Downloads

What is this for?

LOTO consists of a functionality available in Factory Talk View Studio SE and Studio 5000 that allows the safe, direct and indirect digital blocking of equipment in electrical panels, drawers and CMM, controlled by duly accredited users, increasing safety for operators and maintenance people.

General Features

The electrical lock consists of the shutdown of the component responsible for energizing a circuit (usually a circuit breaker) and inserting a padlock into this disconnected circuit breaker, so that it cannot be reconnected by another person during the entire maintenance.

In this way, the electrical block prevents anyone from being able to access and/or maneuver this component and from energizing a certain circuit, where workers are intervening in maintenance.

Locks can be used individually or collectively, through multiplier devices, in situations where multiple teams are working on the same equipment, but on different service fronts. This way, the machine will only be energized when all team locks are removed.

After all, it is important to emphasize that the blockage in the electrical circuits must be carried out mainly in the power circuits and can be complemented with the shutdown of the control circuit.

Next to the locking device, a signaling card is also inserted, usually containing the photo of the person responsible for the lock, its function and allocation sector, in addition to the name of the circuit or equipment that was blocked by it.

Therefore, the purpose of the signal card is to visually alert people not involved in the process that the equipment is blocked for some reason and cannot under any circumstances be energized.

Advantages:

LOTO with Factory Talk View Studio and Studio 5000 make it simple and safe to lock panels, CMM drawers, specific equipment such as valves, motors and instruments in the field.

- Time for configuration

- Request

- Authorization by the area owner

- Indication of padlock placement

- Indication of zero energy test by the area owner

- Removal of the blockade by the owner of the area

- Block outputs

- Label placement

- Label withdrawal

- Authorization by the General Manager

- Break by the maintainer

- More protection for operators and maintenance people

Is this useful for me?

In general, LOTO is recommended specially for automation process control where it requires the need to block equipments for maintenance and repairs.

- Cement process

- Food and Beverage process

- Chemical process

- Steel industry

- Mining Companies

Application areas:

Cement, Food and Beverage, Chemical, Steel, Mining.

Benefits of applications with LOTO systems:

- Secure digital lock management

- Treacebility

- Lock by area and equipment

- SQL Server database for record datas

How can I make it work?

Hardware

- Logix Controllers (ControlLogix / CompactLogix)

Software

- Factorytalk View SE Enterprise v13 or higher

- Studio 5000 Logix Desing v35 or higher

- SQL express (ou SQL Server para FTAlarm&Event)

- FactoryTalk Logix Echo V2 (or Physical Controller)P

Knowledge

Intermediate knowledge of programming and configuration in Logix Design Studio 5000 software:

- Studio 5000 - Ladder language (LD)

- Studio 5000 - Function Block Diagram (FBD)

- Factory Talk View Studio

- Factory Talk Echo

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

Step 1:

Studio 5000 Logix Design:

- Download files documentation available

- Open FILES> LOTO_Aplication Referency_en_EN.docx – Use this document as referency

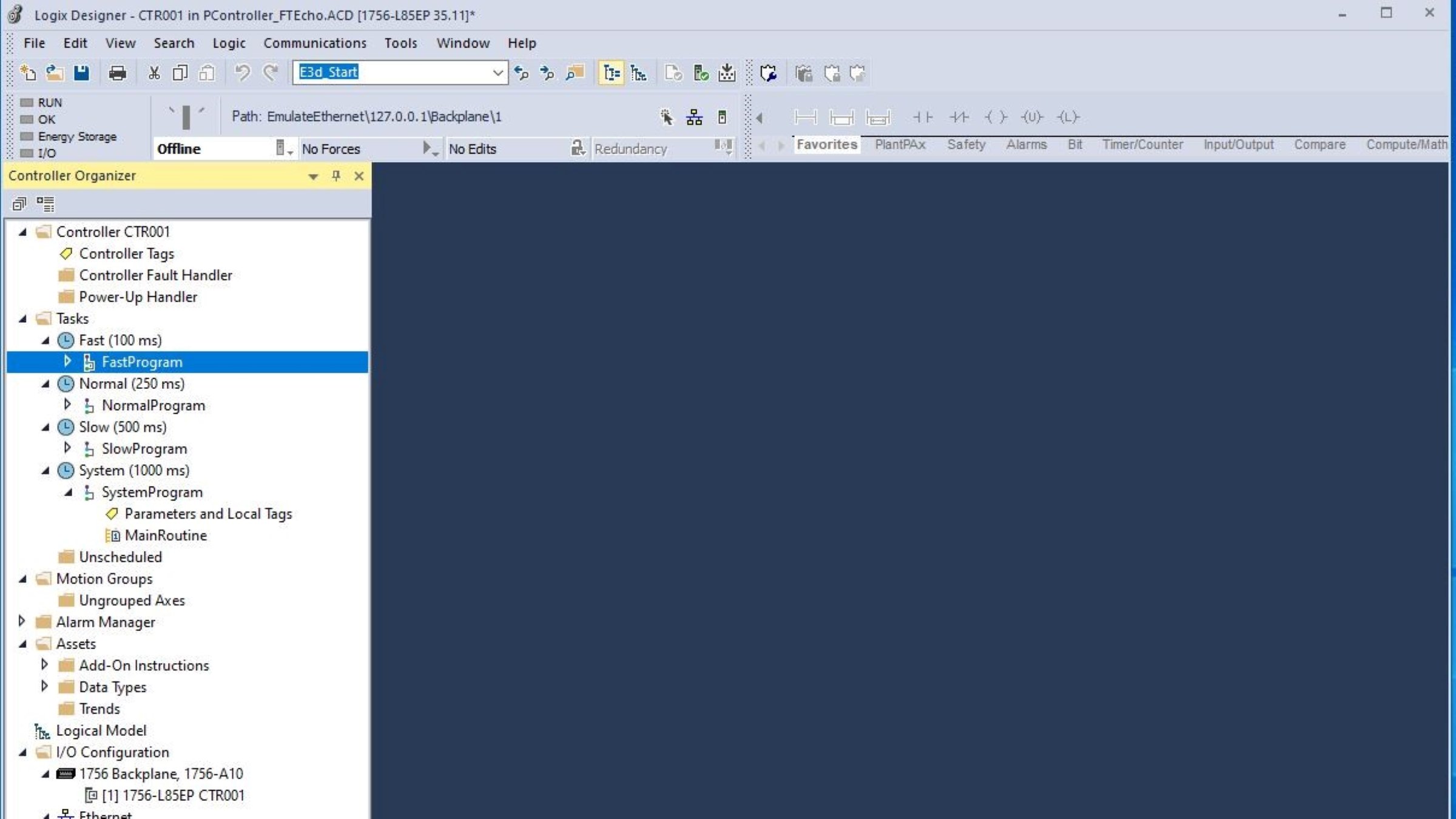

- Studio 5000 Logix Desing, Open program PController_FTEcho.ACD in Files/CS – Control Strategie

- Import the 32Dis Card (to exemplify using the "Connection" where we can modify with the controller running without stopping)

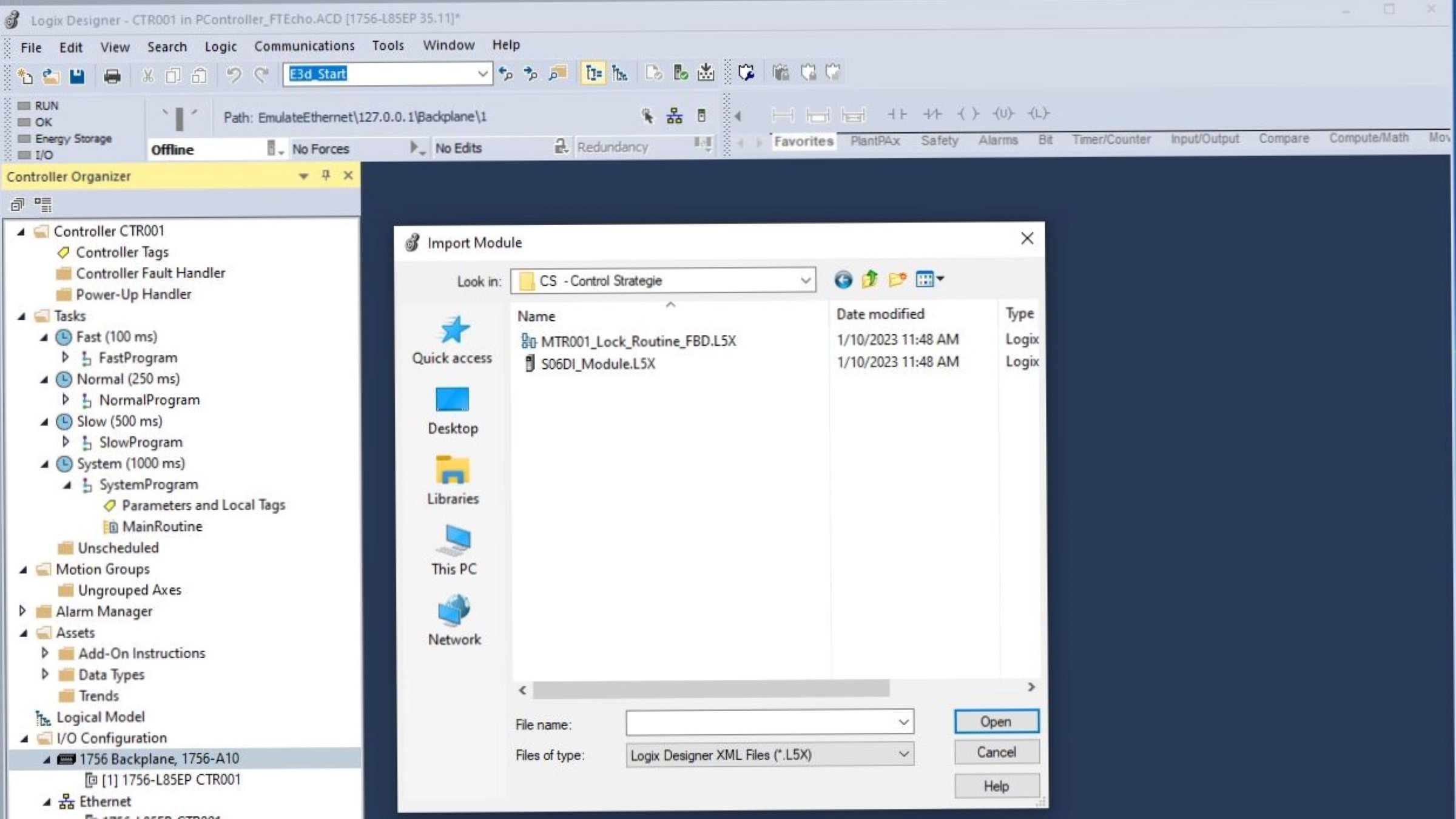

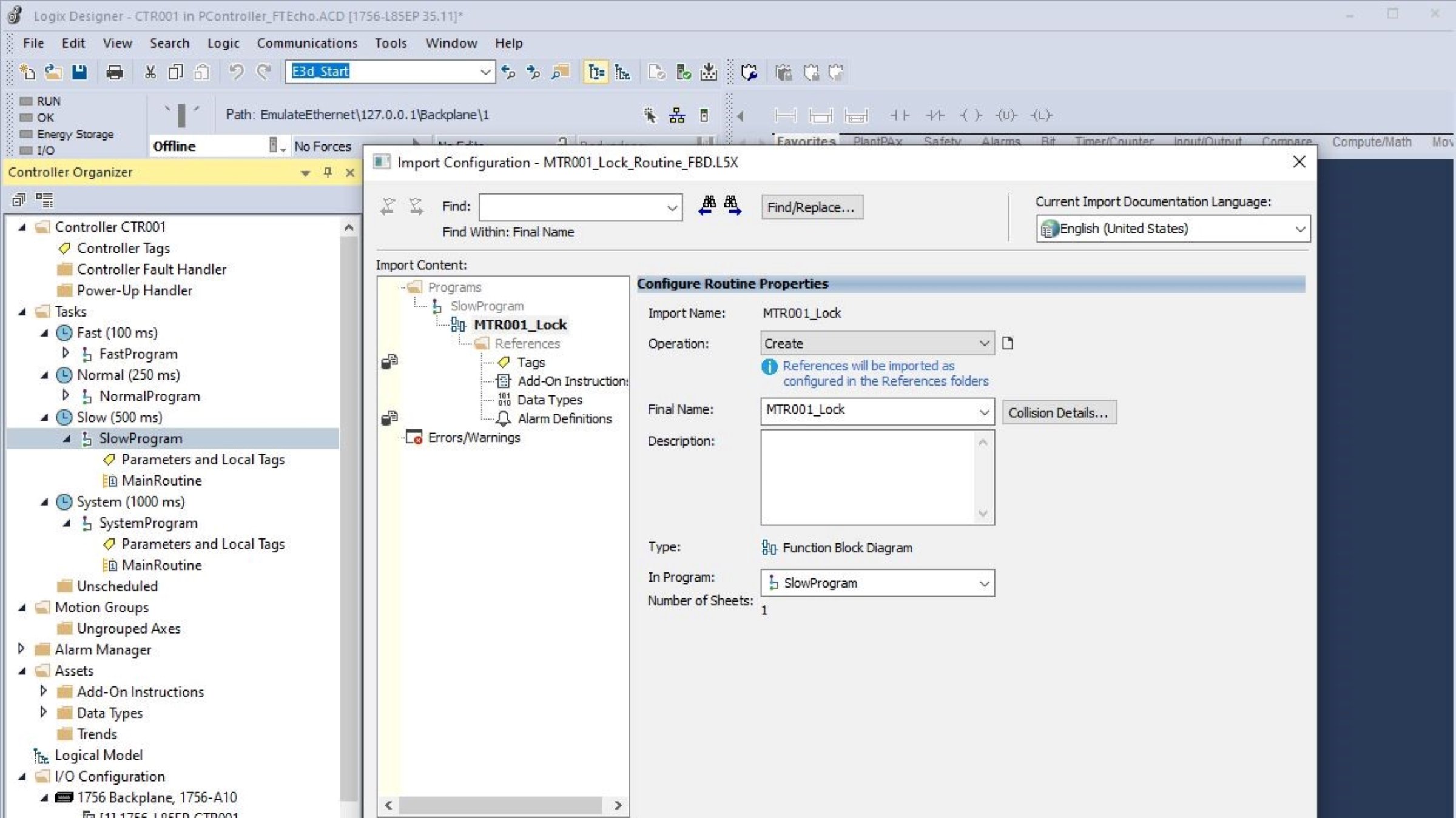

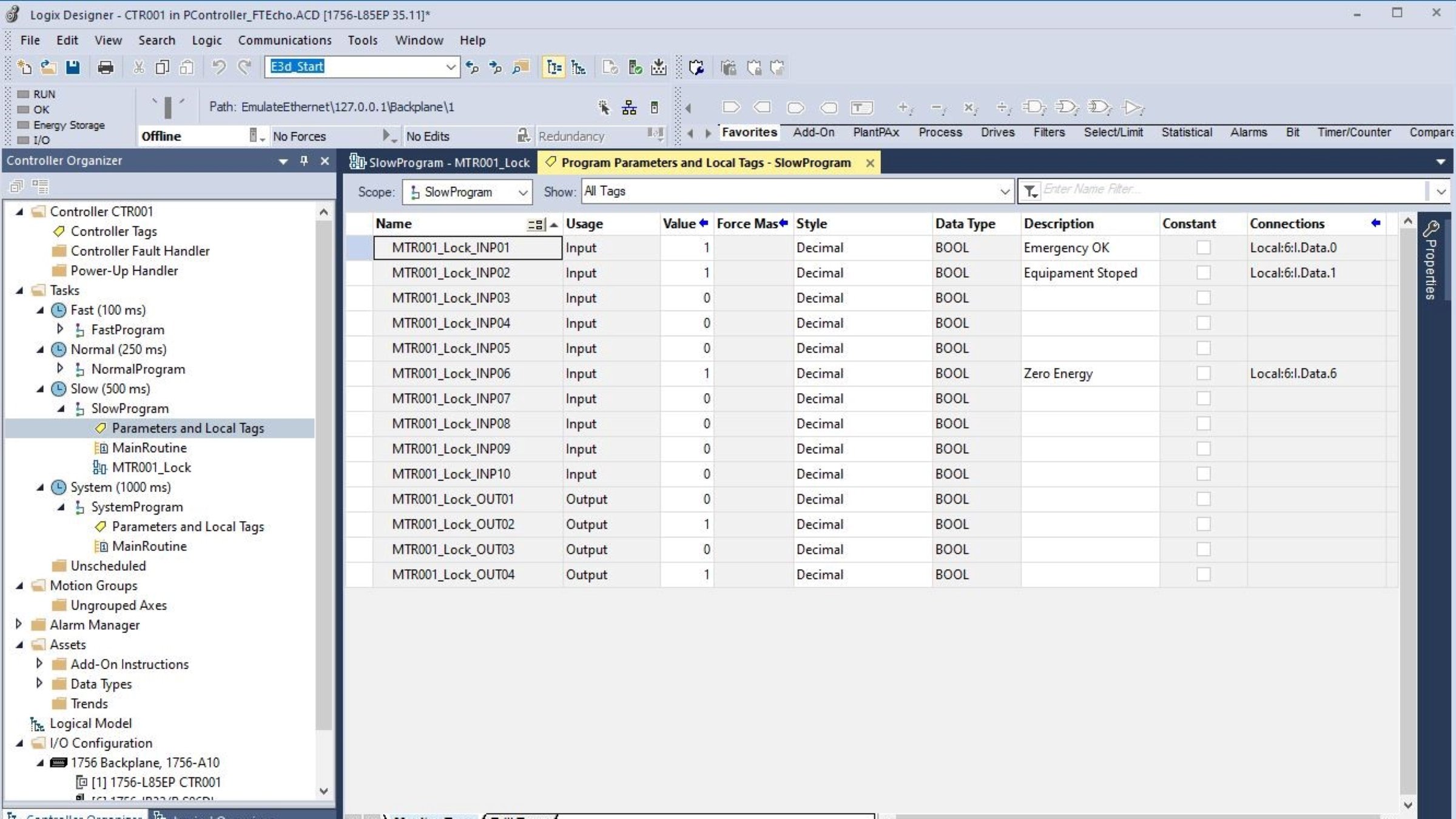

- Slow/Slow Program, import routine MTR_Lock_Routine_FBD.L5X.

Step 2

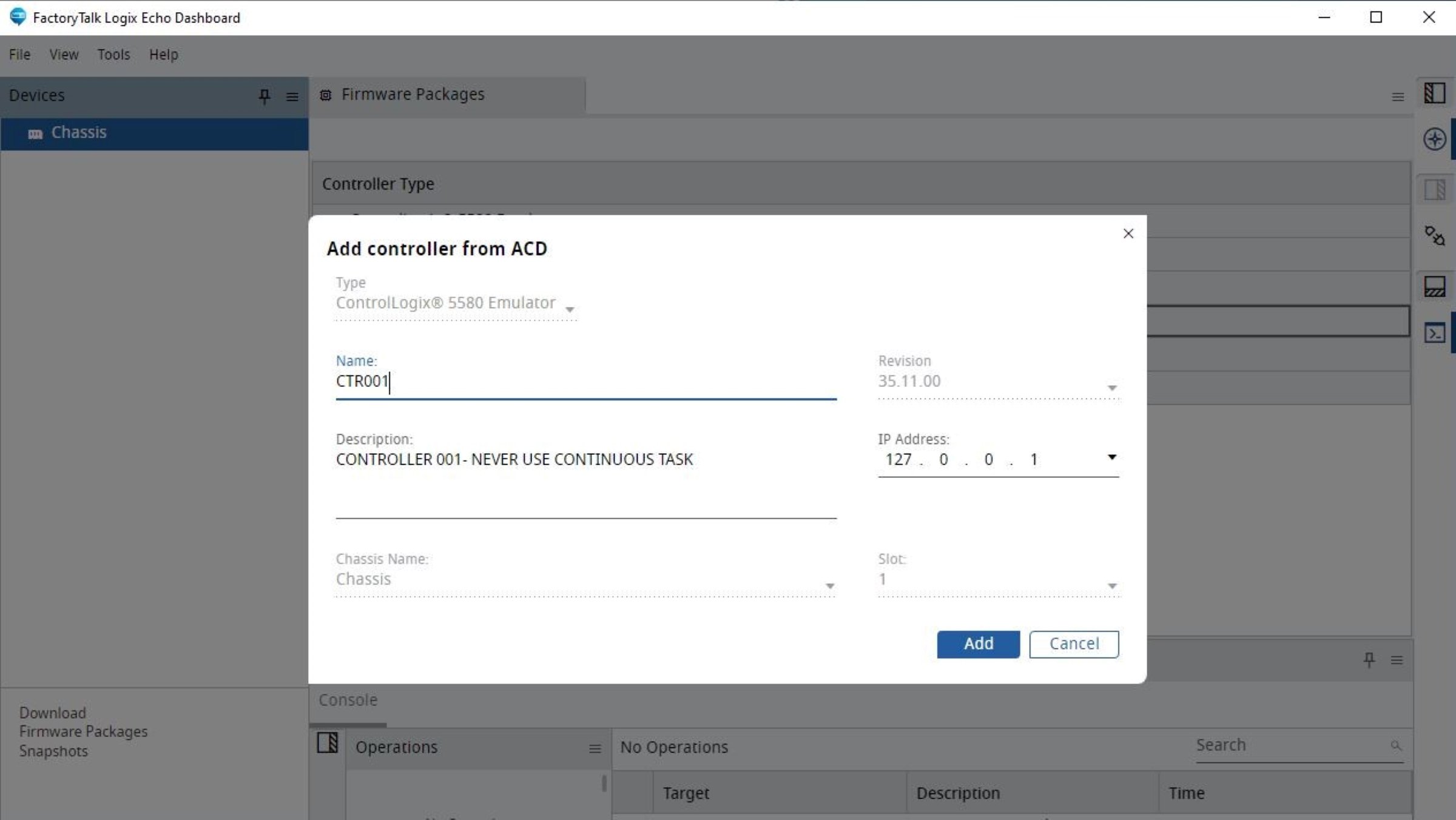

Factory Talk Logix Echo:

- Open FactoryTalk Logix Echo - ControlLogix 5580 Emulator V35

- Add the controller (ACD) PController_FTEcho.ACD

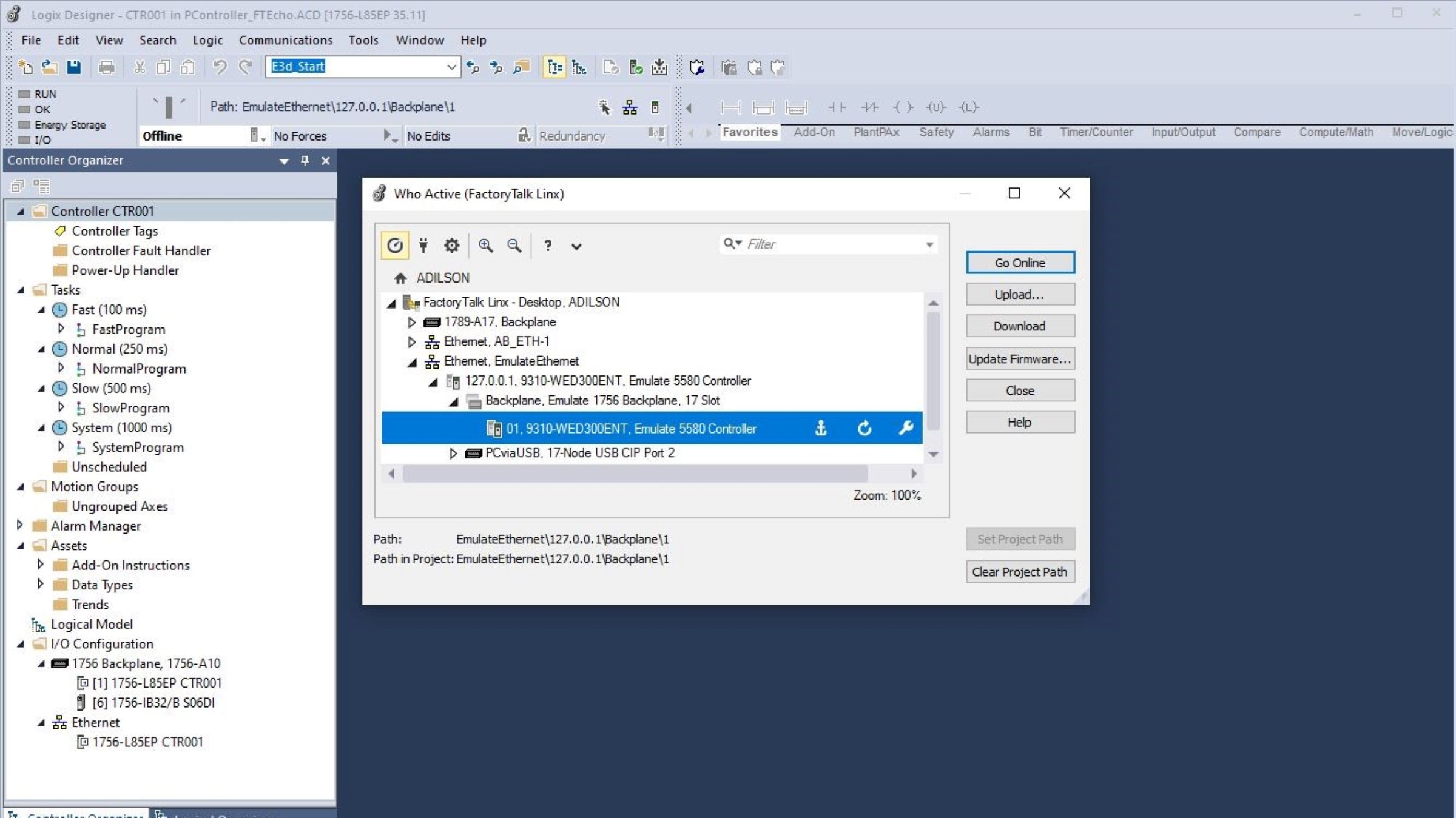

- In Studio 5000, Who Active, Select Emulate 5580 Controller and Download the program and Run Mode.

Step 3:

Factory Talk SE:

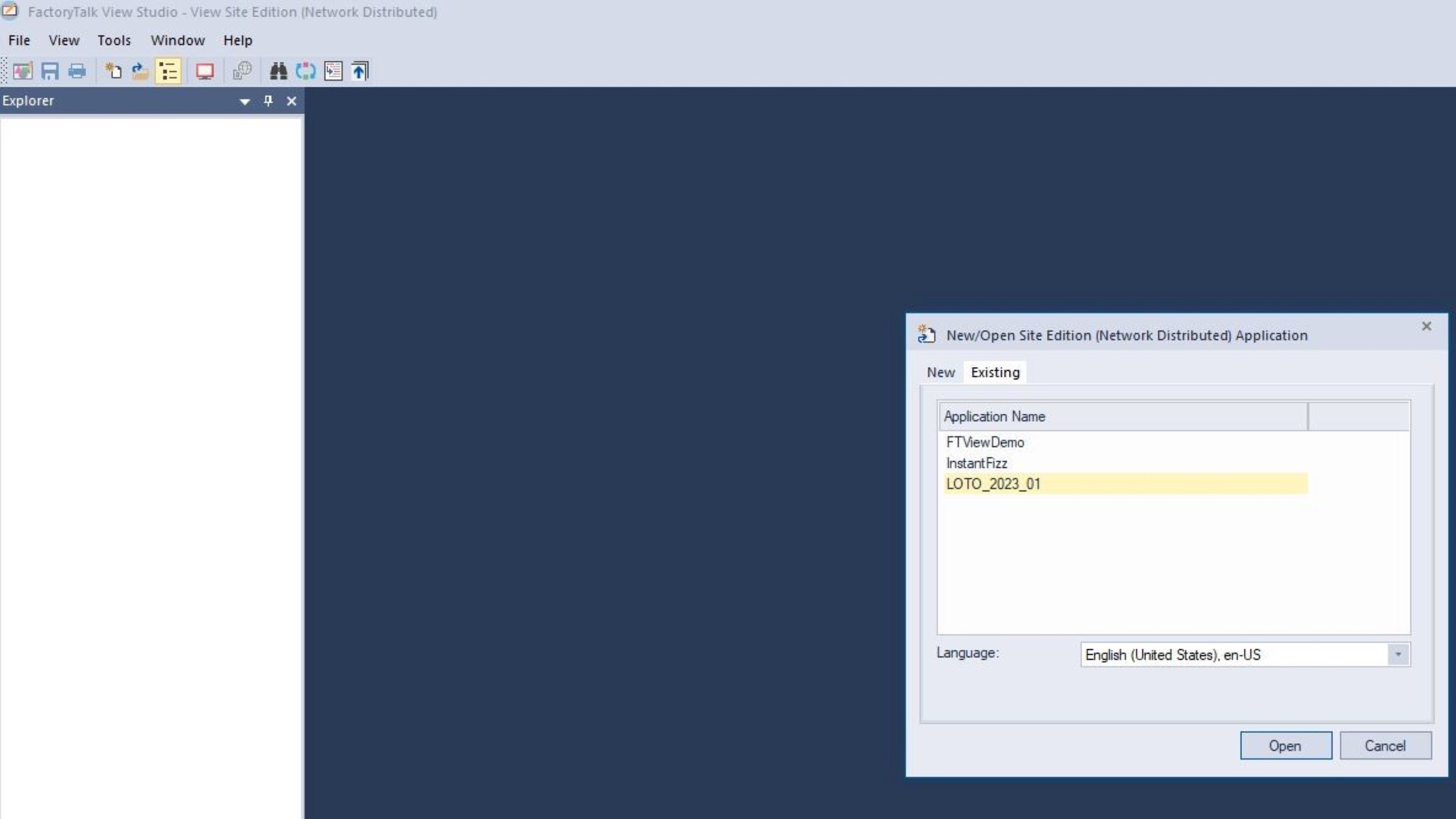

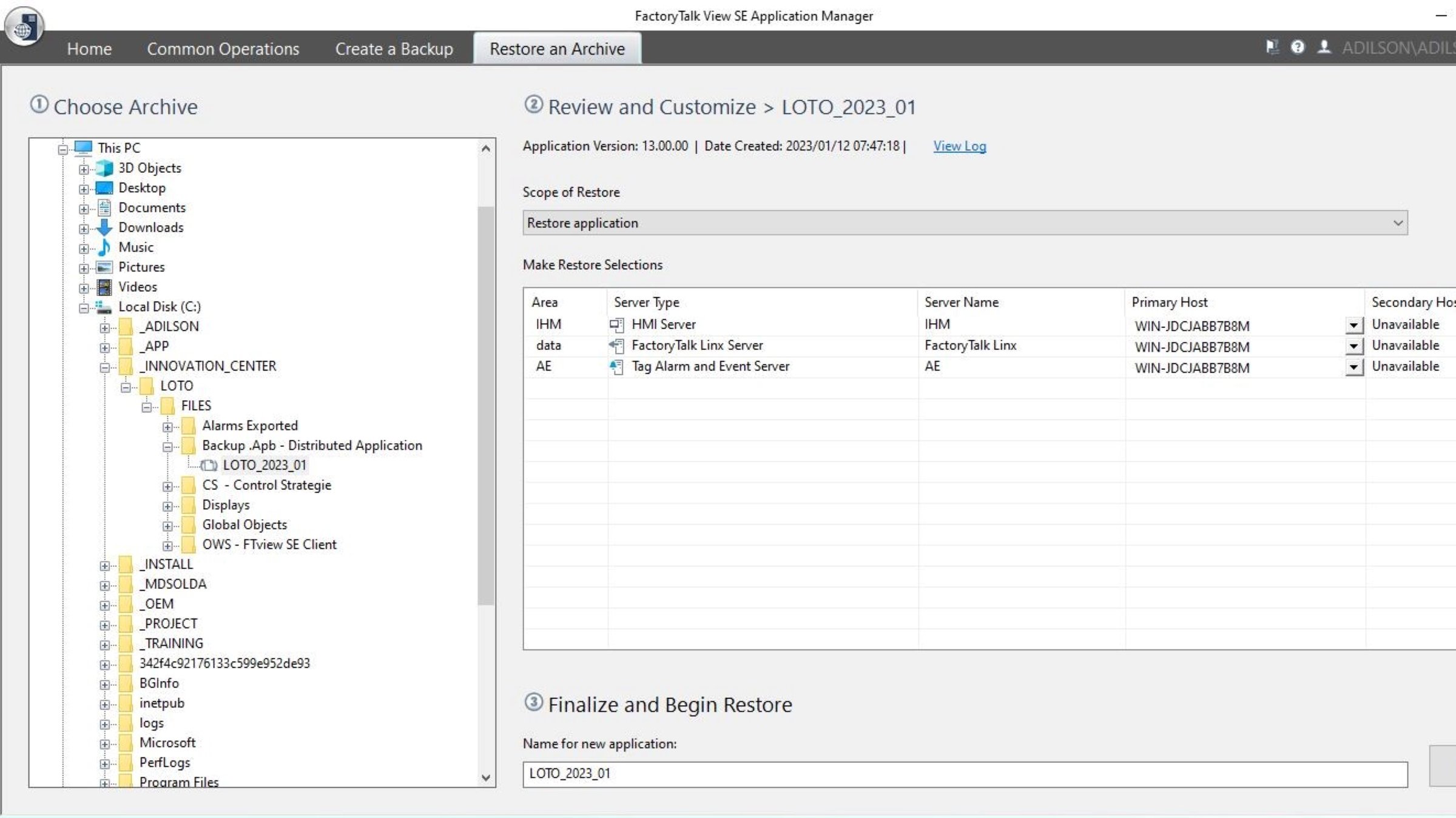

- Open FactoryTalk View SE Application Manager

- Restore an Archive (menu), FILES\Backup .Apb – Distribuited Application, Select LOTO_2023_01.apb application. Check the name of your machine (Primary Host)

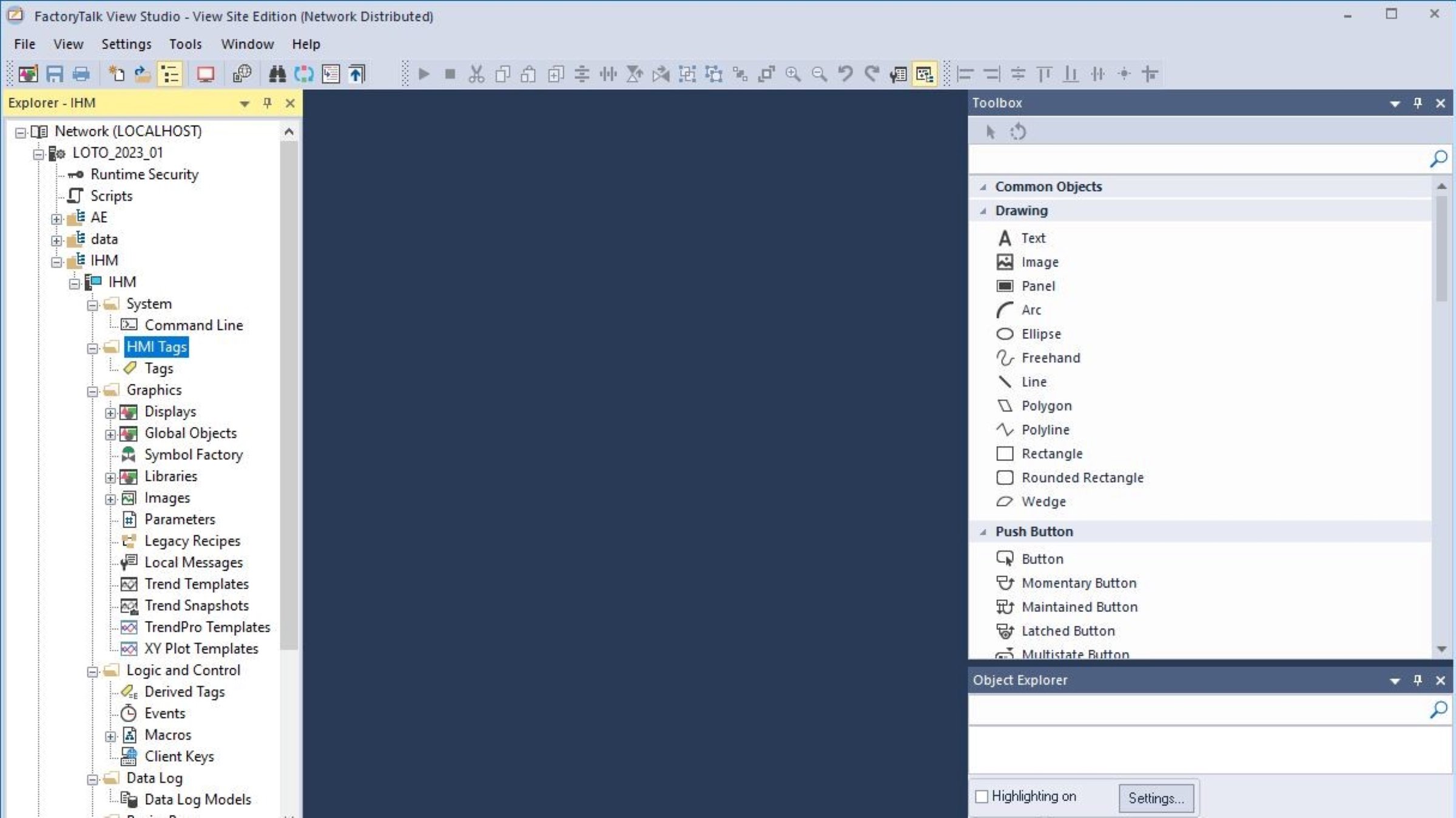

- Open Application in FT View Studio (Network Distributed)

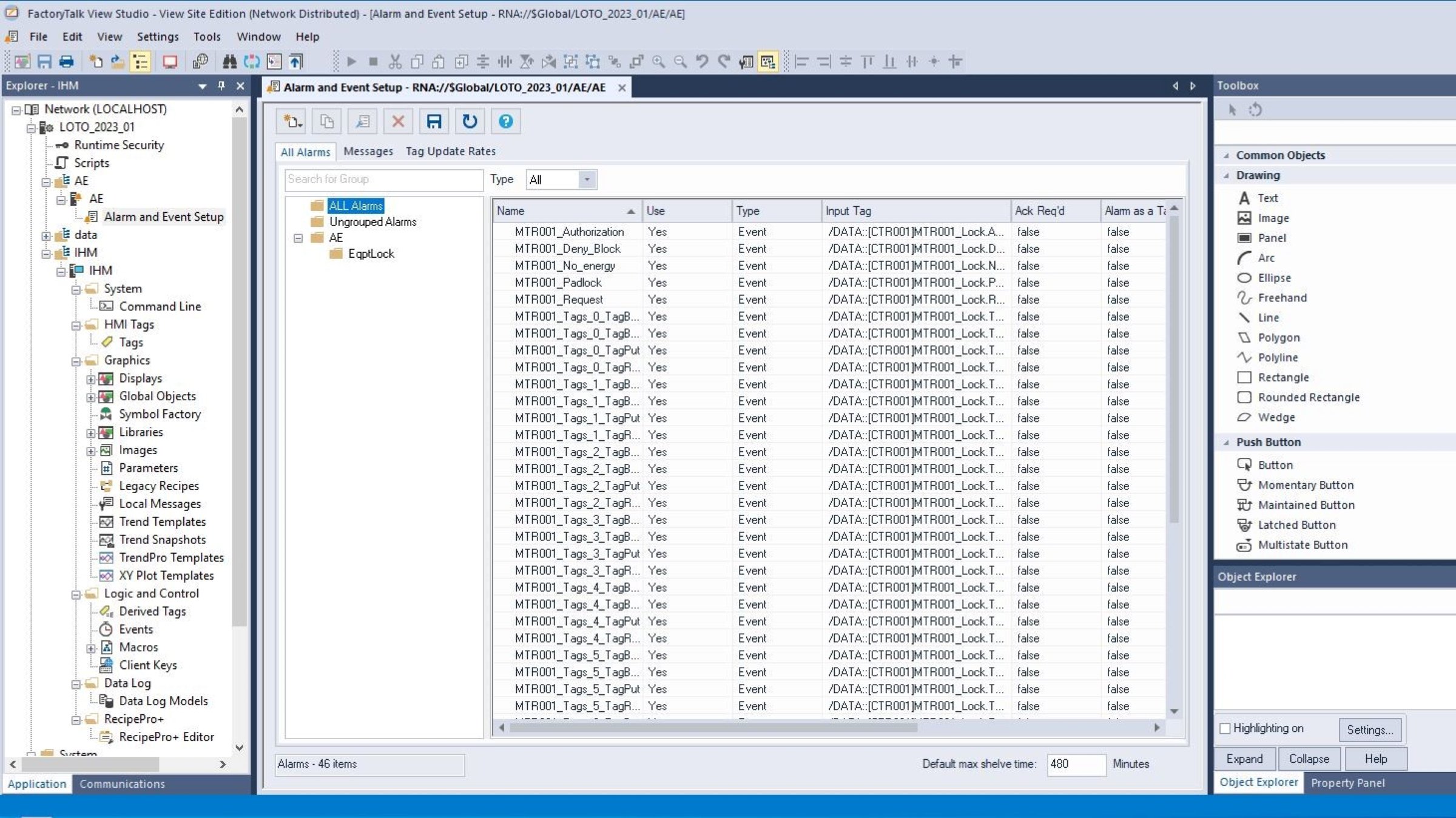

- Import alarm configuration from Excel file. FILES\Alarms Exported > LOTO_2023_01_FTAE_AlarmExport.xls

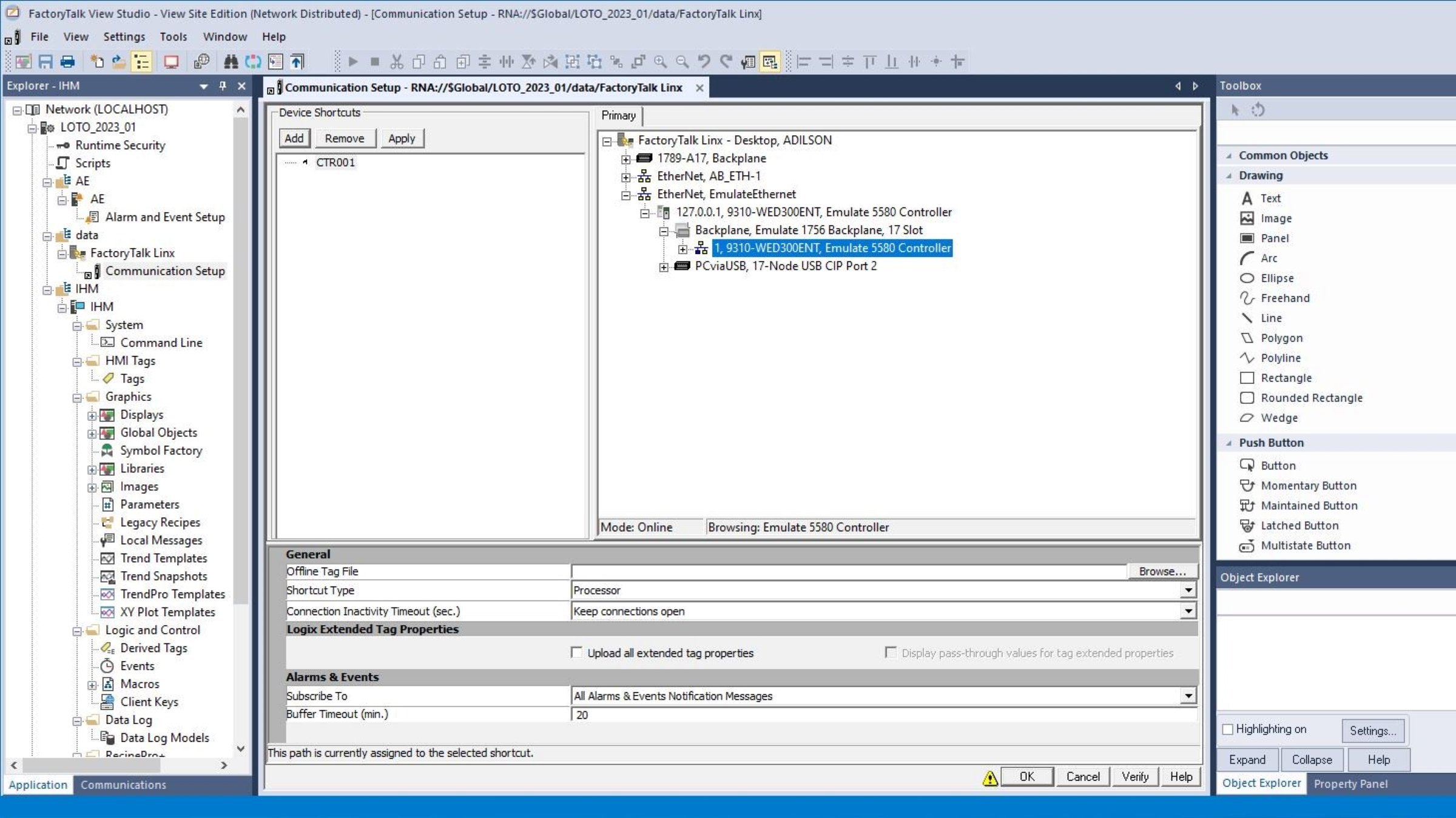

- Configure the communication setup

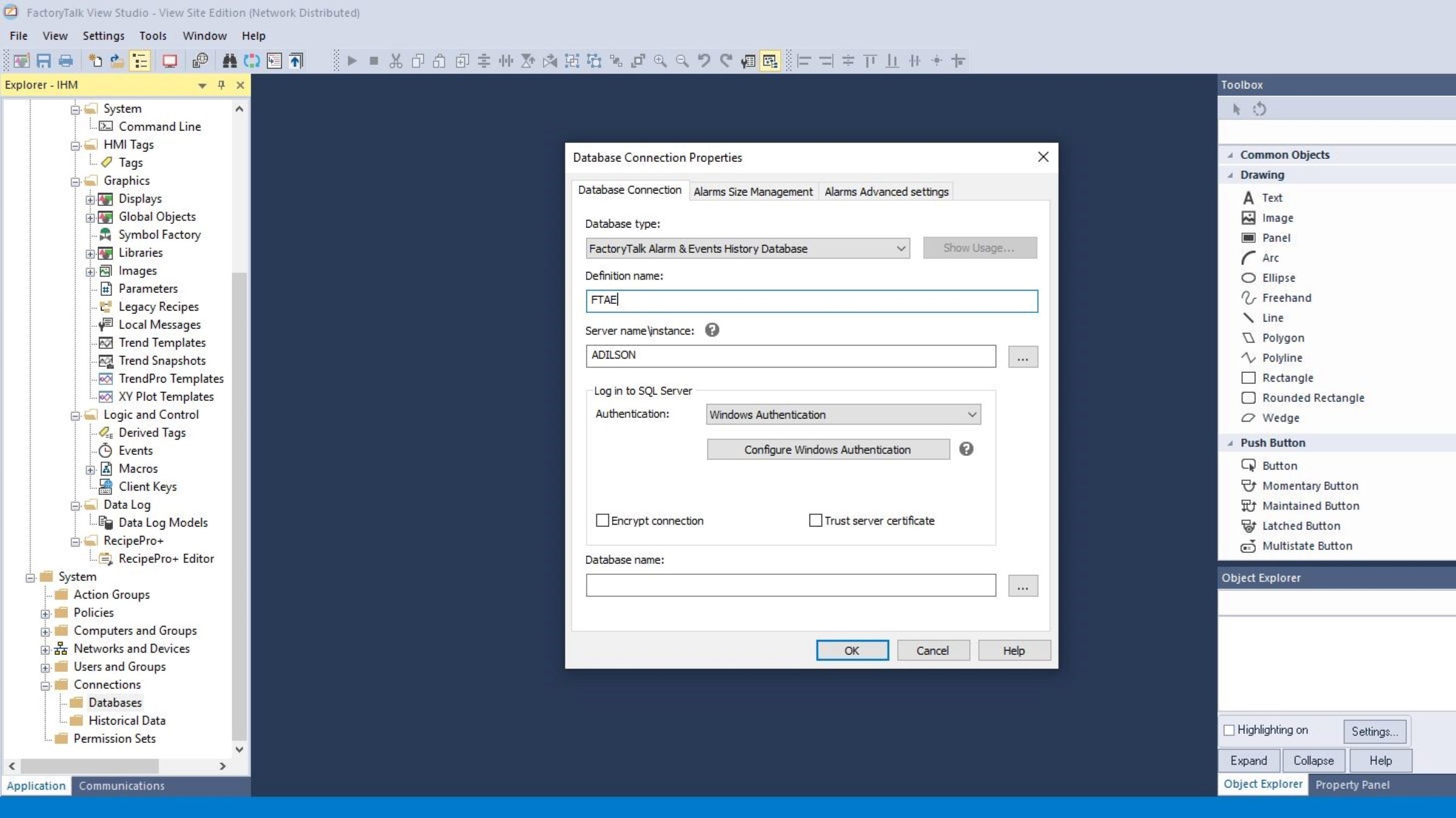

- Add Database in System\Connections\Databases.

Step 4:

Factory Talk SE – Application:

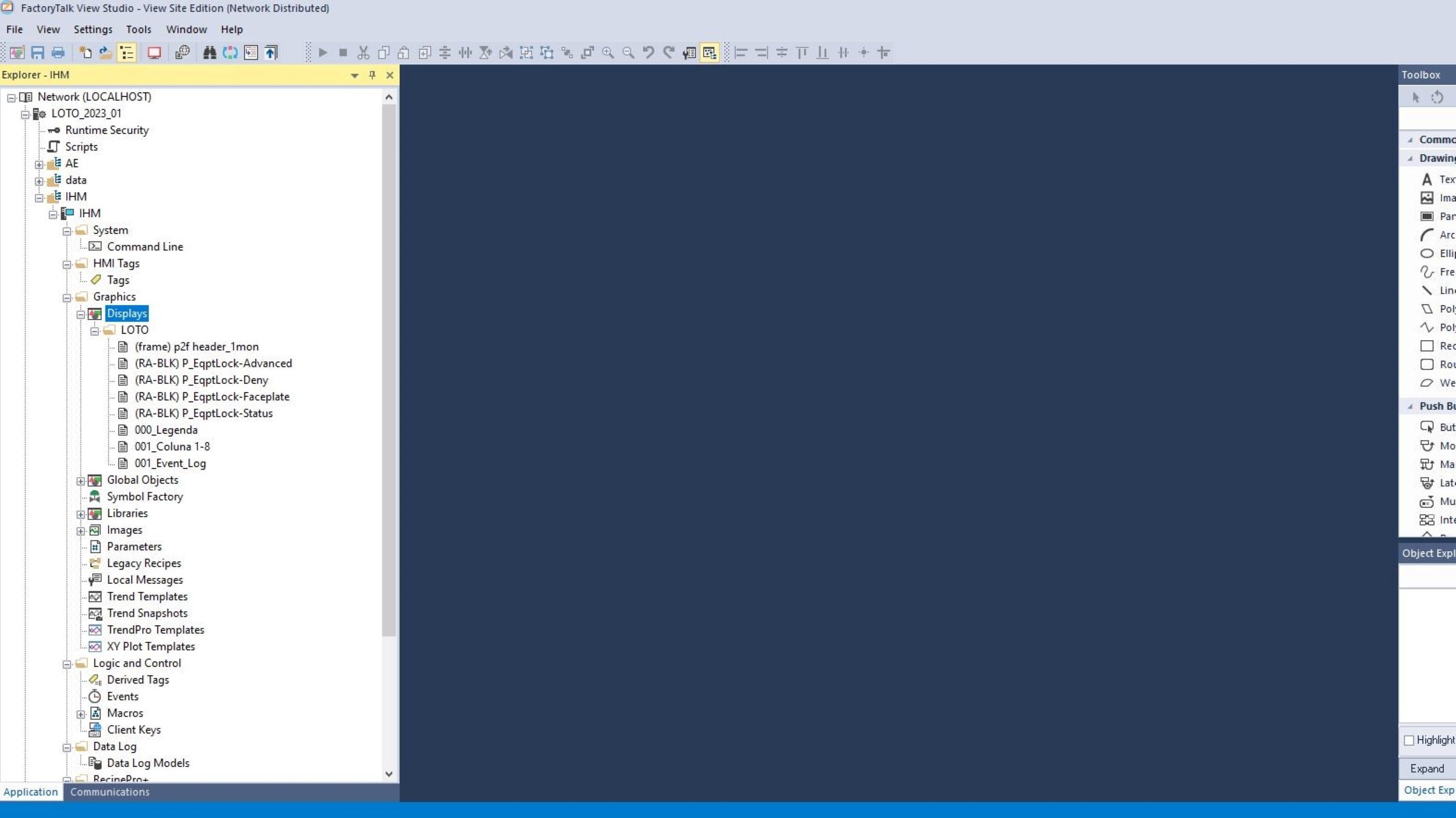

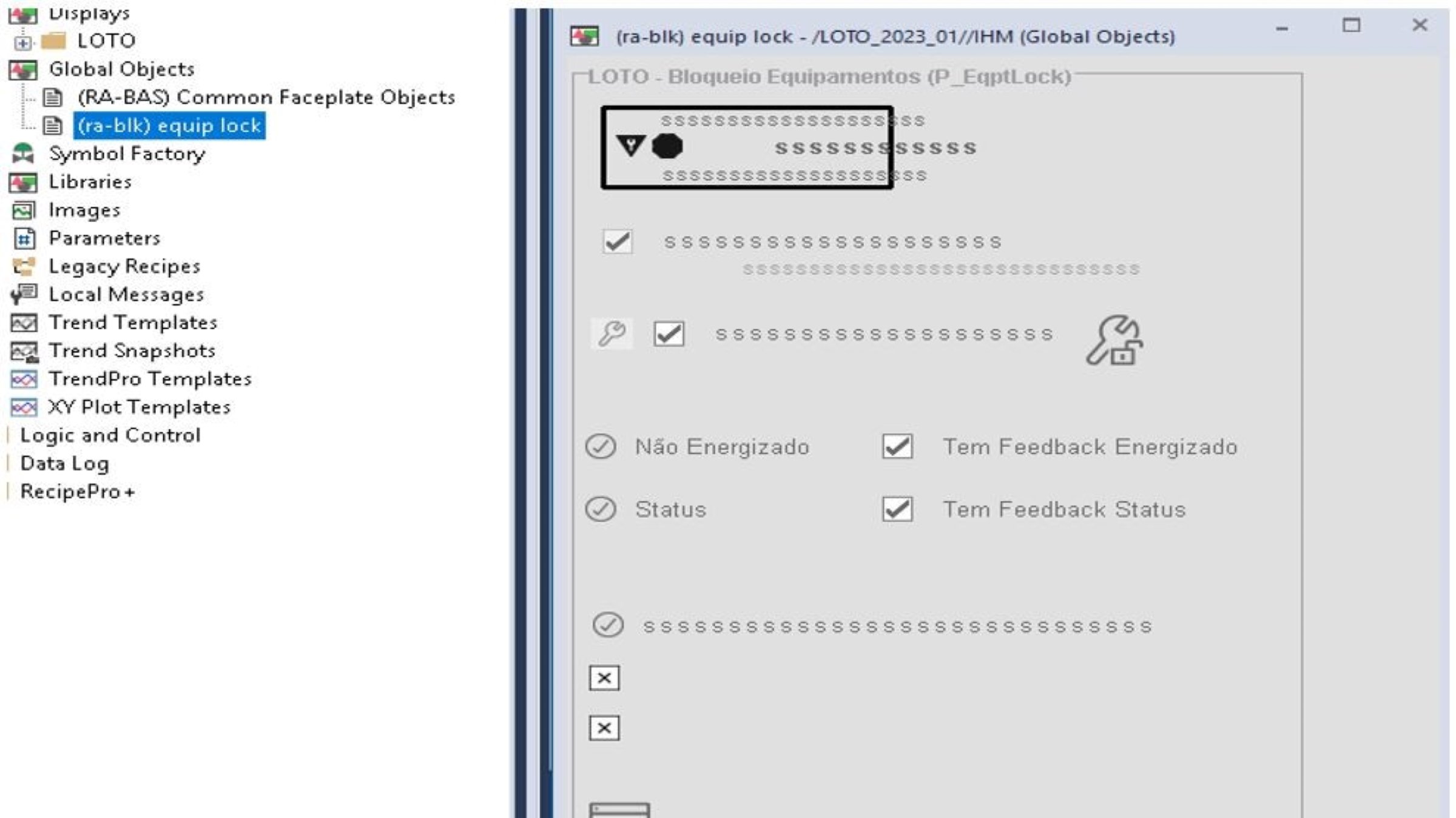

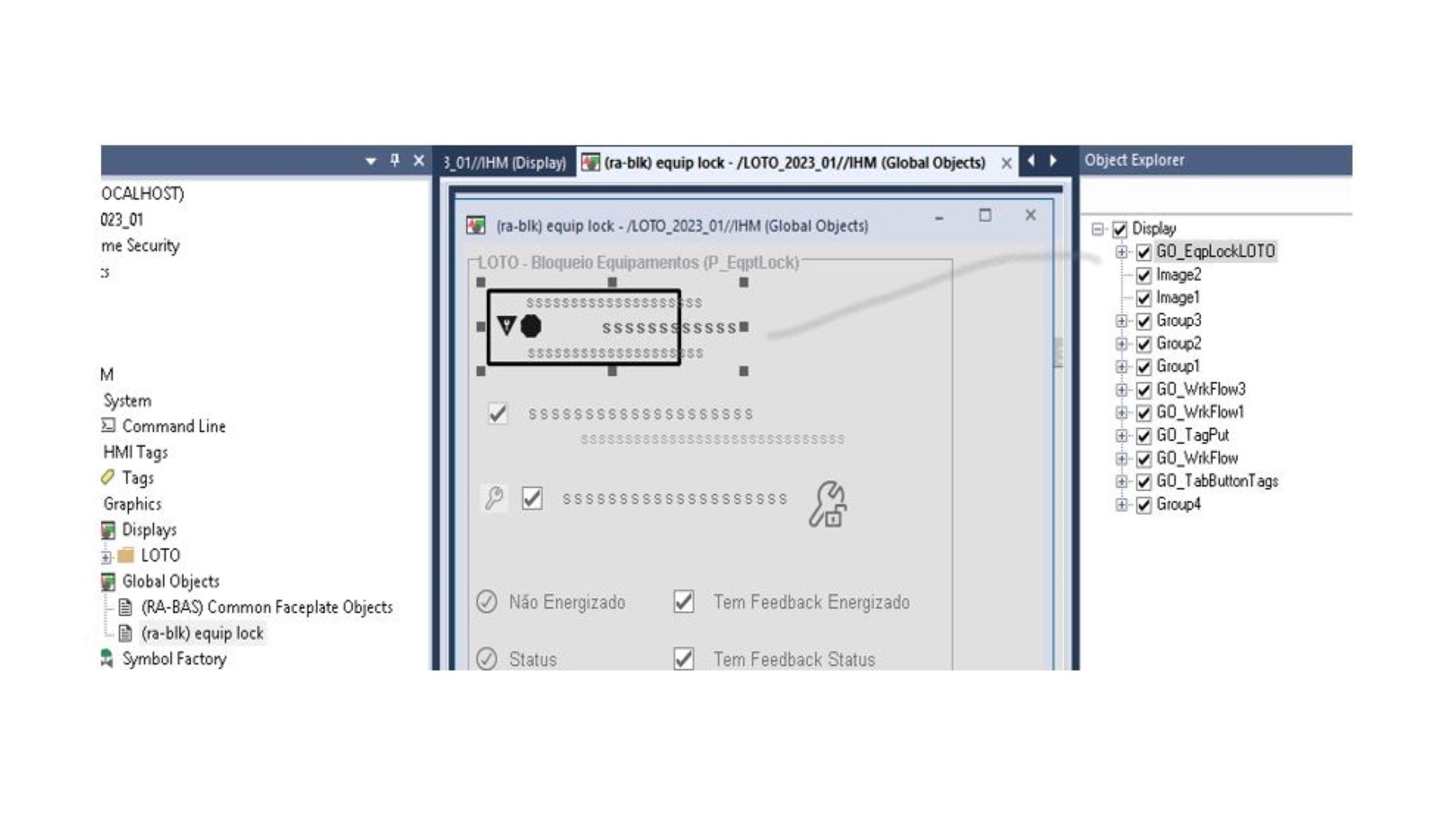

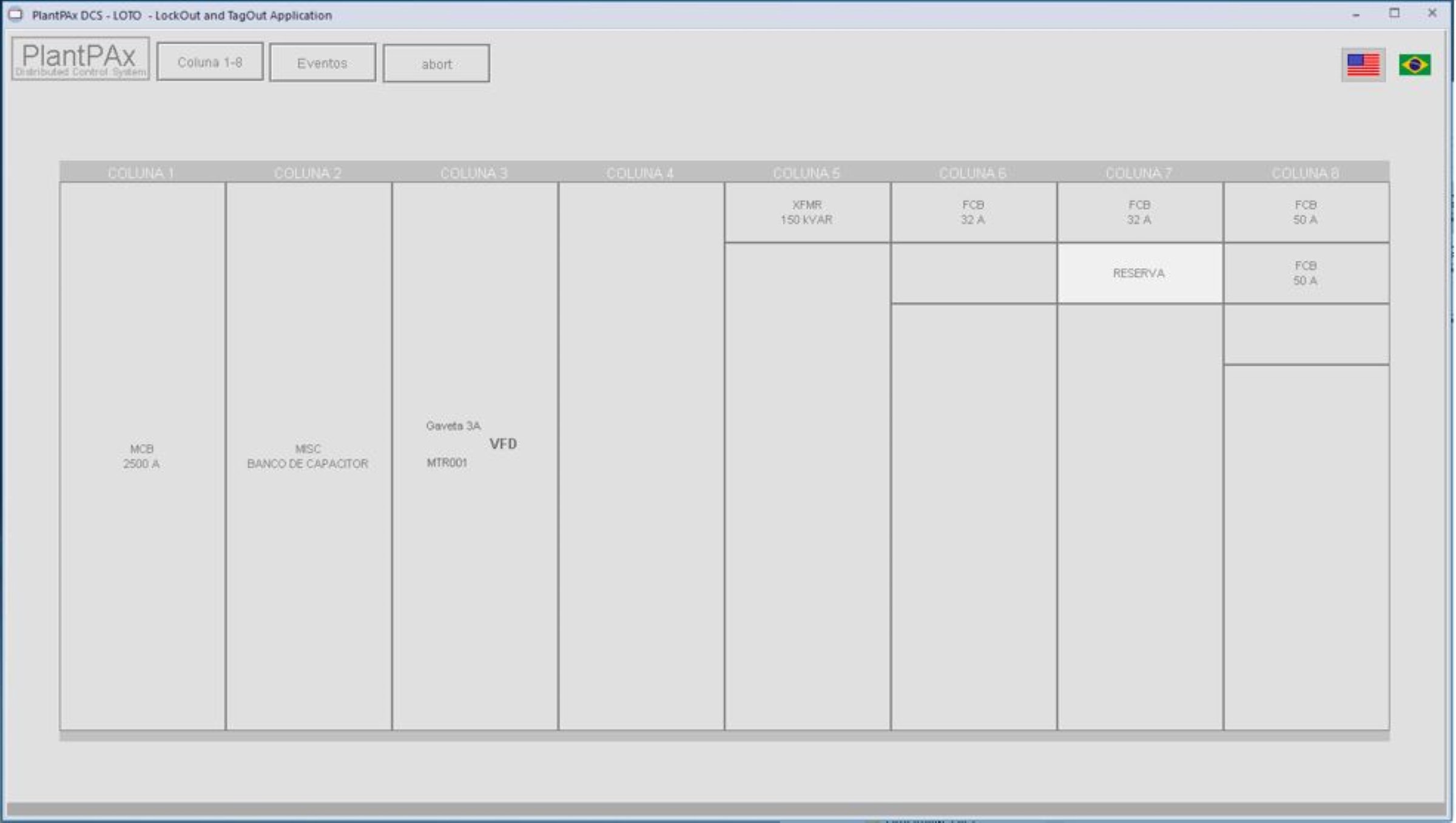

- Where we have a folder called LOTO, the sample screens "001_Coluna 1-8" for use in the application

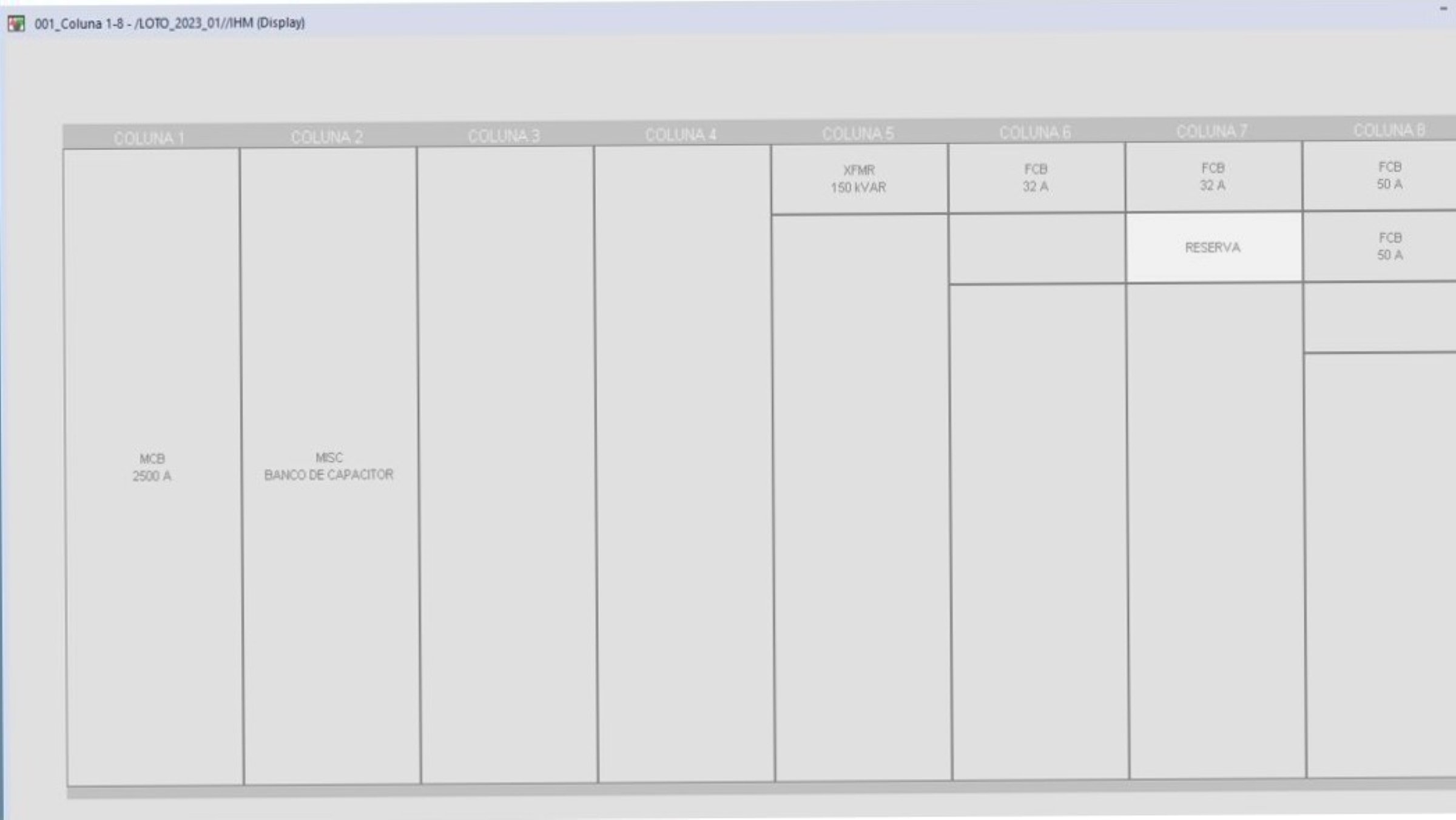

- With the "001_Coluna 1-8" screen open, see that each column contains its devices in each drawer, thus setting up according to your CCM

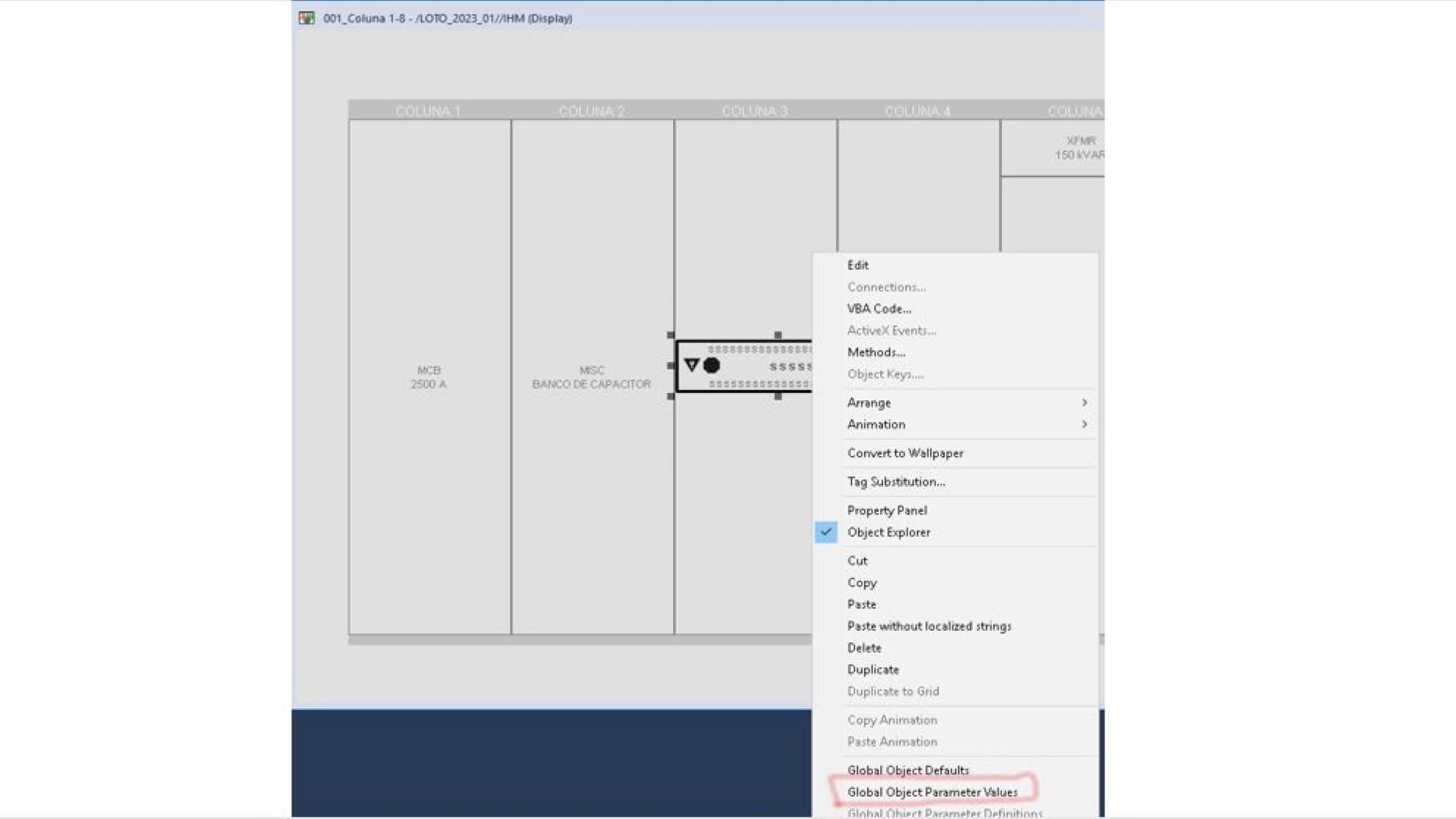

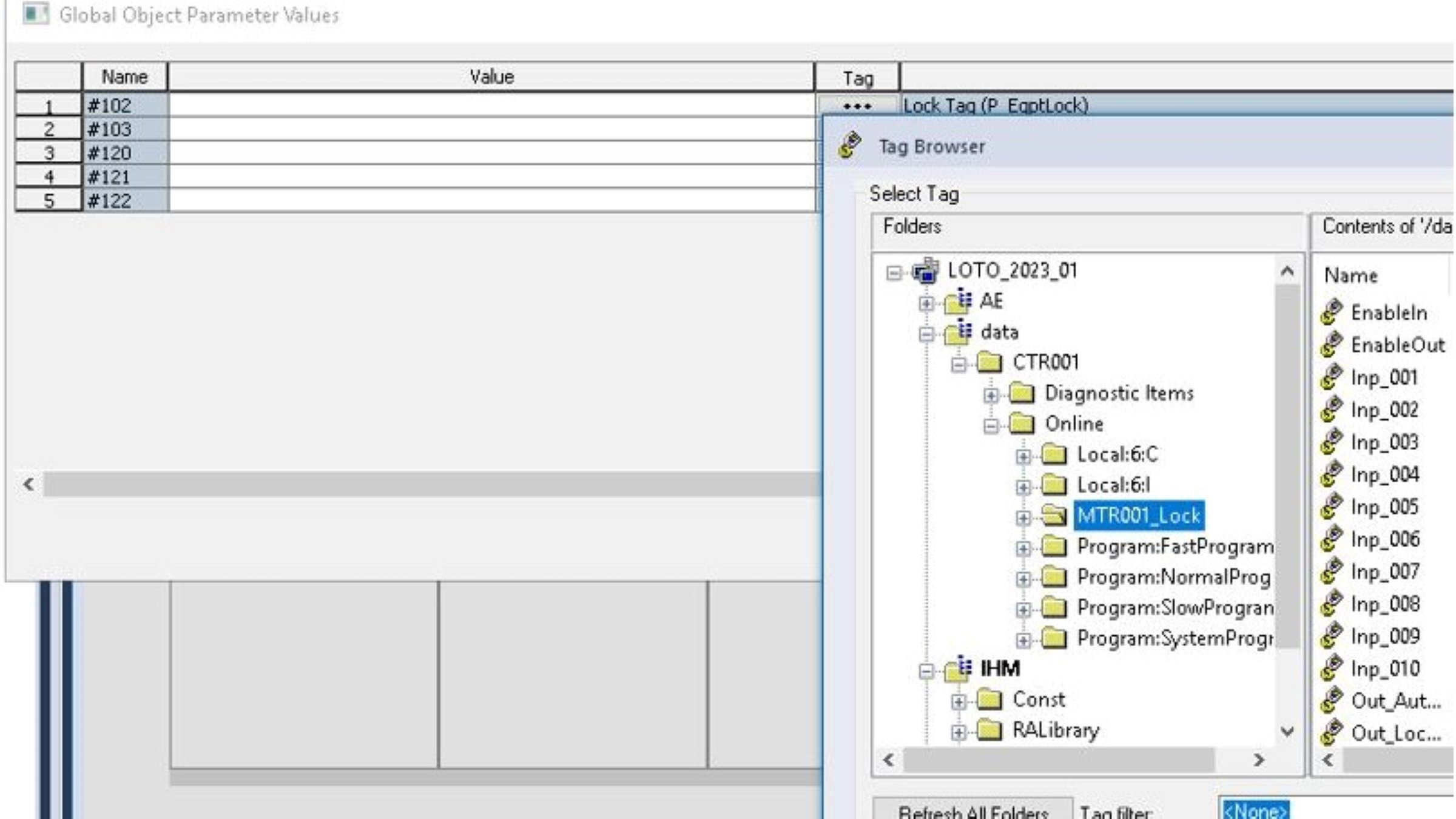

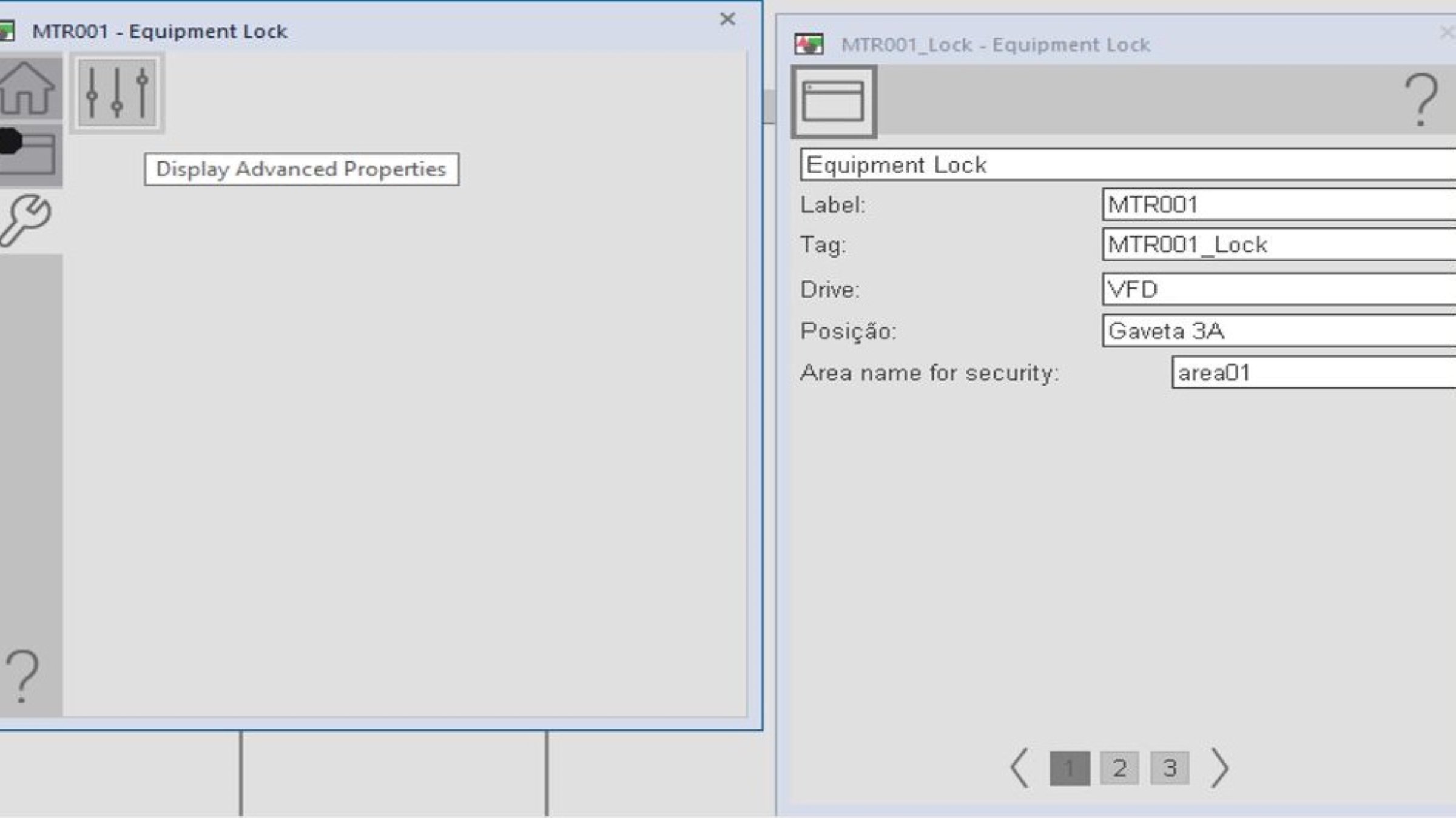

- Add Engine lock MTR001 in Column 3 (ra-blk) equip lock and hold and drag the "GO_EqpLockLOTO" object to Column 3.

Step 5:

Factory Talk SE – Client Application:

- Click on the FactoryTalk View Client file in the folder (if I need to edit to work, please click with the right and Edit). We have in the Example of the PlantPAx DCS template where it can be used.

- Column 1-8" button opens the screen with the CCM

- See that automatically the column we set up appears already configured

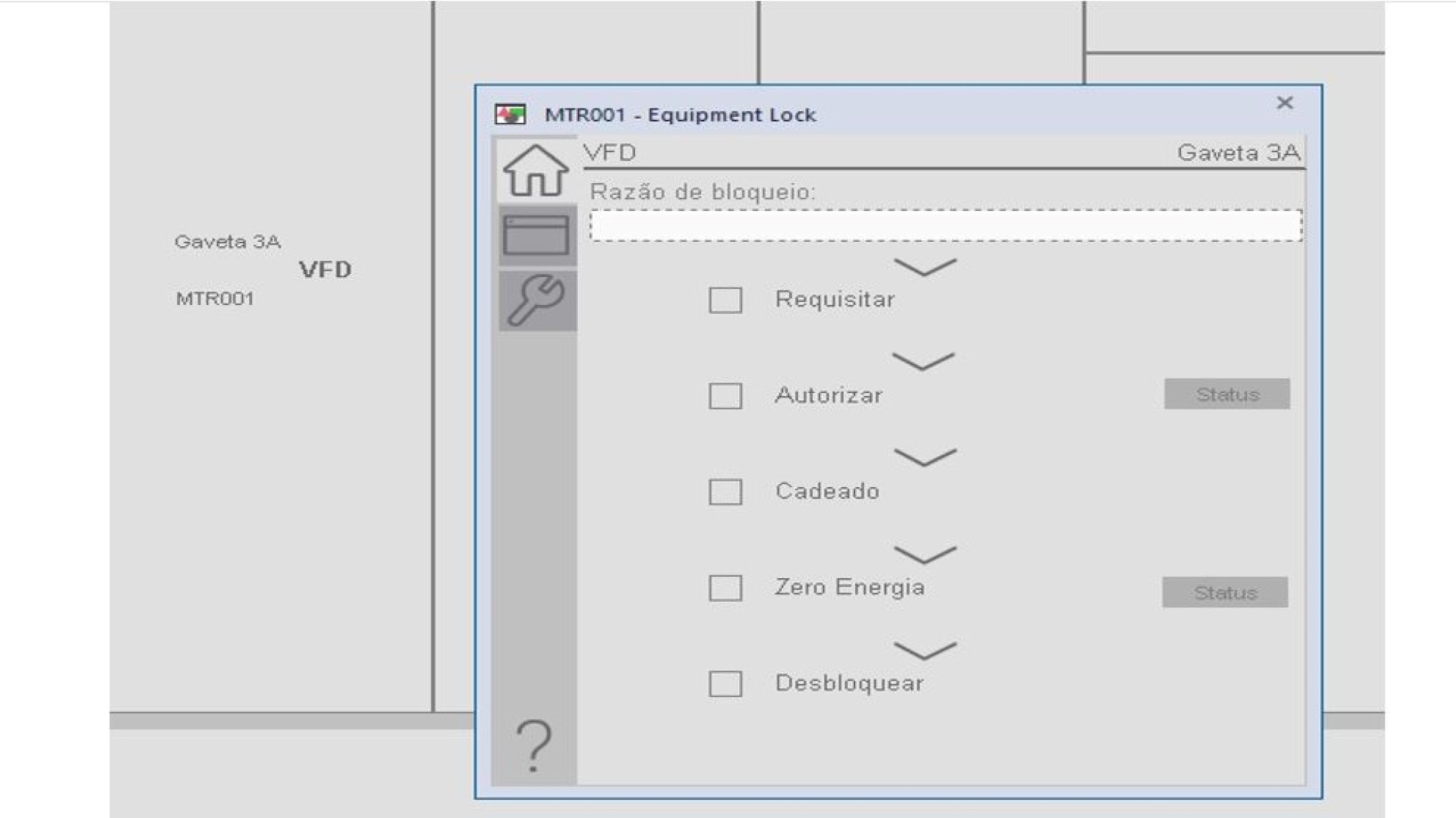

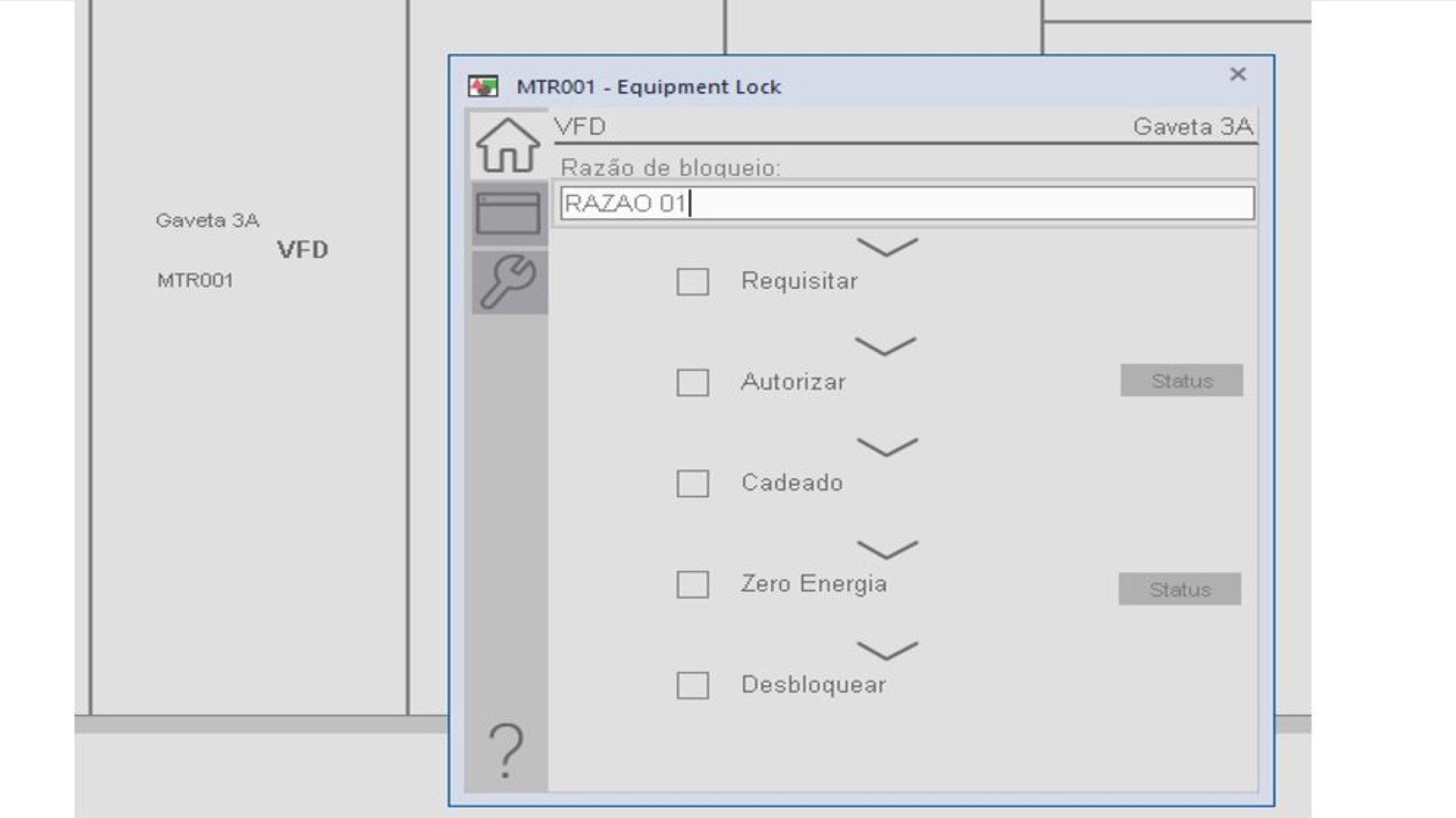

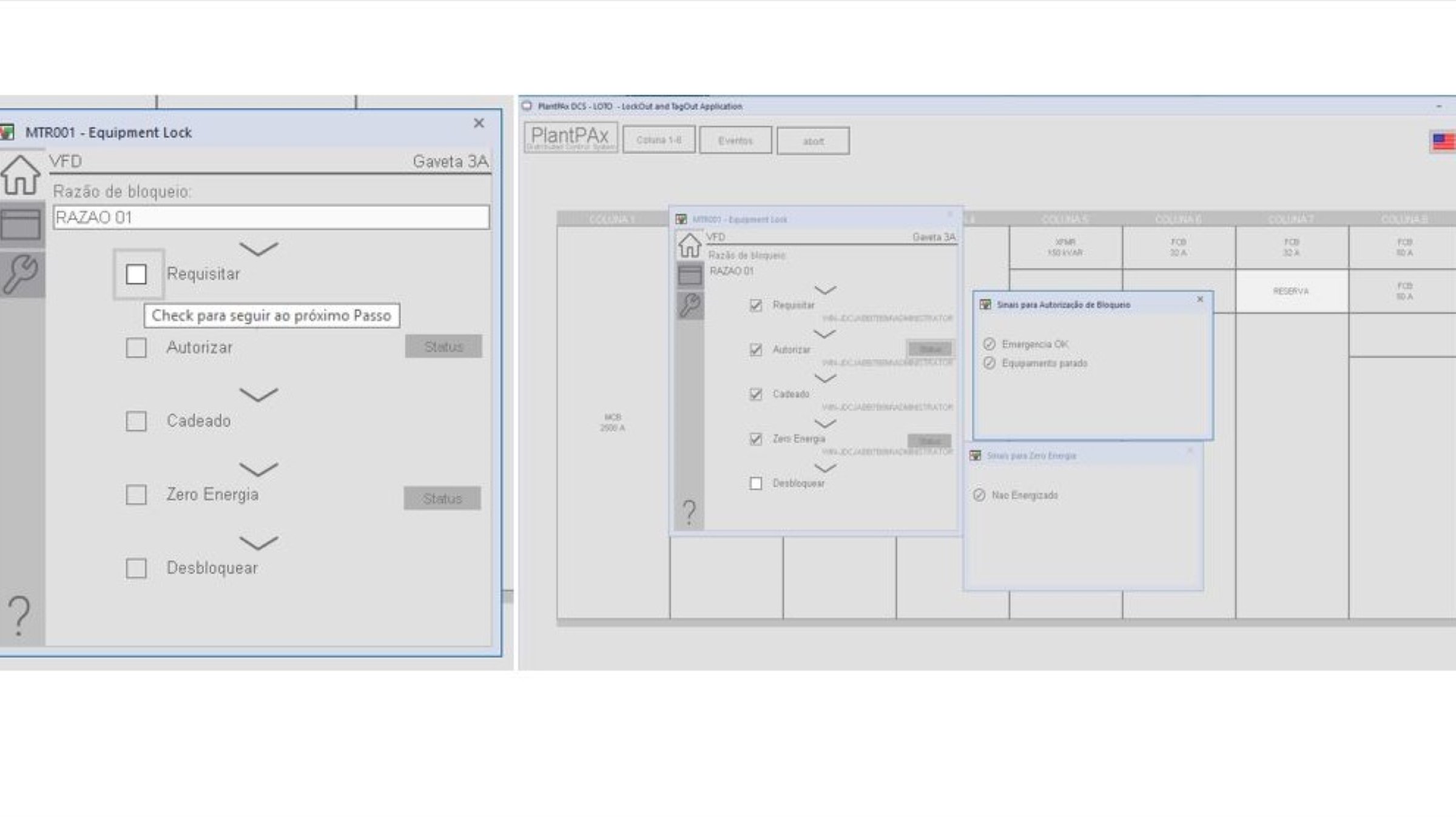

- Type as example "RAZAO 01" and click ENTER to start Digital Lock

- "Request", check to follow the next step

- Follow the steps and see that there is the possibility of checking STATUS (reason) for the following items (Autoruzar and Zero Energia)

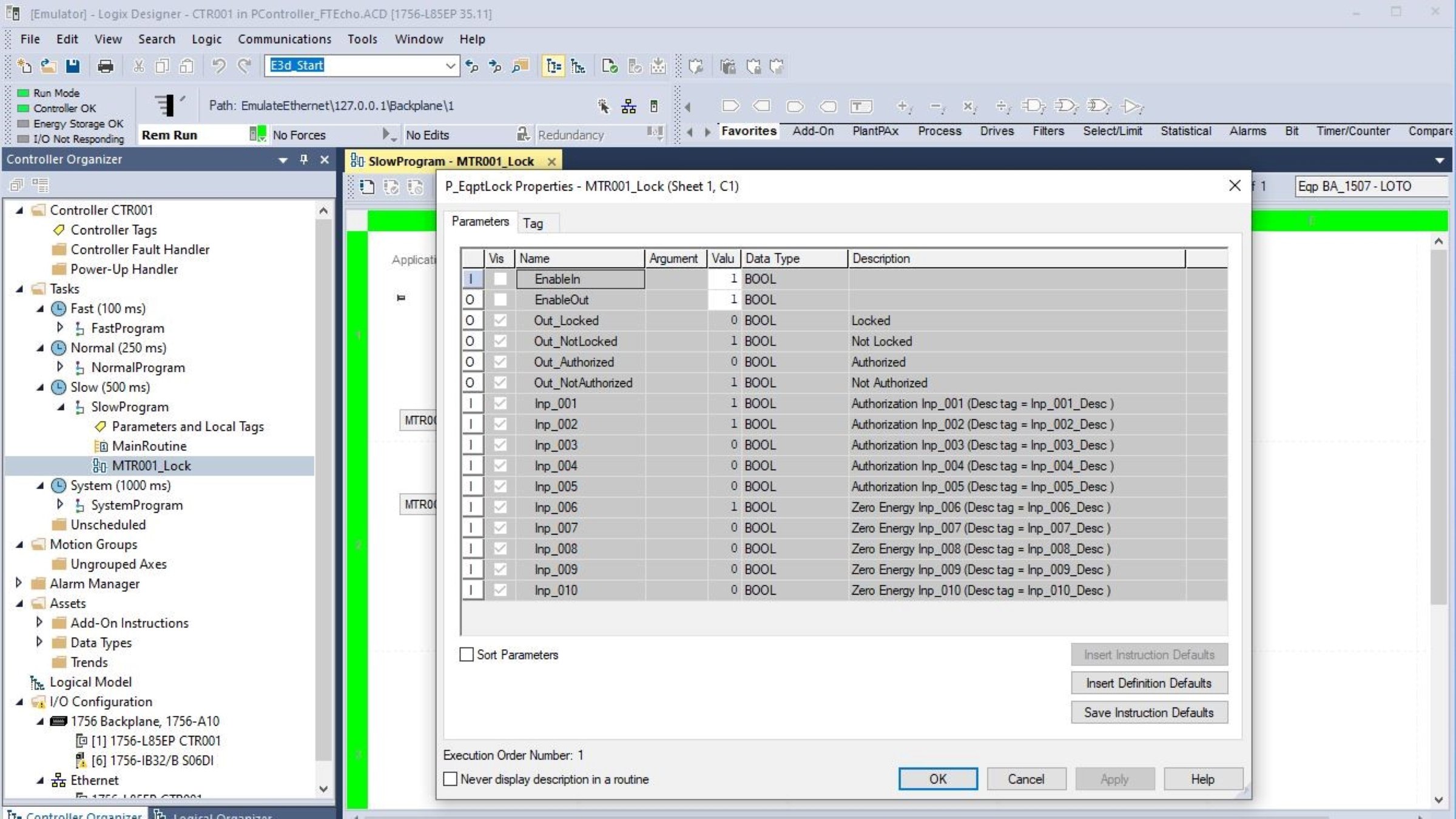

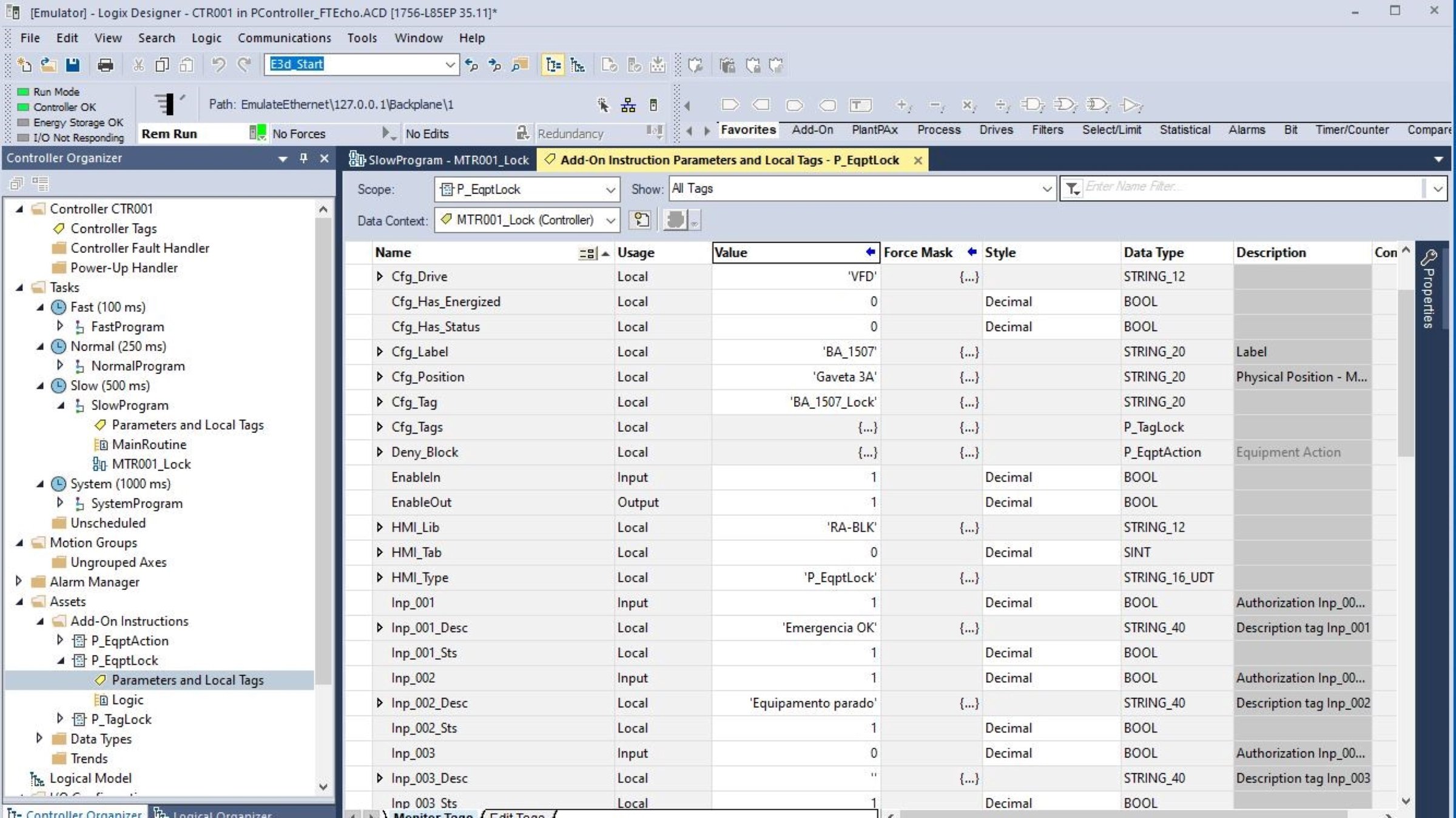

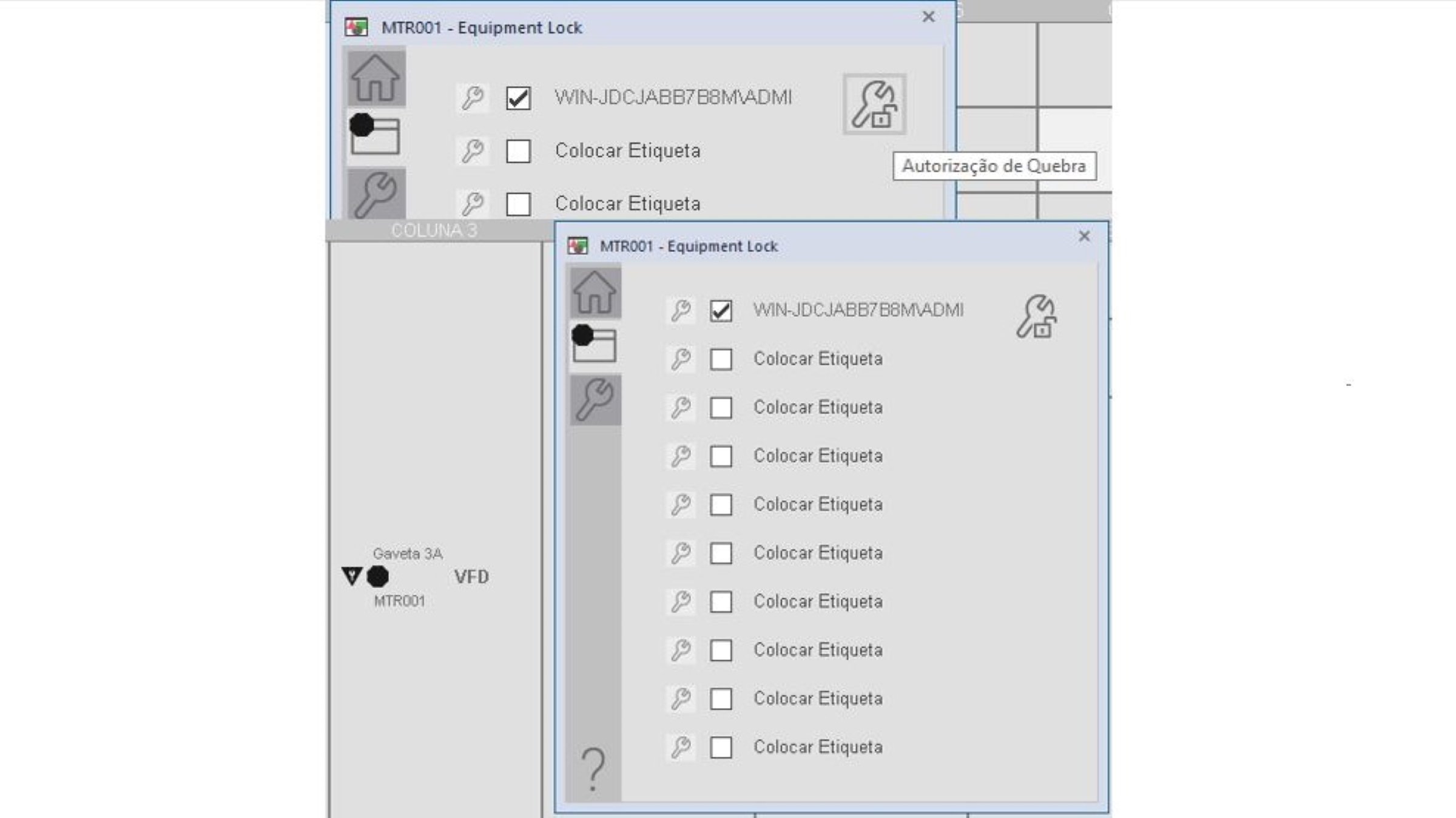

- In the Etiquete we have as shown the option below and in the lock /padlock icon for the execution of the job or the break of the same all recorded in the events). In the Advanced icon, check the other available settings. For modification of descriptions, it can be done via faceplate or via controller in aoi MTR001_lock

- After performing the job, click "Unlock" the faceplate will return to normal mode (all clean action)

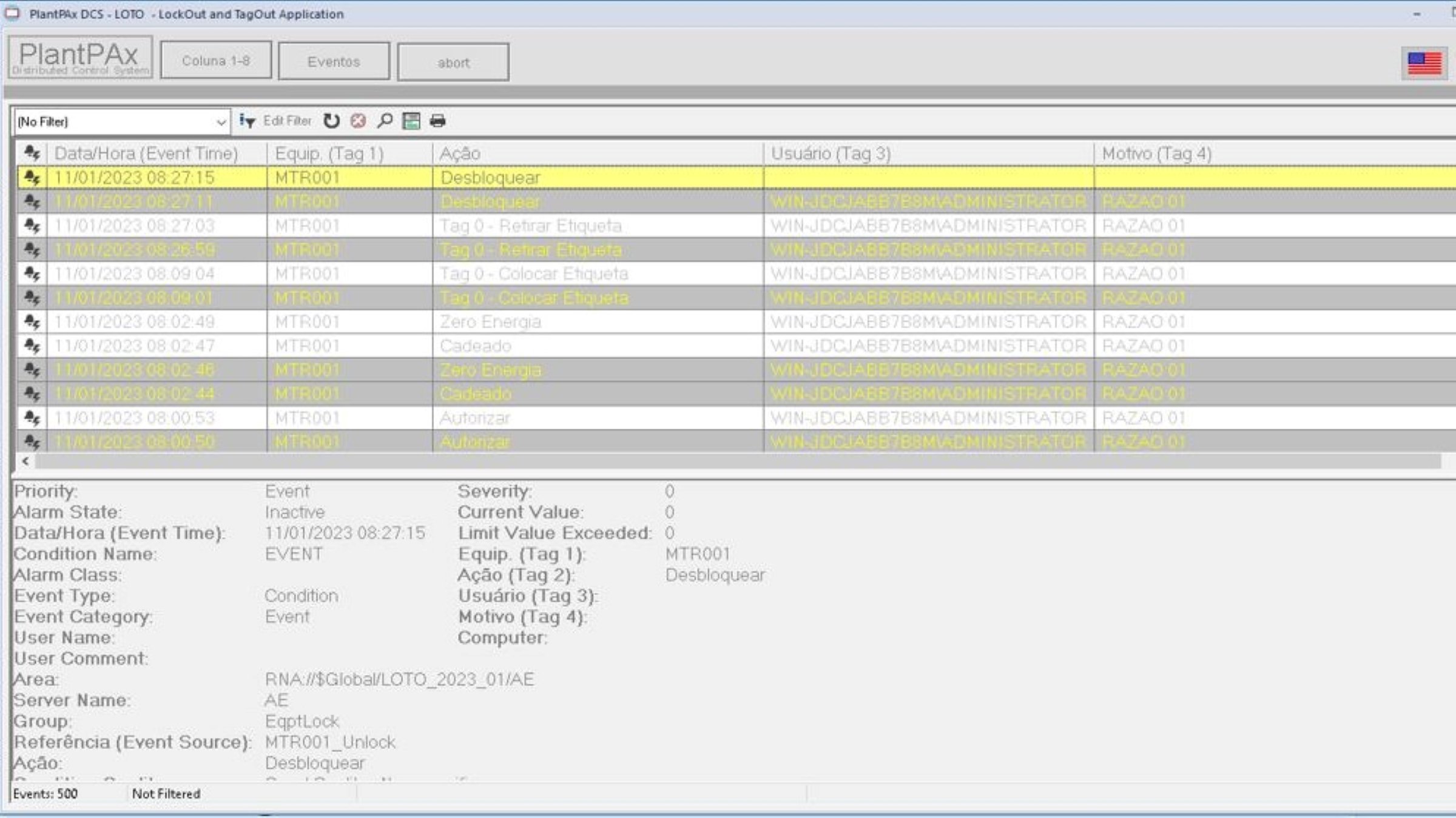

- To Check all the steps taken for blocking, users, comments, click "Events" and navigate each line for detailing