Complex industrial processes make it challenging to be both market driven and sustain profitable operations. Manufacturers must adjust their production methodology to introduce a greater variety of higher value products and shorter production runs. They need to produce more, run efficiently and improve product quality to the limits of available equipment. For this, they must ensure maximum uptime and more efficient transitions with less waste. In addition, manufacturers are facing stronger public demand to reduce their environmental impact and operate within regulated emissions limits.

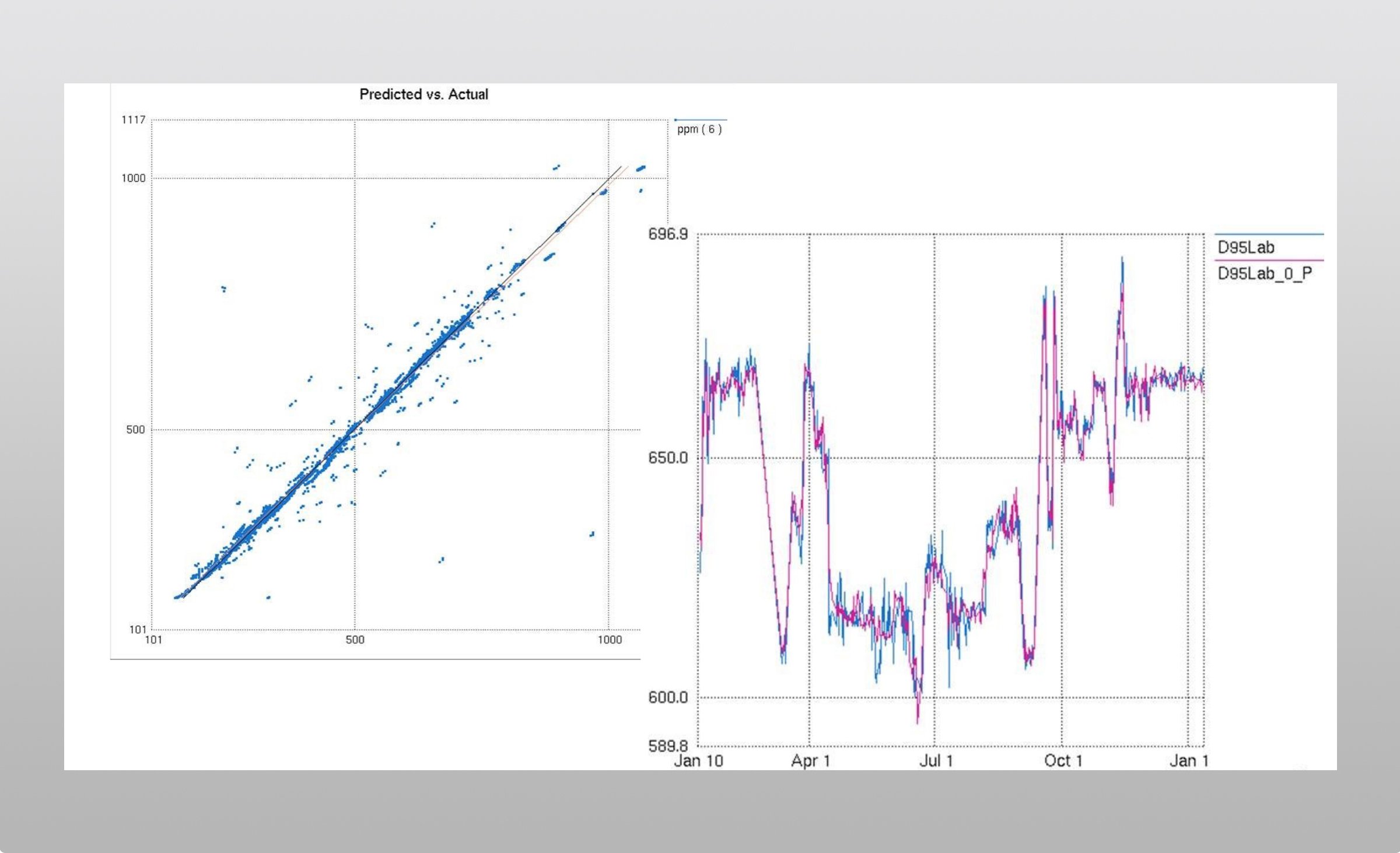

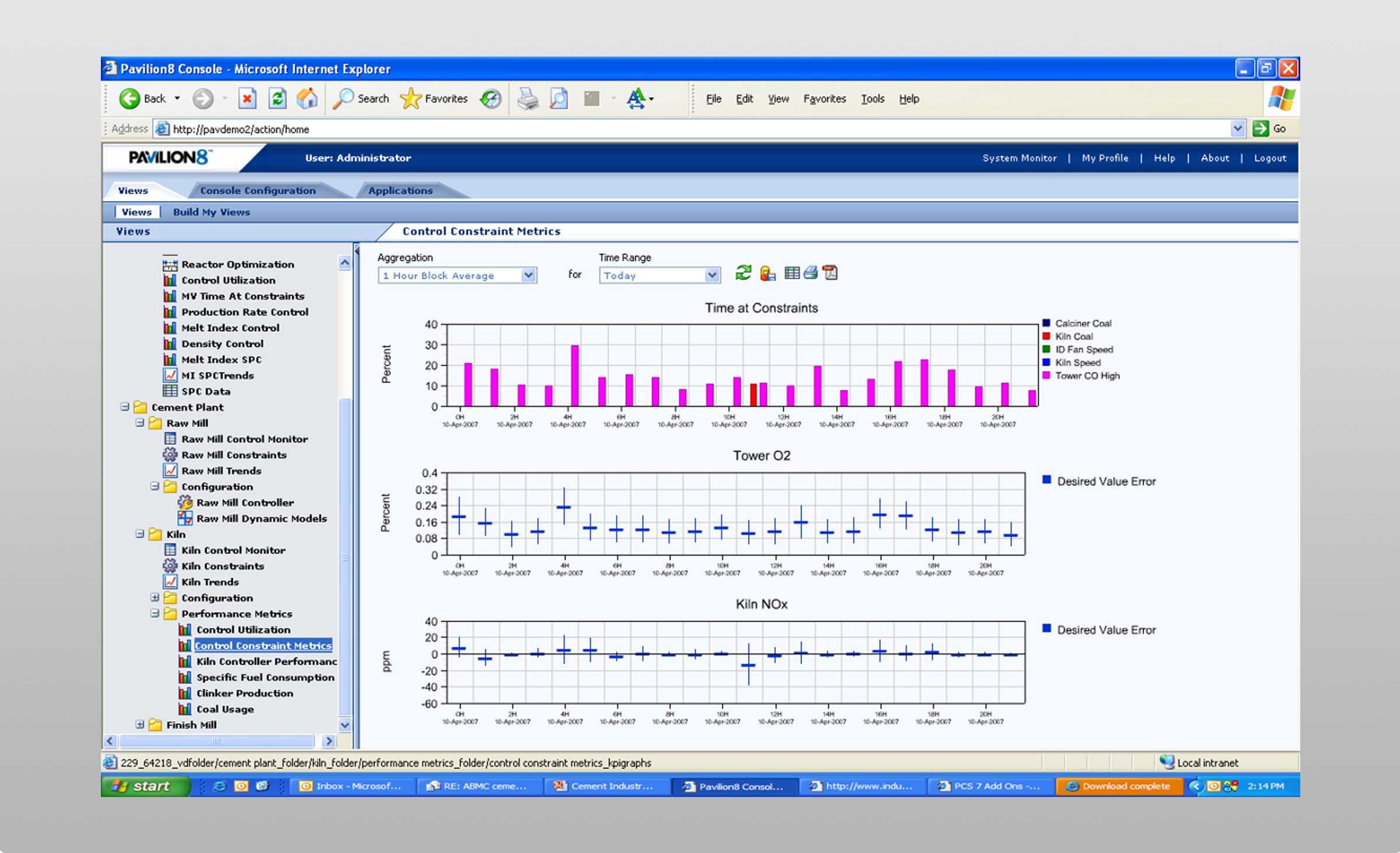

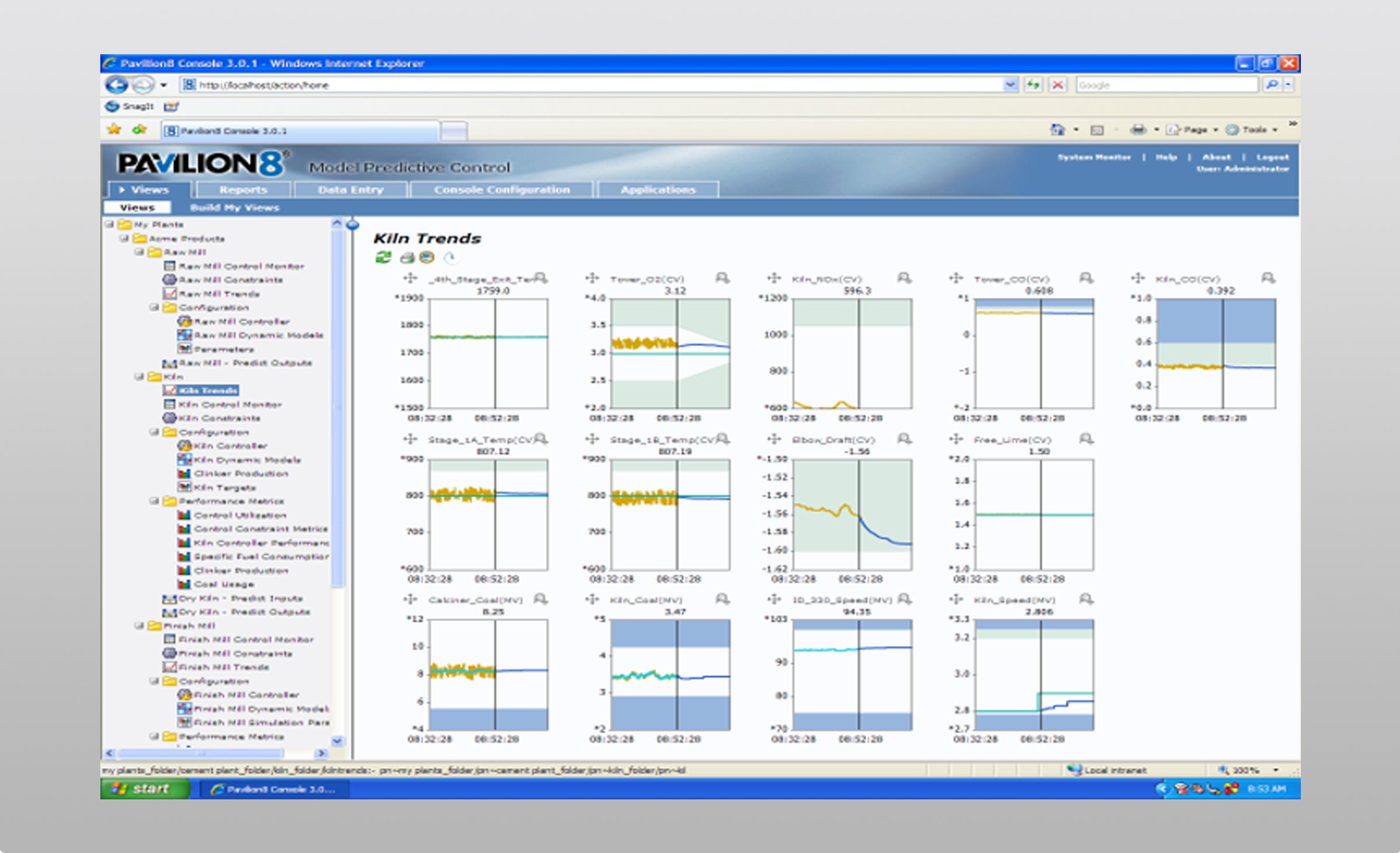

Rockwell Automation FactoryTalk® Analytics™ PavilionX® Model Predictive Control (MPC) is an intelligence layer on top of automation systems that continuously drives the plant to achieve multiple business objectives—cost reductions, decreased emissions, consistent quality and production increases—in real time. FactoryTalk Analytics PavilionX software's flexible hybrid modeling capabilities incorporates all available process knowledge to deliver the most accurate, highest fidelity models possible. It uniquely provides a single solution that can handle both nonlinear and linear processes simultaneously, driving improved results across a wide range of process technologies. Our MPC technology continuously assesses current and predicted operational data, compares them to desired results, and drives new control targets to reduce process variability, operate within equipment constraints and improve performance.