Recommended For You

Industrial producers can now improve the reliability and longevity of their automation systems in hazardous locations.

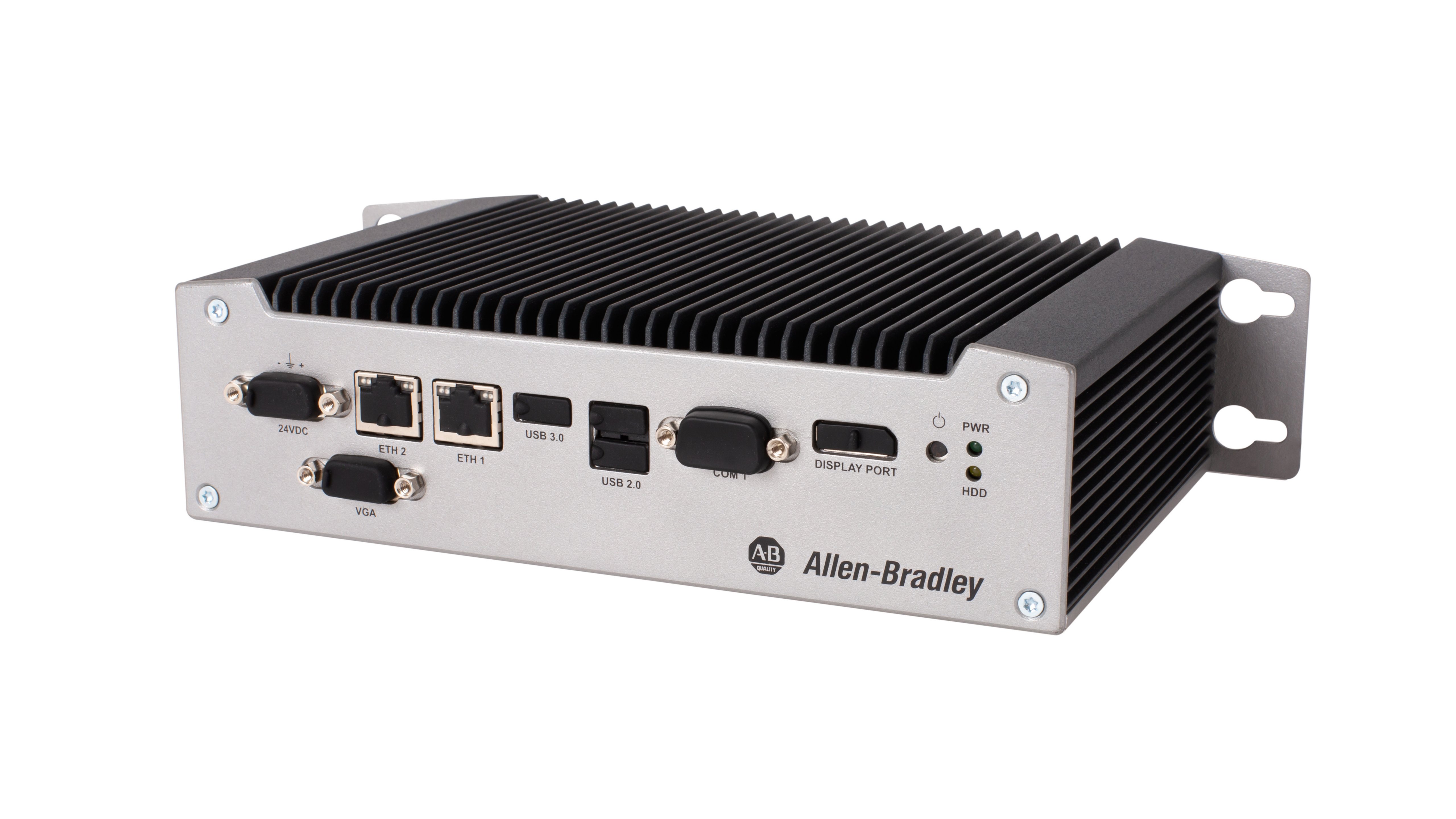

Rockwell Automation has enhanced two of its modern visualization solutions, the Allen-Bradley VersaView 5200 thin clients and VersaView 5400 industrial computers, for use in harsh locations in industries like oil and gas, tire and rubber, and pulp and paper.

Both products are now certified for use in UL Class I Division 2 and ATEX Category 2 hazardous-area applications. In addition, the products carry a BIS certification for markets in India. The products are available with these new certifications at no added cost to customers.

Both products are also now available with conformal coat options. Conformal coating helps protect product circuitry from environmental stresses like moisture, fungus, dust and corrosion.

When used with ThinManager software from Rockwell Automation, VersaView 5200 thin clients can start receiving information as soon as they’re plugged in. Device configuration is not needed, resulting in faster device replacement. And because information is stored on a server instead of locally, sensitive information is less likely to be lost if a VersaView thin client goes offline.

VersaView 5400 industrial computers use an open-architecture design to give producers the freedom to install software that suits their needs. They also serve as an appliance within the FactoryTalk Analytics for Devices software from Rockwell Automation. This combined hardware and software package gives users access to health and diagnostics data for smart devices to help track and improve their performance.

Published December 2, 2020