An integrated automation architecture lays the foundation to bring Industry 4.0 concepts to life. It helps you access the right information at the right time to make critical operational decisions. Additionally, it enables easy integration of equipment into your plant and allows you to pivot quickly based on fluctuating market demands.

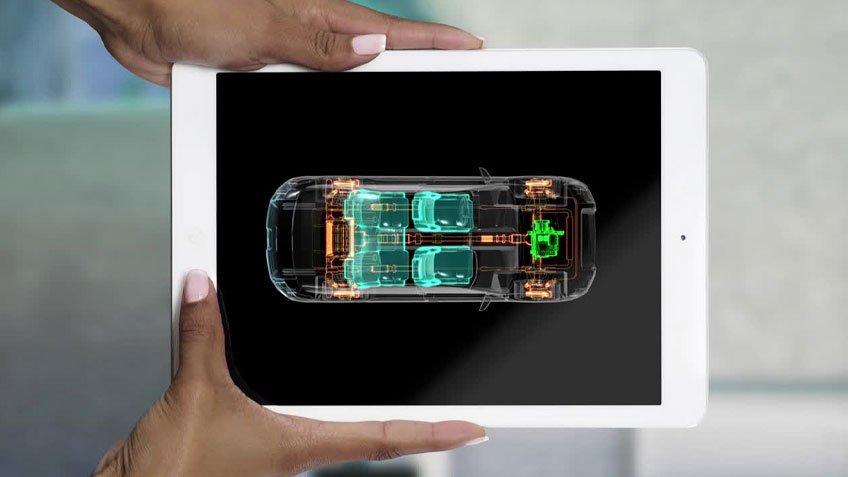

An integrated architecture uses control and information systems that share a standard network, control platform, data structures, and design environment.

A single network, for example, can seamlessly connect your plant systems to each other and to the rest of your enterprise. Also, shared, standardized data structures can help you more easily pull data from across your operations and turn it into actionable information for workers.

With this in place, you can deploy smart technologies and capabilities that can help your electric-vehicle operations run faster and with more flexibility. Some solutions to consider using include:

- Scalable Infrastructure: These offerings can help you converge your networks, connect your plant and business systems, and give your workers access to information to make better decisions. Infrastructure-as-a-service (IaaS), for example, can reduce the burden of designing, deploying, and maintaining your network infrastructure. It combines pre-engineered network products, on-site configuration, and 24/7 remote monitoring into one contract.

- Independent Cart Technology: This is a real notable change for electric-vehicle production. It allows you to move small components such as batteries and electric motors, or even full car bodies, around a plant faster and more precisely than conventional mechanical solutions. Changeovers can happen quickly, with the push of a button. So, with fewer moving parts, these systems can reduce your maintenance needs to improve uptime.

- Modular & Scalable MES: Individual manufacturing execution system (MES) applications can help you understand and manage production without investing in a full MES software. The applications address specific challenges, like quality, machine performance, or genealogy and track and trace. You can start at the machine or work-area level with a single MES application and eventually add other applications or scale up to a full MES.

To learn more, visit our Electric Vehicle Innovation Center, located in San Jose, CA.

Schedule a visit with John Miles, Global Business Leader – Electric Vehicle & Battery at RAEVICops@ra.rockwell.com.

Check out more at rok.auto/electricvehicle.