By Tim Norman, Senior Product Manager, Hardy Process Solutions

New industrial automation projects often involve integrating devices from multiple manufacturers. Yet customers discover the complexity of device integration can be one of the most frustrating and time-consuming aspects of deploying new capabilities.

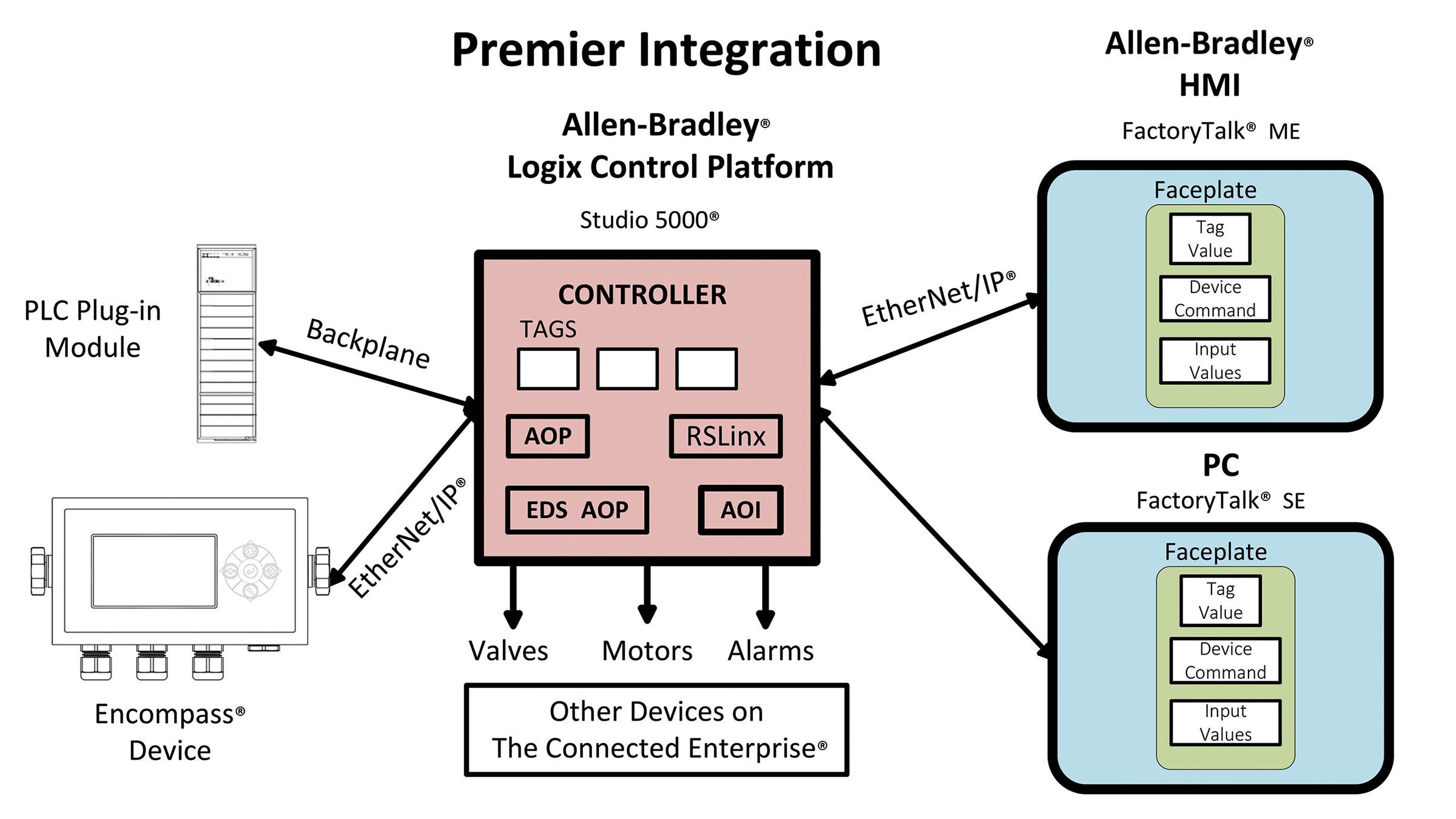

The Rockwell Automation® Logix control platform allows simplified device integration, configuration, operation and maintenance through a holistic approach based on Studio 5000® software integration tools. Called Premier Integration, the goal is to create an environment in which devices from multiple vendors can communicate and exchange data with each other efficiently without the need for time-consuming and costly programming.

Premier Integration combines controller programming, device configuration, and machine operation and maintenance into a single, user-friendly software environment to help engineers reduce integration and configuration times. It also gives operators access to critical machine data, including diagnostic information for improved maintenance, machine uptime and productivity.

Rockwell Automation continuously has improved upon the capabilities of:

- AOPs (Add-On Profiles).

- EDS AOPs (Electronic Data Sheet AOPs).

- Faceplates and AOIs (Add on Instructions).

With these tools, the company has created ease of integration opportunities for third-party Technology Partner products that connect to its control platforms.

However, not all device manufacturers take full advantage of the benefits of Premier Integration, which include: