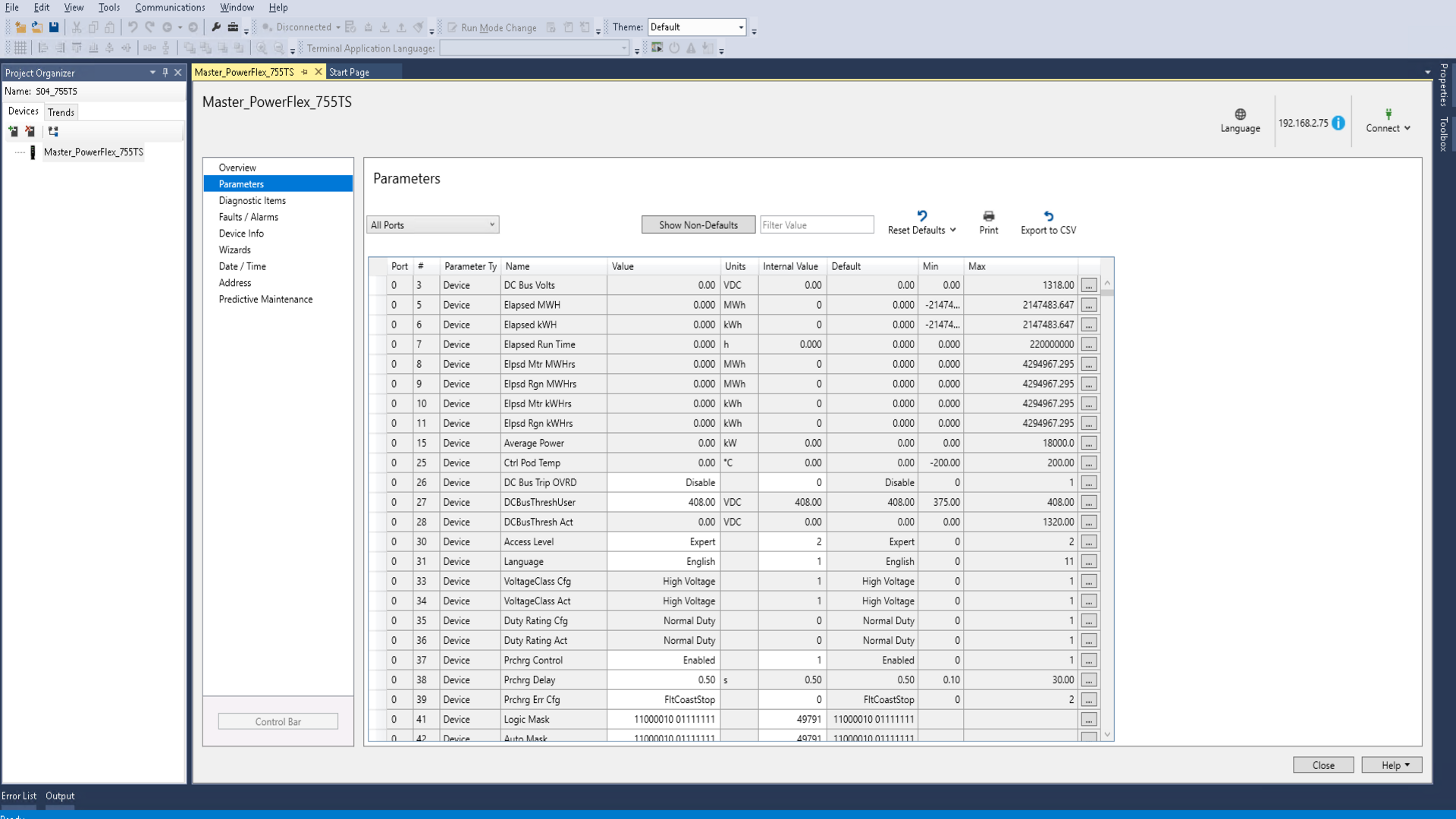

Step 3:

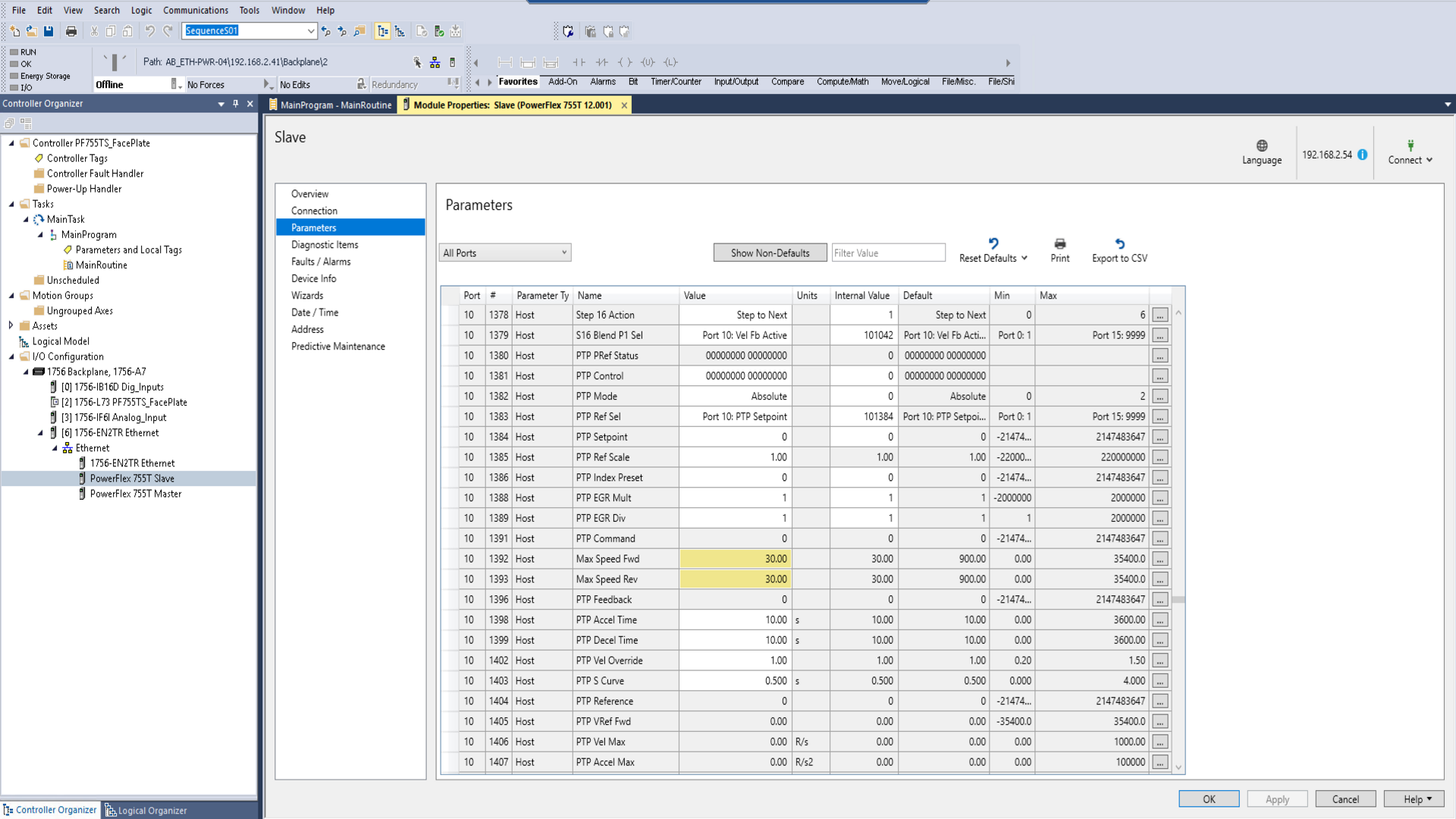

Step 4:

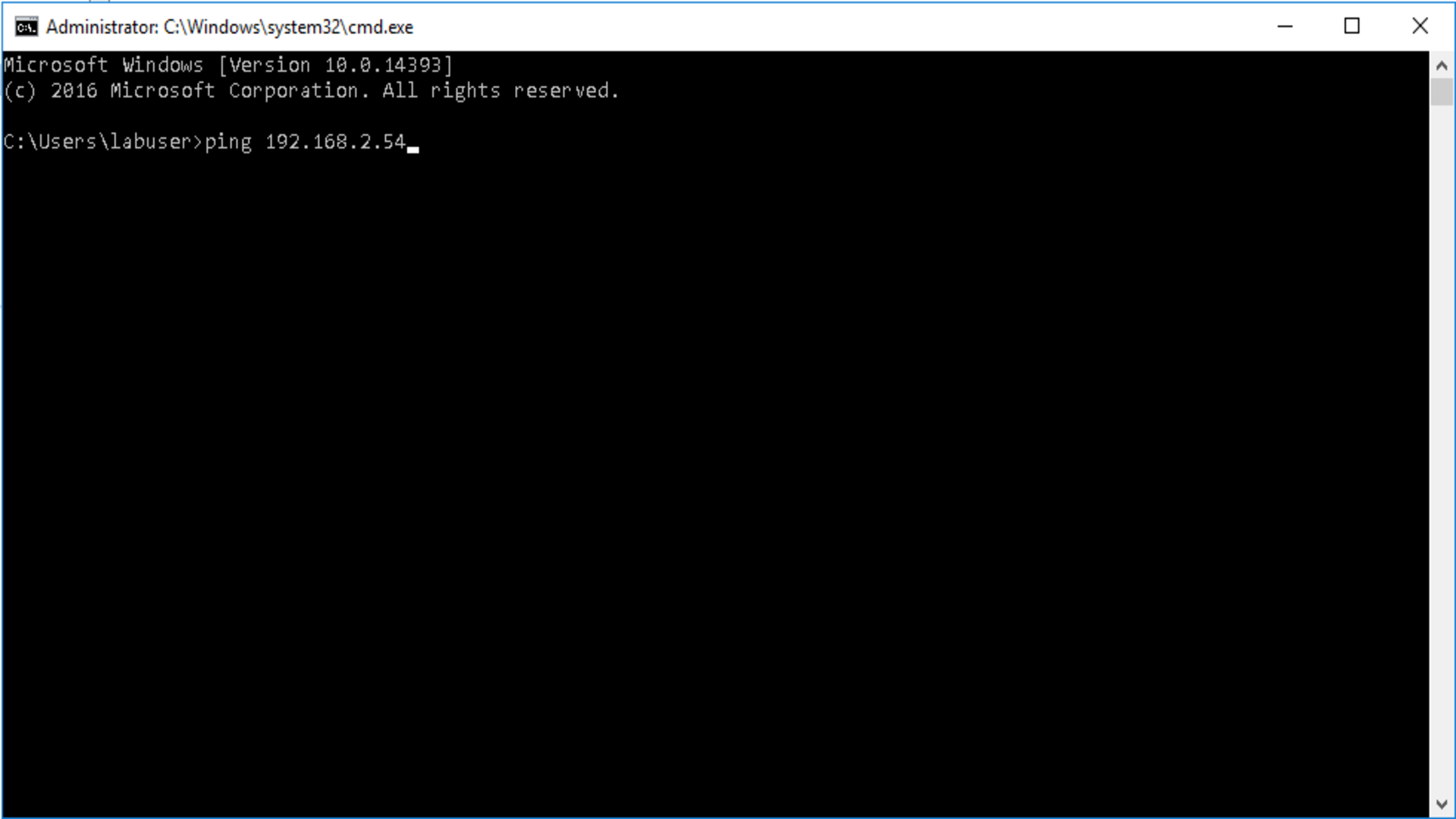

Step 5:

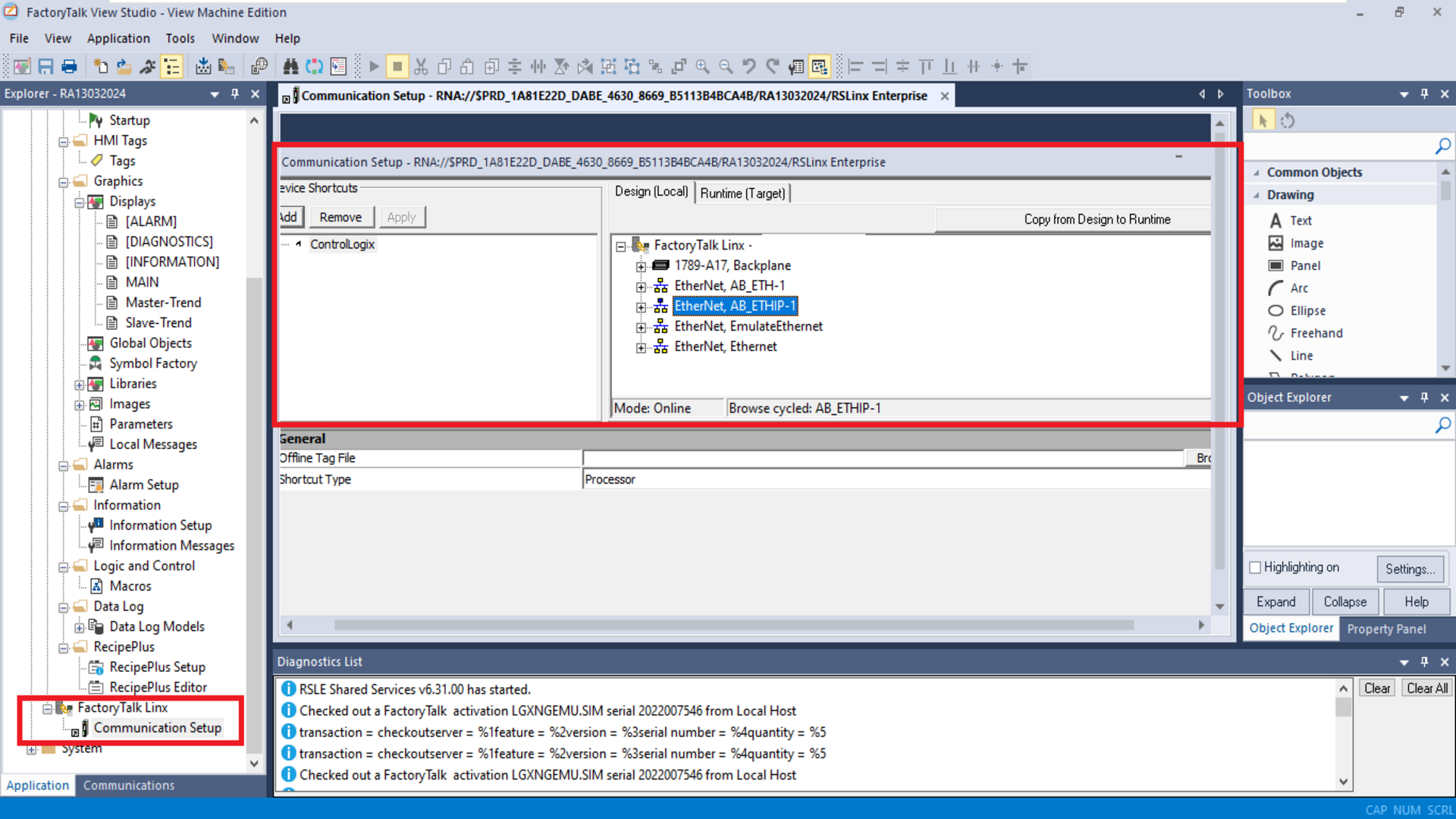

Step 6:

Step 7:

Step 8:

Step 9:

Step 10: