Based in Prato Sesia, Novara, Italy, Cavanna Packaging Group has an admirable philosophy: “to offer innovative technology with respect of man: from the security of those who use our machines to the health of those who consume the product of our customers”.

Founded in 1960, the company counts many leading global brands as customers, where more than 6,000 of its flow packing and cartoning machines – many equipped with vision-guided robots – carefully package countless styles of food and confectionary, along with products from non-food, cosmetics and pharmaceuticals.

“Our machines must offer high reliability and efficiency,” explains Luca Durante, Head of SW engineering at Cavanna. “We also have to factor in other operational metrics, such as sustainability, flexibility, small batches, and wider product ranges, while never losing sight of the primary goal of creating high-quality packaged products for our customers.

“Most of these challenges are addressed highly effectively by the deployment of advanced automation technology,” he continues, “but it is also essential to consider the human factor and operator involvement too. Even though the machines may be technologically complex, we must think about the workforce operating and maintaining them at our customers and make them easy to use. This is why we look to create the clearest and most intuitive HMI experience.”

A window into your system

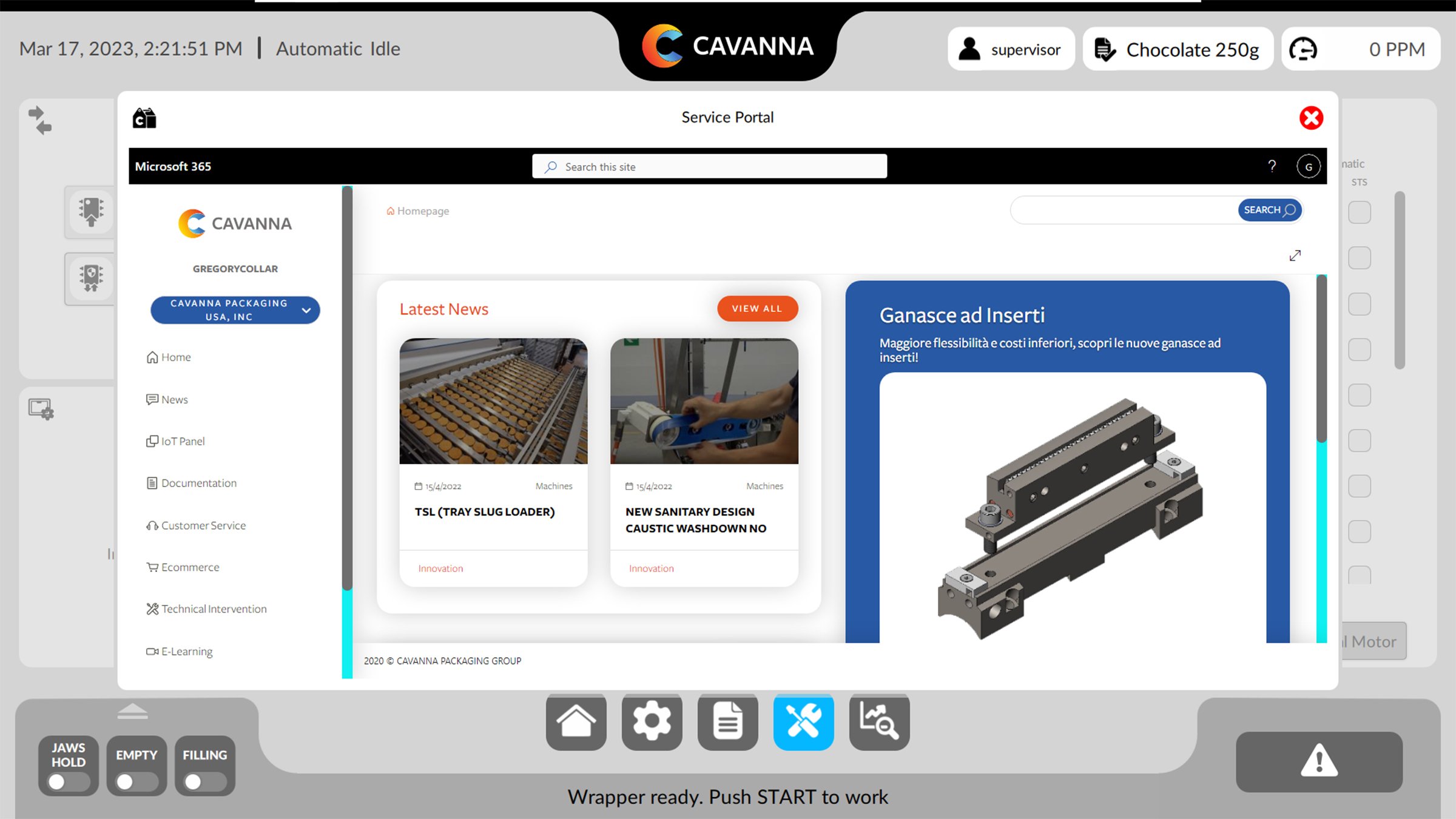

Much like websites becoming ‘shop windows’ into companies, HMIs perform the same role for machines. Giving information to viewers, clearly and unambiguously. But with society now used to the slick designs and style sheets used by modern smart phones and the latest desktop operating systems, some more traditional industrial user interfaces have not aged well.

“This is why we have adopted the FactoryTalk® Optix™ HMI Visualization Platform and OptixPanel™ graphic terminals from Rockwell Automation,” Durante explains. “Our customers are demanding better performance, bigger screens, modern graphics and more user-friendly and intuitive interfaces.”

When quizzed about his company’s HMI/SCADA choice, Durante explains: “The brand is important for Cavanna and we know that Rockwell Automation is present in the markets we serve, both established and new/growing. Another major point is that the open development environment supports a wide variety fieldbus too, so we can use third-party equipment on our machines, knowing that we have a flexible and scalable design solution and interface that will deliver all the necessary interactions, including those with higher-level MES solutions.

Hardware & software combine for clarity

“The combination of these two technologies allows us to create well designed, responsive, and media-rich interfaces, that are very similar to those on modern smartphones,” Durante continues. “We can use pastel colors for information and brighter, bolder colors for warning and alarms. They deliver a much better user experience, not just for us, but also for our customers.”

Durante explains numerous other customer benefits. “It’s CFR 21 Part 11 basic and advanced compliance, with active directory support. You can store and export data, such as alarm historian, variables data logs and audit trails, in csv/pdf formats, while the integrated apps, including an internal browser and PDF reader, give users access to interactive documentation. It’s fast and easy to learn, thanks to the screen organization and the scroll functionality that improves the navigation experience, again, much like a smartphone. Finally, the guided parameterization helps users to modify system variables.”

For Cavanna internally, development is easier too, as the FactoryTalk Optix platform offers a collaborative cloud-based design environment, deployment on multiple HMI formats, extensive library management, IOT-native connectivity and comprehensive OPC UA support.

“Our machines must offer high OEE,” Durante concludes, “which can be more than 95% for a complex packaging line with primary, secondary and tertiary machines and robots. It must also deliver a lower total cost of ownership and fast return on investment. We must also consider extended warranties, which can be as much as 15 to 20 years. It is therefore essential that we deploy technology and operating environments that we know will stand the test of time.”

Our FactoryTalk Optix HMI Visualization Platform and OptixPanel™ graphic terminals are just a small part of our extensive digital offering. Click here to discover our full range.