By Gregory Wilcox, Principal Application Engineer, Innovation & Technology, Rockwell Automation

5G was designed from the ground up with enhanced reliability, low latency and a range of spectrum options in mind to meet the demanding requirements of the Industrial Internet of Things (IIoT) and industrial automation.

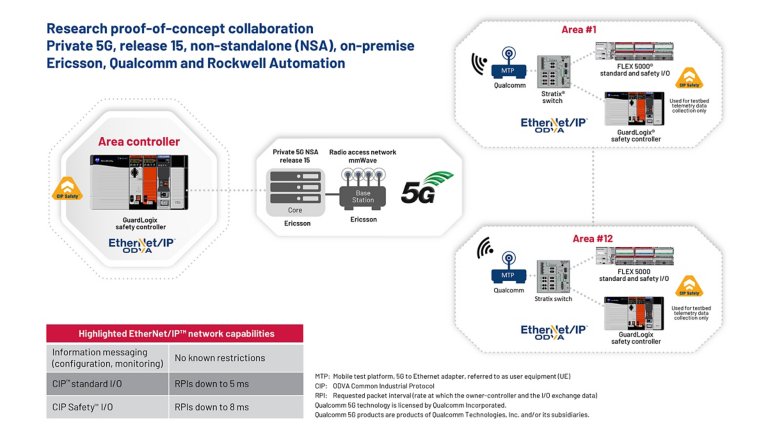

With millimeter wave (mmWave) spectrum and private networks, 5G delivers high capacity and low latency for numerous industrial sensors, actuators and controllers in standard and safety control applications.

5G offers the promise of being a viable technology to augment and even replace traditional wired industrial network connections. This could be a game changer in terms of cost, flexibility, sustainability and time-to-market for industrial operations around the world.

5G and Sustainability

Sustainability policies are growing in importance across all industrial industries. Tethered fixed industrial assets such as skids, machines or equipment require costly wired infrastructure for new installations, and this material usage diminishes sustainability initiatives.

Tethered fixed industrial assets also affect the agility of industrial operations, which slows down quick retooling needed to respond to dynamic market conditions.

Yet, the entire manufacturing industry had to retool industrial operations to meet shifting demand during the global pandemic: switching from soda to sanitizer, clothing to medical masks, or automotive parts to ventilators. The lesson here is that agility, efficiency, resiliency and sustainability in smart manufacturing is a critical national imperative.

In comes Industrial Private 5G, allowing digital transformation to help deliver initiatives such as sustainability and agility by supporting key application that include the following: