Downloads

Easy Dashboards and Control for a Powerflex 520 enables you to have a ready to use code and HMI screens to apply them with PowerFlex 523 and PowerFlex 525 drives. This is a Connected Component Workbench development that provides basic parameters monitoring and control, either from a PanelView 800 or remotely (through VNC).

Target to use with PowerFlex 523 and 525 component drives from Rockwell Automation.

This code can be used with the following equipment:

- PowerFlex 523

- PowerFlex 525

- Micro850

- Micro870

- PanelView 800

What is this for?

The main purpose is to provide visualization and basic control through principal parameters as a ready-to-use development for basic drive control. In addition, it will be possible to access the information contained in the dashboards remotely (Internet).

This can be applied to control systems that include Micro-controllers and Powerflex 520 component drives. Implicit and explicit messaging are used (the most important parameters are handled by implicit messaging).

General Features

- Basic Control parameters modification:

- Reference Speed

- Acceleration Time

- Deacceleration Time

- Position Reference

- Drives faults reset

- Visualization of the following parameters:

- Ready

- Active

- Command Speed

- Actual Speed

- Drives fault

- Output current

- Output voltage

- DC Bus voltage

- Drive temperature

- Consumed energy

- Elapsed power

- Accumulated cost savings

- Remote access to the PanelView 800 screens through FTP functionalities

Limitations/Disadvantages

- Limited to PowerFlex 523 and 525

- Limited to Micro800 and PanelView 800

- Parameters selected are fixed

How can I make it work?

The architecture implies the following hardware:

- PowerFlex 523, PowerFlex 525

- Micro 850, Micro 870

- PanelView 800

And this is the required software:

- Connected Component Workbench, version 21 or higher.

- The firmware of the equipment used must be compatible with the version of Connected Component Workbench.

- User-defined Function Blocks:

- RA_PF523_VEL

- RA_PF525_VEL

- RA_PF525_POS

- RA_PFx_ENET_PAR_READ

- RA_PFx_ENET_PAR_WRITE

Knowledge

Basic knowledge of programing and configuration in Connected Component Workbench software:

- PowerFlex 523/525 and PanelView 800 configuration

- Ladder Language

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

Step 1: Communication Settings

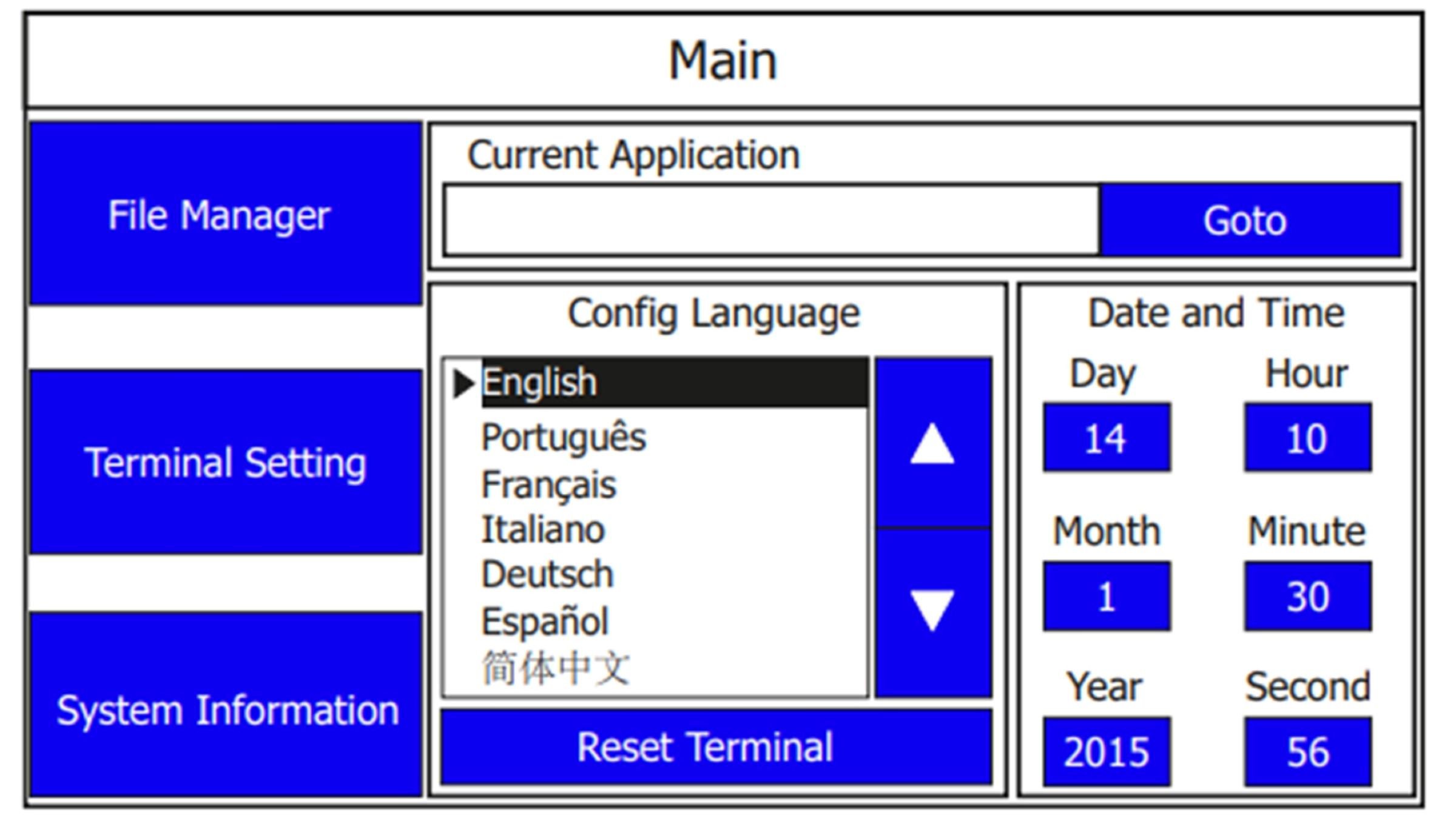

1.1 Configure VNC settings in PanelView 800: Go to the main configuration screen.

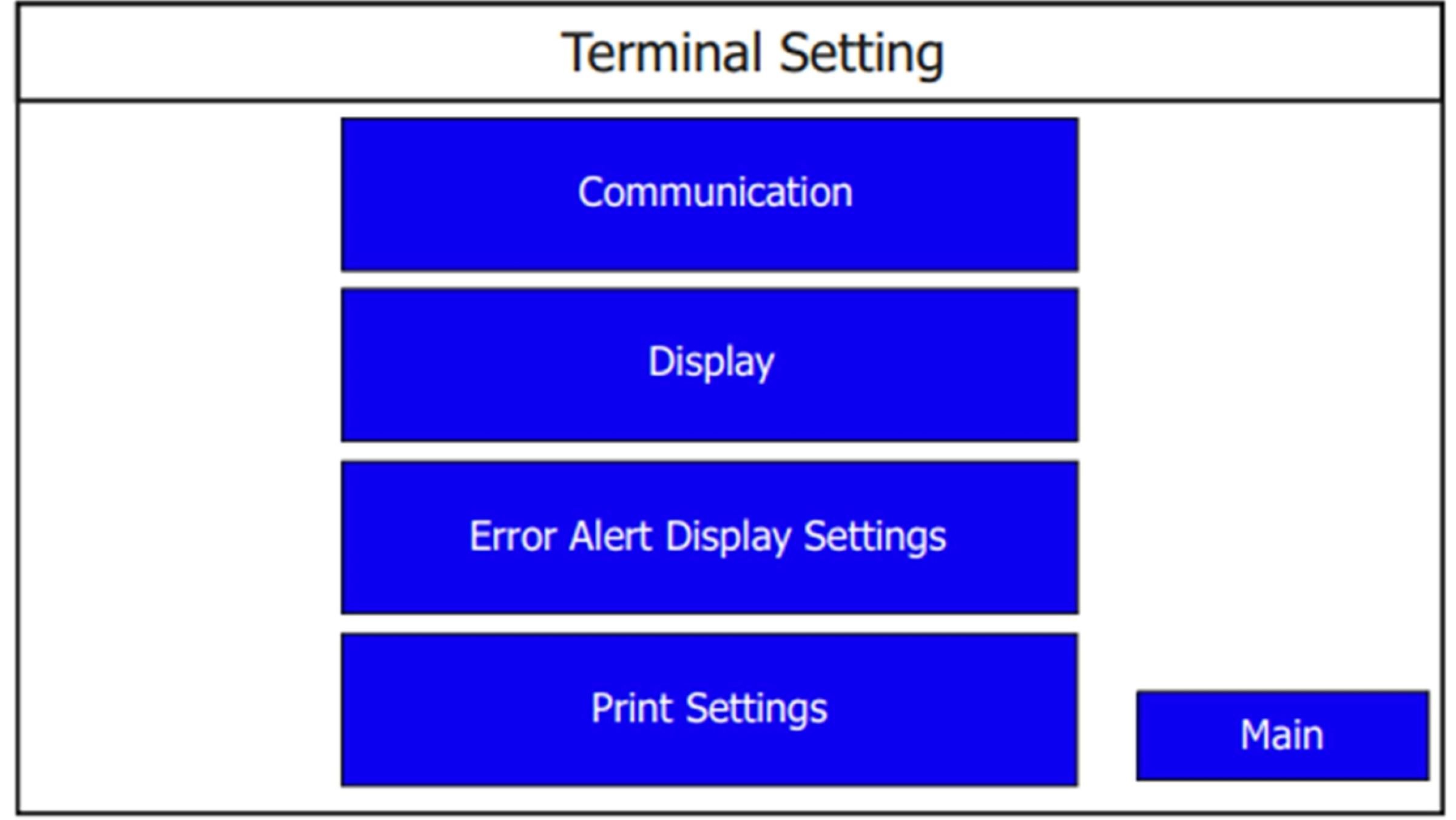

1.2 Press terminal settings.

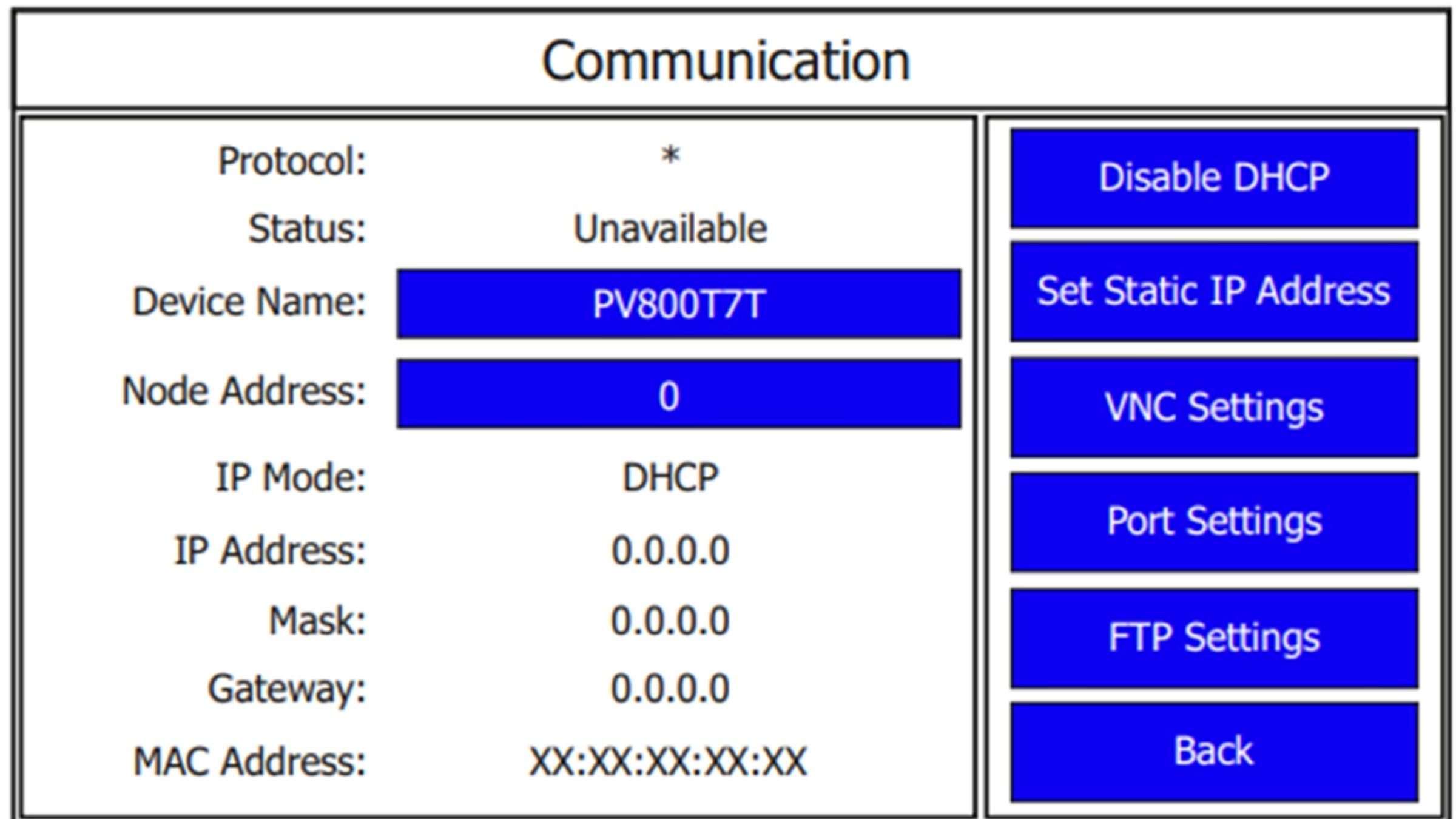

1.3 Press Communication.

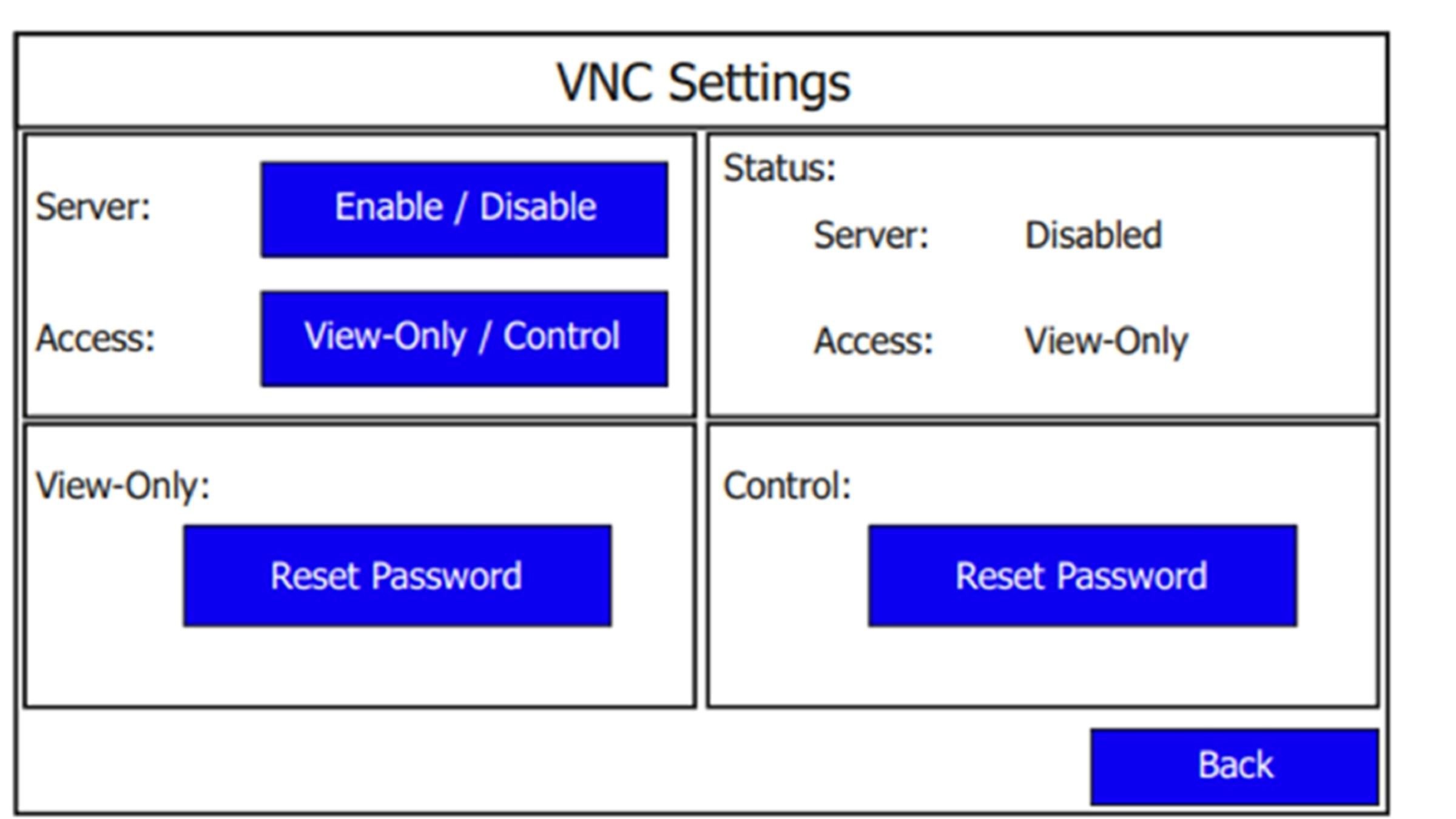

1.4 Press VNC Settings.

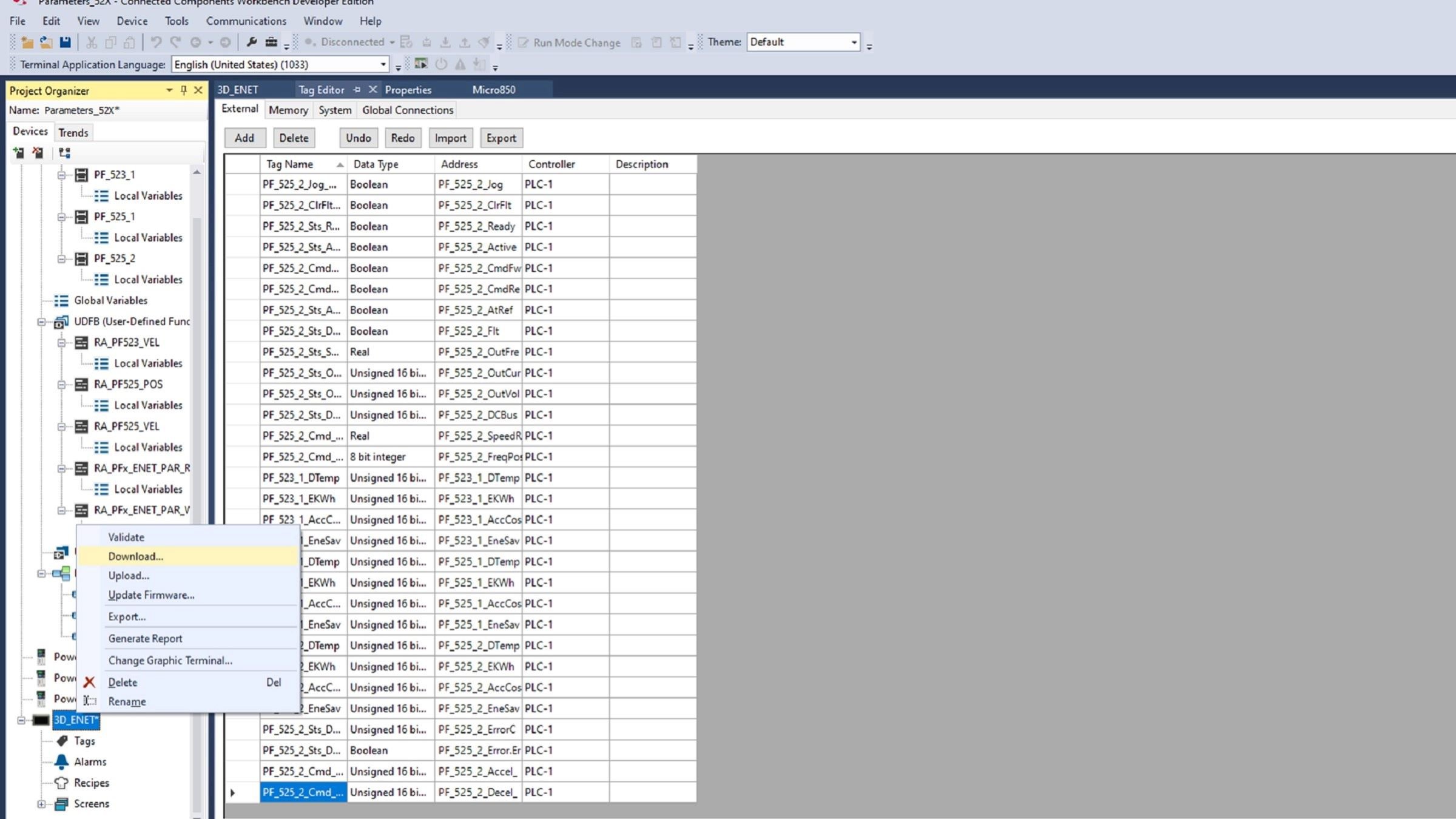

Step 2: Parameters import

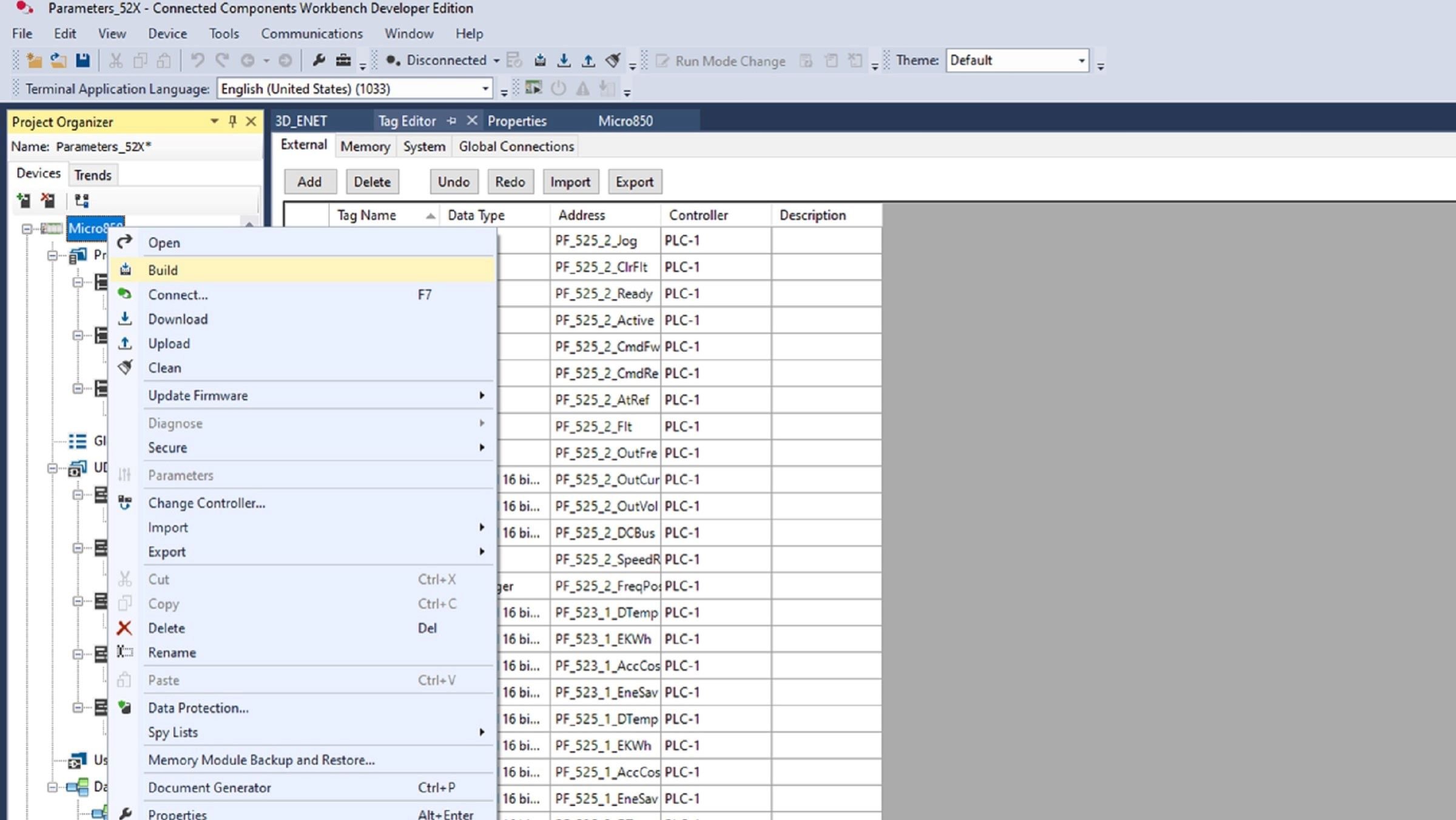

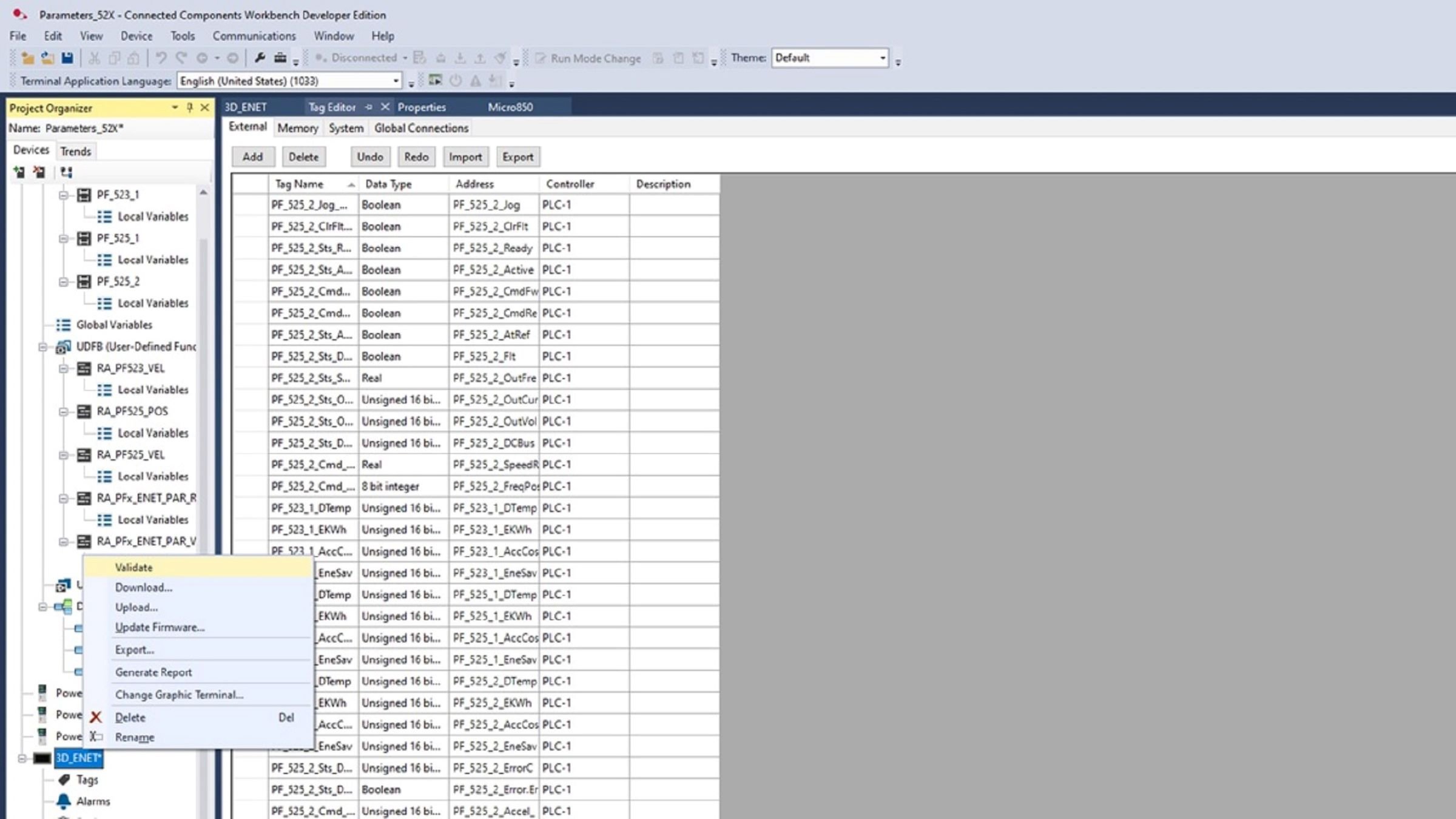

2.1 Import “Parameters_52X”.

Step 3: PanelView800 configuration

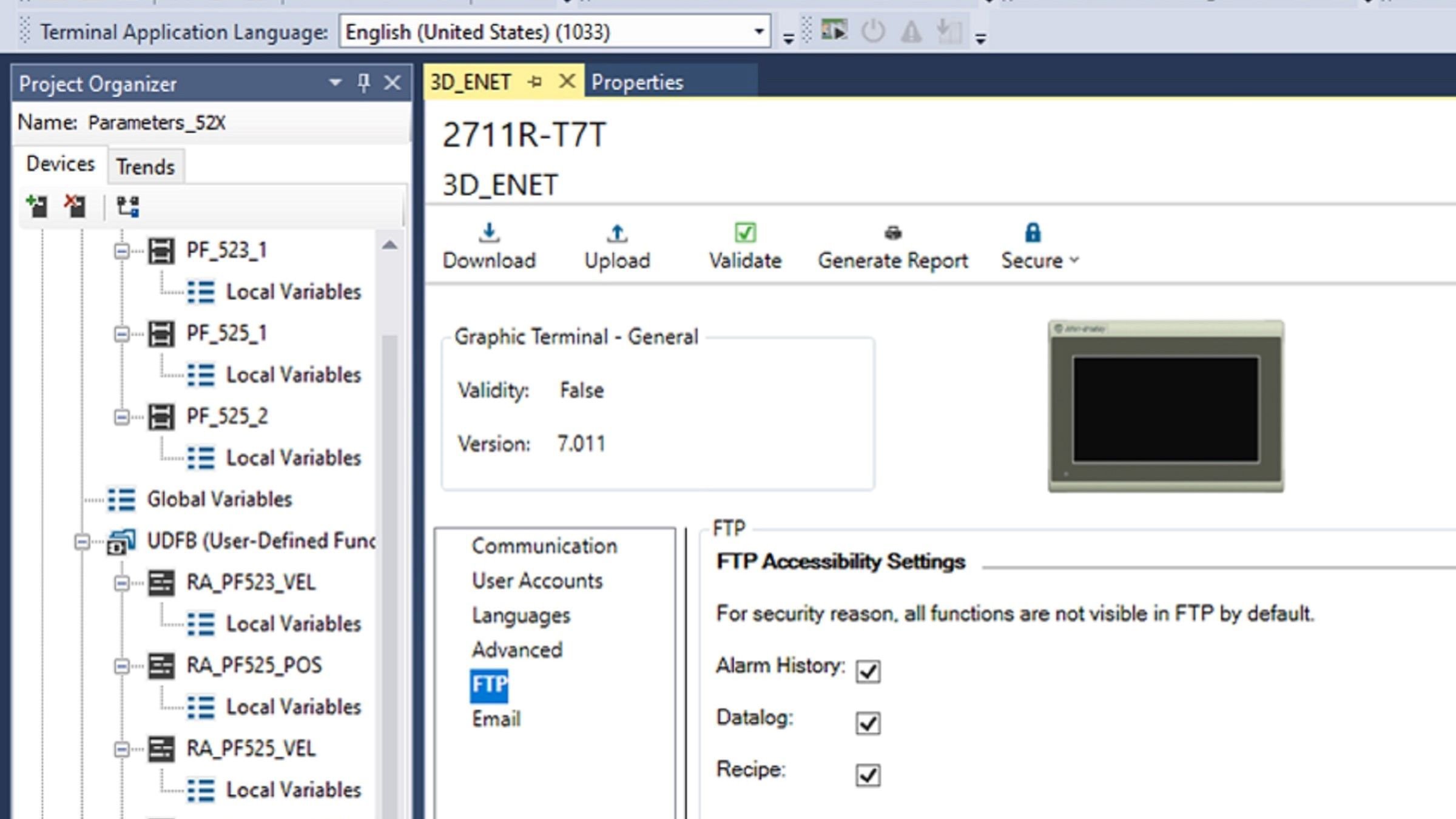

3.1 Verify that all FTP Accessibility Settings are enable.

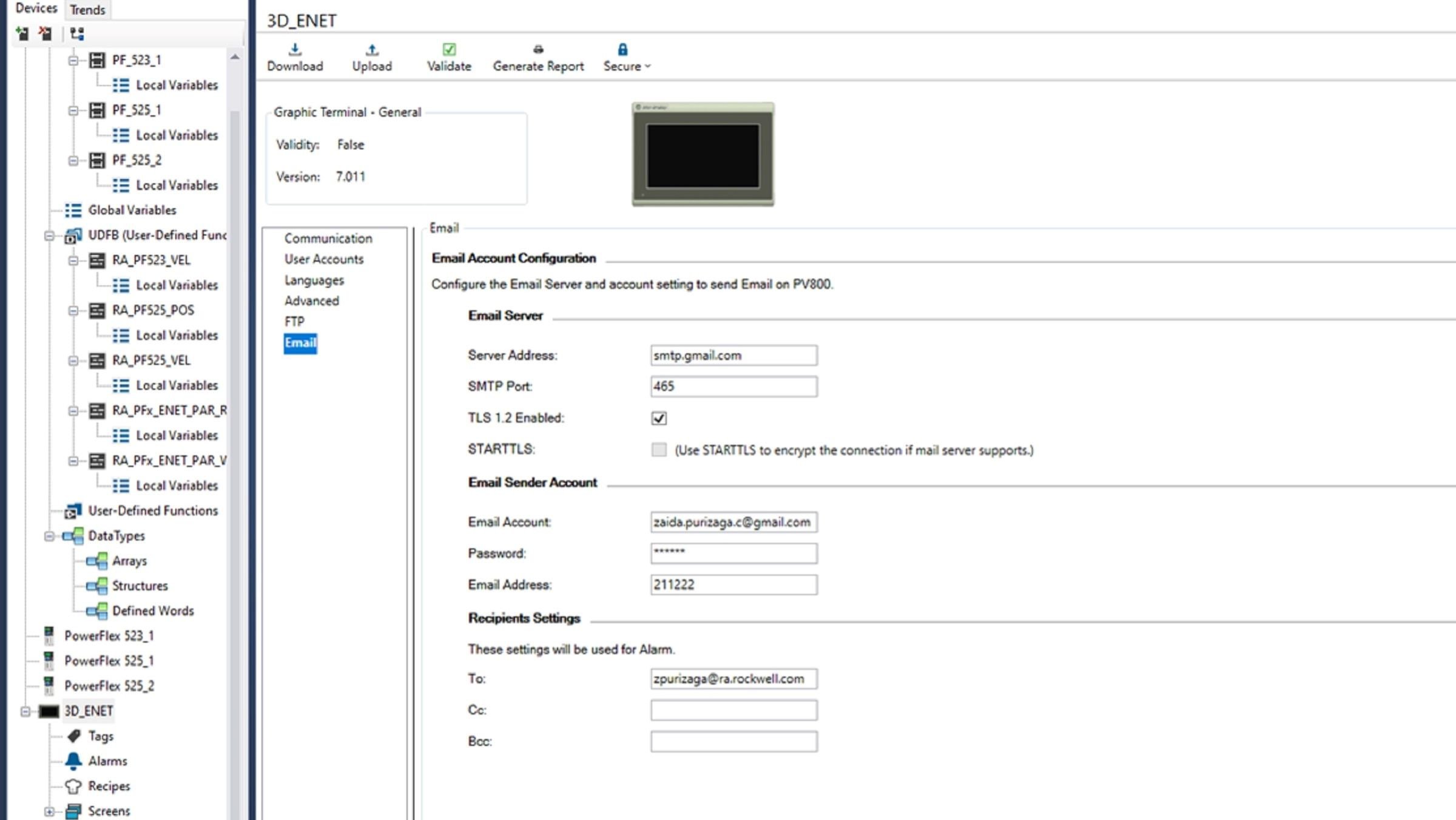

3.2 Configuration of email server and account setting to send email on PV800 (optional).

Step 4: Configuration of the PowerFlex 523/525

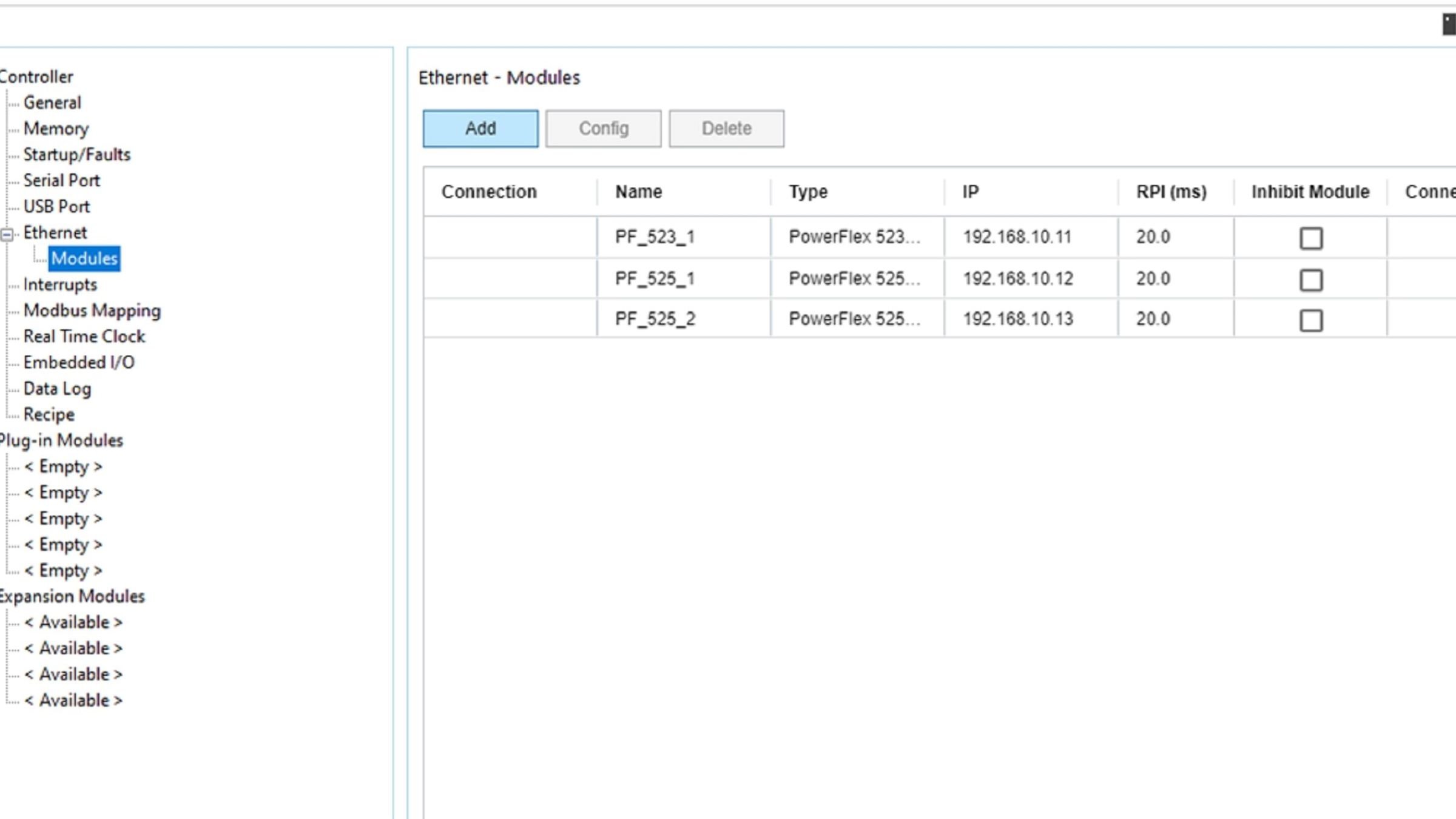

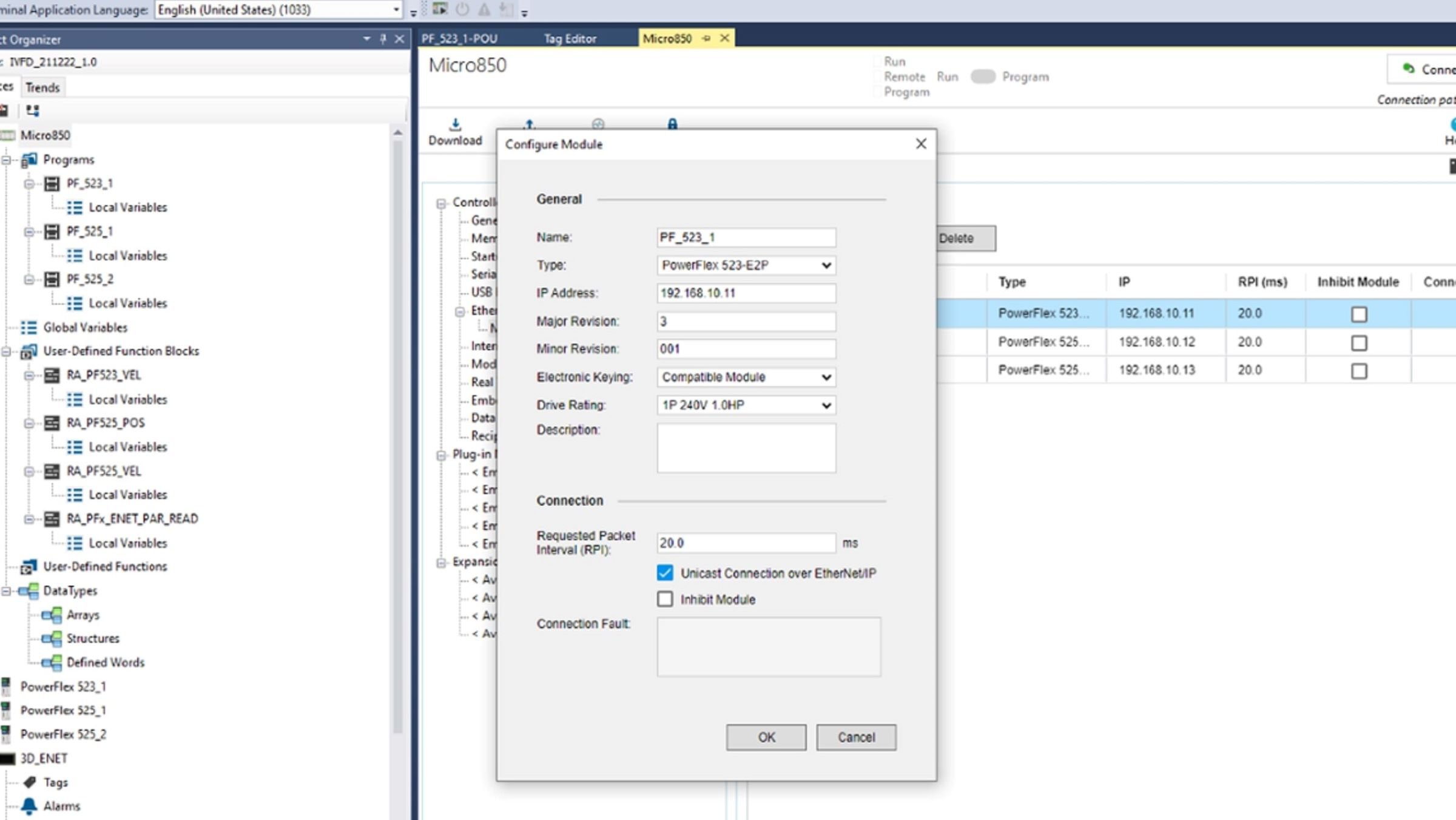

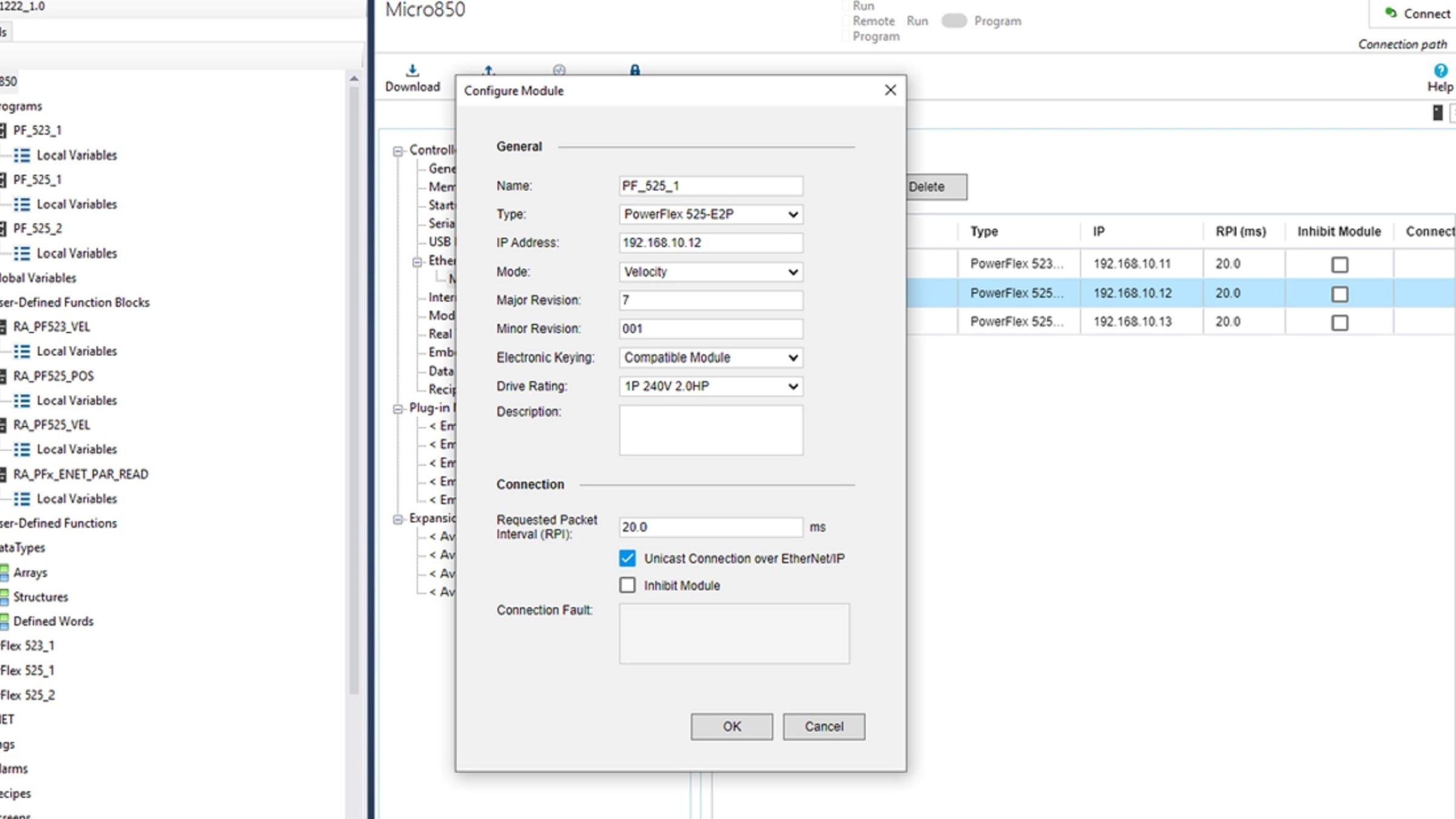

4.1 Create the PowerFlex as Ethernet modules (this enables implicit messaging)

4.2 PowerFlex523 communicated with EIP card (2 ports) and speed control mode.

4.3 PowerFlex525 communicated with EIP card (2 ports) and speed control mode.

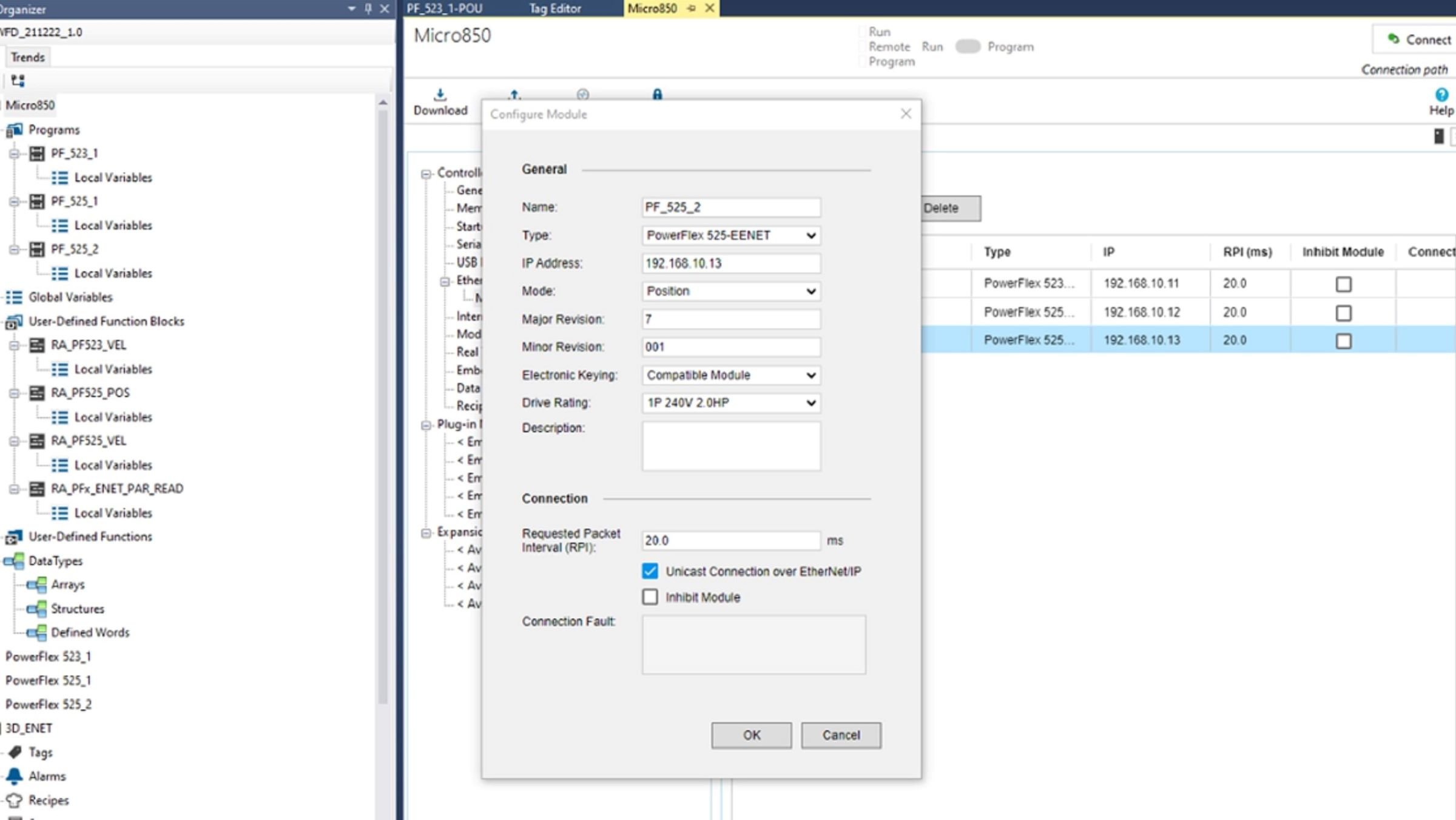

4.4 PowerFlex525 communicated by ethernet Embedded IP and position control mode.

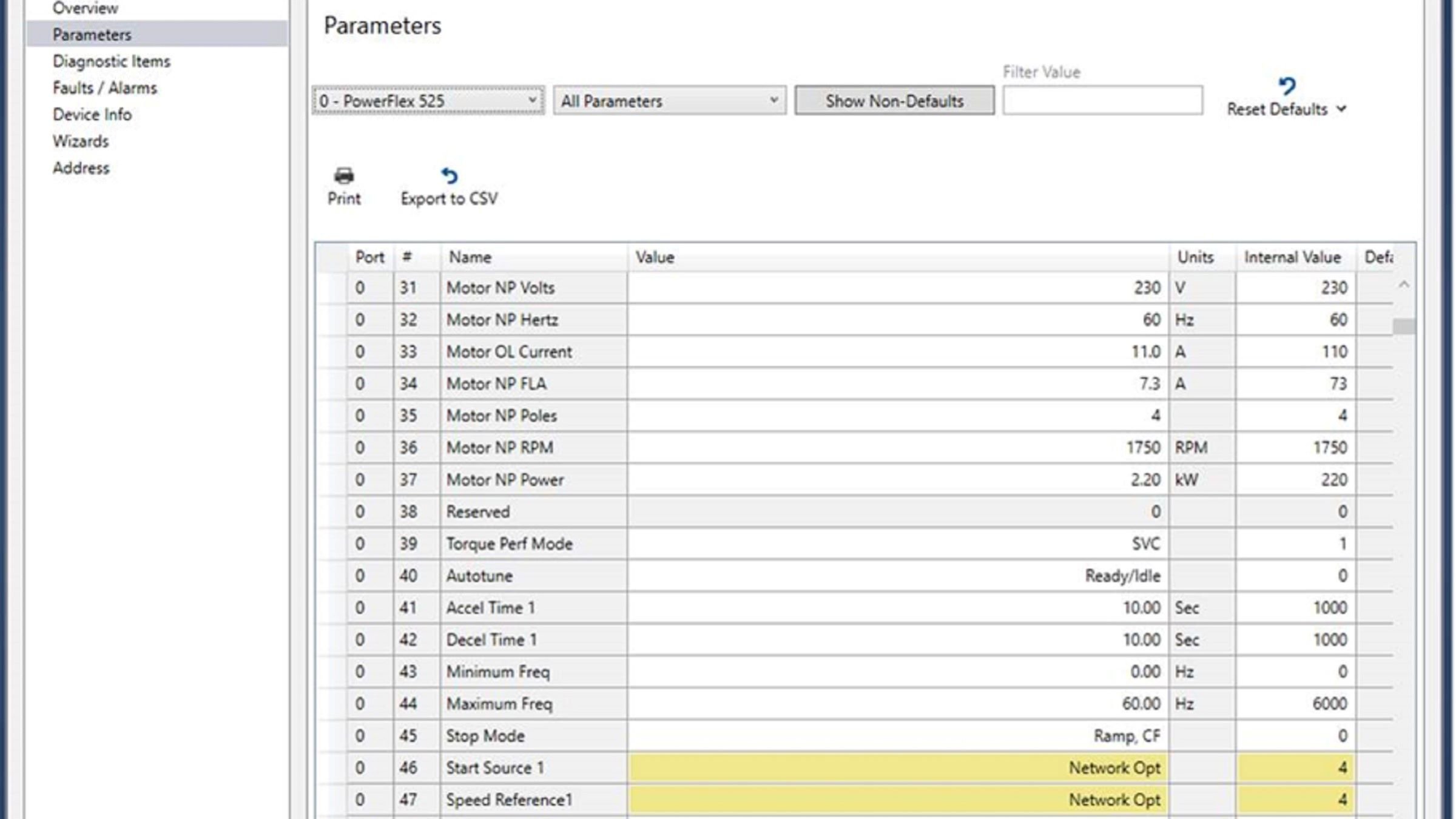

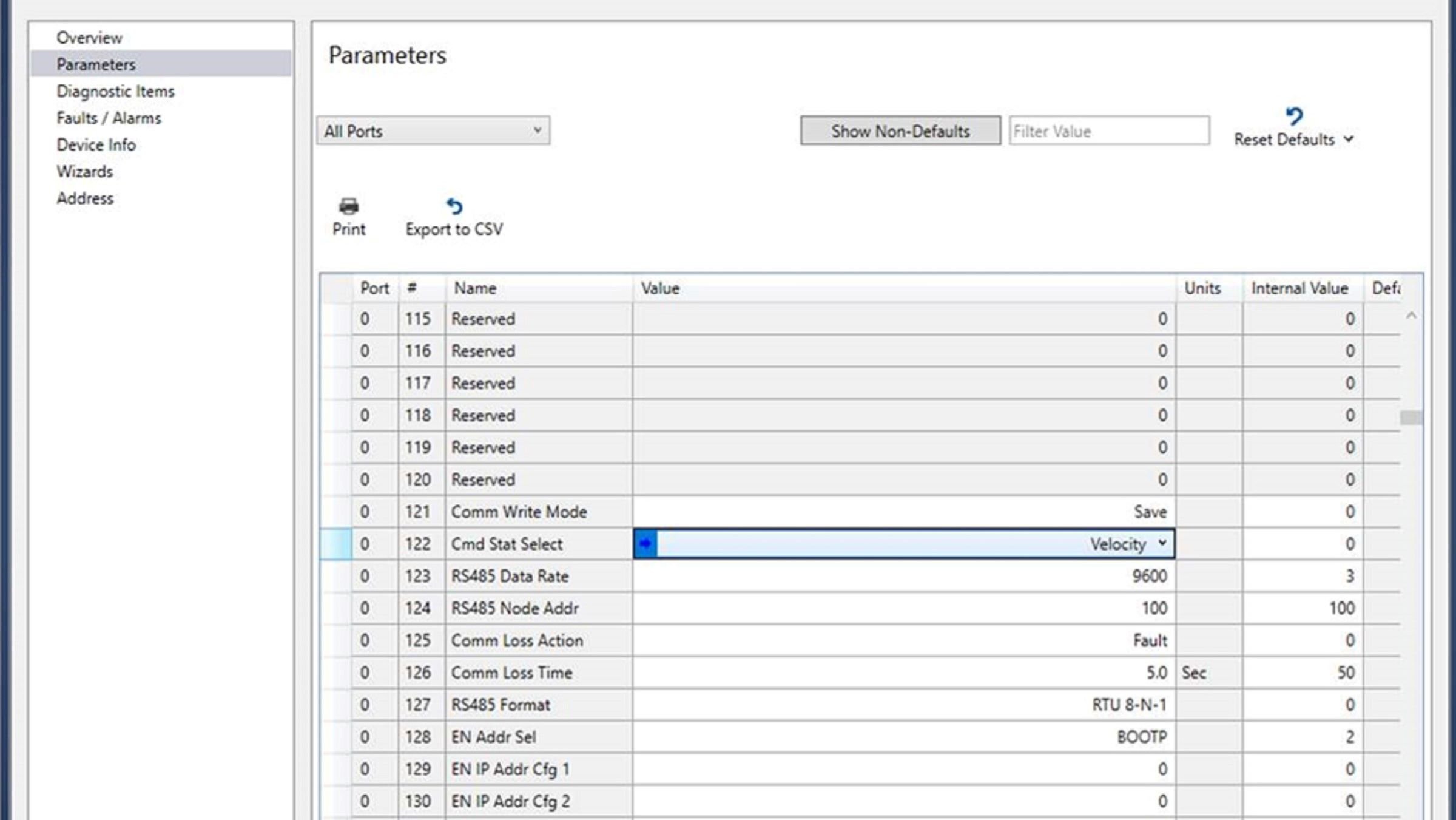

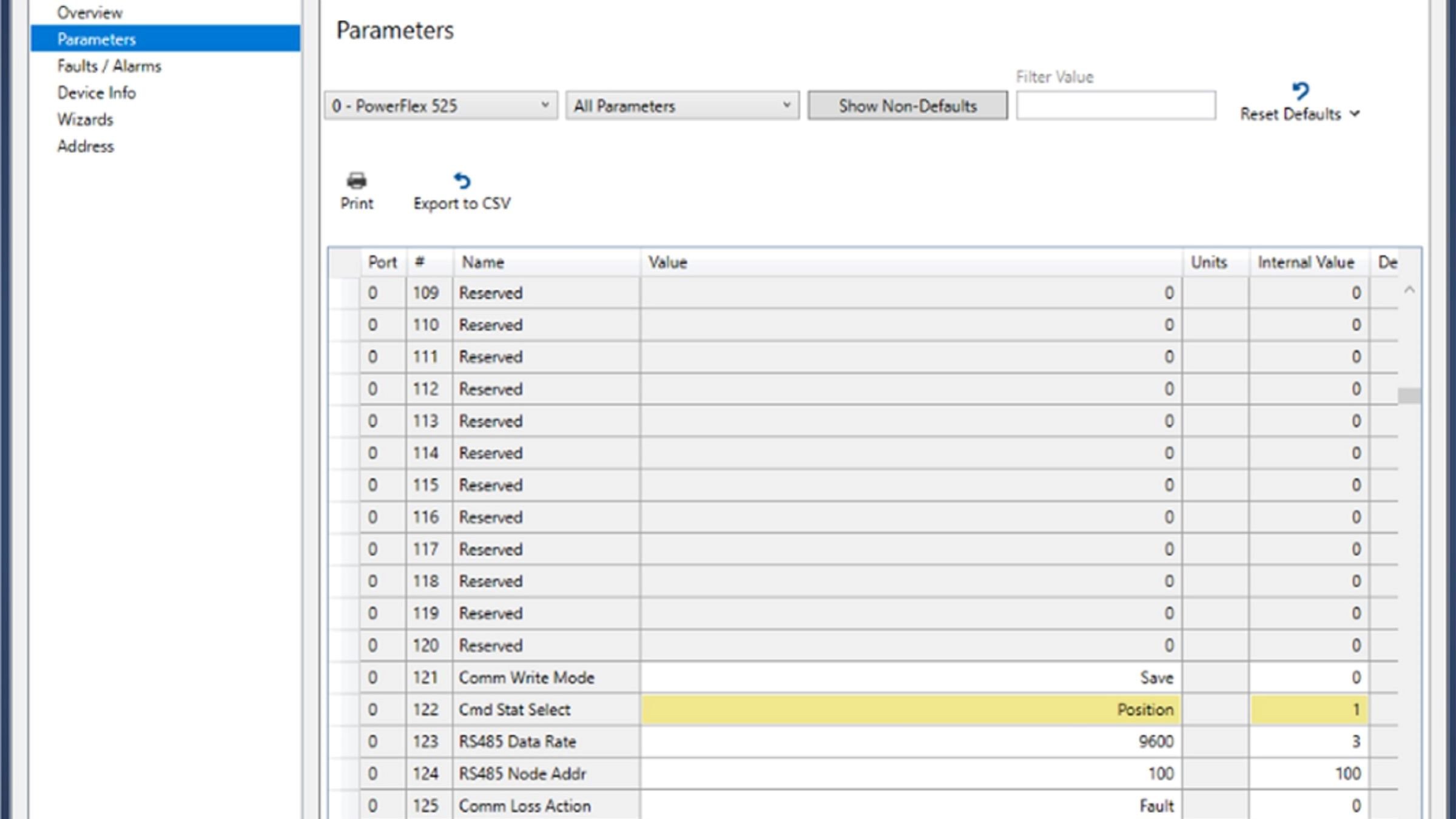

4.5 Configuration of parameters for Ethernet communication. For communication by 25-COMM-E2P card.

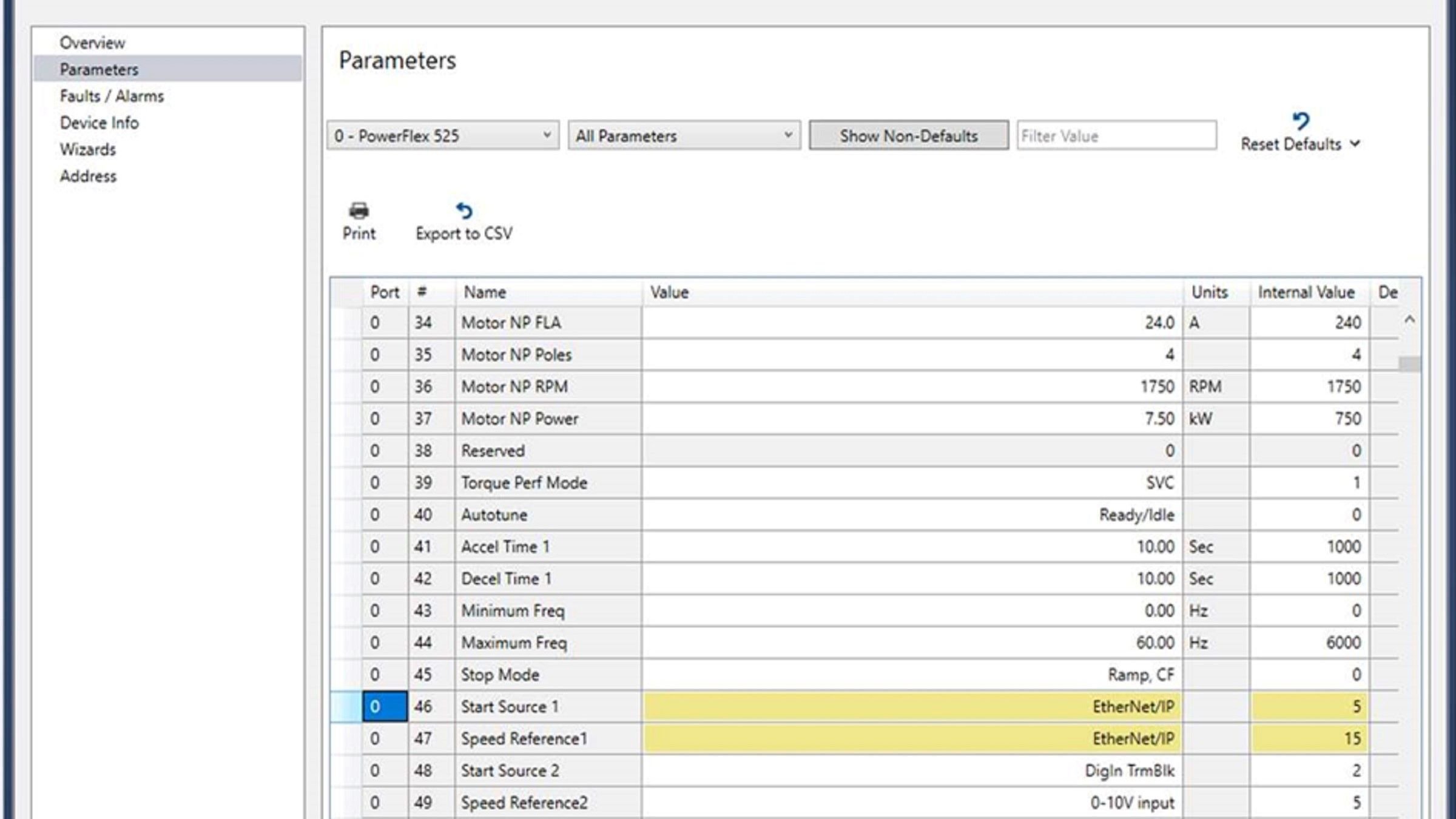

4.6 Configuration of parameters for Ethernet communication. For the communication of the PF525 through the embedded EIP port.

4.7 Parameter setting for control mode: Speed.

4.8 Parameter setting for control mode: Position.

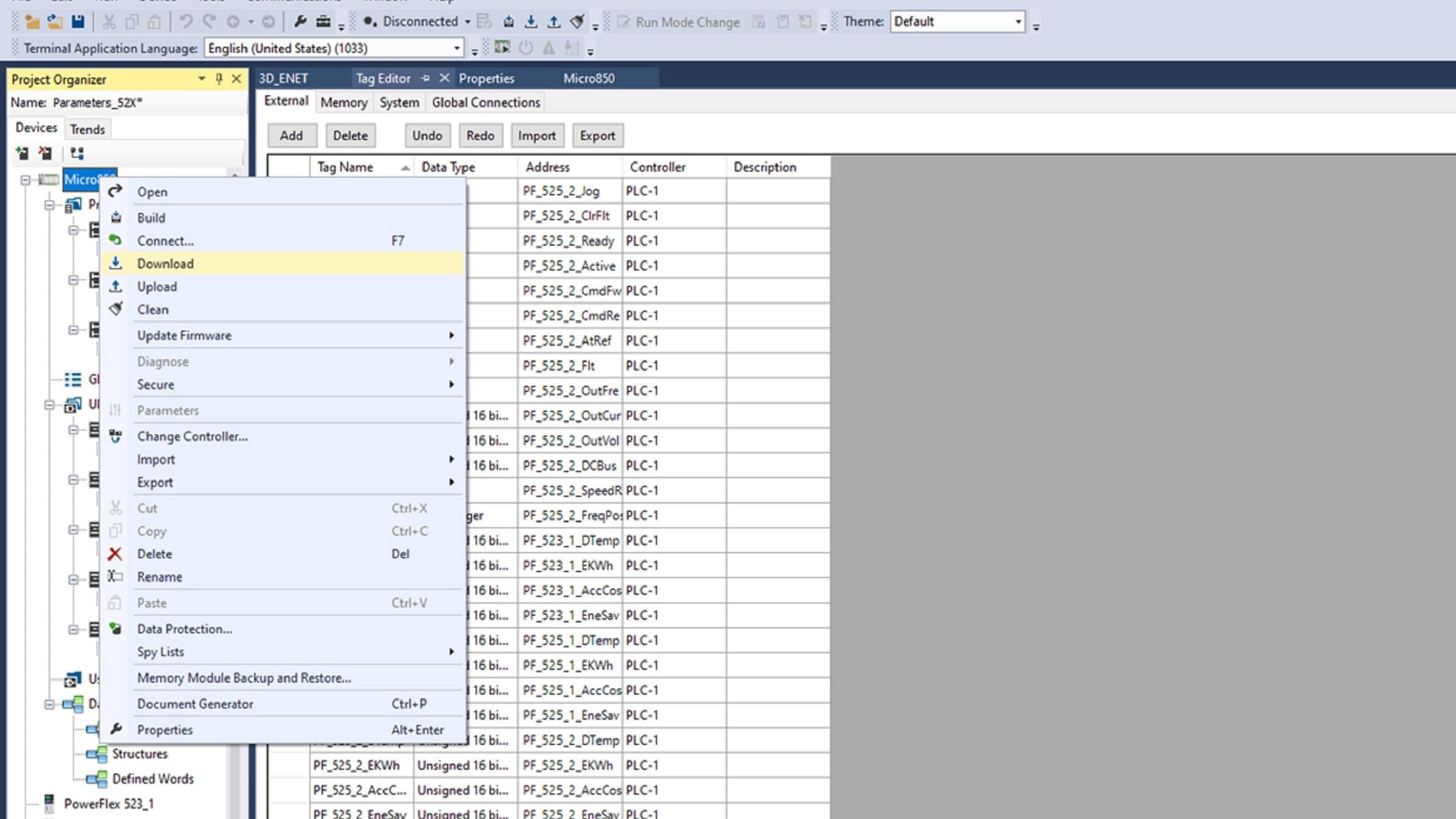

Step 5: Program download and commissioning

5.1 Compile the Micro800 program.

5.2 Validate PV800 application.

5.3 Verify the right connection and IP assignment of the equipment in the Ethernet IP network.

5.4 Download program (without errors) to Micro800 controller and leave in run mode.

5.5 Download the HMI application to the PV800 and execute it.