Chobani is a fast growing, dynamic yogurt company that was founded in the United States, with the belief that people have great taste but needed great options. With a mission to make high-quality, great tasting yogurt available to the masses, Chobani decided to spread its wings to Australia.

Since purchasing a local Victorian dairy company in 2011, Chobani also invested in a new greenfield facility to manufacture their yogurt locally alongside the existing manufacturing plant.

With a strong focus on automation, Chobani called on Metromotion Controls, a leading systems integrator specialising in control and automation systems, to facilitate the design, management and implementation of the new $30 million facility.

In addition to the new manufacturing plant, Metromotion was also commissioned to implement Chobani standards to automate the existing site. The task at hand was to use the latest technologies from Rockwell Automation to automate both new and existing processes at the plants.

Yogurt Production Made Easy

With increasing demand for Chobani yogurt around the world, meeting global supply agreements was a key priority for the company, as failure to do so would result in significant penalties being enforced.

As such, Metromotion Controls were required to meet strict project timelines so the plant could be up and running quickly and effectively.

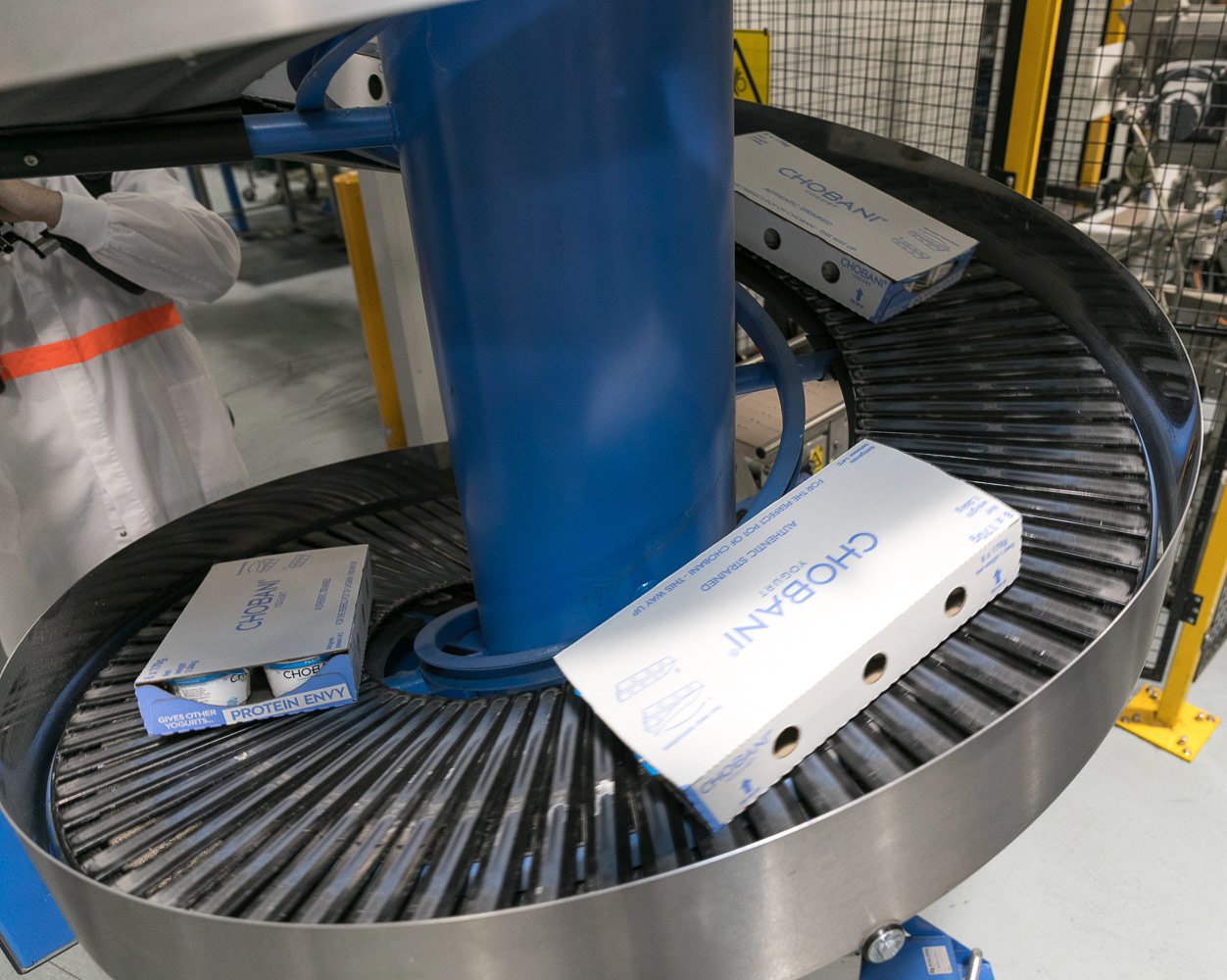

Chobani has a strong focus on automation and at the time of building the factory required ‘on the ground’ automation and electrical resources from Metromotion Controls.

This work involved facilitating the site power upgrade, building services and process power distribution, factory wide automation integration including process, packaging and site services and commissioning and ongoing support both on site and remotely.