Optimized Energy Management is the Foundation of Sustainable Manufacturing

According to the World Economic Forum, industry accounts for 40 percent of global energy use and 30 percent of greenhouse gas (GHG) emissions. Energy is one of the fastest growing production costs driving the need to improve efficiency. In fact, worldwide power consumption is projected to increase over 300% by 2050[1].

The increasing pressure to meet sustainability goals and net-zero commitments as well as to optimize industrial operations to improve energy efficiency and reduce costs underlines the critical importance of monitoring and managing these costs.

Improved awareness of energy usage is the foundation for any strategic energy management program – it helps an organization understand where, when and how it uses energy to establish the necessary scope of its energy savings efforts and define key metrics.

Benefits of Sustainable Manufacturing

- Improved brand reputation

- Reduction of material and energy consumption

- Permits entry into increasingly regulated markets

- Improved company culture and employee engagement

- Increased top and bottom line from recycling programs

Energy management practices involve actively monitoring and controlling energy usage within your manufacturing processes.

What Energy Management Problems are We Trying to Solve?

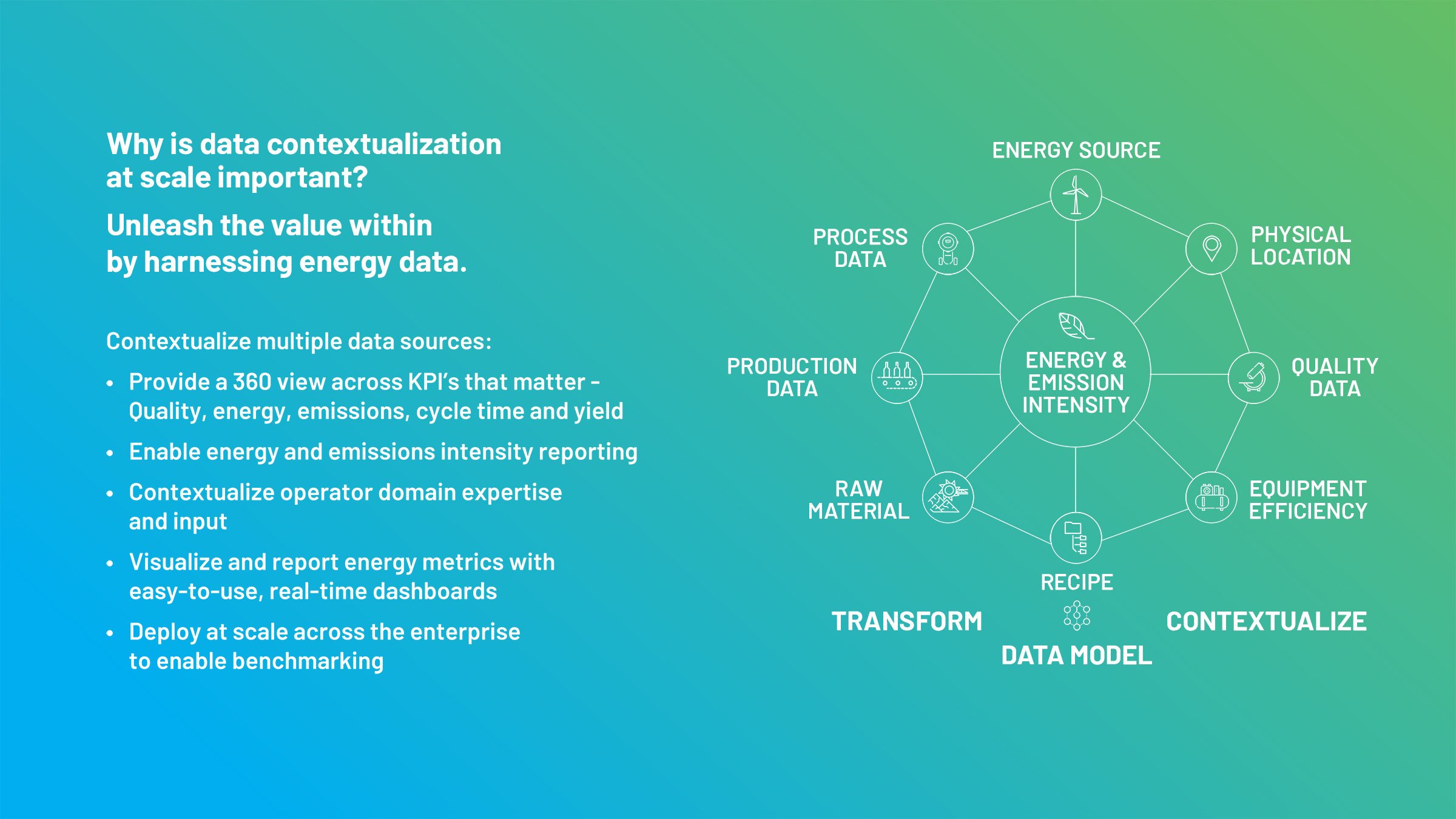

Getting energy performance metrics from industrial equipment is difficult because the data lacks operational technology (OT) context — around time, source, type and relation to the operational condition of other manufacturing components. Without OT context, most industrial data is unstructured and captured at different time stamps, which creates challenges to organize, manage and glean actionable insights. What manufacturers want to know:

- How much energy is consumed to make this product?

- What are the energy intensive processes?

- How do we avoid costly energy demand charges?

- How do we achieve uptime and reduce energy cost?

- How do we increase throughput while reducing energy usage?

- How do we create a more energy efficient machine?

Common Customer Challenges

Some of the most common challenges for manufacturers involve environmental, social and governance or ESG. These three factors are key when measuring sustainability and ethical impact by a company and are of increasing importance to socially responsible investors when deciding to invest in a business or company.

The first is around continuously evolving regulations as well as the complexity of reporting standards since there are multiple reporting frameworks and standards to choose from. The first challenge affects the second challenge – because it is difficult to define, measure and report on ESG goals, it is also difficult to achieve them. The International Energy Agency (IEA) estimates that more than half of the emissions reductions by 2050 could come from energy efficiency measures alone. Water and waste are also top concerns. For waste this includes both material efficiency in operations and circularity in product design.

In 2020, Rockwell Automation conducted a materiality assessment through a third-party consultant. Based on the evidence of impacts, risks and opportunities provided through stakeholder interviews and sources, Rockwell Automation mapped the relative priority of issues to external stakeholders.

One of the top priorities was how to harness our technology to help our customers increase their resource efficiency. Find out about the other areas we prioritized in our 2020 Sustainability report.

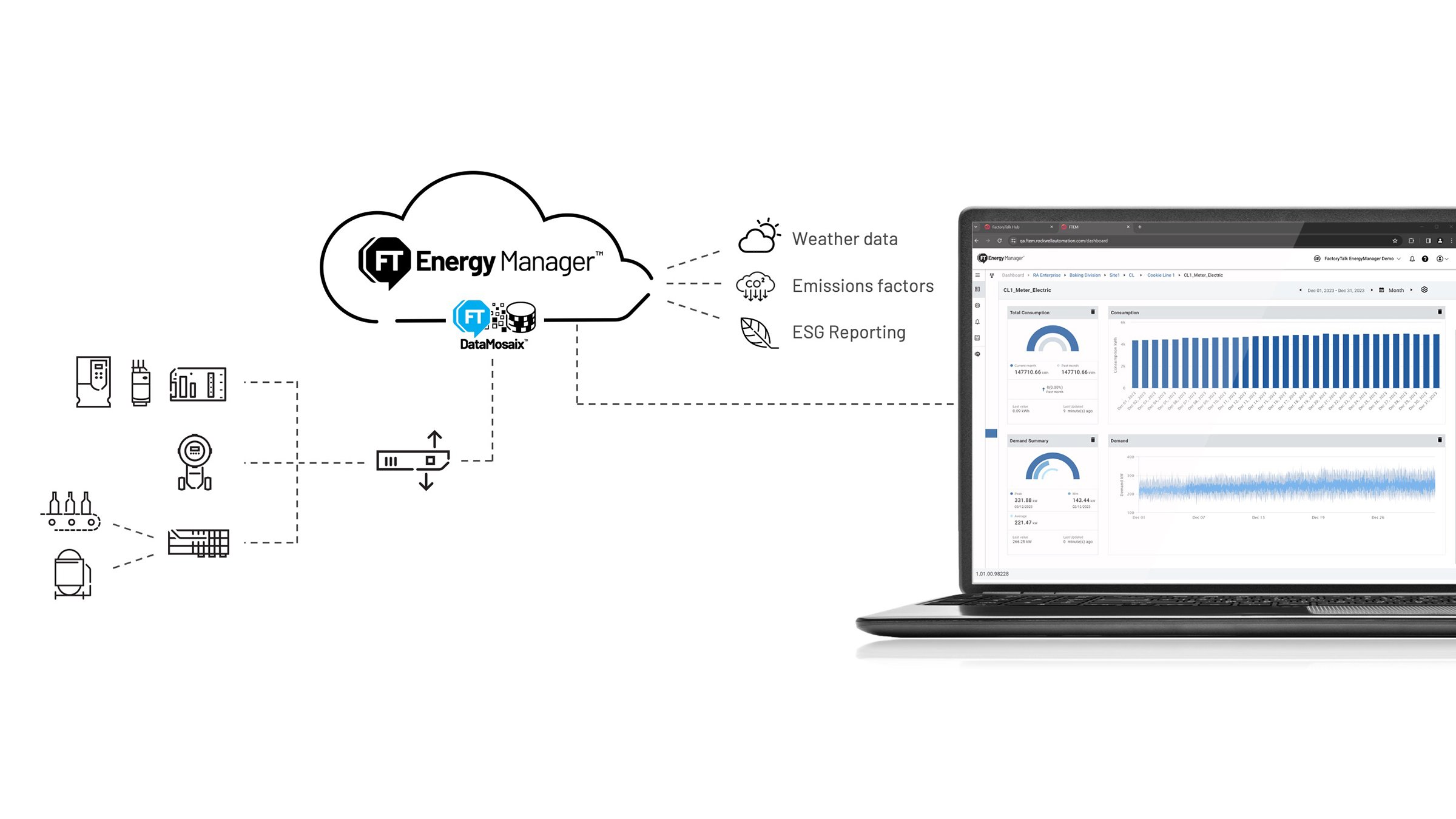

And, in 2023, we launched FactoryTalk® Energy Manager™, an IT/OT convergence platform-based energy monitoring application that provides energy and production information based on an energy plant model of the underlying process at a plant, process area, line and machine level. Manufacturers can understand where, when and how their facilities use energy to establish the necessary scope of their energy savings efforts and define key metrics.

FactoryTalk Energy Manager is built on FactoryTalk® DataMosaix™, an Industrial DataOps solution built for multi-site, enterprise-wide access. The solution provides flexible and scalable tools to accelerate data usability by domain experts and analysts. Manufacturers can now make informed decisions based on their energy consumption with controlled access to relevant and contextualized data and meet their environmental goals.