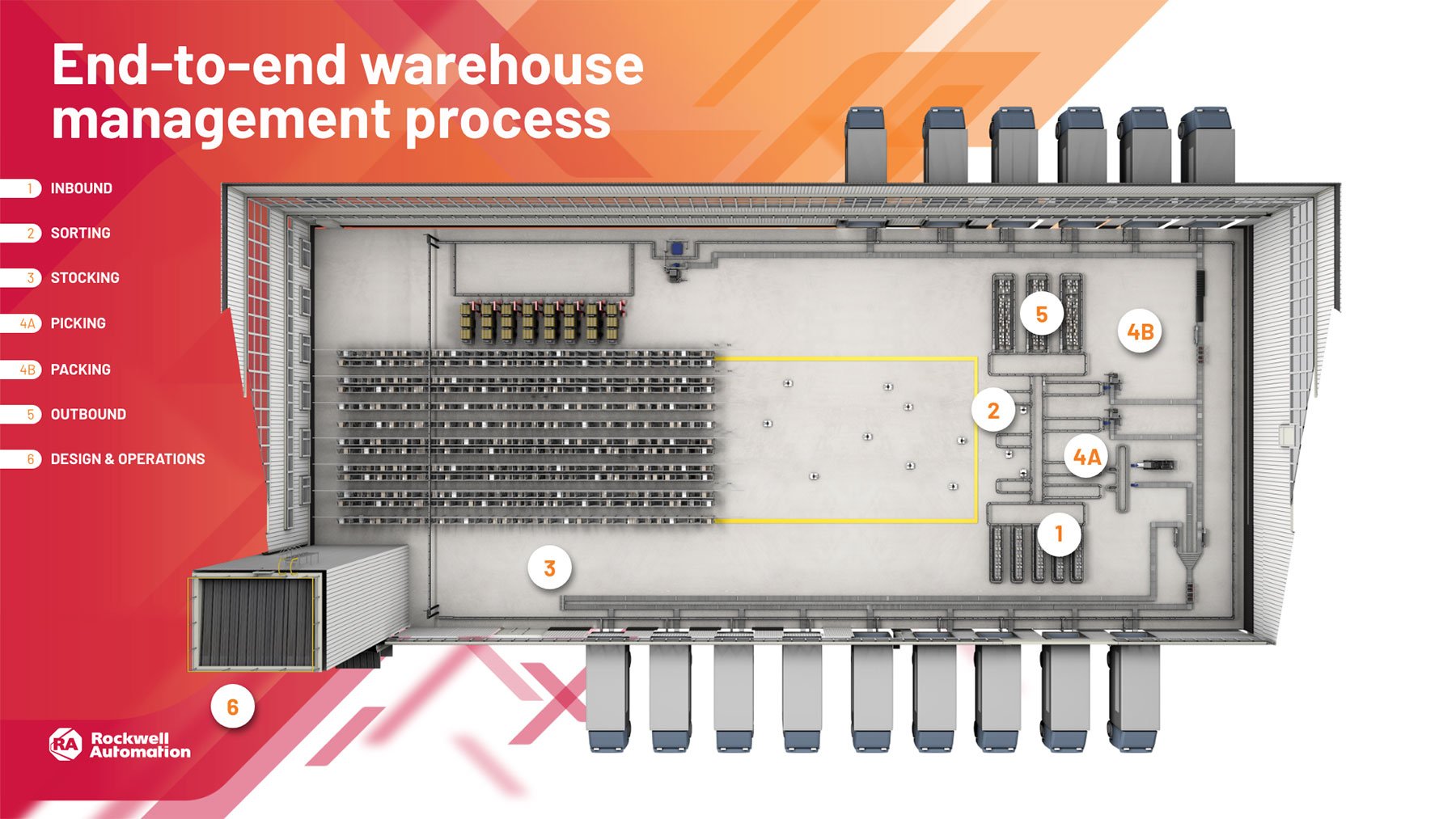

1. Inbound

Once the materials are received in the warehouse, this is where they are unloaded and placed onto conveyors. Fast speed controllers can aid to drive increased performance, capacity, productivity, and security to help meet growing demands. Additionally, remote I/O devices such as the ArmorBlock® I/O modules provide low-cost, hardened, I/O suitable for on-machine use.

2. Sorting

This area is where items are moved across warehouse facility lines, for example, the movement of ordered products from storage to picking areas and completed orders to the loading area for distribution.

The use of robots can help to overcome top operational challenges, from staying productive amid a workforce skills shortage to improving dynamic package handling capabilities and handling a wider range of products. By integrating them into the architecture and with other equipment, operations can become responsive to demands.

3. Stocking

This is where items are labeled and stocked onto racks. By investing in intelligent conveyor systems such as independent cart technology that uses magnets for precise control motion, it can bring increased line speed and flexibility. Solutions such as the MagneMover LITE offers different layout options as it is made of a selection of standard building blocks, each of which is a motorized track section. The system manages the speed and direction of each carrier individual and keeps track of its location.

4. Picking and Packing

Picking is the process of finding and extracting products from a warehouse to fulfill customer orders. Subsequently, the packing procedure typically involves choosing the appropriate materials and containers to pack products, weighing the package, and labeling it with the relevant invoice or packing slip. In this section, the use of smart machines and devices can go a long way to boosting uptime while improving safety. For instance, smart motor control solutions can help to prevent motor failures with an integrated, data-driven approach and on-machine safety.

5. Outbound

This refers to the shipping out of finished goods to customers from the warehouse or distribution center. It consists of the order fulfillment process that includes picking, packing, shipping, and delivery of a package with a particular focus on goods issue processing and shipping orders. The abovementioned automated solutions should be considered here too since there are similar actions in place.

6. Command center

Lastly is the command center, which enables warehouses to function as designed, to perform day-to-day operations, helping businesses to assess what are the optimum resources required to maximize productivity during operations. This is where synchronization between the manufacturing equipment systems and warehouse management system is essential to optimize both data and material flows between logistics and production.

Our FactoryTalk® Warehouse can control all warehouse activities required to support production operations, including inbound processing, storage and operation, and outbound processing. Furthermore, it provides the required tools to easily modify or build workflows, as needed.