Rockwell Automation Acquires Fiix Inc., Cloud Software Company

AI-Enabled Computerized Maintenance Management System Modernizes Operations Planning, Management, and Equipment Failure Prediction for Leading Edge Maintenance Solutions

Rockwell Automation recently announced that it has entered into an agreement to acquire Fiix Inc., a privately-held, AI-enabled computerized maintenance management system (CMMS) company. Fiix, founded in 2008, is headquartered in Toronto, Ontario, Canada.

As the number of industrial connected assets multiplies, the ability to gain insights from maintenance operations is becoming increasingly important to a manufacturer’s ability to gain competitive advantage. This insight enables another level of productivity in addition to the core automation.

Fiix’s cloud-native CMMS creates workflows for the scheduling, organizing, and tracking of equipment maintenance. It connects seamlessly to business systems and drives data-driven decisions. The company’s revenue grew 70% in 2019 with more than 85% recurring revenue. Fiix has more than 2 million assets under management and creates more than 6 million work orders a year.

“We believe that the future of industrial asset management is performance-based,” said Tessa Myers, vice president, product management, Software & Control, for Rockwell Automation. “With the addition of the Fiix platform and expertise, our customers will benefit from a 360-degree view of integrated data across automation, production, and maintenance, helping them to monitor and improve the performance of their assets and optimize how maintenance work is done.”

James Novak, Fiix CEO, said, “From the beginning, Fiix has been on a mission to connect maintenance and operations teams to the tools, resources, and technology they need to modernize and join the future of maintenance. Joining Rockwell Automation will allow us to help even more companies modernize maintenance and increase asset performance by connecting to industry-leading data, automation, and production systems.”

The addition of Fiix directly aligns with Rockwell Automation’s software strategy. It also enhances Rockwell Automation’s capabilities in its Lifecycle Services business, which provides a full range of industrial automation services to help customers maximize the value of their production assets, systems, plants, and processes. Additionally, it illustrates Rockwell Automation’s focus on helping customers be more sustainable. Through a CMMS, businesses can operate more efficiently, reducing waste and energy use while also saving money.

Fiix will be reported as part of Rockwell Automation’s Software & Control operating segment. The transaction is expected to close by the end of the 2020 calendar year, subject to customary approvals and conditions.

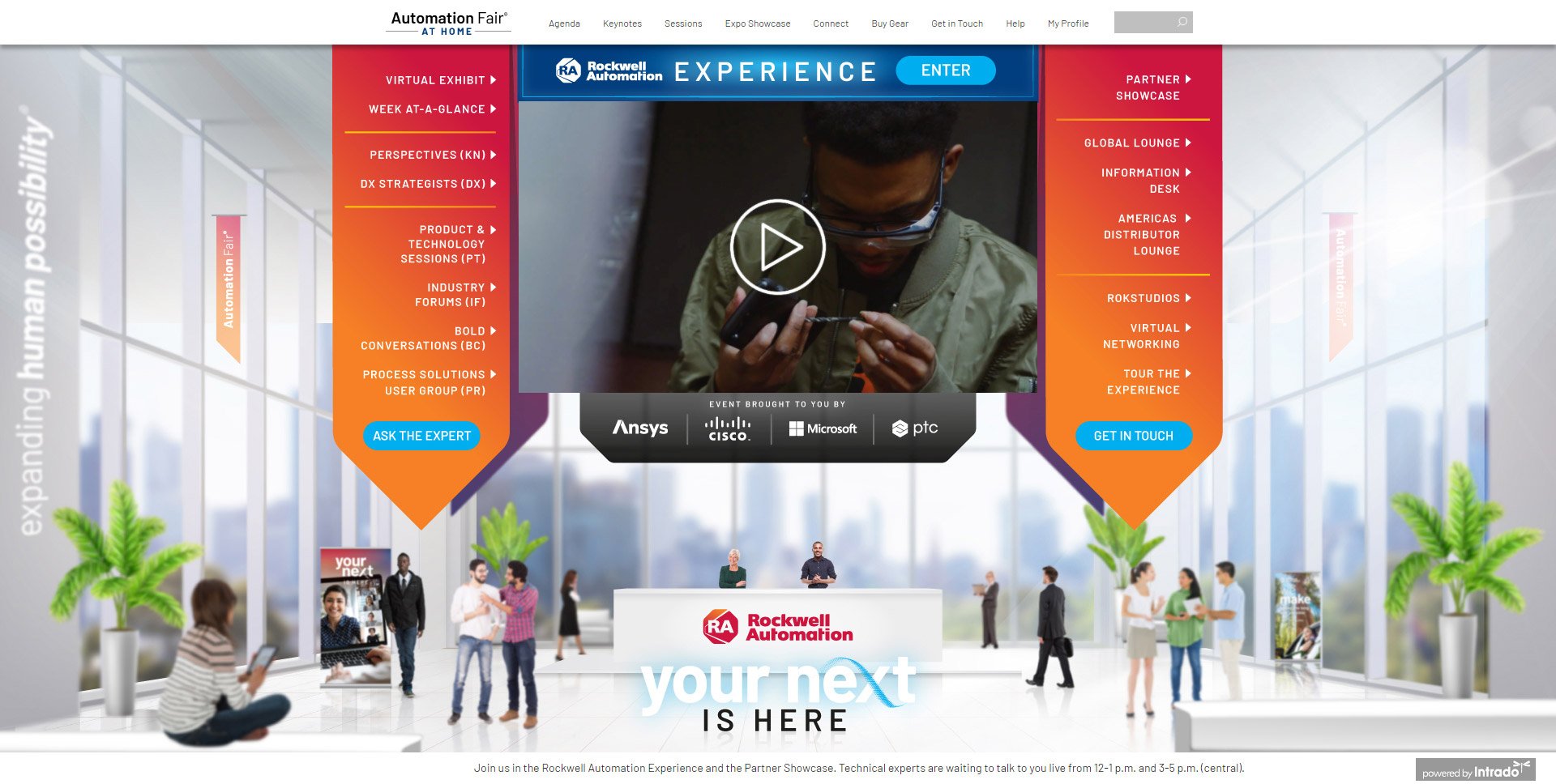

PTC and Rockwell Automation Extend Strategic AllianceHaving already helped almost 250 new customers around the world to achieve their digital transformation goals, PTC and Rockwell Automation announced the expansion and early extension of their strategic alliance.

This extension will ensure continuity in both companies’ sales and product development efforts and expand the agreement to include PTC’s product lifecycle management and software as a service (SaaS) products. This expansion will streamline both companies’ commercial efforts to extend a comprehensive digital thread solution, from upfront design through the operate, maintain and optimize-lifecycle stages. PTC will also offer Rockwell Automation’s virtual machinery simulation and testing software to its own customer and partner network. Under the agreement, both organizations will continue to leverage each other’s resources, technologies, industry expertise, and market presence to seamlessly serve their customers through 2023 and beyond.

The companies’ primary joint offering, FactoryTalk InnovationSuite, powered by PTC, is the industry’s first comprehensive digital transformation software suite that offers fully integrated Industrial Internet of Things (IIoT), edge-to-cloud analytics, manufacturing execution systems (MES), and augmented reality (AR) – required for the connected enterprise. FactoryTalk InnovationSuite makes it simple to rapidly develop, operationalize, and globally scale innovative solutions to operations.

“Our selection of FactoryTalk InnovationSuite, powered by PTC could not have come at a better time for our company,” said Teja Schubert, Director, Controls, Automation and Technology, Norbord, an international producer of wood-based panels. “As the first wave of COVID-19 hit, it became even more important to have a platform that helps us reduce costs, improve our employee's experience, and make better use of our maintenance and training efforts. This ever-important alliance has made it easier for our company to navigate the COVID-19 pandemic so far, and we look forward to leveraging future solutions.”

As manufacturers reset their operations, competitive pressures and demands for better financial performance have accelerated the need to digitally transform products, processes, and people across all business levels. PTC and Rockwell Automation’s industry-leading digital manufacturing solutions provide manufacturers with robust end-to-end digital thread capabilities, empowering them to continue their digital transformation initiatives amid the global pandemic.

Rockwell Automation and Microsoft Expand Partnership to Simplify Industrial TransformationPartnership aims to empower manufacturers with agility, intelligence, and scale to deliver digital transformation initiatives—from the cloud to the edge

Rockwell Automation, Inc and Microsoft Corp. announced a five-year partnership expansion to develop integrated, market-ready solutions that help industrial customers improve digital agility through cloud technology.

“Today, one thing we know for sure is that no business is 100% resilient. Those fortified with digital capabilities and assets are more resilient than others, and the cloud is how they will thrive,” said Judson Althoff, executive vice president of worldwide commercial business, Microsoft. “We are pleased to deepen our already strong, decade-long relationship with Rockwell Automation to help businesses simplify industrial transformation, accelerate business outcomes and innovate with agility.”

To date, the companies have co-developed over 20 use cases across Food & Beverage, Household and Personal Care and Life Sciences industries. The solutions developed from this partnership will augment and enhance our current offerings.

“This partnership provides Rockwell Automation and Microsoft customers with a holistic, simple solution for IIoT development and operations and removes data silos that hinder industrial digital transformation initiatives,” said Blake Moret, Chairman and CEO of Rockwell Automation.

“Our team has seen the preview release of this new solution and we are excited about collaboration between our strategic partners, Rockwell Automation and Microsoft,” said Tristan Hunter, GM Automation & Operational Technology at Fonterra Co-operative Group Limited, New Zealand’s largest company and responsible for 30% of the world’s dairy exports. “Moving data from our on-premise assets securely with context and providing new workflows for us to analyze and drive better outcomes is important to maintaining Fonterra’s high standards across our many plants globally.”

Organizations can access Rockwell Automation solutions now via the Microsoft Azure Marketplace with more solutions currently in development.