General

This "Basic Module Information" (BMI) provides quick access to a list of the main module

functions, some attributes, and the location of more detailed module information.

NOTE

: When developing an application, or troubleshooting a significant problem,

it is

IMPORTANT

to read and follow more detailed module information,

including safety recommendations.

The primary source of detailed module information is

the manual, "IND780 Terminal PLC Interface Manual" available from the IND780 Documentation

CD (P/N # 64057241) included with the terminal. This is referred to as the "manual" in this

BMI.NOTE: In this BMI, the word "tag" refers to data tags in the Logix controller.

Function

The IND780 EtherNet/IP interface kit enables the IND780 terminal to communicate to

EtherNet/IP Programmable Logic Controllers (PLCs) through a direct connection to the

EtherNet/IP network at either 10 or 100 MBPS speed. The kit consists of a

backplane-compatible I/O module, mounting hardware, and a ferrite. Various types of data

exchange to allow reading and writing of different weighing and control parameters for the

IND780 terminal is available. Configuration to setup the type of data exchange resides in

the IND780 terminal.

Features

- User programmable IP address, Subnet Mask and Gateway address.

- Unicast I/O for EtherNet/IP allows for direct point-to-point communication between two devices on a network. This communication format is more efficient when I/O data does not need to be shared between multiple target devices.

- Capability for bi-directional discrete mode communications (Class 1 Cyclic Messaging) of weight or display increments (in integer or floating point format), status, and control data between the PLC and the IND780.

- Support for Explicit Messaging to access IND780 shared data variables.

- Offers specific data integrity bits to allow the PLC to confirm that data exchange is valid.

- There may be up to 12 message slots for discrete data transfer, Class 1 messaging.

- Status LEDs to indicate communication, network and module status.

Network Connectors

Refer to manual for pinouts and Rockwell Automation part numbers of mating connector.

- The wiring between the PLC and the IND780 EtherNet/IP Interface kit uses a standard ethernet twisted pair cable with a RJ-45 connection. Cables are not supplied by Mettler-Toledo.

- The cable installation procedures and specification including distance and termination requirements are the same as recommended by Allen-Bradley for the EtherNet/IP network.

Module Identity

The module Identity includes the following Device attributes:

- Vendor ID '666', and Vendor Name string 'Mettler-Toledo'

- Product Type '12', and Product Type Name string 'Communications Adaptor'

- Product Code '3', and Product Name string 'MT IND-ETHIP'

- Catalog Name string 'IND Ethernet/IP'

Communications

The IND780 EtherNet/IP Interface uses EtherNet/IP Implicit communication for transferring

I/O data to a controller. Certain data can also be accessed using EtherNet/IP explicit

messaging. CIP messages are supported from a host device over the EtherNet/IP network.

Note

: Refer to the manual for full details of these communication protocols.Input and Output Tag Data

The following module Input and Output tags are created in the RSLogix5000 project by the

AOP.

Note

: Logix IO tags are updated by the controller asynchronous to its ladder-logic

program scan. When "block integrity" of this data is important, the CPS ladder instruction

can synchronously copy the data to other Logix tags for use by application logic. Note

: Default RPI

for the IO connection is 25ms

. It is important to

set the Requested Packet Interval for an update time suitable for the application. The

update time chosen determines how often the host will receive Input Image updates from the

IND780 EtherNet/IP Interface. A very long RPI will result in events taking place at the

IND780 EtherNet/IP Interface module that may never be seen by the host logic.Integer or Division Data Format

The Integer data format reports the weight data with an integer value in the current weight

units and Division reports the data with a weight value in the number of divisions (scale

increments). When one of these formats is selected in the IND780 setup configuration, the

IND780 will have two 16-bit words for input data and two 16-bit words for output data in

each Message Slot. Up to 12 message slots are available and each can be assigned for a

specific scale channels data. (The comparator status bits are only available with IND780

software 5.0 or greater.)

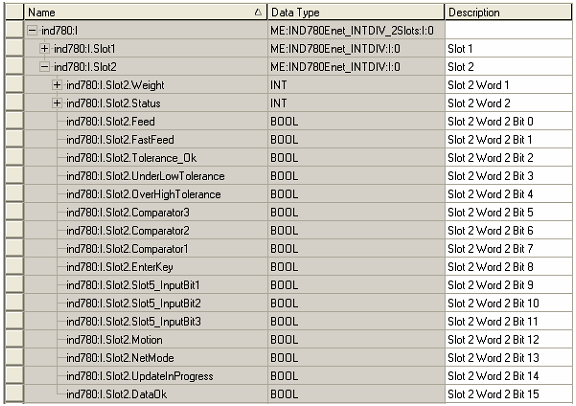

Below is the view of an IND780 device

Integer/Division Input Tag

with 2 message

slots, with the second slot expanded to show the two words, Weight and Status. The 1st word

of the message slot, Weight, is a 16-bit signed integer of the scale weight value in weight

units or divisions. The second word of slot 2, Status, consists of status bits to indicate

scale and I/O statuses. The second word is expanded to show the tag names of the individual

bits. Note

: Decimal bit numbers are shown in the Description column (which is added by the

user). Octal bit numbers can also be used in the IND780 Terminal. Refer to the IND780

Terminal PLC Interface Manual for more details on the data definitions.

RSLogix5000 View of Integer/Division Input Tags - 2 message slots

(description added by user)

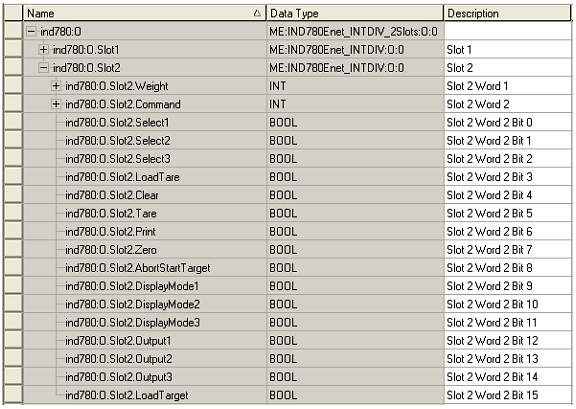

Below is the view of an IND780 device

Integer/Division Output Tag

with 2 message

slots, with the second slot expanded to show the two words, Weight and Command. The 1st word

of the message slot, Weight, is a 16-bit signed integer of the weight value in weight units

or divisions, that is for download to the IND780 as a tare or target value. The second word

of slot 2, Command, consists of command bits to trigger a write of the 1st word output value

to the IND780, and to trigger scale functions and set I/O in the IND780. The second word is

expanded to show the tag names of the individual bits. Note

: Decimal bit numbers are shown in the Description column (which is added by the

user). Octal bit numbers can also be used in the IND780 Terminal. Refer to the IND780

Terminal PLC Interface Manual for more details on the data definitions.

RSLogix5000 View of Integer/Division Output Tags - 2 message slots

(description added by user)

Floating Point Data Format

The floating-point data format reports the weight data with numeric data encoded in IEEE

754, single precision floating point format. The floating point format provides four 16-bit

words of input data and three 16-bit words of output data per Message Slot. Up to 12 message

slots are available and each can be assigned for a specific scale channels data.

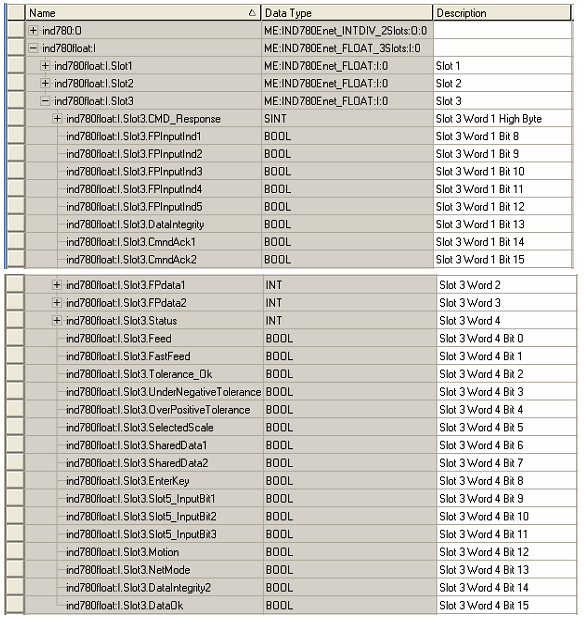

Below is the view of an IND780 device

Floating Point Input Tag

with 3 message slots,

with the third slot expanded to show the four words, Command Response, Data1, Data2, and

Status. The high byte of the 1st word of the message slot, CMD_Response, includes bits to

indicate the type of data that is being sent in the floating point input words and the

command acknowledgement status bits. This SINT is expanded to show the bit tag names. The

low byte of this word is reserved and not shown in the display. The 2nd and 3rd words,

FPdata1 and FPdata2, together represent the 32-bit single precision floating point value of

the scale data that has been requested with the Discrete Write command. The 4th word,

Status, consists of status bits to indicate scale and I/O statuses, and is expanded below to

show the bit tag names. Note: Decimal bit numbers are shown in the Description column (which is added by the user).

Octal bit numbers can also be used in the IND780 Terminal.

Refer to the IND780 Terminal

PLC Interface Manual for more details on the data definitions.

RSLogix5000 View of Floating Point Input Tags - 3 slot example

(decimal bit number)

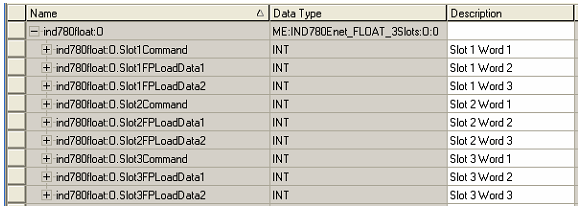

Below is the view of an IND780 device

Floating Point Output Tag

with 3 message

slots, with each slot expanded to show the three words, Command, FPData1, and FPData2. The

1st word of the message slot, Command, is used to instruct the IND780 on what data to send

for the Discrete Read data, to write the floating point load word value into the IND780, and

to trigger scale functions and I/O. The 2nd and 3rd words, FPLoadData1 and FPLoadData2,

together represent the 32-bit floating point load word value that is to be sent to the

IND780.Note: Refer to the IND78r0 Terminal PLC Interface Manual for more details on the command

definitions.

RSLogix5000 View of Floating Point Output Tags - 3 slot example

(decimal bit number)

Provide Feedback