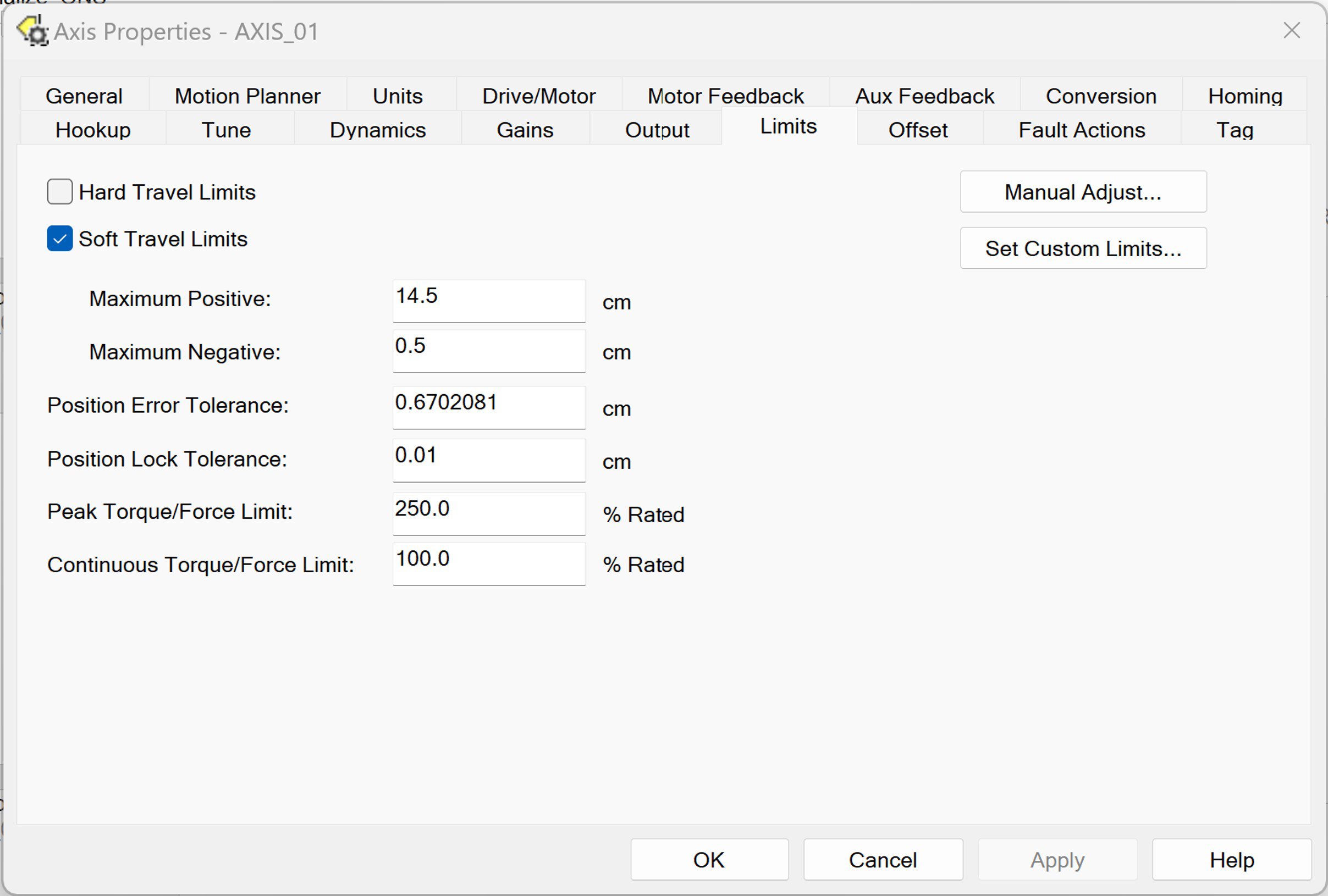

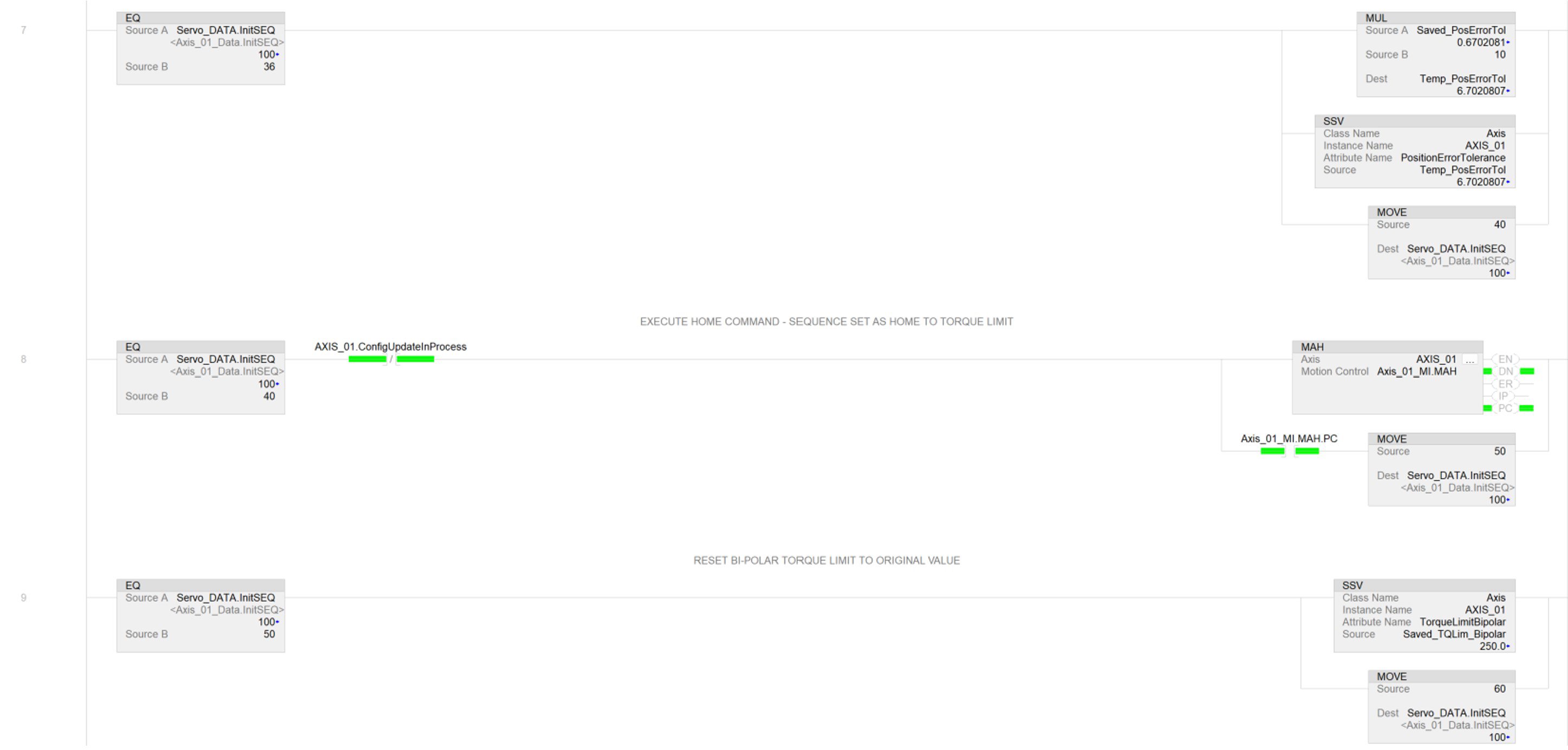

When executing a torque limit homing procedure there is potential for a Position Error fault. As mentioned earlier, for the home to torque limit to complete, the output torque to the motor must reach (or exceed) the specified torque level for a set time of 500 ms. During this time the axis is against the mechanical hard-stop, and following error is increasing in the position loop. If the Position Error Tolerance value is exceeded before completion of the homing instruction, a Position Error fault (E19) will result.

There are two ways to limit the occurrence of an E19.

- Set the Position Error Tolerance value on the Limits tab of the Axis Properties to a value high enough to eliminate a fault from occurring.

- Modify the Position Error Tolerance value via an SSV instruction similar to the method used in code above to change the Bipolar Torque Limit.

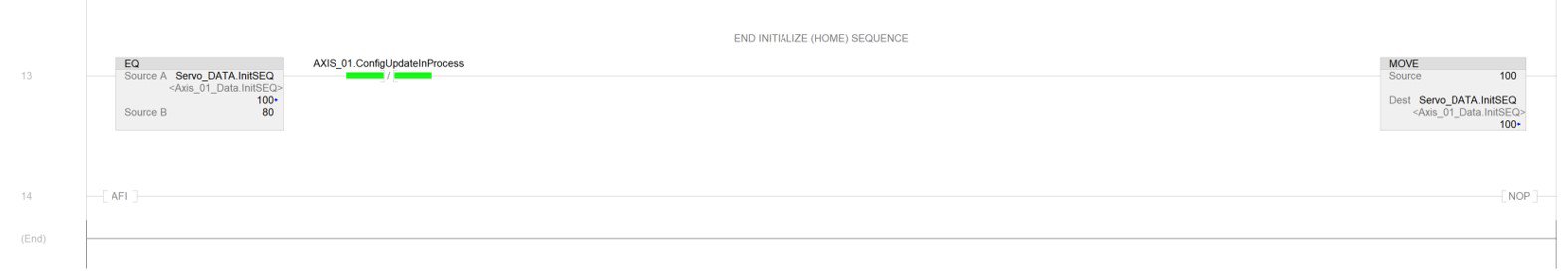

Rung 6 of the ladder code opens the Position Error window. This allows the Homing to complete without causing a Position Error fault. The original value is reset after Homing completes.