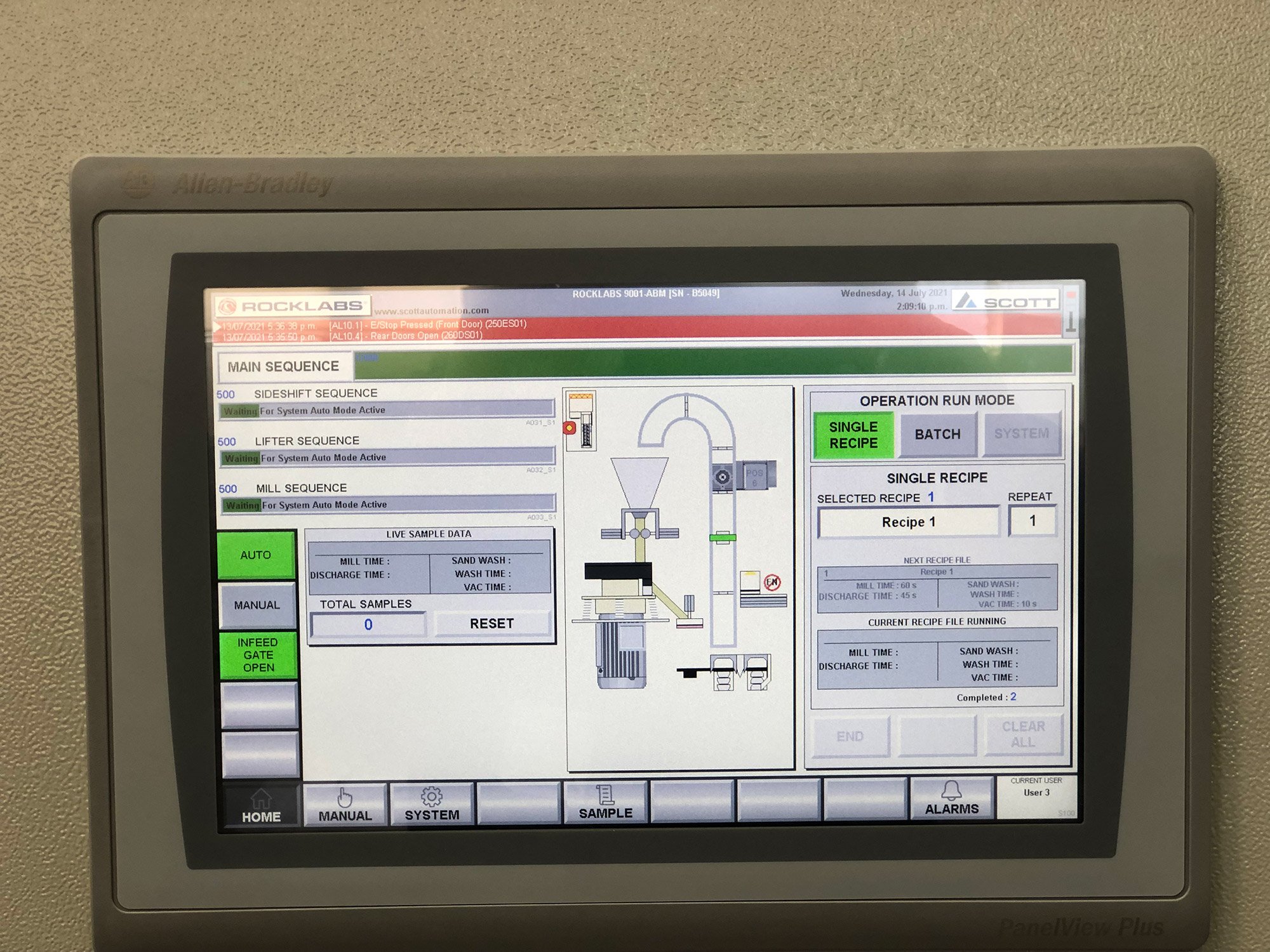

Rocklabs ABM3000 (Automated Batch Mill)

Scott is a world-class builder of advanced automation systems for the appliance, meat processing, mining, materials handling and industrial automation industries.

As a Rockwell Automation Gold Level OEM Partner, Scott has a strong commitment to developing new technologies and bringing them to market.

Rocklabs, a Scott brand, plays a central part in the success of leading organisations in the fields of metals and minerals research, mining and exploration around the world. Through the supply of specialised equipment, Scott delivers industry leading sample preparation equipment to mining clients, commercial laboratories and research institutions.

The latest automated batch milling machine, the ABM3000, incorporates innovative smart technologies to make batch sampling as seamless as possible. It is fully programmable so that each sample can have its own grinding specifications as well as its own wash cycle to ensure no carry-over between samples.