By Todd Gilliam, North America Industry Leader, Consumer Packaged Goods (CPG), Rockwell Automation

Are you ready to comply with the U.S. Food and Drug Association’s Food Safety Modernization Act (FSMA) requirements for Section 204?

As a food and beverage manufacturer, you know the importance of food safety, but this new rule takes it a step further. Food and beverage firms are now required to maintain records containing key data elements for critical tracking events along a food product’s life cycle.

As part of Section 204, the final rule on “Requirements for Additional Traceability Records for Certain Foods” has been published and requires compliance by Jan. 20, 2026.

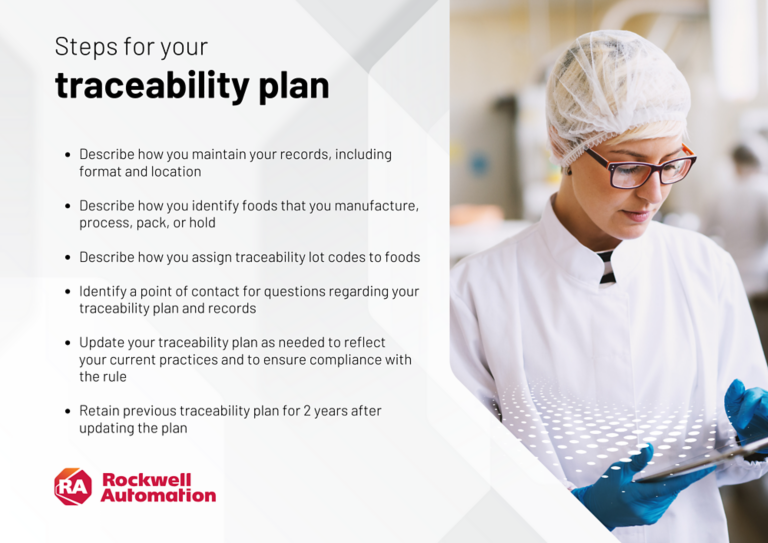

This affects domestic and foreign firms producing food for U.S. consumption and requires a traceability plan (see Figure 1) for all entities throughout the food supply chain. While many larger companies may be compliant in keeping with industry best practices, smaller or mid-size companies may not have everything in place yet to track food products on the Food Traceability List (FTL), from farm to table.

Foods on the FTL include: