| Item | Requirement | Version |

|---|---|---|

| 1 | Tool will be built using Steam properties libraries of PlantPAx | 4.x – 5.x |

| 2 | FactoryTalk View SE/ME | 12.00 |

| 3 | Studio 5000 | 21 and above |

What is this for?

The objective of creating a standard Boiler Efficiency library is to gather knowledge from experience and applications utilizing the best approaches to provide features that will be selected based on the detailed requirements of the project scope. Control, process design, and the configuration approach will utilize a PlantPAx based control system that will be used with standard Boiler Efficiency applications. It is also desired for the controller to be flexible and allow integration of custom requirements and expansion as future technological developments are realized through industries.

The vision is to allow the user to select specific requirements and procedures, including and configuration capabilities, to meet the needs of the required mixing application.

Is this useful for me?

Currently, there is no way to calculate Boiler Efficiency in a standardized way. A standard library with flexibility allows for the same basic building blocks to be utilized.

By standardizing the Boiler Efficiency library, it may be used for multiple industries (F&B, Chem, Life Science, Home & Personal Care) across the globe. This standard will also be able to assist in cost benefit to the organization by lowering the engineer labor to create basic functionality.

Capturing of industry specific knowledge. Future go-to-market features for sales of Plant Pax application. Financial and labor savings are unknown currently. However, reduced development time is expected due to the ability of tool to create basic functionality.

How can I make it work?

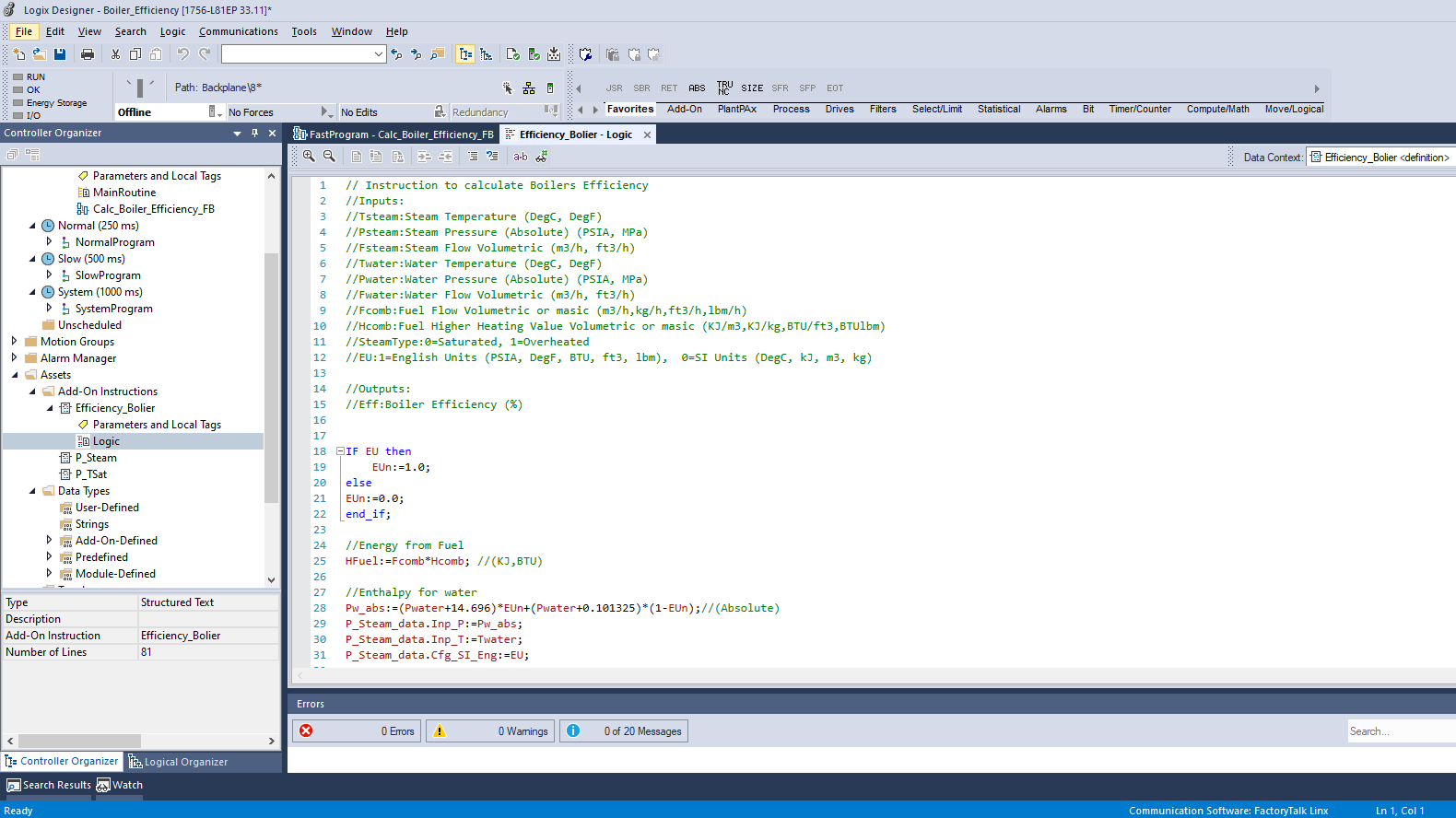

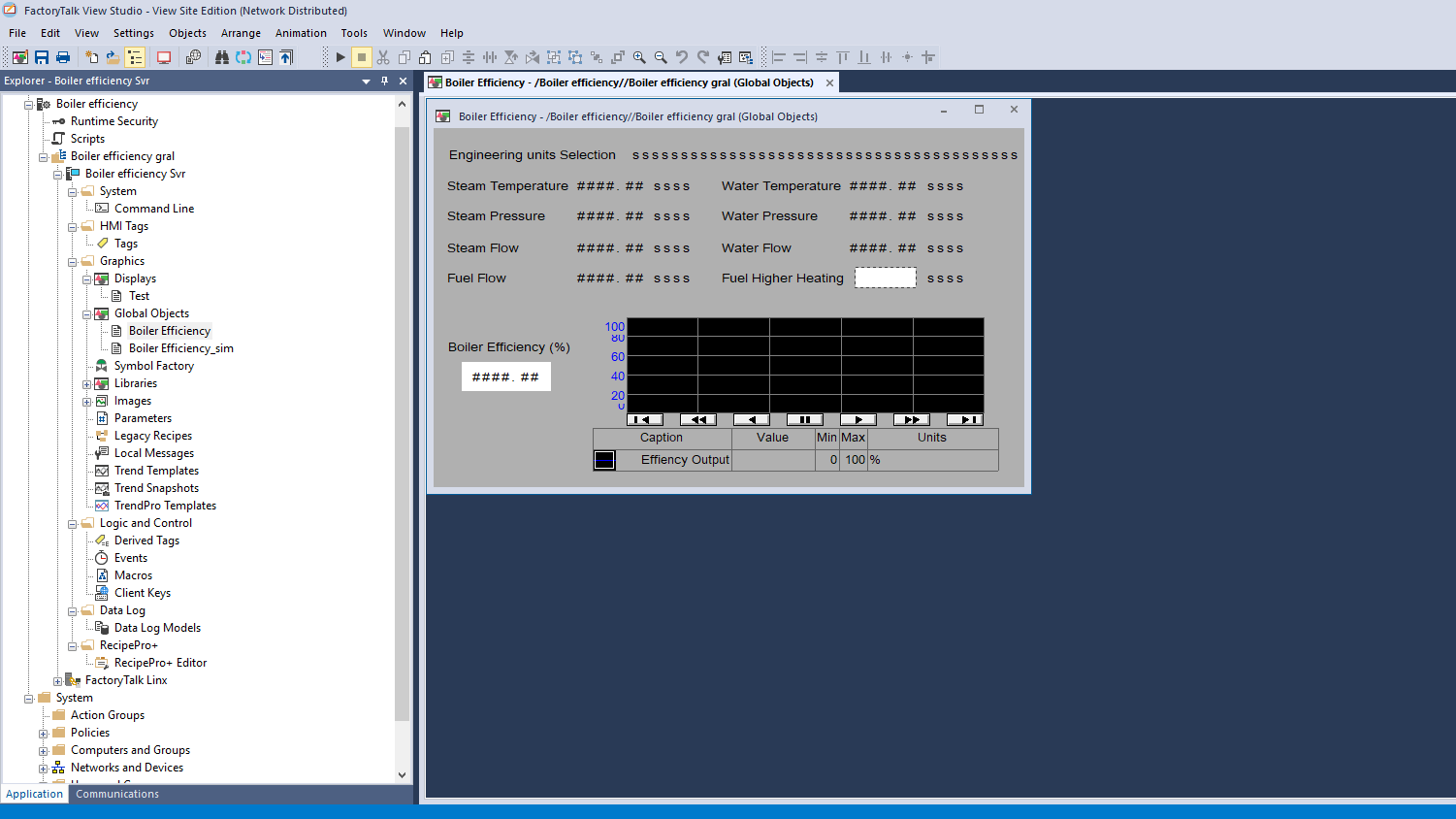

User will enter Boiler system inputs based on standard instrumentation typically used in Boilers.

This first version allows you to have real time efficiency in a Rockwell Automation control system, just import and configure the AOI and the Display, add it in your application and that's it.

System requirements of app:

Process variables will need to be able to be configured including input signal, scaling, and units.

| Item | Instrumentation |

|---|---|

| Temperature (Steam and Water) | Type:

|

| Flow (Steam, Water, Fuel) | Type:

|

| Pressure (Steam, Water) | Type:

|

Knowledge required

Basic knowledge of programming and configuration in Studio 5000 Logix Designer® software and FactoryTalk® View Site Edition Studio.

Downloads

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

Step 1:

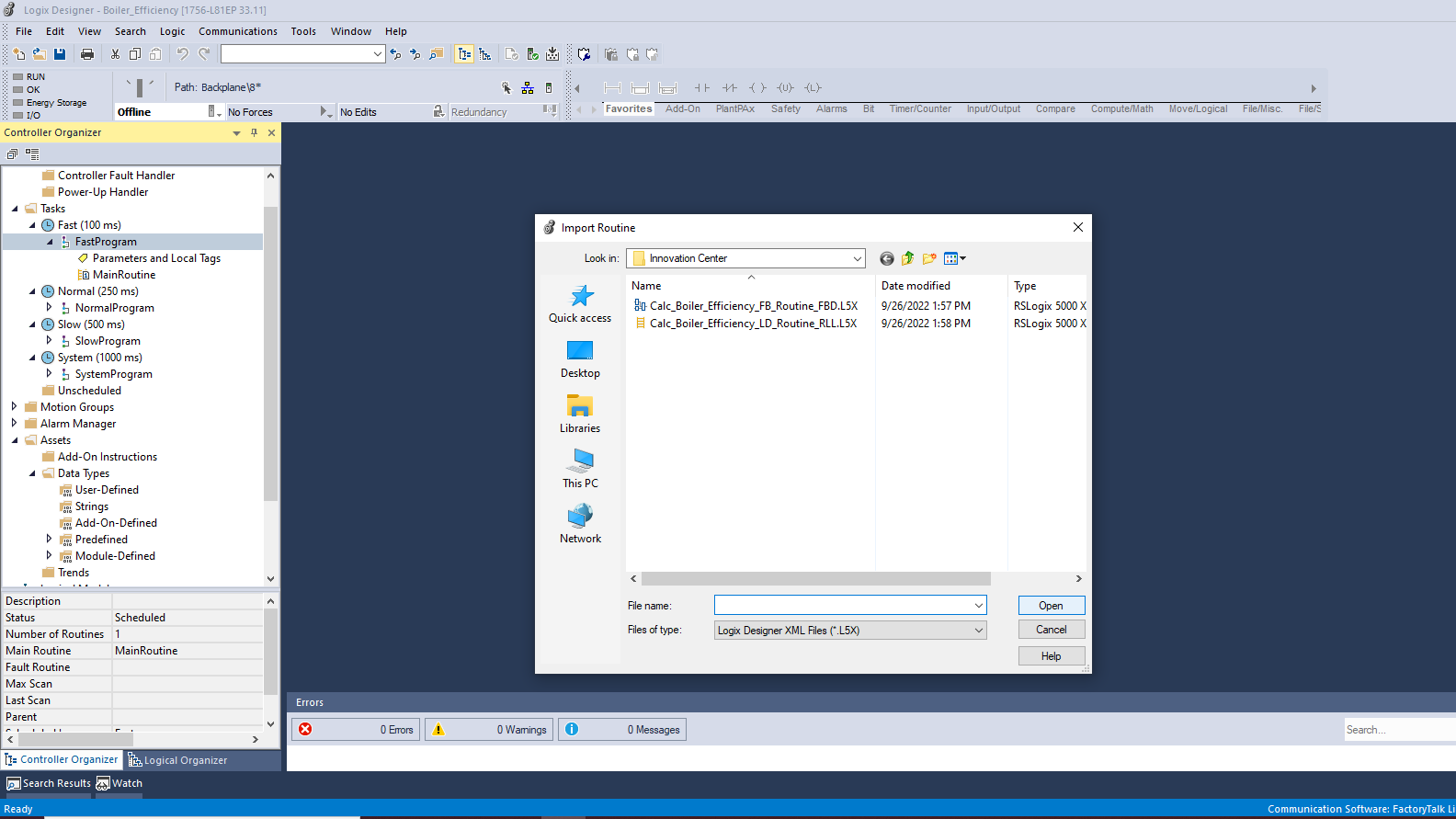

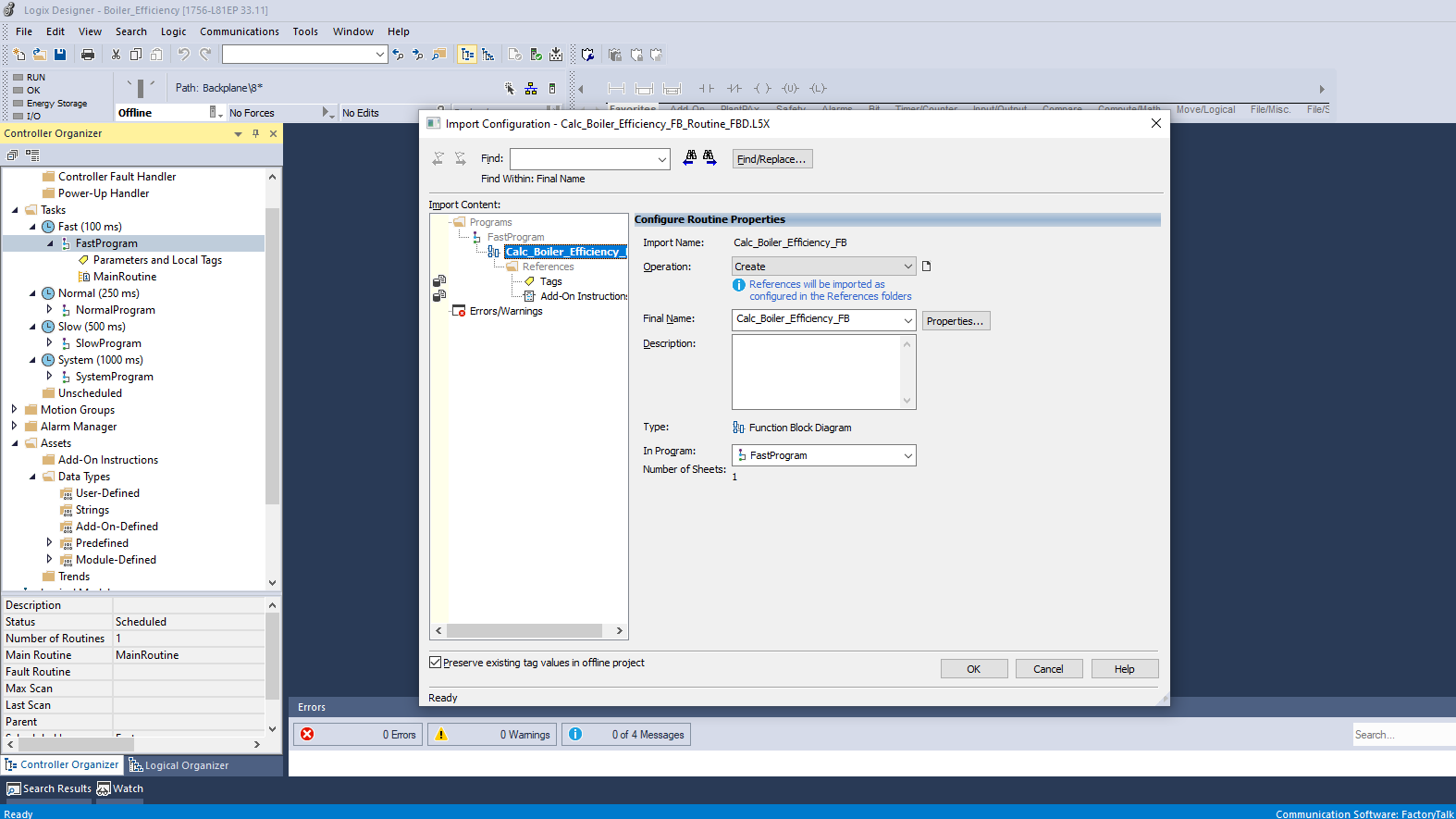

1. Import file L5X for routine according with the programing language to use:

- Calc_Boiler_Efficiency_FB_Routine_FBD. L5X for Function Block.

- Calc_Boiler_Efficiency_LD_Routine_RLL.L5X for Ladder.

Note: Please read the instructions in the program comments

Step 2