You may also be interested in

Challenge

Automobile manufacturer needed to determine which line should be used for the factory.

Solution

A simulation study not only can help engineers discover better options for developing efficient equipment, but also can save time and money from mistakes in redesign and re-fabricating equipment in comparison with conventional methods that for the most part were based on

engineering experience.

Results

The simulation was very useful in investigating the feasibility of new lines. By comparing with reference data of previous similar project quoted from the Finance Division of the company, the simulation study in this project also assisted in reducing project time in the design process (10% of the total designed time) and save costs in line modification (5% of the total equipment investment cost).

Background

Manufacturing lines play a critical and valuable role in the manufacturing system. Developing an efficient manufacturing line and bringing it to realization is the main task of manufacturing line designers. After conducting interviews with several Japanese automobile manufacturers, it was realized that manufacturing lines were traditionally designed following conventional methods that for the most part were based on engineering experience and simple calculations of worker utilization, machine utilization and line productivity with constant processing data. Simulations were not used in manufacturing line investigations.

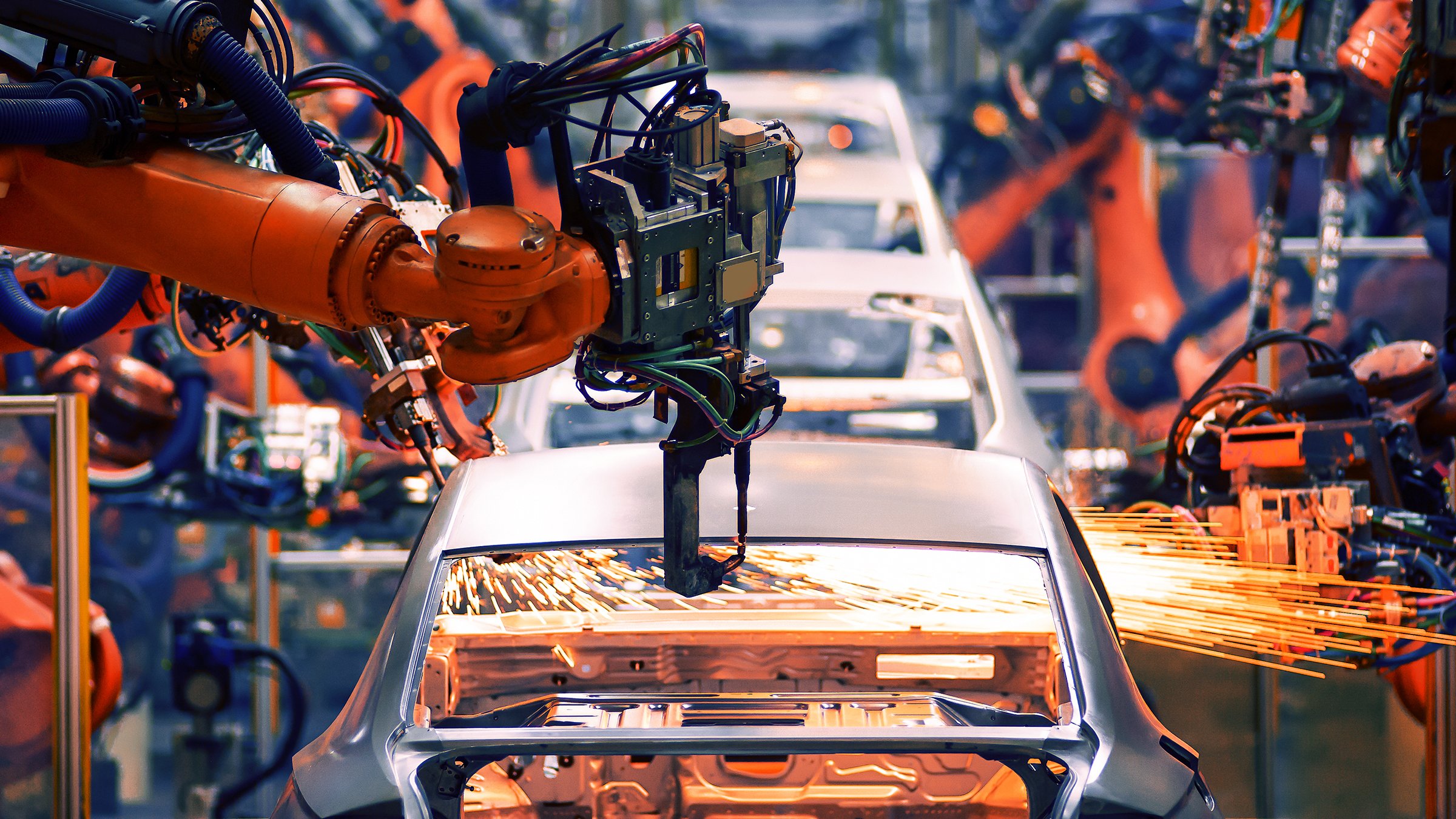

The objective of this research is to introduce a new perspective upon the framework of designing a manufacturing lines in the Japanese automobile plants. Likewise, this research will introduce the methodology of how these simulations were used for investigating design processes via case studies covering design of new welding manufacturing lines of “Company A” for a vehicle component project. The project was completed by a project team led by the author in three years and handed over to the factory in 2007.

Challenge

All manufacturing aspects, manual, automated and hybrid manufacturing lines are considered; however, which line should be used for the factory is always under investigation within the factory. In order to understand the framework of manufacturing line design, a project to design a new automobile component manufacturing line was investigated in this study, and the chosen manufacturing line was also checked by the manufacturing activities in the factory.

Solution

Arena Simulation Software was used to:

- Understand New Project Information

- Investigate whether to Make or to Buy

- Design and Make a New Manufacturing Line

- Check Actual Results of the Designed Line and Hand Over to the Factory

- Investigate the Market Demand for the Product

- Design and Modify the Line

- Check the Modifications and Re-Hand Over to the Factory

Results

After deciding the manufacturing line, the equipment and robots were purchased and fabricated, and it took nearly 8 months to make the manufacturing line. After adjusting the machines, robots and parts to ensure a good quality condition, the final trial was completed by pilot members. Five working days of trials were carried out reconfirm the feasibility of the line (due to time and budget constraints, we could not run a trial as long as the simulation conditions). The average trial result of resource utilization and line productivity were shown in Table 5. Actual trial results were very close to the simulation results because of high worker skill and the actual failure time was shorter than the simulation condition. The actual results also showed that the chosen manufacturing line satisfied the design target, this line could be handed over to the factory for manufacturing activities.

Published August 1, 2014