Increase Pulp and Paper Production and Reliability

Maximize Uptime with Modern, Sustainable Pulp and Paper Mills

In an evolving industry like pulp and paper manufacturing, you must keep up with global competition, get the most value possible from your current assets and improve reliability. Smart systems and technologies make it possible to develop a truly connected mill, increasing visibility and automating key stages of the pulp and paper production process to simplify operations, maximize productivity, and improve quality.

Improvements in visibility and reliability can translate into increased efficiency and throughput while minimizing risk. Whether you would like to reduce your energy consumption and waste, modernize legacy assets or make better use of the data you generate, we can help.

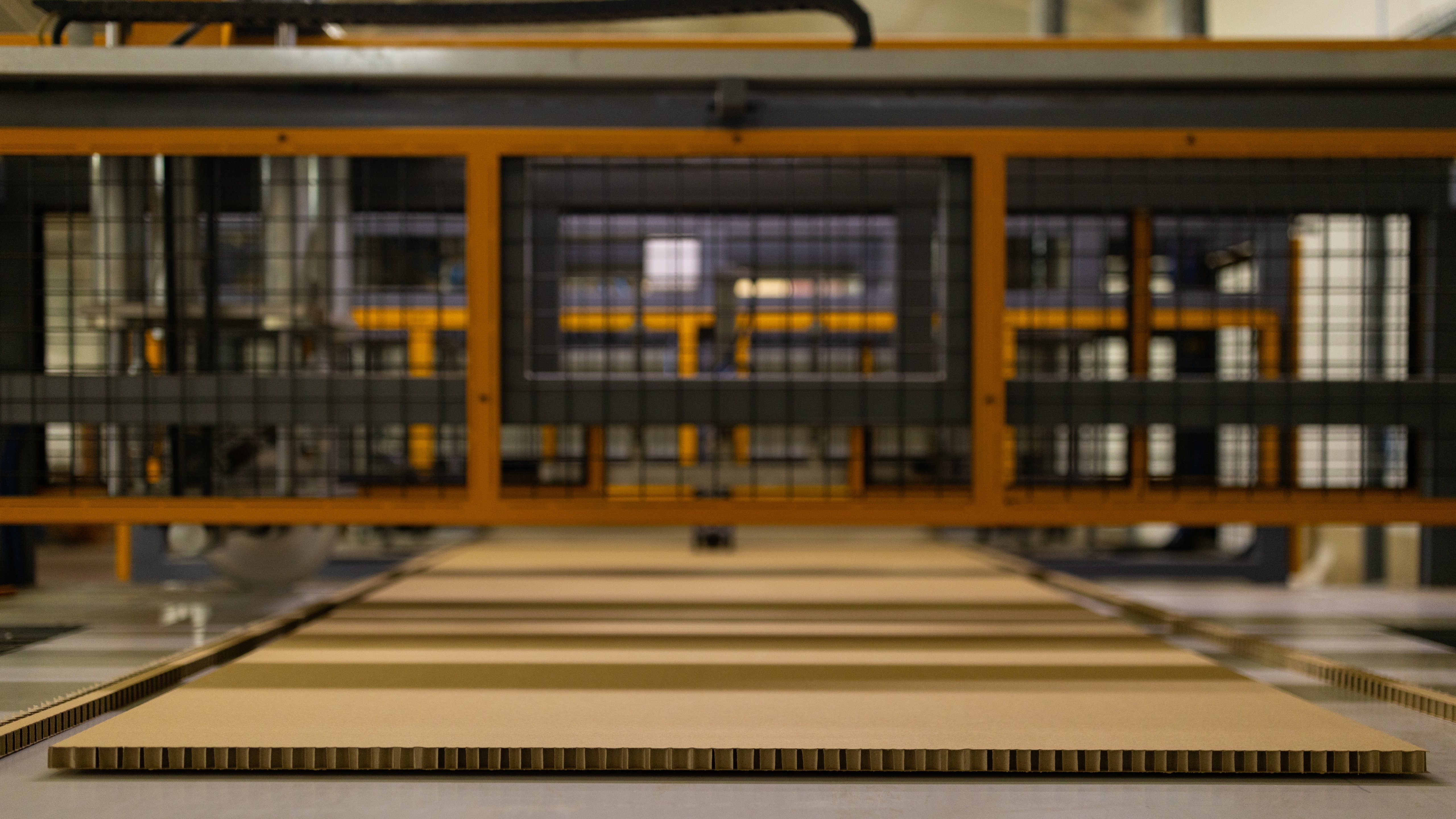

Together with our global partner network, we provide the services, expertise, and world-wide support to deliver end-to-end pulp and paper mill production solutions. From the wood yard to finishing and shipping, we can help you modernize your mill to increase visibility, reliability, and productivity—all while minimizing waste and risk.