The Critical Role of Risk Mitigation

To support the new direct-to-consumer paradigm, companies both large and small are reevaluating and expanding warehouse operations. Even small retailers that never considered warehousing – much less automated distribution – are exploring investments that can deliver a more seamless buying experience.

As with any major transaction, your customers must carefully evaluate risk before any CapEx funding is released for a warehouse project. Here are a few key questions they will likely consider:

- Will the system really respond to dynamic changes as described?

- What if the spreadsheet calculations the equipment supplier provided aren’t accurate?

- What if this solution isn’t any better – and is perhaps worse – than what we currently have?

- Are we spending too much?

Mitigating these risks is key to your value proposition as a supplier. And simulation software is one of the most effective tools available to allay customer concerns. In fact, more warehouse operators now require simulation models as part of the proposal process.

Accurate Predictions. More Efficient Engineering.

I’m guessing we’ve all experienced the discomfort of an on-site commissioning not going as planned. When system design and control systems come together for the first time, there’s always the risk that something will not operate as expected.

While a “can-do” spirit and last-minute design changes can often save the day, it’s not an efficient way to work. And your inability to get it right the first time could erode your customer’s confidence and compromise the startup date.

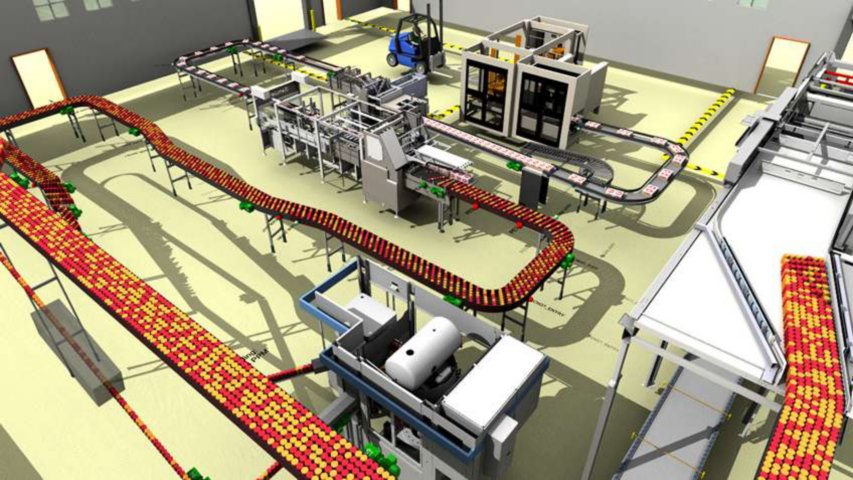

With simulation and emulation software like Emulate3D™, you can build an accurate virtual model – or digital twin – of your system. Then, use this model to simulate operation in essentially any scenario. Experiment at flow rates far faster than real time. Run a limitless number of runs and variable combinations – and share the predictions with your customer. It’s all possible in simulation.

The software also goes a step further. It enables you to connect the literal PLCs and SCADA system to the model and emulate – or mimic exactly – operation in real time. As a result, you can validate the PLC code long before arriving on site.