Challenge

Eventually, the abuse takes its toll, and every few years, a machine must be pulled out of service, and retooled with state-of the-art controls and electronics before it is reinstalled.

A mining company in Illinois recently faced that proposition with one of its long-walls. But the company didn't want a run-of-the-mill upgrade. The highest productivity mine in the U.S., as measured by tons per man-hour wanted a compact, high-performing, customised electronic control package – and they wanted Rockwell Automation® products.

Enter Intermountain Electronics (IE). With 275 years of combined mining operations experience among its leaders, engineers and project managers, IE designs and installs custom electrical distribution and control equipment.

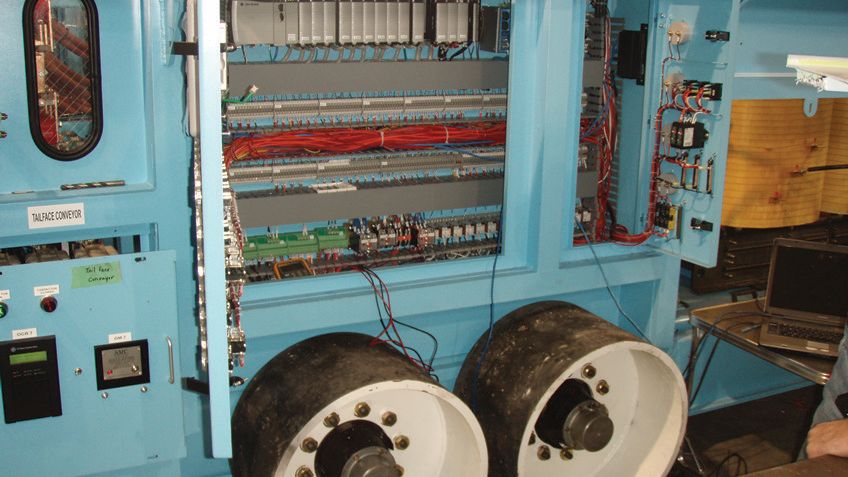

“We've worked with Rockwell Automation for years, which really helped us with this client because they wanted to standardize on Rockwell Automation control system equipment,” said Pat Lemmon, project engineer, IE. “In this case, the challenge was the real estate we had to

work with.”

Lemmon was referring to the small space available to house the new variable frequency drives (VFD's) that would power the machine's motors. The enclosure could be just 72 inches high. However, the VFDs that the mining company wanted are usually mounted vertically and stand 91 inches tall.

Additionally, much of the allotted control space needed to be reserved for ventilation or coolant systems to protect the power equipment from overheating. That added an additional layer of complexity to the existing space limitations.