A virtual environment gets you ahead of the game

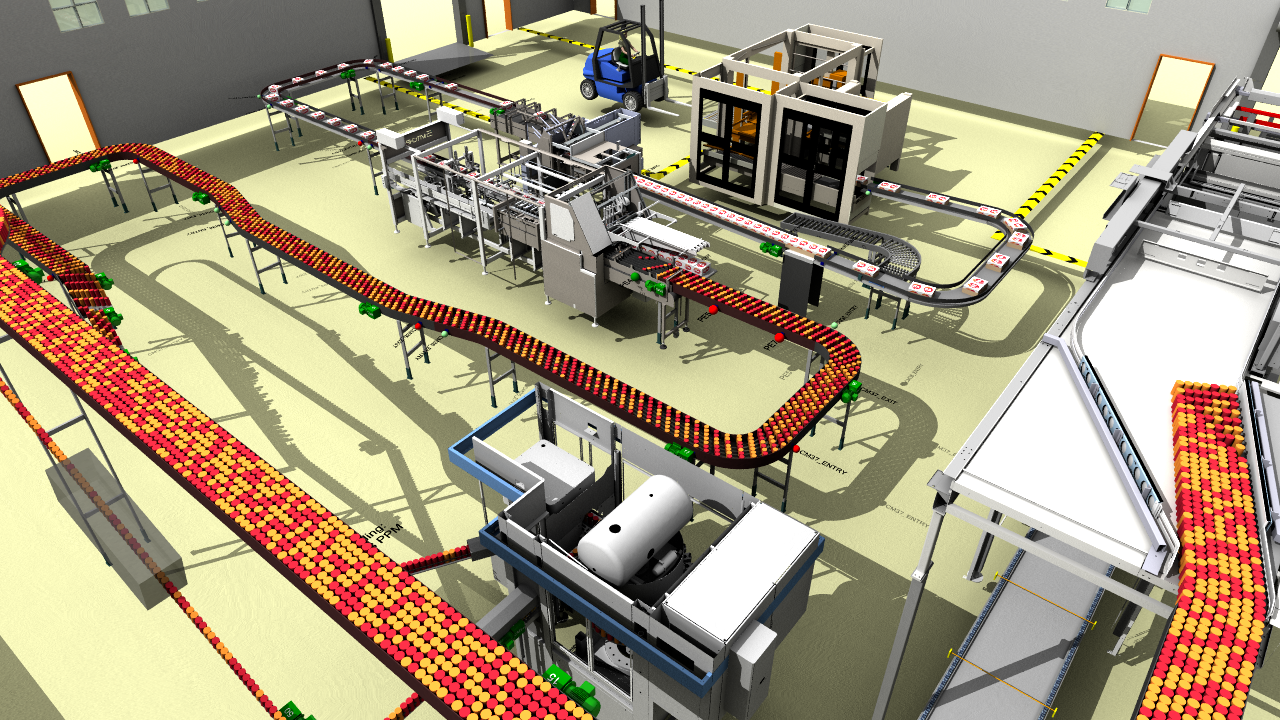

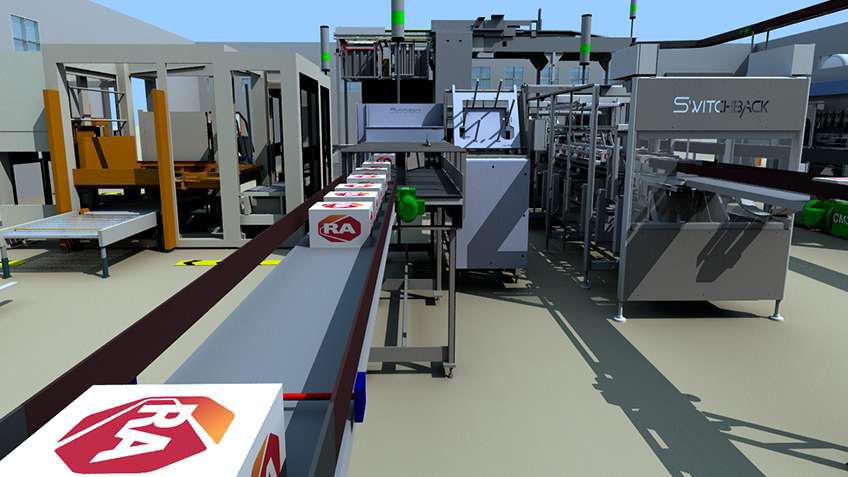

Traditional methods of machine and production line design, commissioning and startup can be costly and impede speed to market. CPG producers are turning to emulation as a tool to research, test and validate their process in a virtual space. Before making physical changes to plant layout and workflow.

Employing a virtual system that uses real operational logic and connects to PLCs can help minimize the resources it takes to bring a line from design to production. With an emulation model, you’re doing two things:

- Gaining the ability to fully test controls, reducing the amount of variability and risk in your project. Here you can test the coming together of the mechanical CAD and logical operation.

- Conducting tests off a project’s critical path, in parallel to the system build and as soon as design is agreed upon.

We’ve had clients report a reduction in on-site controls commissioning times from three weeks to four days on a bottling line. This scale of reduction is typical, and is a big factor in driving adoption.