David’s job is to manage the company’s overall technology strategy as well as their implementation of new, innovative solutions. It’s a large scope of work. David originally approached Plex Systems to get help tearing down data silos across areas of the plant and addressing what he calls, ‘stale data’.

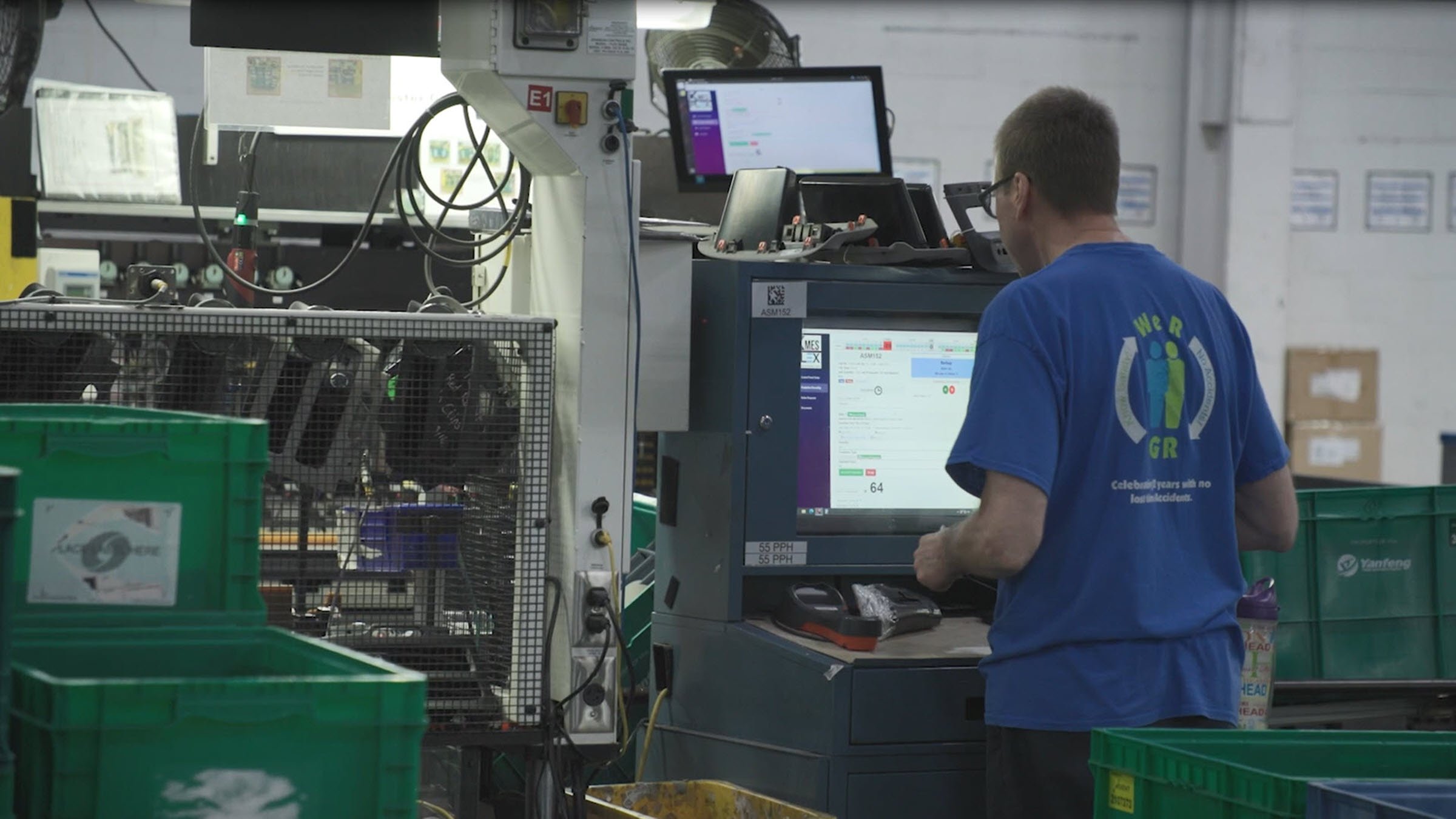

Meet David! David Chupp is the IT Manager at Kendrick Plastics. Kendrick Plastics is a plastic interior trim supplier for the automotive industry. Next time you’re sitting in the driver’s seat of your car – look around! See all those interior trim pieces? Kendrick produces these types of parts using injection molding processes, welding, painting technology, and assembly operations.

“Before transitioning to Plex, some of our data was as much as 24 hours old. Imagine: it’s raining outside, and you have to wait 24 hours for someone to tell you it’s raining. You’re going to walk outside no umbrella… data visibility is so important.”

David’s goal was to reduce what the company was spending on controllable costs. Specifically, David was looking to reduce scrap. He knew that even the slightest shift in equipment function or the smallest variation in a process could cause quality issues that required product to be scrapped. With Plex Systems, David hoped to gain a more real-time view into equipment and process performance so the team could quickly identify and fix any issues that might impact quality.

Kendrick Plastics implemented the Plex Manufacturing Execution System, and also built an application layer on top to meet its specific business needs, in about seven months, with very little production disruption. And the results were awesome. David goes on to say:

“Just having that data accessibility and visibility to what is actually occurring allowed us to significantly reduce our scrap!”

This wasn’t the only result Kendrick Plastics achieved. Check out the full video to hear more from David, including his advice for other companies looking to use data to improve the way their they do business. And read more about the great work Kendrick Plastics is doing here.

Published October 2, 2022