The Production Line

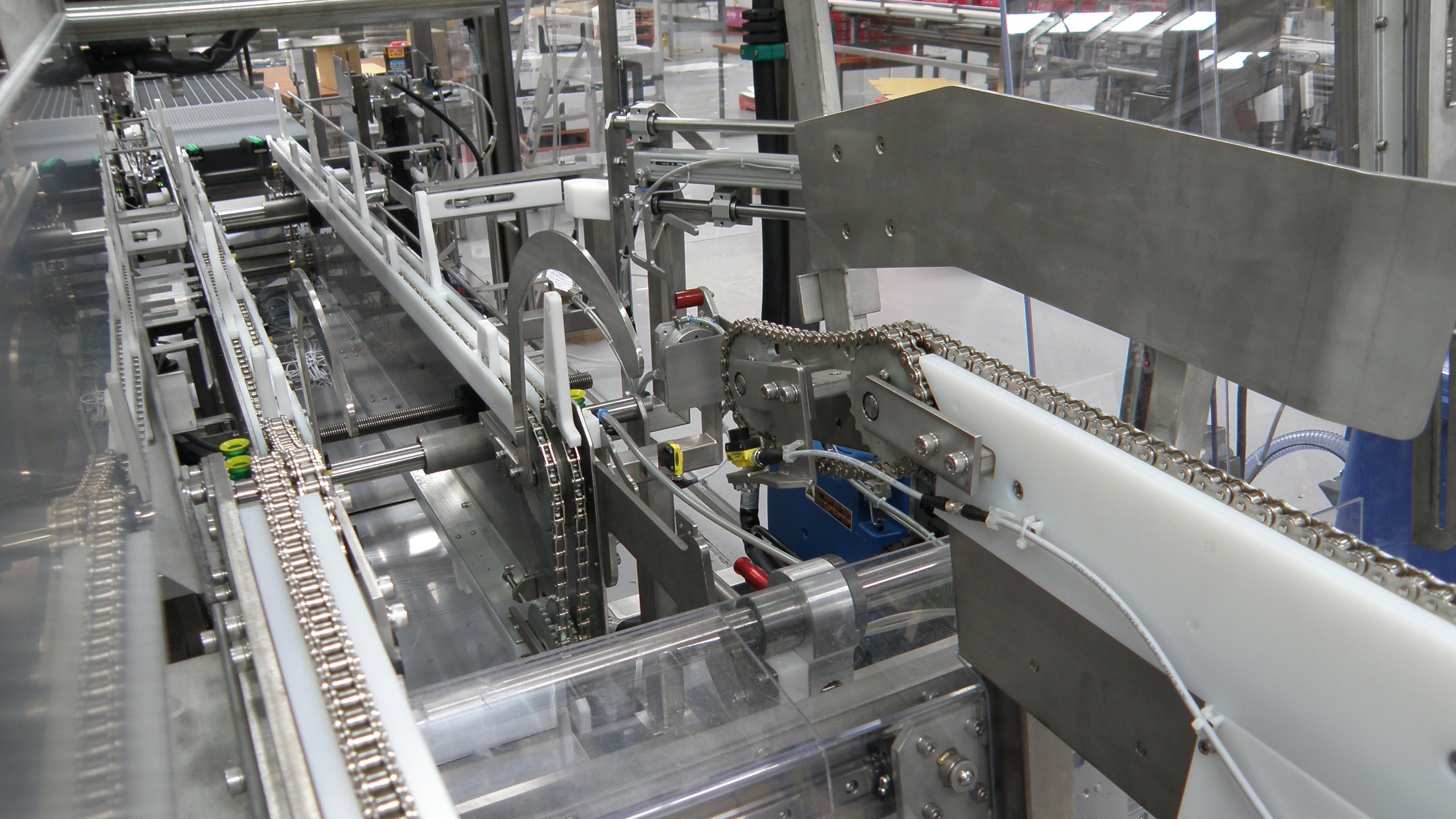

To meet growing demand, the manufacturer had previously upgraded their main condiment production line to produce twice as much product in half the time. Bottles are sterilized, filled, capped and labels applied.

The production line produces different sized and shaped bottles ranging from 500ml to 4 litre. To accommodate this, there is a multiple range of case sizes, pack configurations and bottle shapes.

According to Warren Booker NSW State manager at HMPS, “In Australia, manufacturers are challenged by having to produce so many different products in the one machine. In countries with larger populations, like the US and Europe, one machine can be dedicated to a specific product which makes the machine design more simplistic.

The Australian market has a unique requirement where they need a machine to be flexible to grow with the business and pack a range of different products in different packing arrangements”

HMPS worked closely with the customer to design a fully automated system that meets all the requirements for this application today but also has the flexibility to meet future demands.

Precise Motion Control

The challenge ahead was to pack bottles that are coming off the production line at 100 bottles per minute into a six by three pack configuration with labels forward facing.

“There were fundamental considerations that required attention in the design phase to achieve this with a key focus on detailed simulation to make sure the advanced level of motion control required could be achieved,” explained Warren.

Given the large range of products which was being produced and the need for shelf ready cartons meant this production line had clear and precise requirements which HMPS had to comply with.

Using the latest technology and working closely with the customer specified needs has allowed this project to be a smooth transition into full production speed maintaining high efficiency and reliability.

HMPS works with a variety of component suppliers and integrators.