Head to Houston for the 2017 Automation Fair® Event

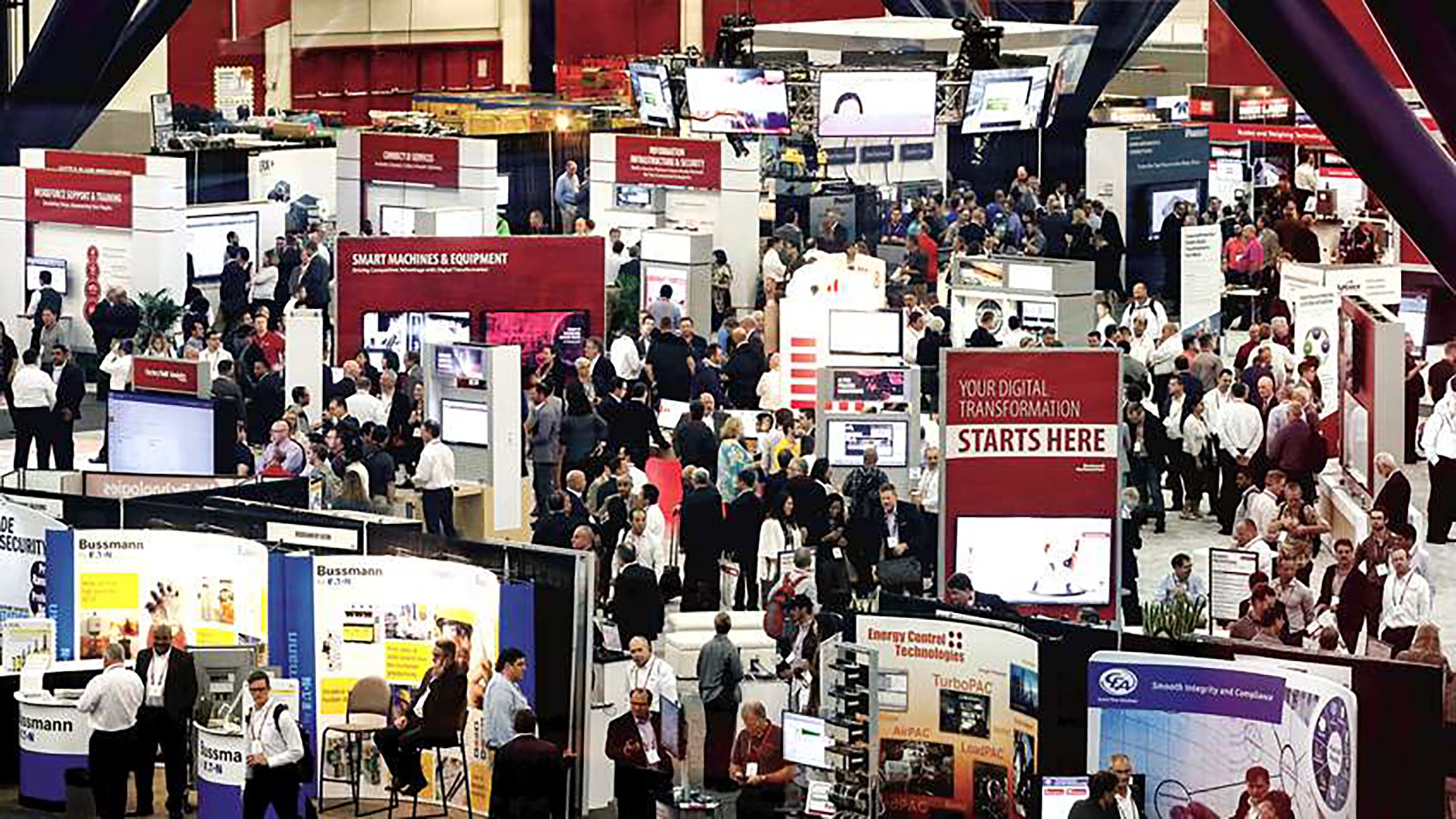

The Automation Fair® event is taking place on Nov 15-16 at the George R. Brown Convention Center, in Houston, Texas, U.S. This annual event brings together Rockwell Automation and its comprehensive, global network of partners to help manufacturers learn about the latest technologies and trends in a single venue exclusive to manufacturers and producers around the world.

Last year at the event, there were more than a hundred of industry forums, user-group meetings, hands-on labs, technical sessions and demonstrations hosted for over 11,000 visitors to learn and use of the latest control, power, and information technologies.

This year, the event uses over 45,000 square feet exhibit floor featuring more than 140 exhibitors from Rockwell Automation and its PartnerNetwork™ program, showcasing their latest products and solutions.

There will be 19 hands-on labs, over 90 technical sessions and nine forums that give visitors opportunities to learn best practices for their operations.

The popular hands-on labs, offered up to four times a day, allow participants to work directly with Rockwell Automation products. Technical sessions are 60-minute presentations from leading industry and product specialists, and the forums provide real-world examples of how companies have increased their productivity and improved efficiency. Visitors are encouraged to sign up for hands-on labs, technical sessions and forums in advance to help plan the day ahead.

There are also co-located events that will be held prior to the opening of the Automation Fair® event, including – the Process Solutions User Group (PSUG) annual meeting on Nov 13-14 and Automation Perspectives, a global media forum, on Nov 14. Executive leadership and industry authorities will share their vision, strategies and real-life business experiences relating to smart manufacturing and The Connected Enterprise®.

*There is an admission charge for the PSUG event.

The Automation Fair® event is free, including lunch and refreshments.

Online registration is now available and will remain open through the event. Details and session schedules are available on the Automation Fair® event page website. Registration for the event as well as sessions can also be done via the online system.