Achieving autonomy across an enterprise requires capabilities that span the full intelligence spectrum, from observation and inference to decision-making and action. These capabilities are relevant across all operational areas, including product design, manufacturing, supply chain, distribution, direct-to-customer channels, and demand forecasting.

Manufacturing operations, in particular, have seen progress through Model Predictive Control (MPC), which continuously analyzes real-time and forecasted data to optimize process control within defined constraints. While MPC is a strong example within manufacturing, broader autonomy demands extending similar intelligent systems across the enterprise.

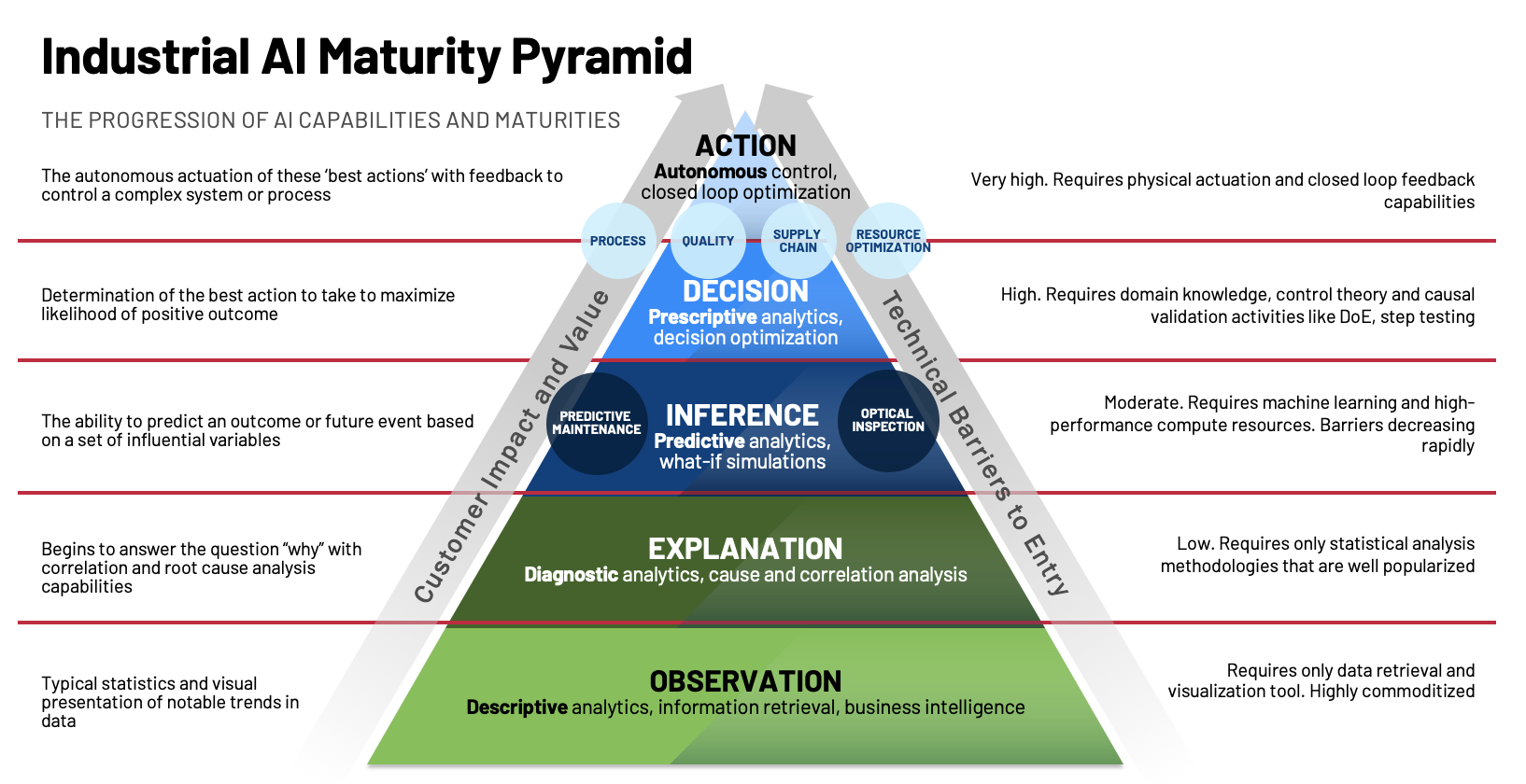

This journey is captured in the industrial AI maturity pyramid, which outlines a progression from basic data integration and visualization to predictive analytics, prescriptive decision-making, and ultimately, autonomous operations. As organizations climb this pyramid, they adopt machine learning, real-time automation, and self-learning systems. Each stage requires not just technological upgrades but also cultural and structural transformation.

Asset Monitoring

Find downtime root causes

Looking at the Industrial AI Maturity Pyramid, asset monitoring is an entry and transition point from observation into explanation. This is a great example of how changes in technology have shifted use cases into different layers of the pyramid. Effective asset monitoring is crucial for maintaining operational efficiency and minimizing downtime. By better understanding sensor data trends, alarming, and maintenance work order context, businesses can quickly identify and address root causes of downtime through engineering analysis.

Additionally, comparing the reliability and performance of similar equipment across multiple plants allows for more informed decision-making and optimized asset utilization. This approach not only helps in preventing unexpected failures but also ensures that maintenance activities are scheduled proactively, thereby extending the lifespan of assets and reducing operational costs.

Quality Control

Predict when quality issues are likely to occur

Moving up the pyramid into the inference layer usually involves a capability like quality control, adaptive manufacturing or predictive maintenance. Maintaining high product quality is essential for customer satisfaction and regulatory compliance. AI can detect and suggest corrections for deviations that impact product quality, automate the inspection process, and predict when quality issues are likely to occur. By monitoring the quality of incoming materials, businesses can reduce the risk of defects.

A notable example is our own application at our Twinsburg manufacturing plant, which focuses on electronic assembly. In this case, Industrial AI provides alerts for potential faults that allow teams to take proactive action. While this approach stops short of making the changes itself, it significantly enhances the decision-making process. The ability to predict and address quality issues before they escalate ensures that products meet stringent quality standards, reducing waste and improving overall efficiency.

Adaptive Manufacturing

Change supporting resources around the production line

Adaptive manufacturing leverages real-time data to adapt production schedules, shift resources, and pivot quickly to changes in demand. AI analyzes production and market conditions to autonomously adjust schedules, equipment, and workflows in real-time.

While this approach does not change what happens on the production line, it supports the resources around it. This concept is particularly relevant in scenarios where production needs to be adjusted based on downstream feedback, ensuring optimal efficiency and responsiveness. For instance, if a slowdown is detected further downstream, signals can be sent upstream to adjust production rates accordingly, preventing bottlenecks and maintaining a smooth flow of operations.

It’s important to highlight that you're managing supporting resources for production, and this is really where your autonomous manufacturing begins.

Predictive Maintenance

Automate decision for repair

Predictive maintenance is a proactive approach to scheduling maintenance, improving asset utilization, and lowering costs. Under this approach, AI analyzes historical data and current state equipment information to recognize patterns and make predictions, further optimizing maintenance schedules and automating decision-making for repairs. Although AI does not conduct the repairs itself, it significantly minimizes unplanned downtime and associated costs.

This approach is similar to providing alerts to the team that a fault could occur, allowing them to take preemptive action. By anticipating maintenance needs, businesses can avoid costly disruptions and extend the operational life of their equipment, ultimately leading to more efficient and reliable operations.

Every organization has a maintenance department, each at a different stage of maturity. However, when adopting advanced solutions, many face challenges related to skills, talent retention, and ongoing training. With significant progress in edge computing and analytics, there’s now a powerful opportunity to infuse innovation directly into intelligent devices through machine learning.

Predictive maintenance offers a comprehensive solution. It’s hardware, software, and services brought together seamlessly under one roof, representing the next evolution in condition monitoring technology.

Process Optimization

Recognize variables and course correct

As we discussed earlier, a common application for industrial data and AI we’re seeing for our industry clients is within the model predictive control (MPC) space. By leveraging industrial data and AI technologies, businesses can make better, faster, and more informed decisions, ultimately unlocking AI capabilities, moving up to the decision layer of the pyramid and paving the way for autonomous operations.

Detailed insights into production processes enable the identification and resolution of inefficiencies. MPC allows for the modeling of specific operations within a plant, managing set points within a PLC to control equipment, and using data science to course-correct in real-time. MPC systems provide a feedback loop that continuously adjusts production parameters to maintain optimal performance, even as conditions change.

With MPC, organizations are not only reading data from various sensors on the production line and the PLC that controls production but are simultaneously writing back to the PLC and giving instructions to change the line rate as needed.

Conclusion

The integration of industrial data and AI is transforming operations across various domains, from asset monitoring to predictive maintenance. By unlocking Industrial AI capabilities, businesses can move closer to achieving autonomous operations, making better, faster, and more informed decisions. As technology continues to evolve, the vision for fully autonomous operations becomes increasingly attainable, promising a future of enhanced efficiency, reliability and adaptability.

The journey towards autonomous operations involves incremental steps, each bringing businesses closer to a state where systems can independently manage and optimize processes, ensuring sustained growth and resilience in a competitive market.

This blog post is a replicated version, with the original available on the Kalypso website. To access the original version, please click here.