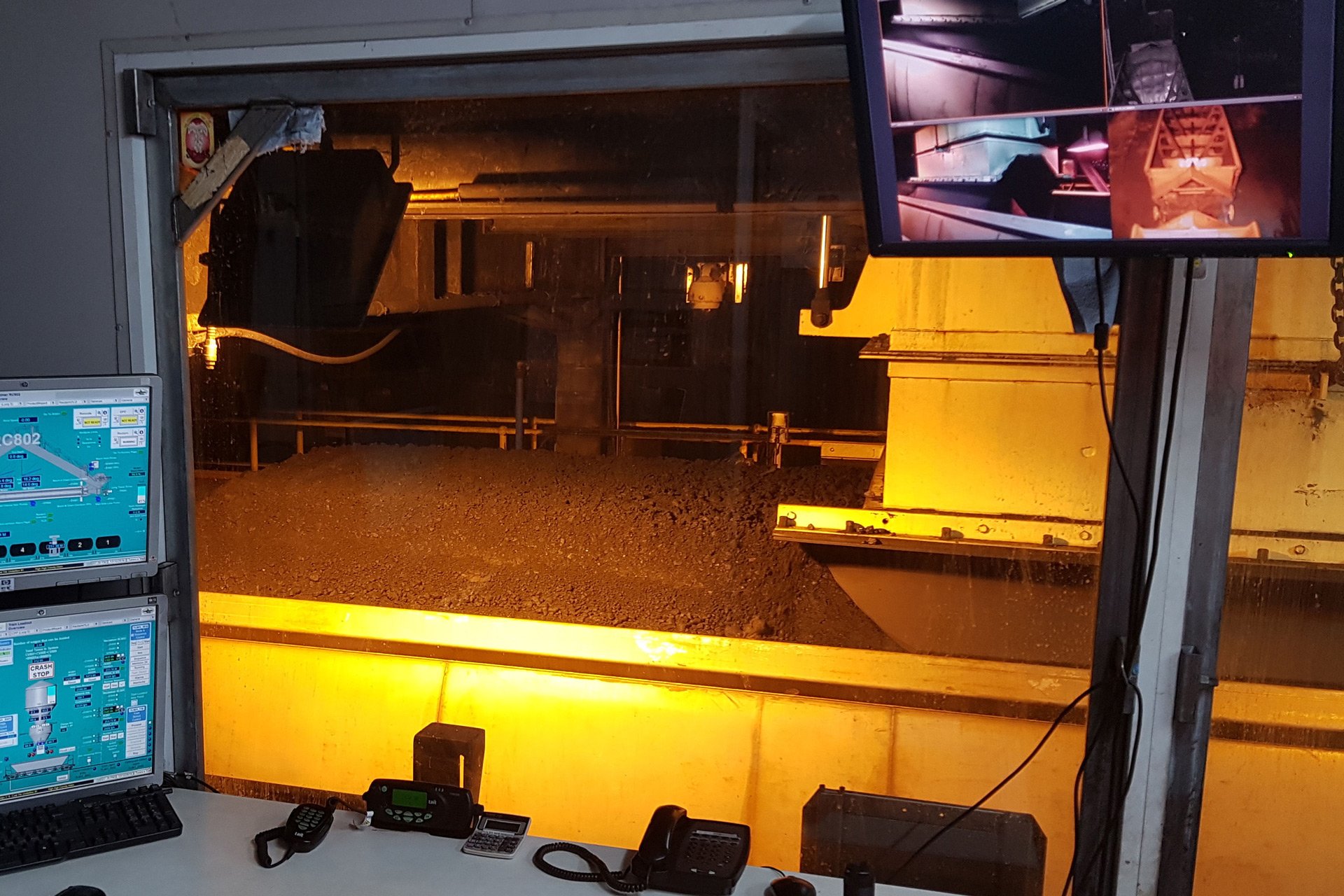

The automated TLO is monitored from the central control room

Challenge

- To automate the train load out process at German Creek for improved reliability and profitability

Solutions

Automated control

- Allen-Bradley® ControlLogix® controller provides the functionality required for automated TLO

Seamless integration & communication

- Allen-Bradley ControlLogix integrates seamlessly with MRA’s automated TLO system via Ethernet/IP communications using a Stratix™ switch

Results

Automated loading

- The automated TLO provides efficient and reliable loading

- TLO system accounts for variables such as environmental conditions, time of day and operator fatigue

Ease of commissioning

- Detailed simulation prior to commissioning reduces downtime

- Remote commissioning by accessing the controller online provides increased efficiency and flexibility

Unrivalled ROI

- ROI of less then four months for the system

- Solution provides significant ROI per month

Automating the TLO process delivers improved capacity, profitability and safety at Anglo American’s German Creek mine

The reliability and efficiency of the train load out process at coal mines can be a ‘make or break’ when it comes to meeting production timelines and profitability.

Anglo American is the world’s third largest exporter of metallurgical coal. The company uses the latest technology to run their operations in the best possible way and strive for continuous improvement at existing assets.

Train loading stations are often considered a bottleneck, as these facilities are typically operated manually resulting in variable performance, wagon over or under loading and poor reliability. As a result, companies are often faced with heavy fines and in some cases substantial costs to obtain additional trains to meet required throughput.

MRA Electrical & Automation Engineering (MRA) was initially involved in the first automation of a train load out (TLO) in Australia more than fifteen years ago. As such, the company has a detailed understanding of the systems required.

At that time there were some limitations in the technology that resulted in some shortcomings of the early systems. These limitations culminated in issues with accuracy and environmental conditions. To address this, MRA conducted extensive research and development, using the latest technologies to overcome these shortfalls and develop an efficient and reliable automated TLO solution.

When Anglo American tasked MRA with automating their TLO process at the German Creek coal mines, the result exceeded expectations and provided an intelligent and intuitive system that not only improved efficiency and reliability but also delivered a state of the art solution with an unrivalled return on investment.

Clever control technology

Initially MRA investigated primarily vision based systems, but were subject to accuracy issues as a result of changing environmental and weather factors such as sun, rain and fog. As laser and sensing technologies advanced, they provided a more reliable alternative that is not as vulnerable to the effects of these often harsh mining environments.

According to Stephen Mount, general manager at MRA, “We built the robust automated TLO system on the fundamentals of train speed and position to improve the accuracy of the process. The raw data is filtered and moved into our system to perform the correct analysis to overcome any issues with environmental conditions.”

There are three major components to the system, the first being the sensors in the field, the laser scanners and RFID tag reader; the second is the PC-based server that performs all the filtering and analysis of data prior to communicating to the PLC, the third component of the system.

“The system architecture of this TLO demonstrates the power of the ControlLogix platform for data processing and integration as well as control,” said Geoff Irvine, mining industry manager, Rockwell Automation.

The Allen-Bradley® ControlLogix® PLC is programmed to provide centralised control for the entire TLO process. The MRA system has been engineered to integrate seamlessly with the controller via Ethernet/IP communications using point to point networking via a Stratix™ switch.

“We incorporate as much functionality as possible inside the Logix controller which delivers unmatched fault-finding capabilities and advanced integration between the PC and controller,” explained Peter McPherson, engineering manager at MRA.

“Laser sensors detect information about the wagon location that is communicated to the Logix controller. Also, information about coal profiling is concurrently fed back to the controller which is programmed to analyse this information and provide advanced feedback control of the TLO process in real time,” he said.

Automated loading

Prior to the automation of the TLO process, operators were only able to load wagons based on the available tools at their disposal. However, significant advancements in automation technology has enabled operators to consistently load train wagons with uniform and symmetric profiles to meet coal height and bogie loading requirements.

Automation technology enables operators to consistently load train wagons

“There are substantial penalties involved if a train is not loaded correctly with the right profile over the bogies. Over loading results in significant penalties but there is also an issue with under loading that needs to be considered. By under loading, each wagon is losing capacity, which directly impacts on efficiency and profitability, but it also entails a safety issue and risk of derailment. Reducing weight variations in order to optimise the amount of coal loaded per train is the ultimate goal in automating the TLO,” explained Mount.

Considering variables such as operator fatigue, time of day and environmental conditions presented challenges for MRA in developing the automated TLO system. To address this, MRA’s solution was developed to use predictive modelling and advanced filtering methods to compensate for aberrations in raw data and also allows for environmental compensation through scanning methods and adaptive software.

The Logix controller provides the platform for feedback control and real time output of data through Ethernet/IP communications. This use of smart technology with self-diagnostics and alarming provides an intelligent and intuitive system that removes the guesswork for operators. By automating the TLO, the operator performs a supervisory role either from the TLO or a central control room during loading to monitor the system.

According to Anthony Manousso, Capcoal Control System Coordinator, Anglo American, “When you automate a process, you have to consider all the variables in the design and commissioning phase. We did that and the way the system is running now, the operators can sit in the control room and monitor the process. The operator interface is easy to use so training requirements are minimal.”

The TLO is an integral part of the pit to port operation

Remote commissioning reduces downtime

When it comes to a TLO, time is money and therefore any amount of time that the system is down has direct impact on profitability. One of the features of MRA’s TLO system is that the outage time for installation is minimal. “It took less than a day’s downtime to go from the existing system at German Creek to the new automated TLO. The bulk of our commissioning is done remotely by accessing the PLC online to make any required changes, which saves significant costs with no need to go to site,” said McPherson.

“Once the scanners are installed prior to the cutover we record live data from the site and undertake detailed simulation prior to installation to make sure it’s working as per the specification. This reduces not only the commissioning time but also the need to delay trains post installation,” he added.

Impressive return on investment

Having been in operation for approximately three years now, German Creek has recorded real time results indicating a return on investment of less than four months for the TLO automation system.

Prior to the upgrade, the subjected TLO was consistently achieving average payloads in the order of 9100 to 9300 tonnes per train. Post upgrade, the subjected TLO is now averaging 10,000 tonnes per train. “With this monthly average increase of approximately 700 tonnes per train, based on 40 trains per month, this equates to an approximate efficiency gain of significant returns per month,” said Mount.

Post upgrade, the TLO is now averaging 10,000 tonnes per train

Automating the TLO also provides significant benefits in terms of improved safety by reducing the risk of derailment from under loading, which can also have detrimental environmental effects resulting from spillage. In addition, automation of the TLO process removes operators from potentially hazardous situations and fatigue issues can also be avoided.

“The coding that MRA developed within the ControlLogix PLC is extremely efficient and reliable. We are now using it for 98 percent of loading with only 2 percent being loaded manually as a result of external factors. This TLO system is an integral part of our pit to port operation - the end goal is to make sure our trains are fully loaded,” explained Anthony Manousso.

Company background

Rockwell Automation Australia and Rockwell Automation New Zealand are subsidiaries of Rockwell Automation, Inc.—a leading global provider of industrial automation and information solutions that helps manufacturers achieve a competitive advantage in their businesses. The company brings together leading global brands in industrial automation which include Allen-Bradley® controls and services and Rockwell Software® factory management software. Its broad product mix includes control logic systems, sensors, human-machine interfaces, drive controllers, power devices, and software.

Rockwell Automation, Inc. (NYSE:ROK), the world’s largest company dedicated to industrial automation and information, makes its customers more productive and the world more sustainable. Headquartered in Milwaukee, Wis., Rockwell Automation employs approximately 22,000 people serving customers in more than 80 countries.

Allen-Bradley, ControlLogix, Rockwell Software and Stratix are trademarks of Rockwell Automation, Inc.

Ethernet/IP is a trademark of the OVDA.

Media contact:

Christine Filippis

Teraze Communications

61 3 8391 0701

christine@teraze.com.au

Published February 28, 2017

Recommended For You