Rockwell Automation, Inc. (NYSE: ROK), the world’s largest company dedicated to industrial automation and digital transformation, today announced a deal to provide Belgian recycling start-up Triple Helix with state-of-the-art process solution and intelligent power control systems.

To achieve the level of precision and dependability required to make its vision a reality, Triple Helix chose Rockwell Automation PlantPAx 5.2 DCS process control combined with modular, configurable CUBIC power control panels.

“For the new plant to work, we need complete control over every stage of the process,” said Triple Helix CEO Steven Peleman, “The system had to give us the insights and flexibility we needed to constantly optimize; we couldn’t afford it to be a ‘black box’. We also needed a partner with a global presence, who could work with us as we roll this technology out internationally. All these factors meant it had to be Rockwell Automation.”

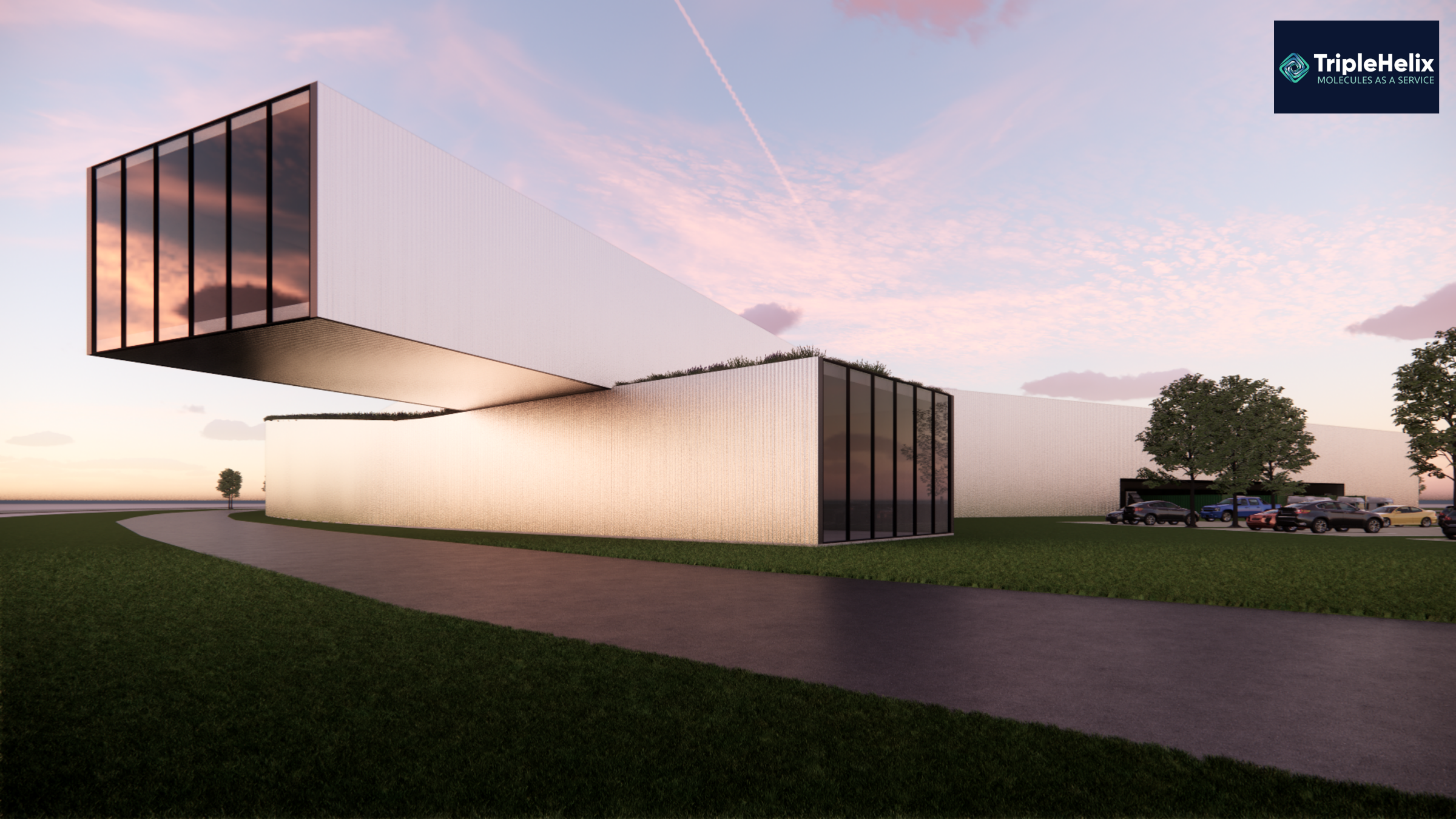

Founded in 2020, Triple Helix specializes in advanced materials recycling. Based in Antwerp Belgium, the company is building an innovative new polyurethane foam recycling plant. Each year, European factories produce more than a million tonnes of polyurethane foam.

Using its SurePure recycling technology, Triple Helix cleans used foam that has reached the end of its life, breaks it down into its chemical components and then uses these to produce new products. Material reincarnation or trying to preserve existing molecules at their end of life, is the core business of Triple Helix Molecules as a Service.

The recycling process is highly energy efficient, produces almost zero waste and compared with conventional disposal methods, it cuts greenhouse gas emissions by 50%. But for the new plant to work, Triple Helix needs constant precision control over the recycling process.

The company must be able to monitor and adjust every aspect of the process to ensure the highest-quality product and compliance with stringent safety standards. It also needs to be able to quickly re-configure to accommodate different grades of foam and to produce different end products, depending on what the market requires.

“We’re proud to be the technology launch partner for Triple Helix,” said Pierre Teszner, regional vice president for central and eastern Europe at Rockwell Automation. “Rockwell Automation is committed to helping our customers innovate and achieve their net zero targets. Triple Helix is a fantastic example of both. We’re extremely excited to work with the company on its plant in Antwerp and on its eventual global roll out.”