Recipe Editor

Use

FactoryTalk Batch Recipe Editor

to create and configure master recipes for use in batch automation. A master recipe is a type of recipe that accounts for equipment capabilities and may include process cell-specific information. The interface contains IEC 61131‑3 sequential function charts to graphically organize recipes into procedures, unit procedures, operations, and phases. Build recipes using either the SFC format or a table-based format.

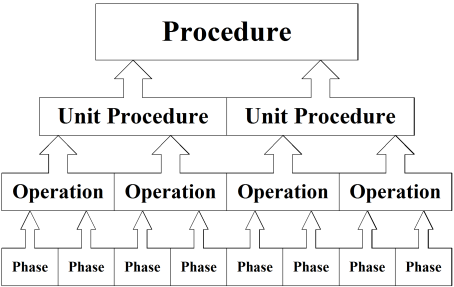

Procedural levels:

Recipes use the ISA S88.01 Batch Control Standards for configuration and display, which define these levels for the procedural model:

- Batch control: Consists of a sequence of one or more steps (phases) that must be performed in a defined order for a finite period of time to process finite quantities of input material to produce finished product.

- Procedure: The strategy for carrying out a process. In general, it refers to the strategy for making a batch within a process cell. It may refer to a process that does not result in the production of a product.Examples:Make Product AMake Product B

- Unit Procedure: A strategy for carrying out a contiguous process within a unit. It consists of contiguous operations and the algorithm necessary for the initiation, organization, and control of those operations.Examples:EmulsificationDehydrogenation

- Operation: A procedural element defining an independent processing activity consisting of the algorithm necessary for the initiation, organization, and control of phases.Examples:FiltrationReaction

- Phase: The lowest level of the procedural element in the procedural control model. A phase consists of the control steps and the algorithm necessary for the initiation, organization, and control of those steps.Examples:AgitateHeat

The recipe phase is the lowest level within a recipe. The phase provides an interface to basic control. The recipe phase maps directly to the engineered logic on the plant floor. Base an added phase on a phase already defined in the area model using the

FactoryTalk Batch Equipment Editor

. Based on the unit requirements specified in the recipe, a phase in the FactoryTalk Batch Equipment Editor

maps to a specific phase (an instance of a phase class). This phase is mapped (using tags) to equipment phase defined in the engineered logic.An operation consists of one or more recipe phases, and it must run within a single unit in the area model. Combine multiple operations into a single unit procedure if each operation runs in the same unit in the area model. Unit procedures combine to create a procedure, the highest recipe level. Procedures can run across multiple units, allowing for unit-to-unit transfers.

Provide Feedback