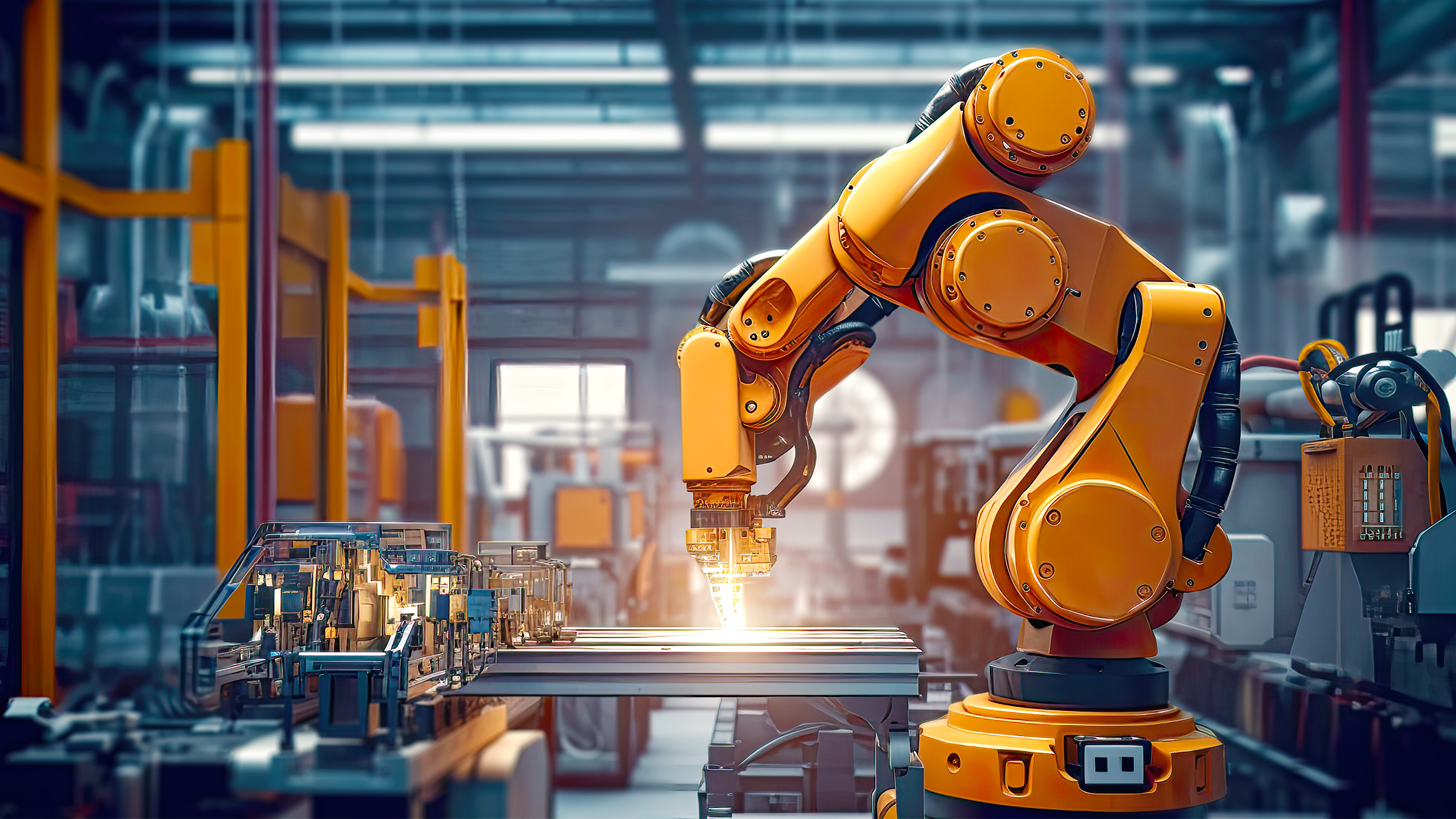

The keynote at Automation Fair 2025 was clear: “From automation to autonomy,” wherein industrial systems acquire cognitive capabilities for anticipatory diagnostics, dynamic optimization and decision support at unprecedented scale, marks a fundamental shift in manufacturing’s technological evolution.

Rockwell Automation Chairman and CEO Blake Moret delivered the keynote, explaining that autonomy is not simply acting on rigid rules driven by connectivity and data aggregation. Autonomy requires intelligence — the ability to assess situations, identify obstacles and determine optimal solutions from multiple options.

The Manila Times interviewed Scott Wooldridge, president for Rockwell Automation Asia Pacific, to add context to the keynote. He said the trajectory from automation to autonomy holds particular significance for Southeast Asian manufacturers.

“Autonomy has migrated from an aspirational concept to an operational imperative,” Wooldridge said. “Manufacturers confronting supply chain fragmentation, regulatory intensification and sustainability mandates increasingly recognize autonomous systems as foundational infrastructure for competitive resilience.”

Wooldridge said the sector is crossing a critical threshold.

“Traditional automation excelled at executing predetermined workflows,” he said. “Autonomous systems can perceive conditions, synthesize data streams, formulate decisions and execute actions — often independently, yet always within human-supervised frameworks.”

This evolution aligns with Industry 5.0 principles, where technology amplifies rather than displaces human capability. Demonstrations at Automation Fair showcased AI-driven quality inspection, predictive maintenance ecosystems and adaptive edge-to-cloud architectures capable of continuous operational refinement.

Won’t replace people

“Throughout Asia Pacific, manufacturers confront talent scarcity, workforce transitions and escalating complexity,” Wooldridge said. “Autonomous systems absorb computational burdens — continuous optimization, pattern recognition and anomaly detection — freeing human capital for innovation, safety governance and strategic value creation.”

This framework resonates particularly in Southeast Asia, where manufacturing expansion continues across electronics, automotive, food and beverage, life sciences and energy infrastructure.

“This region occupies a critical position within global value chains,” Wooldridge said. “What distinguishes the current moment is technological leapfrogging — manufacturers bypassing incremental modernization to adopt digital-native, autonomous operational frameworks directly.”

That acceleration reflects structural necessity. Supply chain disruptions, sustainability imperatives and elevated customer expectations are pushing organizations to cultivate operational agility. Autonomy enables manufacturers to respond with greater speed while maintaining quality assurance and regulatory compliance.

AI at enterprise scale

Artificial intelligence (AI) dominated Automation Fair’s thematic landscape.

“Manufacturers across Asia Pacific have moved beyond questioning AI’s efficacy,” Wooldridge said. “The focus now is scalable deployment — integrating machine learning into quality control, asset performance management, energy optimization and cybersecurity.”

AI is the foundational layer of autonomy. Rockwell Automation’s approach emphasizes secure-by-design architectures, algorithmic transparency and deep domain expertise to ensure AI augments — rather than destabilizes — operational integrity.

When asked about sustainability in Southeast Asia, where economic growth must be balanced with environmental stewardship, Wooldridge said autonomy offers pragmatic pathways.

“Autonomous systems enable real-time energy optimization, renewable integration and waste reduction without compromising throughput,” he said. “They turn sustainability from a compliance burden into a competitive advantage.”

As governments across the region introduce stricter environmental rules, such capabilities are increasingly differentiating market leaders. Wooldridge cited examples in Singapore, Malaysia and Indonesia, with early adopters emerging across the Asean region.

“What Blake Moret articulated represents an observable industrial evolution,” Wooldridge said. “We are entering an era of autonomy, where intelligent, interconnected systems empower manufacturers to operate with greater confidence, resilience and purpose.”

Originally published on The Manila Times