By Alexander Rose, Manager and Chris Barnes, Senior Manager, Data Science, Kalypso: A Rockwell Automation Business

For many organizations. maintenance is still predominantly a reactive endeavor. As simple predictive solutions become more commonplace, leading enterprises are looking beyond predictive capabilities to prescriptive insights to advise maintenance functions on what assets and tasks to prioritize.

Organizations now have access to vast amounts of data, and ideas for using that data continue to proliferate. The real challenge has become prioritizing which opportunities to pursue.

To advise maintenance functions, organizations are using advanced analytics and predictive maintenance. Predictive maintenance (PdM) uses statistical, machine learning (ML) and artificial intelligence (AI) techniques to predict asset health issues before they arise.

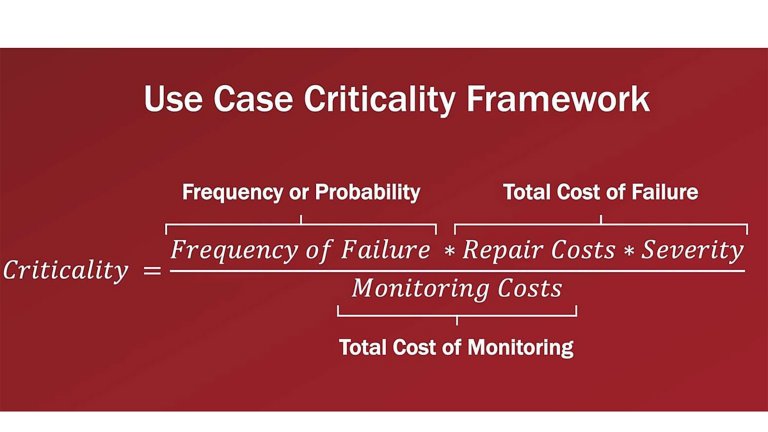

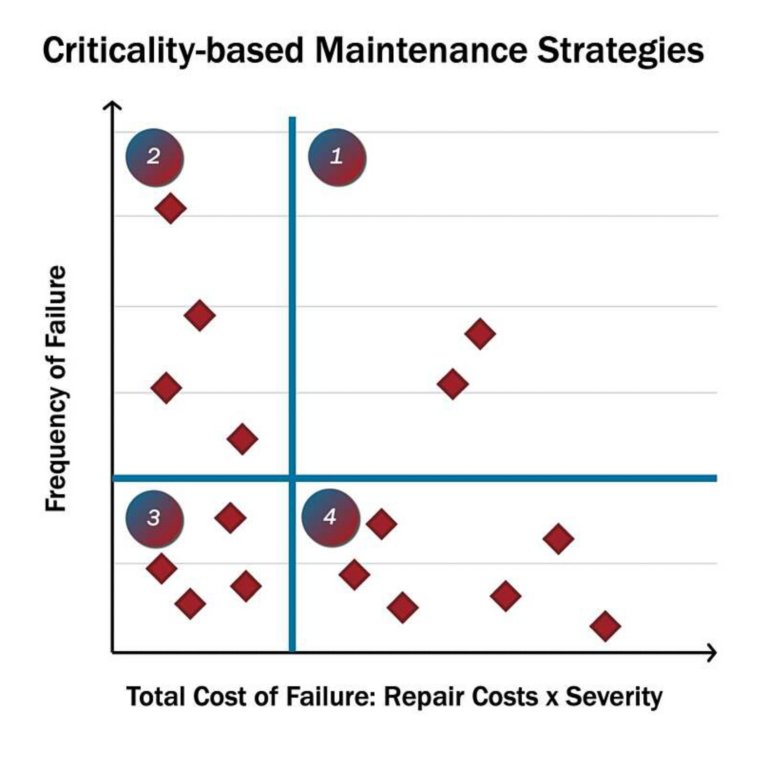

When successful, these predictive technologies provide a prescriptive approach that balances the potential severity of a particular failure mode with an estimate of how likely that failure is to occur. This measure, commonly called criticality, empowers teams to focus their time and resources on the assets, systems and subsystems most critical to business outcomes.

The effective use of PdM strategies can help manufacturers reduce mean time to repair (MTTR) and improve first-time fix rates (FTFR), which may further decrease the non-value-added “windshield time” associated with field service requests.

For leaders at organizations who want to improve their maintenance operations and routines by using data from connected assets, the question remains: “How do we start?”

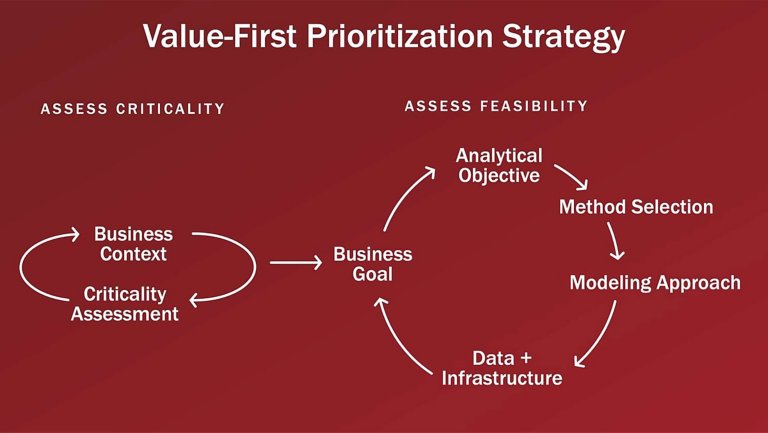

“Value-First” Prioritization Strategy

It may be tempting to begin collecting and storing every data point available to an organization. However, undirected data collection can result in high levels of activity with few measurable results. To protect against this common pitfall, we offer a framework for “value-first” prioritization.