By Daniel Craner, Product Specialist, POSITAL-FRABA Inc.

Accidental explosions in industrial and commercial installations, triggered by flammable gases or dust, have a tragic history of causing severe damage and loss of life. To reduce the risk of these accidents, industrial safety authorities in many parts of the world have mandated the use of explosion-proof electrical equipment.

It's important for both equipment manufacturers and end users to understand the conditions that can create hazardous environments, the measures that can be taken to reduce risks, and the systems designed to help regulate the use of electrical equipment in these environments.

About Hazardous Environments

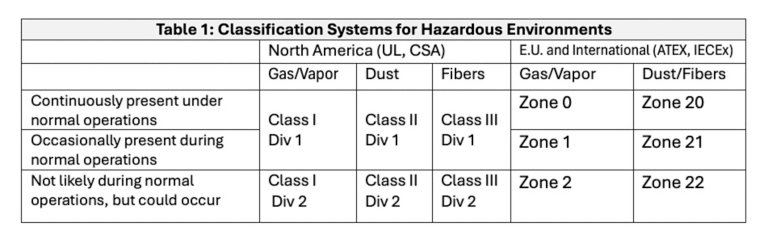

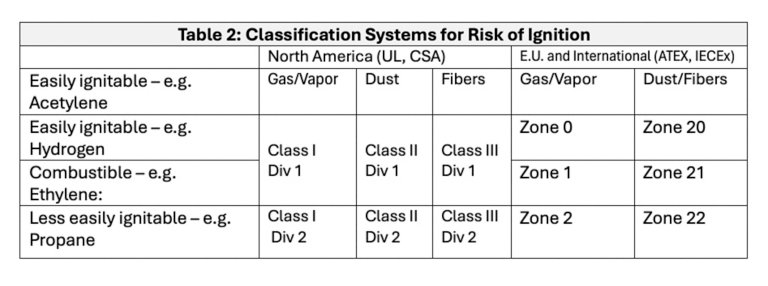

“Hazardous environments” are defined in industrial safety regulations as areas where there is a risk of dangerous concentrations of combustible gases or dust (this is sometimes referred to as “explosive atmospheres”).

Hazardous environments involving gases or fumes can occur in oil and gas refineries, chemical plants and fuel transfer facilities. Dangerous concentrations of flammable dust can occur in underground mines, grain handling facilities, milling operations and woodworking facilities. Emerging industries, such as hydrogen production, might also face risk of accidental explosions.

The term “explosion-proof” refers to equipment that has been designed to minimize the risk of starting an explosion or igniting a fire in a hazardous environment.

Designing to Reduce Risk

According to industry experts, there are three basic principles for managing the risk of explosions from combustible gases or dust.

Rule 1: Avoid. A good place to start is to design facilities and equipment to minimize leakage of combustible gases. Where gases or dust will be present, good practice calls for these areas to be well-ventilated, reducing the risk of dangerous concentrations. If explosive atmospheres are unavoidable, equipment must be designed and tested for explosion-proof properties.

Rule 2: Reduce. If there is a possibility of an explosive atmosphere due to leaks, equipment malfunction or other extraordinary circumstances, reduce the risk by installing equipment that has been certified as explosion proof.

Rule 3: Isolate and contain. To deal with any residual risk, facilities should be designed to keep the damage from an explosion as localized as possible.