Downloads

What is this for?

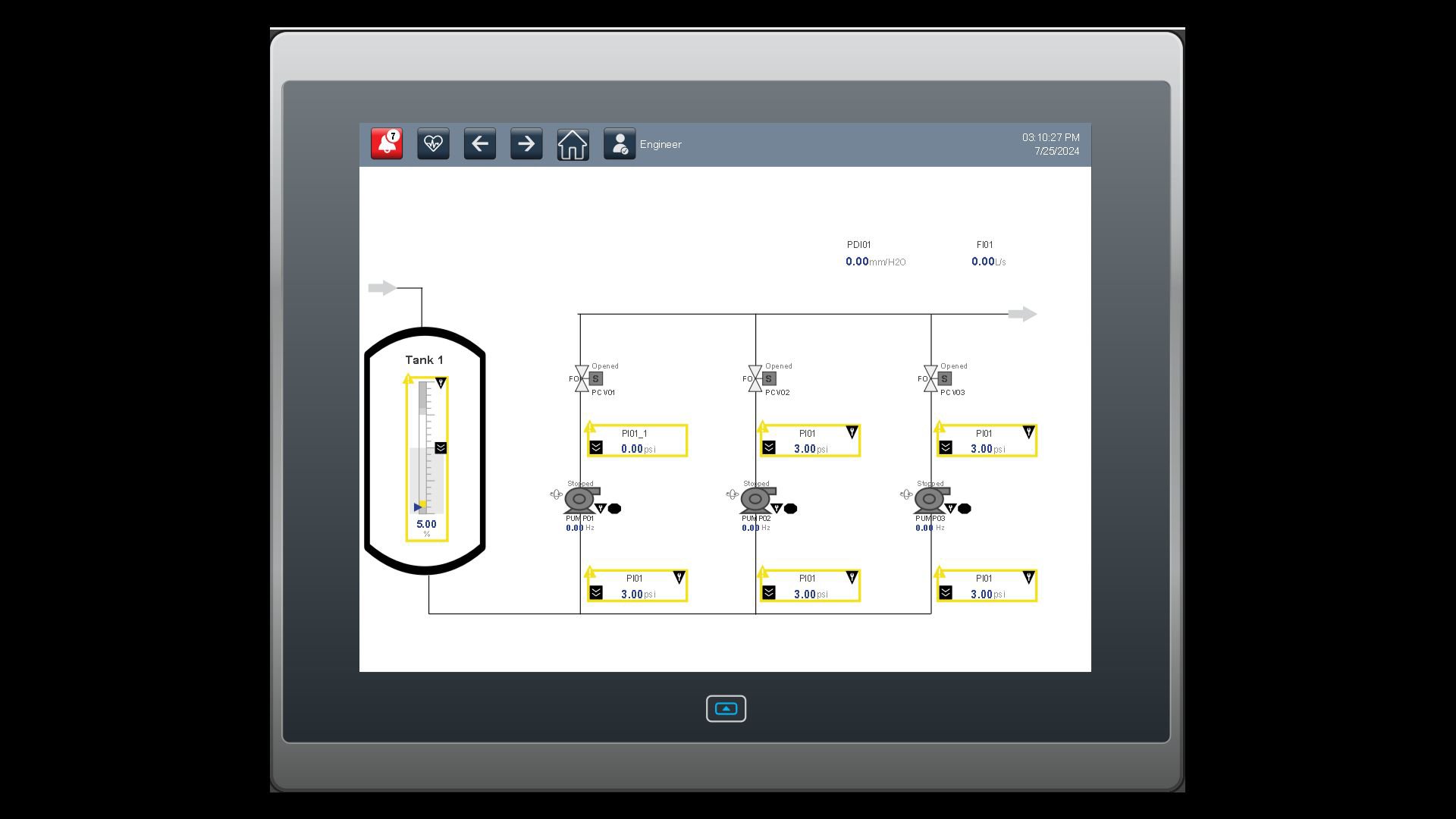

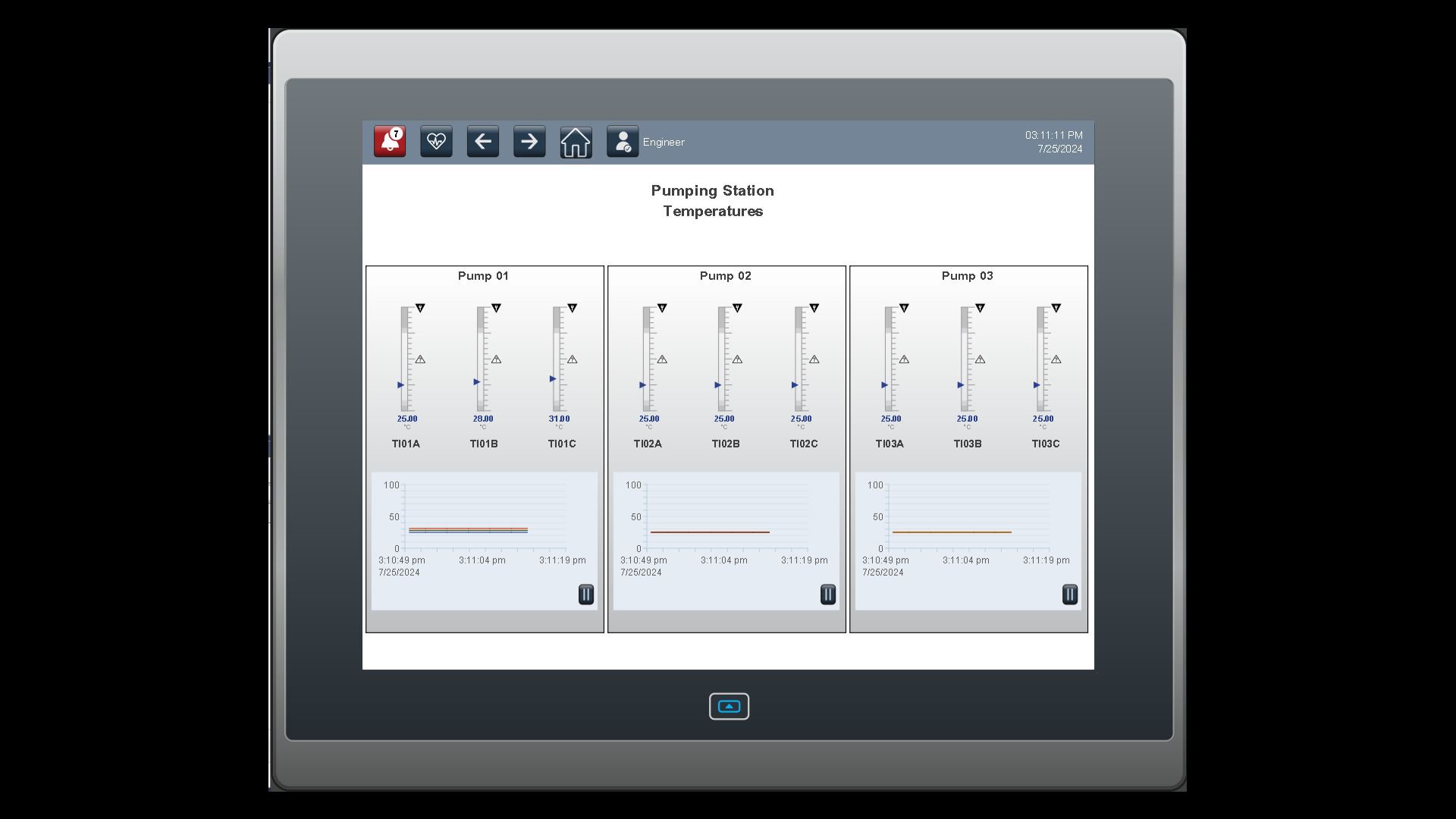

The objective of this development is to show the ease of implementation of the control system in water pumping stations, using predefined objects of process control and motor control strategies in local graphical interfaces: Panel View 5000 family with process control objects library.

The pumping of water in stations is a recurring operation in various types of industry with water treatment plants, or particularly, in mining, where it is a key resource in different process stages and optimizing its use is vital. This liquid is driven from or to a storage network or distribution network, making the assurance of resource availability, maintaining the operation, and equipment condition crucial tasks.

Implementing this type of system is relatively straightforward, as the operation of a pumping station is comparatively simple. These are areas with low signal density where controllers can be used to guarantee good performance at an optimized cost. Depending on the type of water moved throughout the process, there will be more or fewer elements with specific functionalities requiring particular adjustments. However, using previously tested objects developed by Rockwell Automation to integrate local monitoring and control into centralized system allows:

- Optimize development time for control strategies and operation screens

- Ensure approval and repeatability at a graphical level from a local interface

- Facilitate the familiarization and adoption of an operating environment based on the ISA 101 standard at the local level

- Facilitate connectivity to a centralized system, completely compatible with other plant areas

- Use more recent hardware and software components

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

- Use of the Engineering Station template with the following applications:

- FactoryTalk Services platform software, version 6.31.00

- FactoryTalk Linx software, version 6.31.00

- FactoryTalk View Site Edition Server software, version 13.00.00

- FactoryTalk View Studio Enterprise software, version 13.00.00

- Studio 5000 Logix Designer ® application, version 36

- Logix View Designer version 9.02

- FactoryTalk Logix Echo, version 3.00.00

- Power Device library version 3.02

- Process library version 5.10.01

- Panelview 5510 15”

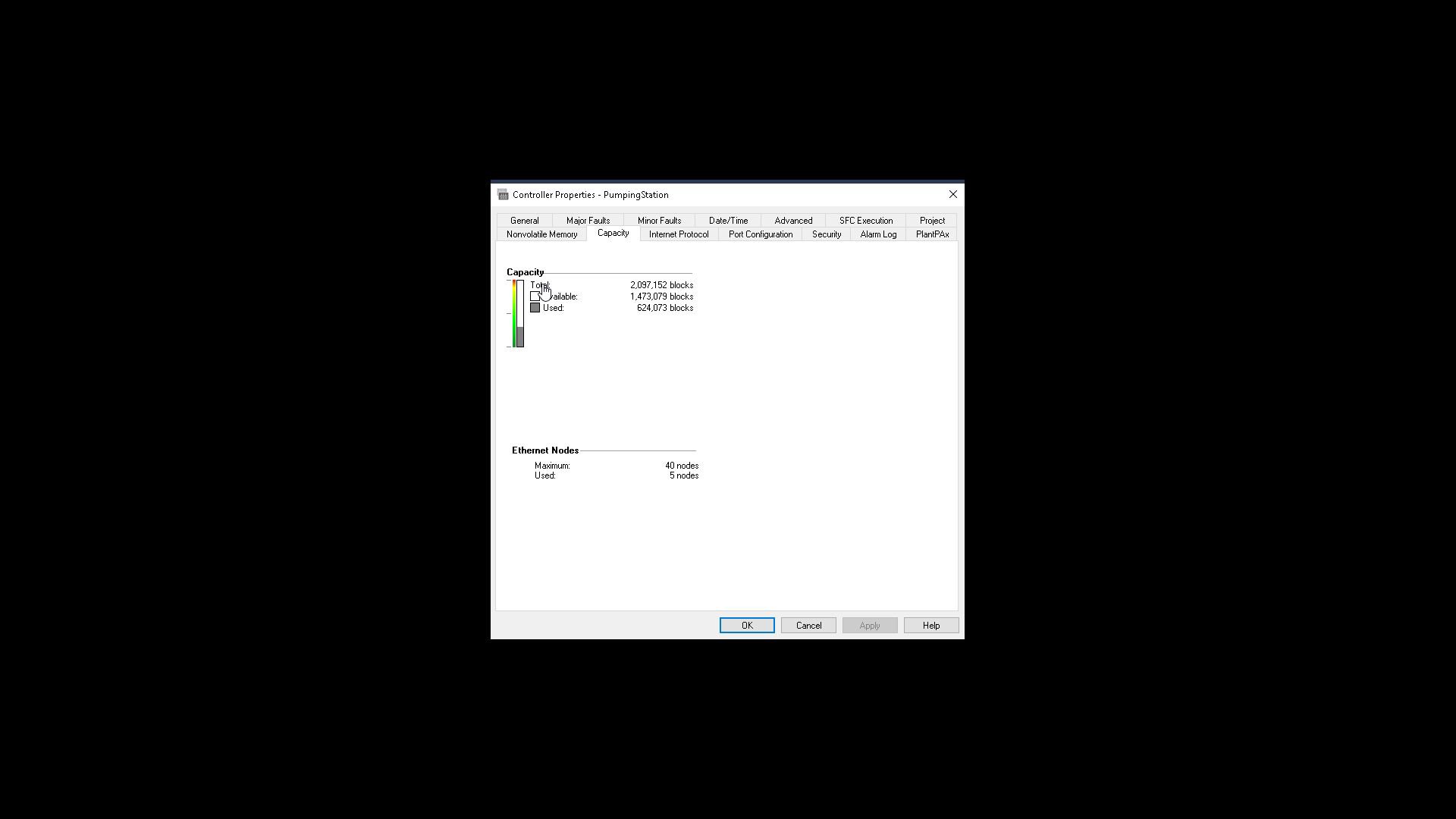

- CompactLogix 5069-L320EP

- 5069-IF4H Analog Input Modules

- Endress+Hauser HART Instrumentation

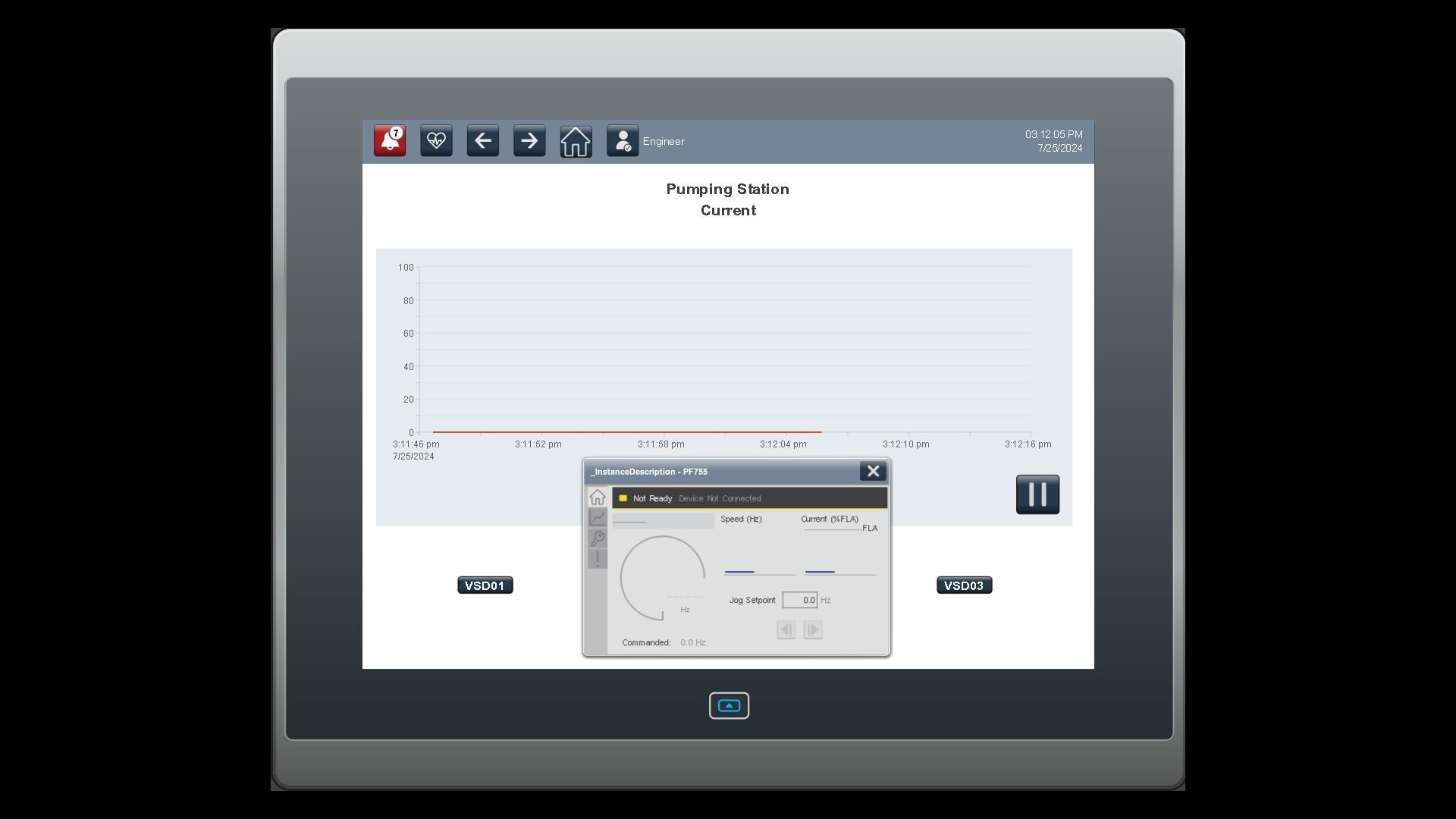

- PowerFlex 755

The physical components, as well as the configuration of the control strategies may vary in a real implementation but can be taken as a basis for development. For testing purposes, all hardware components are configured as inhibited so that they do not generate alarms due to lack of hardware.

Installation Guide

The station where the application is developed must contain all the aforementioned applications.

One option to guarantee software compatibility is the use of Rockwell templates; the image of a PASSC (Process Automation System Server Consolidated) can be used.

Step 01

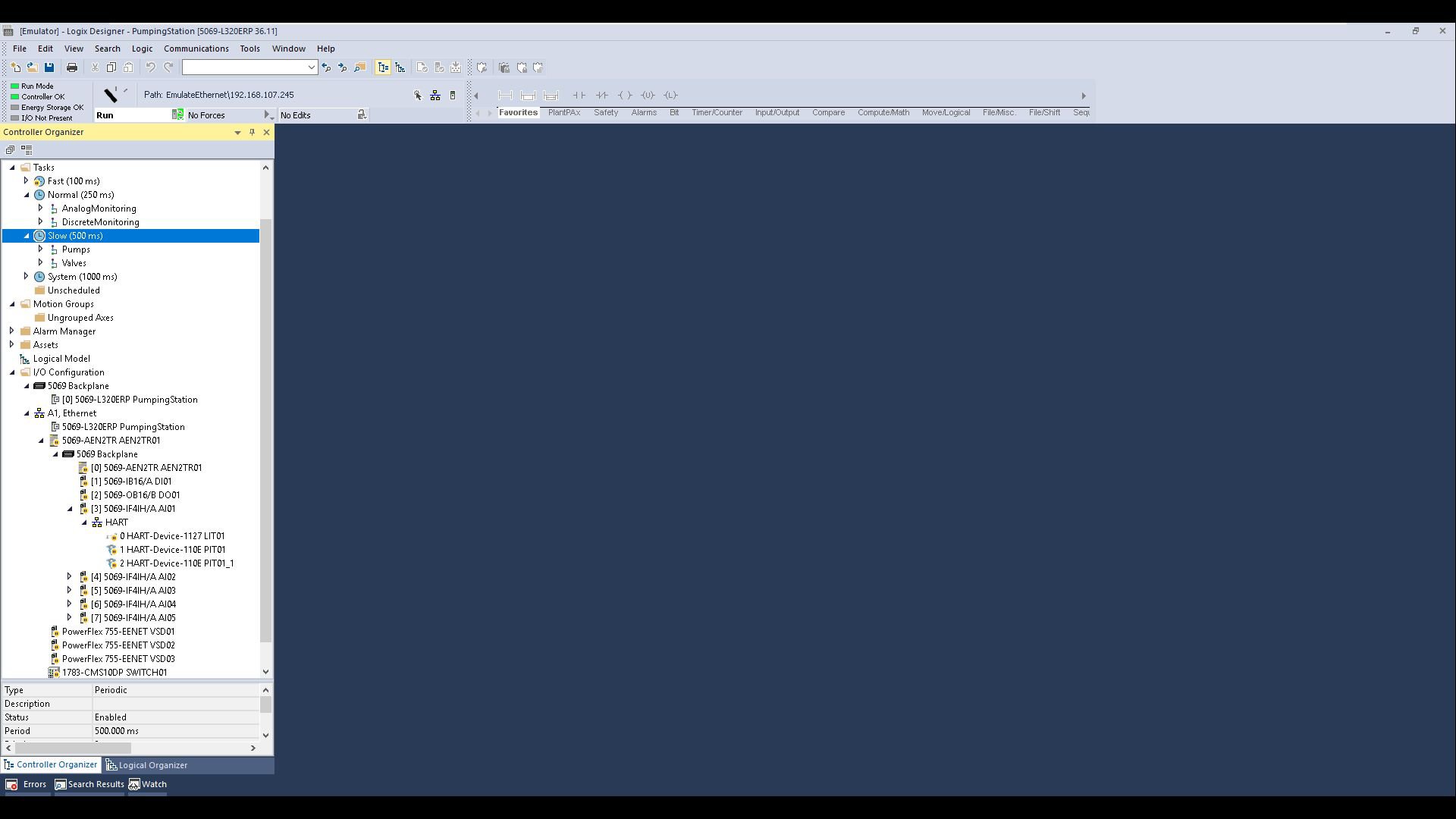

- Restore the application backup by opening the PumpingStation.ACD file

You will notice that it has been used:

- CompactLogix process in v36

- I/O Modules with HART

- Endress+ Hauser Instrumentation

- PowerFlex 755 Drives

- Stratix 5200 Switch

- 15” PaneView 5510

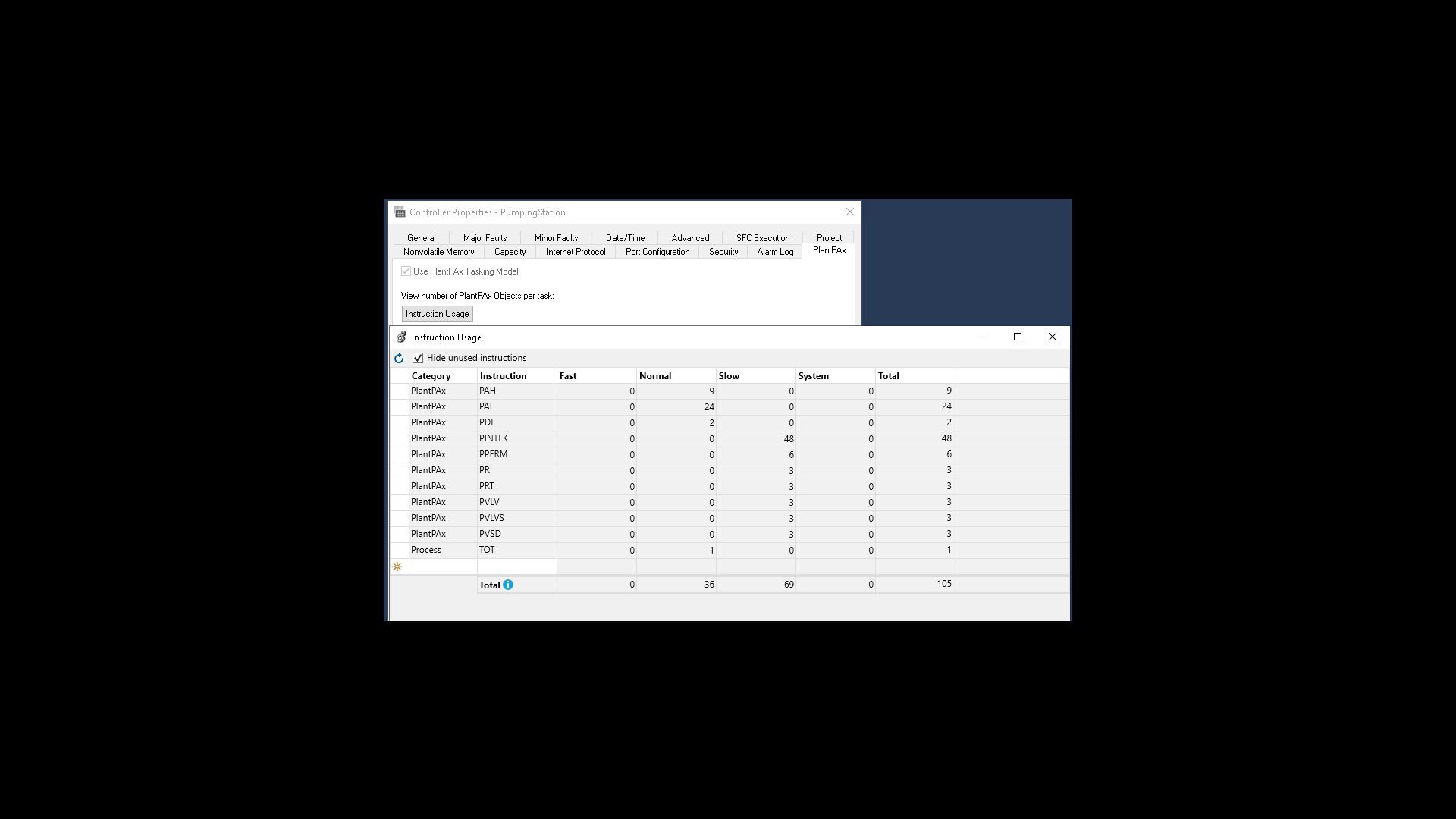

- Process control strategies in v5.10

- Create an emulated controller in FactoryTalk Logix Echo to test, add, modify, or remove control strategies

- Download the project to the controller and select RUN mode

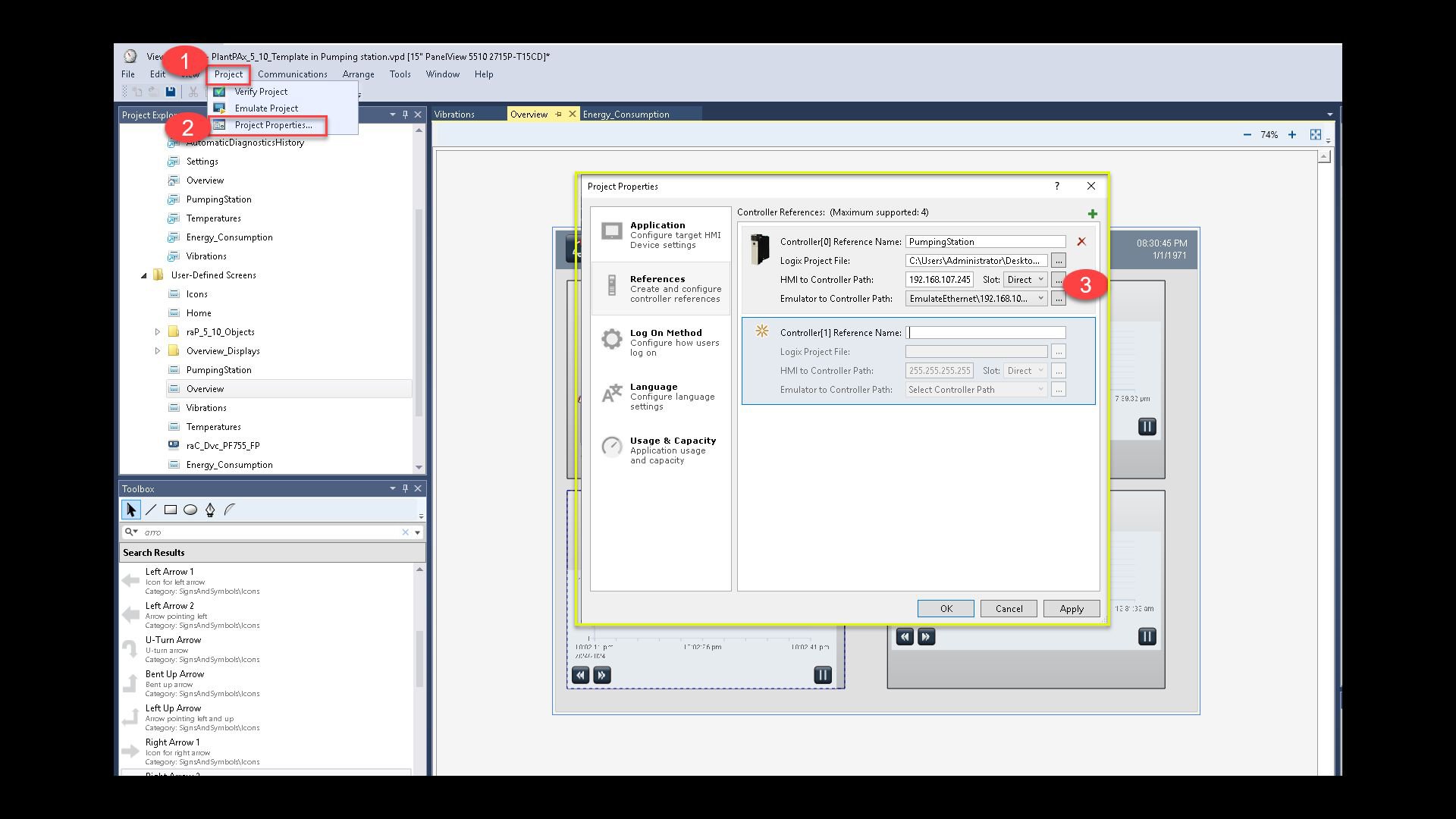

Step 02

Note: The project was initiated using the template developed in View Designer for control system applications that use process objects in versions 5.10 and later. There are components not used in the application but left for future use, which when emulating the project will show alerts that do not impact the performance of this application.

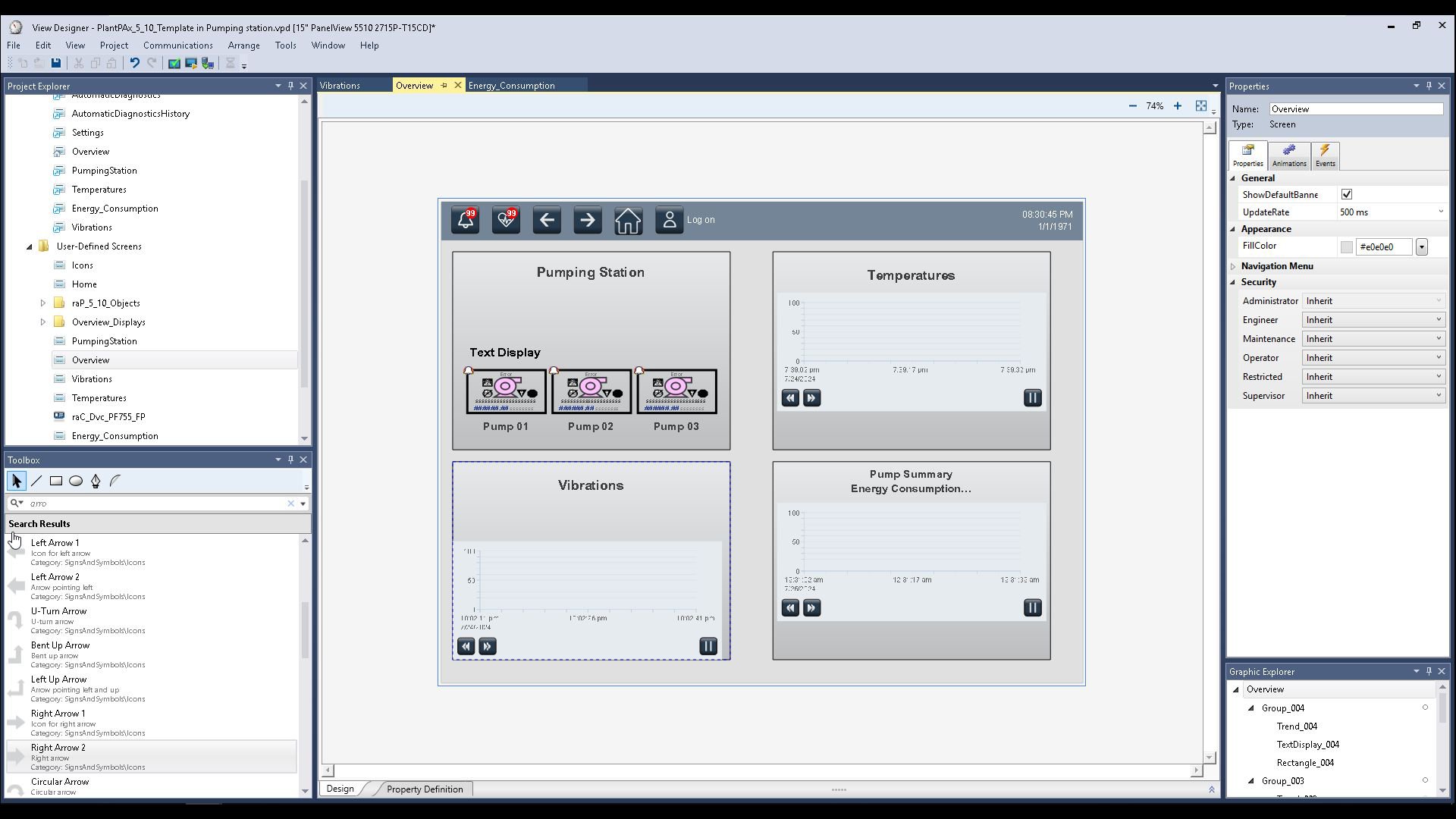

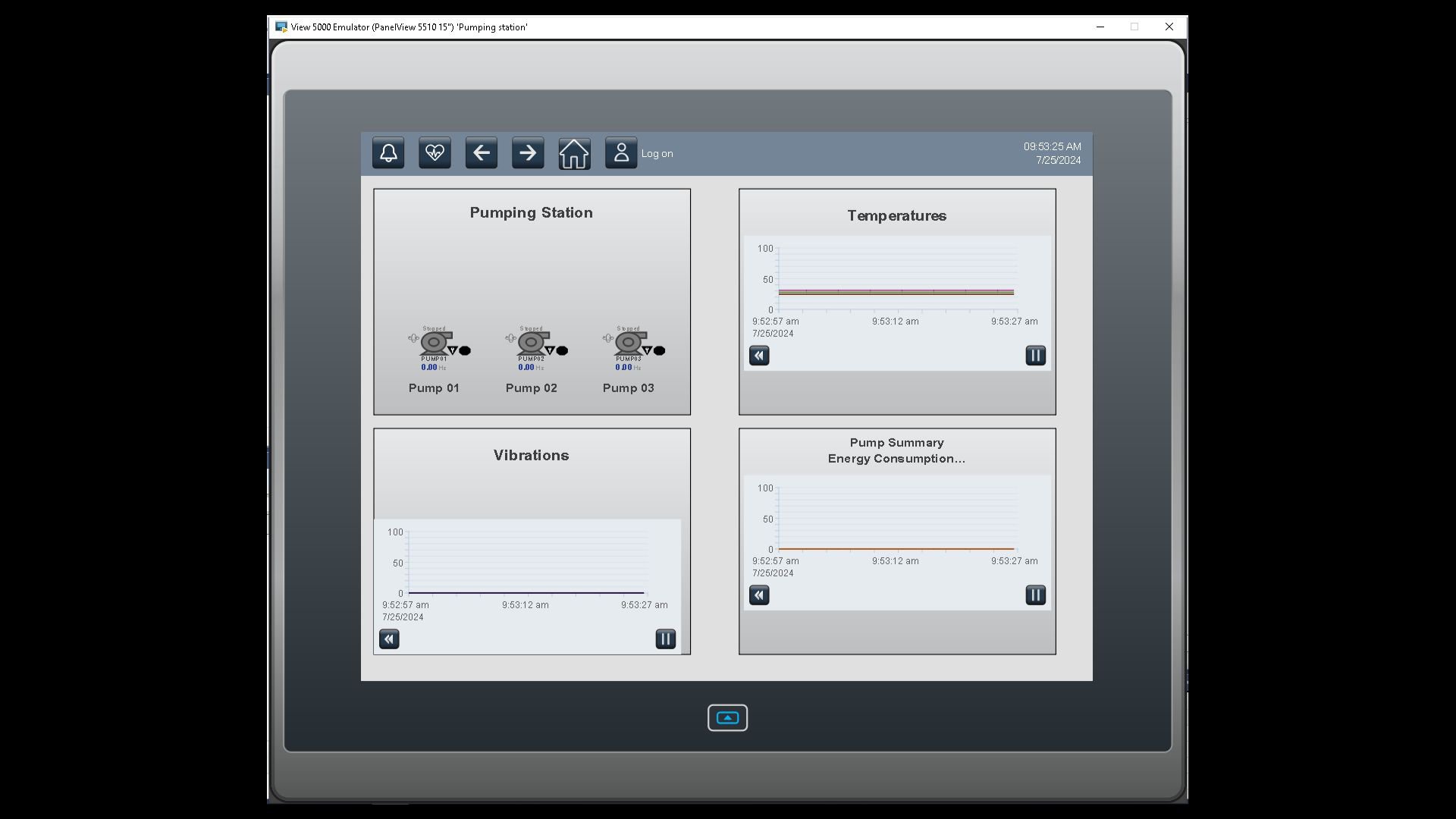

- Emulate the project and navigate the screens. The developed screens allow navigation through a general view with access to screens that enable deeper detail, as established by the ISA 101 standard.

As the data has been collected in the project, as many screens as necessary can be generated to show generalities or details of the Pumping Station status without compromising the performance of the controller and panel. In the following images, you can see the conditions in which this implemented application is left.

Local Control System in a pumping station with PlantPAx v5.20

Version 1.0 - August 2024