Recreating products and processes in the digital world can unleash new insights and efficiencies in your physical operations. Whether you’re designing and commissioning machines, or managing production in a plant, digital engineering can help you get to market at record speeds, reduce your risk and redefine productivity.

A Better Way to Work

Improve Your Products and Processes in a Digital Environment

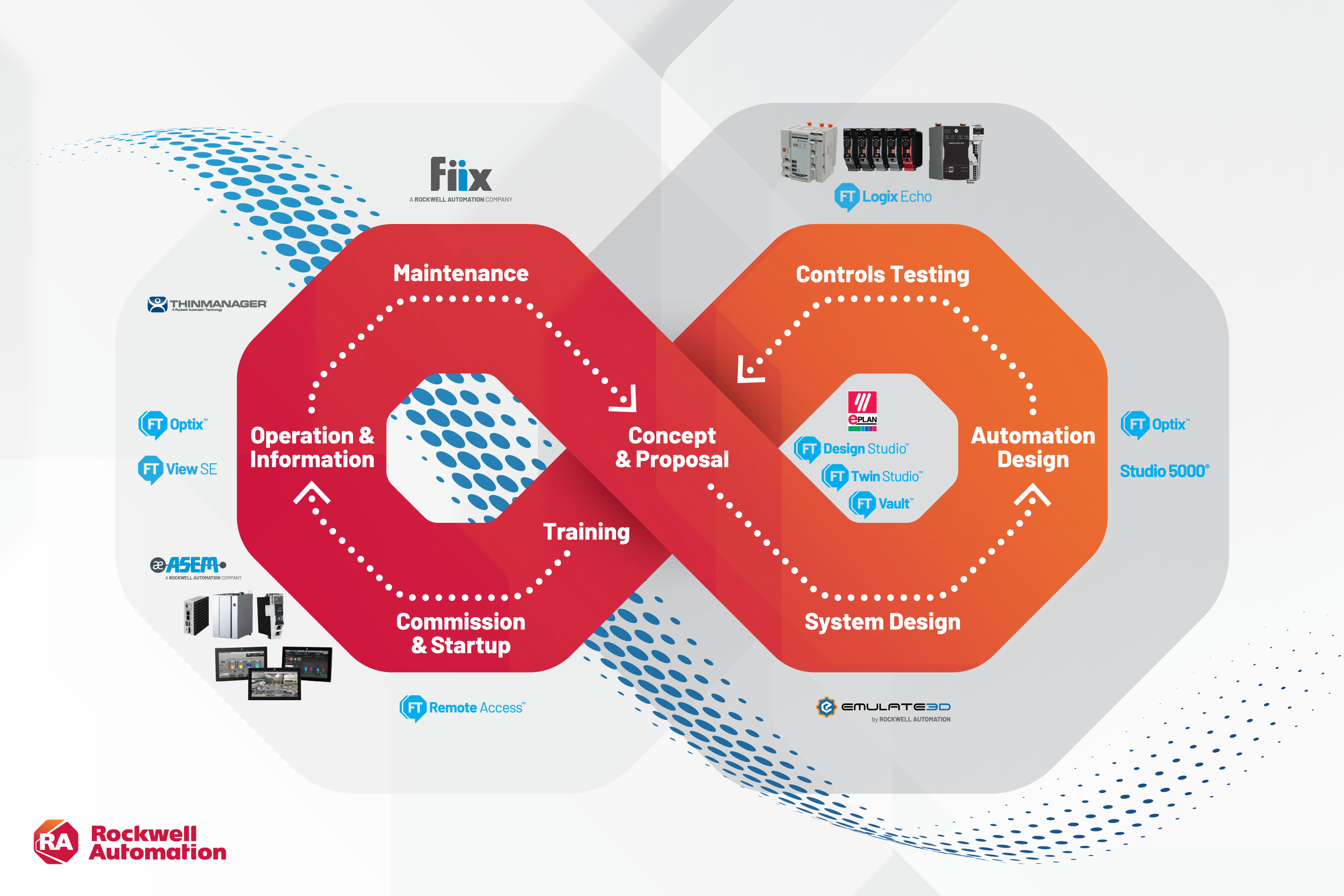

Digital twins, advanced analytics and augmented reality are forever changing how automation systems are designed, operated and maintained. But for many, these capabilities are so big and broad that their value is hard to grasp. A digital twin, for example, can improve a machine design or production process in nearly unlimited ways.

This is why it can be helpful to first look at how digital engineering is changing the ways we work today. Then, once you have a better understanding of the technology, you can decide which use cases for deploying it are right for you.

Unlock the potential of your Digital Engineering

Sign up for your free exclusive workshop and learn how to connect your engineering technologies across every step of your projects, for better productivity, collaboration and product quality.

Our workshops can be run at your place of business or online, depending on your preferences. At the end, you’ll receive a range of free trials and incentives to help you explore our solutions with your own use cases.

Discover a Better Way to Design

How you design machines isn’t overhauled with digital engineering. It’s elevated. Your processes and tools can stay the same. But before you build a design in the physical world, you can test it in a virtual one.

You can create a digital twin of your machine in the form of a 3D model and apply physics to it. See how it behaves on its own, with other machines and with operators. Even slip on a VR headset and watch it run as if you were standing in front of it. Then, you can fix any problems or make any improvements with just some clicks, rather than days of labor.

And that’s only the start. Because you can pass on a digital twin to a customer to help them optimize a machine over its life. And you can reuse it to create similar machines for other customers without rebuilding them from scratch.

Avoid Surprises in Commissioning

Save Time and Reduce Risk with Virtual Commissioning

Commission faster and reduce the risk of last-minute surprises by using a digital twin to test machines earlier in the project cycle.

When a machine and its control system meet for the first time at a customer’s site, there’s a risk they won’t be aligned. But with virtual commissioning, controls testing can be done while a machine is still in an OEM’s shop. This can make sure problems like controls-integration or line-sequencing issues are seen and solved before a machine goes on-site.

Unlock New Levels of Productivity

Help Production Workers Confidently Operate and Manage Machines

Take productivity to new levels when you use digital simulations and data-based insights to improve training and production decisions.

Training Without Limits

Training in the real world has its limitations. There are only so many scenarios workers can learn. And equipment isn’t always available.

Break free from these limitations by training workers in a virtual environment. Simulate different scenarios to help workers learn not only ideal operations but also how to respond to events like faults. Allow workers to make and learn from mistakes without disrupting production. And require that they show competency before they touch real controls.

Knowledge-Driven Operations

Make better decisions in almost every aspect of production with digital simulations and better insights.

Compare what’s happening in your physical operations to what’s possible based on a digital model. And virtually test changes like new product runs. This can help you identify issues like machine misconfigurations or downstream bottlenecks before they happen in your real process.

Detect process anomalies and stay ahead of downtime using advanced analytics with machine learning that are embedded in a controller. And give operators the data they need to optimize productivity, quality and uptime by using the right communications software.

Reduce Your Downtime

Predict Problems Before They Happen and Speed Up Repairs

Real-time insights into your systems and machines is essential to keeping production up and running. Here’s just some of what we can help you do:

- Quickly address problems with information appliances that can detect devices on your network, collect their diagnostic data and alert workers of issues that may require maintenance

- Prevent downtime by using predictive analytics that can learn your processes and identify machine issues before they happen

- Monitor network health and quickly respond to switch-level alarms using network-management software

- Improve MTTR by virtually training technicians on problems before they happen in production and by using AR technology to overlay digital work instructions on top of physical assets

- Recover faster by using asset-management software to store application code and device configurations

Innovate and Improve

Use Information to Expand Possibilities in Your Operations

Project cycles never end, whether you’re an OEM or end user. You’re always trying to innovate, improve and extend the life your machines and production processes.

The data and connectivity in today’s smart devices and systems allow you to redefine what’s possible in your offerings. You can use data from the life of an asset to help it run longer. You can use AR technology to demonstrate products or machines for customers with a physical asset. Or even bring OEMs, automation vendors and end users together into a virtual plant long before you sketch a machine design or pour concrete into the foundation.

Connect With the Best

Find Partners that Can Help You Design, Build and Maintain Better Solutions

Our global ecosystem of solution and support providers can help drive the speed and success of your automation project. Partner program members have experience delivering products or services that are designed to work with our solutions. And they take a collaborate approach to help you simplify project implementations and get the most value from your investments.

Recommended for You

Others also viewed

Based on your activity