By Steve Wetzel, Principal Application Engineer, Southwire Company

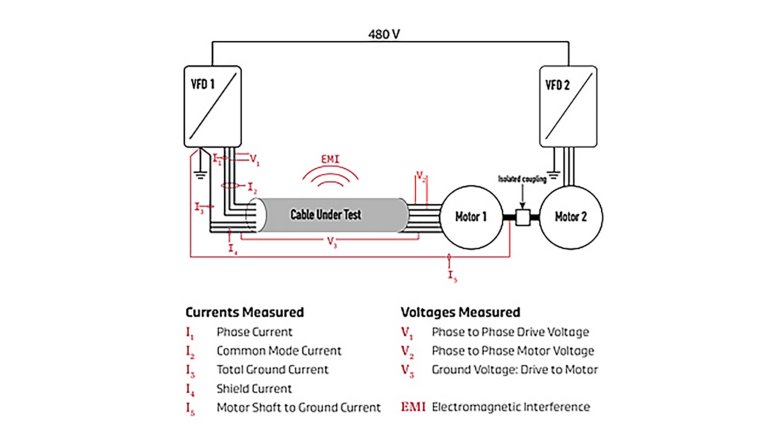

Editor’s Note: This article is adapted from the white paper, “Testing Data Shows Why VFD Cables & Installation Matters,” from Southwire Co. Download the full paper for comprehensive information about what was tested and how; testing results; the impact of cable type and installation on system performance in variable-frequency drive-to-motor operations; and the impact of cable constructions in variable-frequency drive on motor operations.

It's a simple concept, but many are shocked by the difference the proper drive-to-motor cable can make in their facility's operational performance. And, without the appropriate test equipment, the difference is imperceptible.

Variable-frequency drives (VFDs) are unique devices that combine high voltages and currents with high-frequency waveforms. We usually don’t work with devices like this. Usually, we limit high power to 60 Hz (or up to 400 Hz in aircraft applications) and high frequencies to low-power applications. Drives combine them. Even a relatively small drive can put out many amps at hundreds of volts with frequency components in the tens of megahertz.

This combination of high voltage, current and frequency can create unexpected problems. Motors can fail, drives can trip or fail, and other equipment, including radios, sensors, alarms and programmable logic controllers (PLCs), can have problems operating and fail prematurely. Fortunately, it’s possible to mitigate these issues simply by using properly terminated VFD cables between drives and motors.