By Zachary Woltjer, Data Cyber Analyst, Verve, A Rockwell Automation Company

When it comes to prioritizing vulnerabilities in operational technology (OT), many teams still lean on methods created for IT, where data protection often takes center stage. In OT, however, even a brief security lapse can halt a production line or jeopardize worker safety. Tools like the Common Vulnerability Scoring System (CVSS) offer a starting point, but they rarely capture the complexities of a bustling factory or a 24/7 power station.

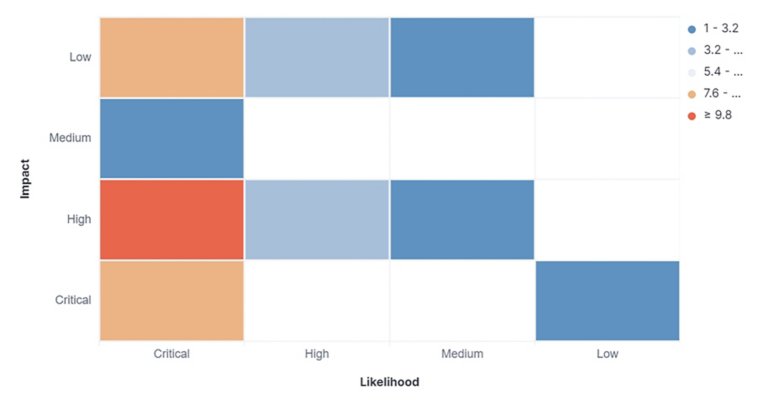

OT cybersecurity is about more than just keeping operations running — it’s about identifying which systems, if compromised, could trigger widespread disruptions and prioritizing those vulnerabilities first. A single system trip in a critical production line can cause significant downtime or safety hazards, while a less crucial component might have a more limited impact. This leaves OT teams repeatedly asking the same question: Which issues need to be addressed immediately, and which ones can wait?

That dilemma springs from more than just a difference in priorities: it’s also about resources and uptime. OT systems can’t be paused for patches without risking major operational losses, and specialized staff are often spread thin. As a result, teams struggle to make headway on vulnerability backlogs.

Simply put, IT-based frameworks don’t fully address the unique demands of OT, leaving engineers, plant managers, and security professionals without a clear roadmap for meaningful progress.