Airports are finely orchestrated logistical operations, moving people, planes and products safely, securely and without delay.

Even the smallest hiccup can create chaos, so companies like Intellimodus, a solutions integrator, specialize in designing systems for airports that deliver baggage to passengers at destinations all over the world.

An advanced system is crucial to seamless operation at SEA Airport. More than 50 million people passed through SEA in 2019. SEA has been the fastest growing airport in the U.S. in the last five years.

The airport needs a flawless baggage handling system (BHS) to maintain excellent traveler satisfaction and meet additional Transportation Security Administration (TSA) requirements with explosive detection system (EDS) machines for improved security and passenger safety.

The airport wanted to move its BHS to decentralized control with a safe and redundant system. This would improve customer satisfaction – ensure that the system was always available – and allow the airport to continue to grow to meet global travel demands.

Decentralized Strategy

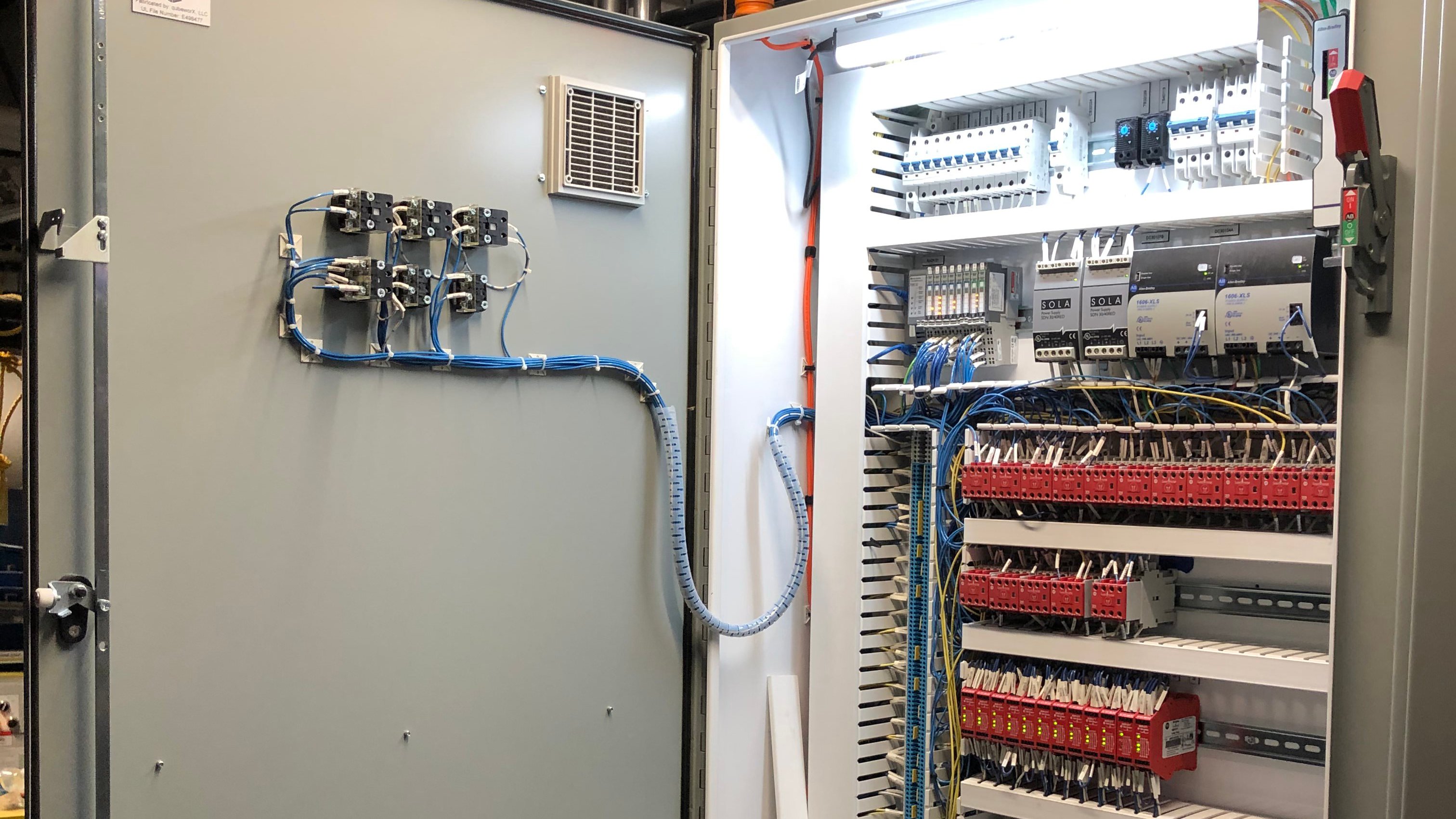

SEA’s engineering firm worked with Intellimodus and Rockwell Automation to develop a system that did not have a single point of failure in the decentralized system. For the Baggage Optimization Project in the domestic terminals and the International Arrival Facility Project, Rockwell Automation, with BNP Associates and Intellimodus, developed the Drive-In-A-Box (DIAB).

The DIAB configuration uses PowerFlex 525 drives with automatic device configuration (ADC), allowing for the non-disruptive replacement of a drive within minutes – maintaining a positive traveler experience by reducing the risk of potential baggage delays.

With so much at stake in this design, the team worked to prove the network using a redundant PLC arrangement while keeping the DIAB as small as possible. The system uses more than 300 DIABs, each with a PowerFlex 525 variable frequency drive, rotary disconnect, pilot devices, 1799E I/O card, terminal blocks and quick cord set connectors at the bottom.