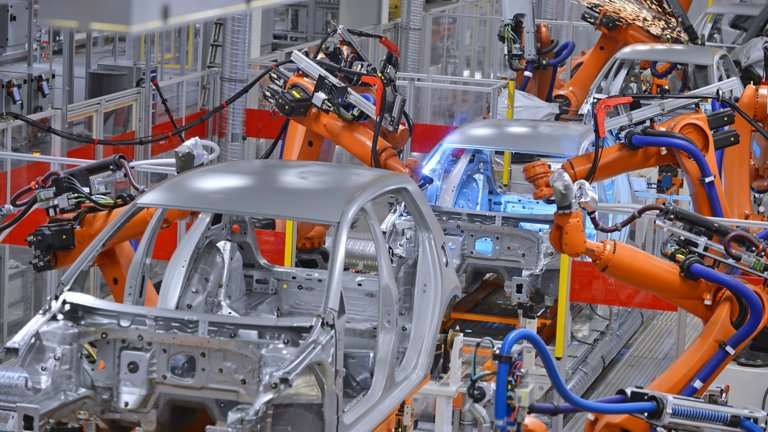

Take control of your plant floor with full visibility into your production lifecycle and full connectivity to your manufacturing Enterprise Resource Planning (ERP).

Key Capabilities: Take Control of Your Shop Floor

Plex MES is a comprehensive manufacturing software solution that provides real-time, paperless production management to drive enterprise-wide compliance, quality, and efficiency.

With Plex MES, you’ll gain control of your plant floor with a comprehensive view of your entire production lifecycle and full connectivity to your ERP. You’ll easily automate tasks, help prevent errors, drive in-line quality, and synch up the top floor with the plant floor. The result? Less risk, higher quality, happier customers and a healthier bottom line.

Plex MES offers the flexibility and functionality required to enable smart manufacturing. Key capabilities include:

- Production finite scheduling to determine which jobs to schedule to which work centers, with resource availability in mind

- Close-loop quality management to maintain quality procedures directly from the control plan for increased process repeatability and predictability

- Inventory management to track and manage your inventory in real time, and stay in control with end-to-end traceability

- Production management to make the right quantity of the right product at the right time for improved overall equipment effectiveness (OEE)

Say goodbye to paper and manual spreadsheets and hello to maximum efficiency, productivity and visibility! Plex Manufacturing Execution System (MES) is the only single-instance, multi-tenant cloud-based SaaS production platform that operates at scale. This allows for a common production ecosystem that supports a real-time, single source of data. It can tie production and inventory to quality with end-to-end, detailed traceability. With Plex, you can connect people and systems, automate processes, track data from end to end, and capture and analyze information like never before.

8th Annual State of Smart Manufacturing Report

As a manufacturer, you are navigating a complex landscape: aiming for increased profitable growth without sacrificing quality; stretching to make operations more sustainable; and tackling workforce and supply chain challenges.

What can we learn from our common struggles? And how can we leverage global trends to achieve our own goals?

Download the 8th State of Smart Manufacturing report to uncover how leading manufacturers are leveraging technology to improve quality and drive higher profitable growth.

Plex MES Delivers Real Value

What Problems Does Plex MES Solve?

Today’s manufacturers need to increase resilience in their operations—no one can afford to be mediocre at anything they’re doing in manufacturing. If manual processes and disconnected systems are causing your organization to experience any of the challenges below, your operation will benefit from the Plex MES.

- High levels of scrap and rework

- Excessive inventory carrying costs

- Traceability issues

- Limited visibility into work-in-progress

- Missed production schedules

- Poor production throughput

- Extreme errors

- Operating with old data

- Slow reaction times

With Plex MES, the paper chase ends. Control, transparency, and synchronization become your “modus operandi”. New levels of performance are achieved and doing more without adding more becomes the norm.

How Can a Cloud Solution Transform Your Operations?

Drive better visibility

Gather real-time and accurate material and traceability data to make sure that your production is always running smoothly.

Cut costs

Streamline operations to reduce the time it takes to make each product, decrease downtime, and minimize waste.

Increase productivity

Choreograph production processes directly from the control plan to shorten cycle times and improve efficiency. Eliminate manual process errors with paperless operator control.

The Total Economic Impact™ Of Plex Smart Manufacturing Platform

How did a food manufacturing company achieve an ROI of 412% with the help of the Plex Smart Manufacturing Platform? With its cloud-based Smart Manufacturing Platform, Plex transforms manufacturers’ understanding of their production processes and how to improve them.

Plex, by Rockwell Automation, Recognized by Gartner as a Leader in MES

The 2022 Gartner® Magic Quadrant™ for MES Report recognizes Rockwell Automation as a visionary for its FactoryTalk® ProductionCentre and Plex as a leader for its Smart Manufacturing Platform.

Get an overview of the vendor landscape and the dynamic MES marketplace from an independent source.

Gartner, Magic Quadrant for Manufacturing Execution Systems, By Rick Franzosa, Christian Hestermann, 31 May 2022

Plex was acquired by Rockwell Automation and is recognized in this report as Rockwell Automation.

Gartner and Magic Quadrant are registered trademarks of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission. All rights reserved.

Gartner does not endorse any vendor, product or service depicted in its research publications and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s Research & Advisory organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.